height INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1574 of 2395

SEL690V

Gyro (Angular Speed Sensor)NBEL0228S0204IThe oscillator gyro sensor is used to detect changes in vehicle

steering angle.

IThe oscillator gyro periodically senses oscillatory variation at

the oscillation terminals. This variation is caused by changes

in the vehicle angular velocity. Voltage variations are sensed

by ceramic voltage sensors at the left and right sides of the

terminals. Vehicle angular velocity corresponds directly with

these changes in voltage.

IThe gyro is built into the display & navigation (NAVI) control

unit.

MAP DISPLAY

BIRDVIEW

R

SEL636X

BIRDVIEWTNBEL0228S0205The BIRDVIEWTprovides a detailed and easily seen display of

road conditions covering the vehicle's immediate to distant area.

SEL691V

DescriptionNBEL0228S0206IDisplay area: Trapezoidal representation showing approximate

distances (Wn, D, and Wd).

ITen horizontal grid lines indicate display width while six verti-

cal grid lines indicate display depth and direction.

IDrawing line area shows open space, depth, and immediate

front area. Each area is to a scale of approximately 5:6:25.

IWhen the ªZMþº button is pushed, the view point height is

increased. Pushing the ªZM+º button decreases the height.

Pushing the ªZMþº button or the ªZM+º button during operation

indicates the scale change and the view point height at the

left-hand side of the screen.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

NAVIGATION SYSTEM

System Description (Cont'd)

EL-389

Page 1644 of 2395

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION...............................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................8

NVH Troubleshooting - Engine Noise .........................9

OUTER COMPONENT PARTS.....................................10

Removal and Installation ...........................................10

TIGHTENING PROCEDURES...................................12

MEASUREMENT OF COMPRESSION PRESSURE....14

OIL PAN.........................................................................15

Components...............................................................15

Removal .....................................................................15

Installation ..................................................................18

TIMING CHAIN..............................................................20

Components...............................................................20

POSITION FOR APPLYING LIQUID GASKET............21

Removal .....................................................................23

Inspection...................................................................29

Installation ..................................................................29

OIL SEAL.......................................................................35

Replacement ..............................................................35

VALVE OIL SEAL.....................................................35

OIL SEAL INSTALLATION DIRECTION.....................36

FRONT OIL SEAL....................................................36

REAR OIL SEAL......................................................36

CYLINDER HEAD..........................................................38

Components...............................................................38

Removal .....................................................................39

Disassembly...............................................................41

Inspection...................................................................42

CYLINDER HEAD DISTORTION...............................42

CAMSHAFT VISUAL CHECK....................................42

CAMSHAFT RUNOUT..............................................42

CAMSHAFT CAM HEIGHT.......................................42

CAMSHAFT JOURNAL CLEARANCE........................42

CAMSHAFT END PLAY............................................43

CAMSHAFT SPROCKET RUNOUT...........................43

VALVE GUIDE CLEARANCE....................................43

VALVE GUIDE REPLACEMENT................................44

VALVE SEATS.........................................................45

REPLACING VALVE SEAT FOR SERVICE PARTS....45

VALVE DIMENSIONS...............................................46

VALVE SPRING.......................................................46

VALVE LIFTER........................................................46

Assembly ...................................................................47

Installation ..................................................................47

Valve Clearance.........................................................52

CHECKING.............................................................52

ADJUSTING............................................................54

ENGINE ASSEMBLY.....................................................57

Removal and Installation ...........................................57

REMOVAL...............................................................58

INSTALLATION........................................................60

CYLINDER BLOCK.......................................................61

Components...............................................................61

CYLINDER BLOCK HEATER....................................62

Removal and Installation ...........................................62

Disassembly...............................................................62

PISTON, CRANKSHAFT AND OIL JET......................62

Inspection...................................................................63

PISTON AND PISTON PIN CLEARANCE..................63

PISTON RING SIDE CLEARANCE............................64

PISTON RING END GAP..........................................64

CONNECTING ROD BEND AND TORSION...............65

CYLINDER BLOCK DISTORTION AND WEAR...........65

PISTON-TO-BORE CLEARANCE..............................66

CRANKSHAFT.........................................................67

BEARING CLEARANCE...........................................67

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

..........................................................70

DRIVE PLATE RUNOUT..........................................70

Assembly ...................................................................71

PISTON..................................................................71

OIL JET..................................................................71

CRANKSHAFT.........................................................71

REPLACEMENT OF PILOT CONVERTER.................74

DRIVE PLATE.........................................................74

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1685 of 2395

SEM861E

InspectionNBEM0019CYLINDER HEAD DISTORTIONNBEM0019S01Clean surface of cylinder head.

Use a reliable straightedge and feeler gauge to check the flatness

of cylinder head surface.

Check along six positions shown in the figure.

Head surface flatness: Limit 0.1 mm (0.004 in)

If beyond the specified limit, resurface or replace it.

The limit for cylinder head resurfacing is determined by the

cylinder block resurfacing.

Resurfacing limit:

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit : A+ B = 0.2 mm (0.008 in)

After resurfacing cylinder head, check that camshaft rotates freely

by hand. If resistance is felt, cylinder head must be replaced.

Nominal cylinder head height:

126.3 - 126.5 mm (4.972 - 4.980 in)

SEM191F

CAMSHAFT VISUAL CHECKNBEM0019S02Check camshaft for scratches, seizure and wear.

CAMSHAFT RUNOUTNBEM0019S031. Measure camshaft runout at A and B as shown in the figure.

Runout (Total indicator reading):

Limit 0.05 mm (0.0020 in)

2. If it exceeds the limit, replace camshaft.

SEM549A

CAMSHAFT CAM HEIGHTNBEM0019S041. Measure camshaft cam height.

Standard cam height:

Intake and exhaust

44.465 - 44.655 mm (1.7506 - 1.7581 in)

Cam wear limit:

0.2 mm (0.008 in)

2. If wear is beyond the limit, replace camshaft.

SEM862E

CAMSHAFT JOURNAL CLEARANCENBEM0019S051. Install camshaft bracket and tighten bolts to the specified

torque.

2. Measure inner diameter ªAº of camshaft bearing.

Standard inner diameter:

No. 1: 26.000 - 26.021 mm (1.0236 - 1.0244 in)

No. 2, 3, 4: 23.500 - 23.521 mm (0.9252 - 0.9260 in)

CYLINDER HEAD

Inspection

EM-42

Page 1689 of 2395

SEM188A

VALVE DIMENSIONSNBEM0019S12Check dimensions of each valve. For dimensions, refer to SDS

(EM-76).

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM288A

VALVE SPRINGNBEM0019S13SquarenessNBEM0019S13011. Measure dimension ªSº.

Out-of-square ªSº:

Less than 2.0 mm (0.079 in)

2. If it exceeds the limit, replace spring.

EM113

PressureNBEM0019S1302Check valve spring pressure at specified spring height.

Pressure:

Standard

202 N (20.6 kg, 45.4 lb) at height 37.0 mm (1.457 in)

Limit

More than 436 N (44.5 kg, 98.1 lb) at height 28.2

mm (1.110 in)

If it exceeds the limit, replace spring.

SEM960E

VALVE LIFTERNBEM0019S141. Check contact and sliding surfaces for wear or scratches.

SEM961E

2. Check diameter of valve lifter and valve lifter guide bore.

Valve lifter outer diameter:

34.960 - 34.975 mm (1.3764 - 1.3770 in)

CYLINDER HEAD

Inspection (Cont'd)

EM-46

Page 1708 of 2395

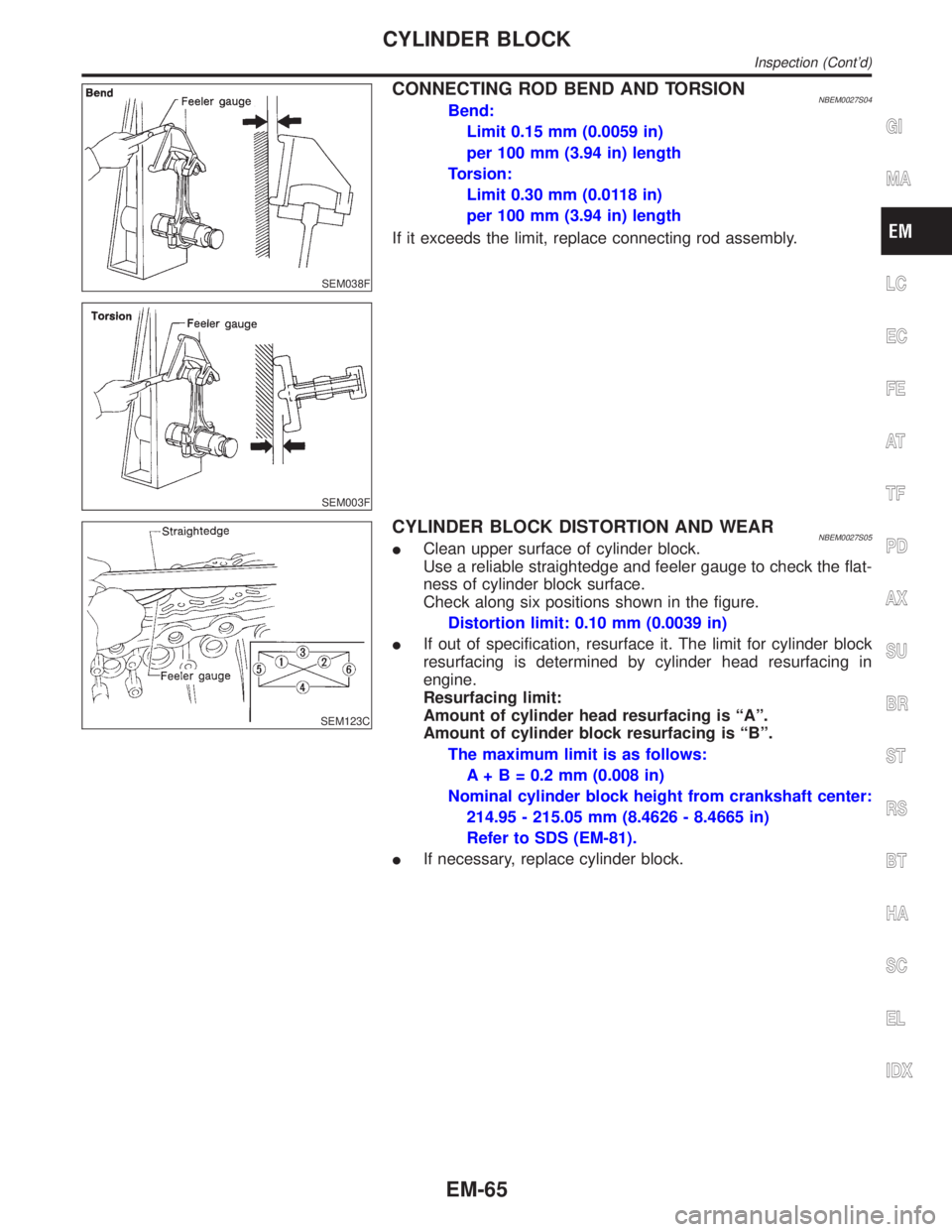

SEM038F

SEM003F

CONNECTING ROD BEND AND TORSIONNBEM0027S04Bend:

Limit 0.15 mm (0.0059 in)

per 100 mm (3.94 in) length

Torsion:

Limit 0.30 mm (0.0118 in)

per 100 mm (3.94 in) length

If it exceeds the limit, replace connecting rod assembly.

SEM123C

CYLINDER BLOCK DISTORTION AND WEARNBEM0027S05IClean upper surface of cylinder block.

Use a reliable straightedge and feeler gauge to check the flat-

ness of cylinder block surface.

Check along six positions shown in the figure.

Distortion limit: 0.10 mm (0.0039 in)

IIf out of specification, resurface it. The limit for cylinder block

resurfacing is determined by cylinder head resurfacing in

engine.

Resurfacing limit:

Amount of cylinder head resurfacing is ªAº.

Amount of cylinder block resurfacing is ªBº.

The maximum limit is as follows:

A + B = 0.2 mm (0.008 in)

Nominal cylinder block height from crankshaft center:

214.95 - 215.05 mm (8.4626 - 8.4665 in)

Refer to SDS (EM-81).

IIf necessary, replace cylinder block.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER BLOCK

Inspection (Cont'd)

EM-65

Page 1721 of 2395

Thickness mm (in) Identification mark

2.82 (0.1110) 282

2.83 (0.1114) 283

2.84 (0.1118) 284

2.85 (0.1122) 285

2.86 (0.1126) 286

2.87 (0.1130) 287

2.88 (0.1134) 288

2.89 (0.1138) 289

2.90 (0.1142) 290

2.91 (0.1146) 291

2.92 (0.1150) 292

2.93 (0.1154) 293

2.94 (0.1157) 294

2.95 (0.1161) 295

SEM966E

VALVE SPRINGNBEM0032S04

Free height mm (in)47.10 (1.8543)

Pressure N (kg, lb) at height mm (in)Standard 202 (20.6, 45.4) at 37.0 (1.457)

Limit 436 (44.5, 98.1) at 28.2 (1.110)

Out-of-square mm (in)Less than 2.0 (0.079)

VALVE LIFTERNBEM0032S05Unit: mm (in)

Valve lifter outer diameter 34.960 - 34.975 (1.3764 - 1.3770)

Lifter guide inner diameter 35.000 - 35.021 (1.3780 - 1.3788)

Clearance between lifter and lifter guide 0.025 - 0.061 (0.0010 - 0.0024)

SERVICE DATA AND SPECIFICATIONS (SDS)

Valve (Cont'd)

EM-78

Page 1723 of 2395

SEM621F

Standard Service

Cylinder head seat recess diameter (D)Intake 38.000 - 38.016 (1.4961 - 1.4967) 38.500 - 38.516 (1.5157 - 1.5164)

Exhaust 32.200 - 32.216 (1.2677 - 1.2683) 32.700 - 32.716 (1.2874 - 1.2880)

Valve seat interference fitIntake 0.081 - 0.113 (0.0032 - 0.0044)

Exhaust 0.064 - 0.096 (0.0025 - 0.0038)

Valve seat outer diameter (d)Intake 38.097 - 38.113 (1.4999 - 1.5005) 38.597 - 38.613 (1.5196 - 1.5202)

Exhaust 32.280 - 32.296 (1.2709 - 1.2715) 32.780 - 32.796 (1.2905 - 1.2912)

Height (h)Intake 5.9 - 6.0 (0.232 - 0.236) 5.05 - 5.15 (0.1988 - 0.2028)

Exhaust 5.9 - 6.0 (0.232 - 0.236) 4.95 - 5.05 (0.1949 - 0.1988)

Depth (H)5.9 - 6.1 (0.232 - 0.240)

Depth (L)Intake 41.07 - 41.67 (1.6169 - 1.6405)

Exhaust 41.00 - 41.60 (1.6142 - 1.6378)

Camshaft and Camshaft BearingNBEM0034Unit: mm (in)

Standard Limit

Camshaft journal to bearing clearanceNo. 1

0.045 - 0.086 (0.0018 - 0.0034)

No. 2, 3, 4

0.035 - 0.076 (0.0014 - 0.0030)0.15 (0.0059)

Inner diameter of camshaft bearingNo. 1

26.000 - 26.021 (1.0236 - 1.0244)

No. 2, 3, 4

23.500 - 23.521 (0.9252 - 0.9260)Ð

Outer diameter of camshaft journalNo. 1

25.935 - 25.955 (1.0211 - 1.0218)

No. 2, 3, 4

23.445 - 23.465 (0.9230 - 0.9238)Ð

Camshaft runout [TIR*] Less than 0.02 (0.0008) 0.05 (0.0020)

Camshaft sprocket runout [TIR*] Less than 0.15 (0.0059) Ð

Camshaft end play 0.115 - 0.188 (0.0045 - 0.0074) 0.24 (0.0094)

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)

Valve Seat (Cont'd)

EM-80

Page 1724 of 2395

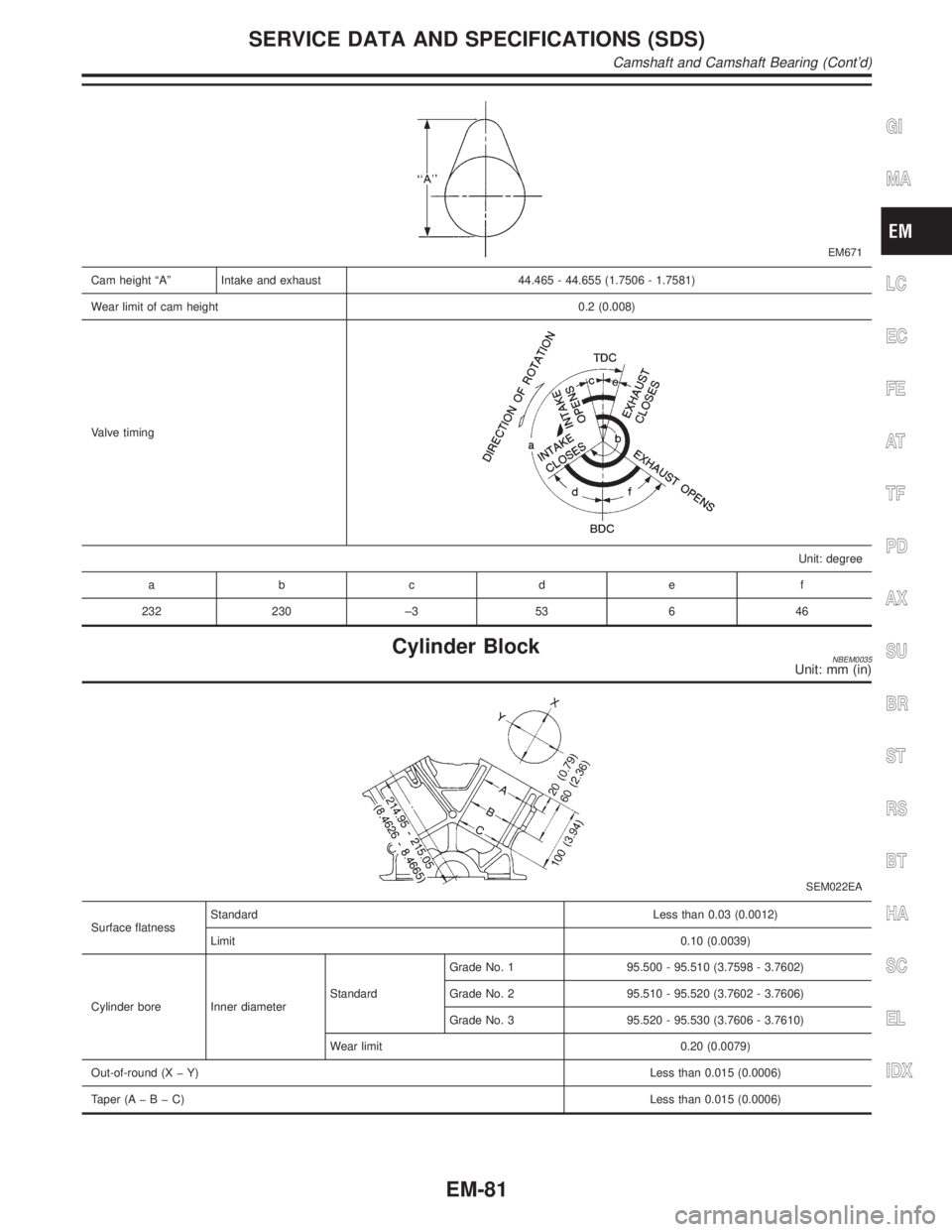

EM671

Cam height ªAº Intake and exhaust 44.465 - 44.655 (1.7506 - 1.7581)

Wear limit of cam height 0.2 (0.008)

Valve timing

Unit: degree

abcde f

232 230 ±3 53 6 46

Cylinder BlockNBEM0035Unit: mm (in)

SEM022EA

Surface flatnessStandardLess than 0.03 (0.0012)

Limit0.10 (0.0039)

Cylinder bore Inner diameterStandardGrade No. 1 95.500 - 95.510 (3.7598 - 3.7602)

Grade No. 2 95.510 - 95.520 (3.7602 - 3.7606)

Grade No. 3 95.520 - 95.530 (3.7606 - 3.7610)

Wear limit 0.20 (0.0079)

Out-of-round (X þ Y)Less than 0.015 (0.0006)

Taper (AþBþC)Less than 0.015 (0.0006)

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Camshaft and Camshaft Bearing (Cont'd)

EM-81

Page 1737 of 2395

Removal and InstallationNBFE0005CAUTION:

IAlways replace exhaust gaskets with new ones when reassembling.

IWith engine running, check all tube connections for exhaust gas leaks, and entire system for

unusual noises.

ICheck to ensure that mounting brackets and mounting insulators are installed properly and free

from undue stress. Improper installation could result in excessive noise or vibration.

IDiscard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

IBefore installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 of J-43897-12 and approved anti-seize lubricant.

IDo not overtorque the oxygen sensor. Doing so may cause damage to the oxygen sensor, result-

ing in the MIL coming on.

EXHAUST SYSTEM

Removal and Installation

FE-8

Page 1745 of 2395

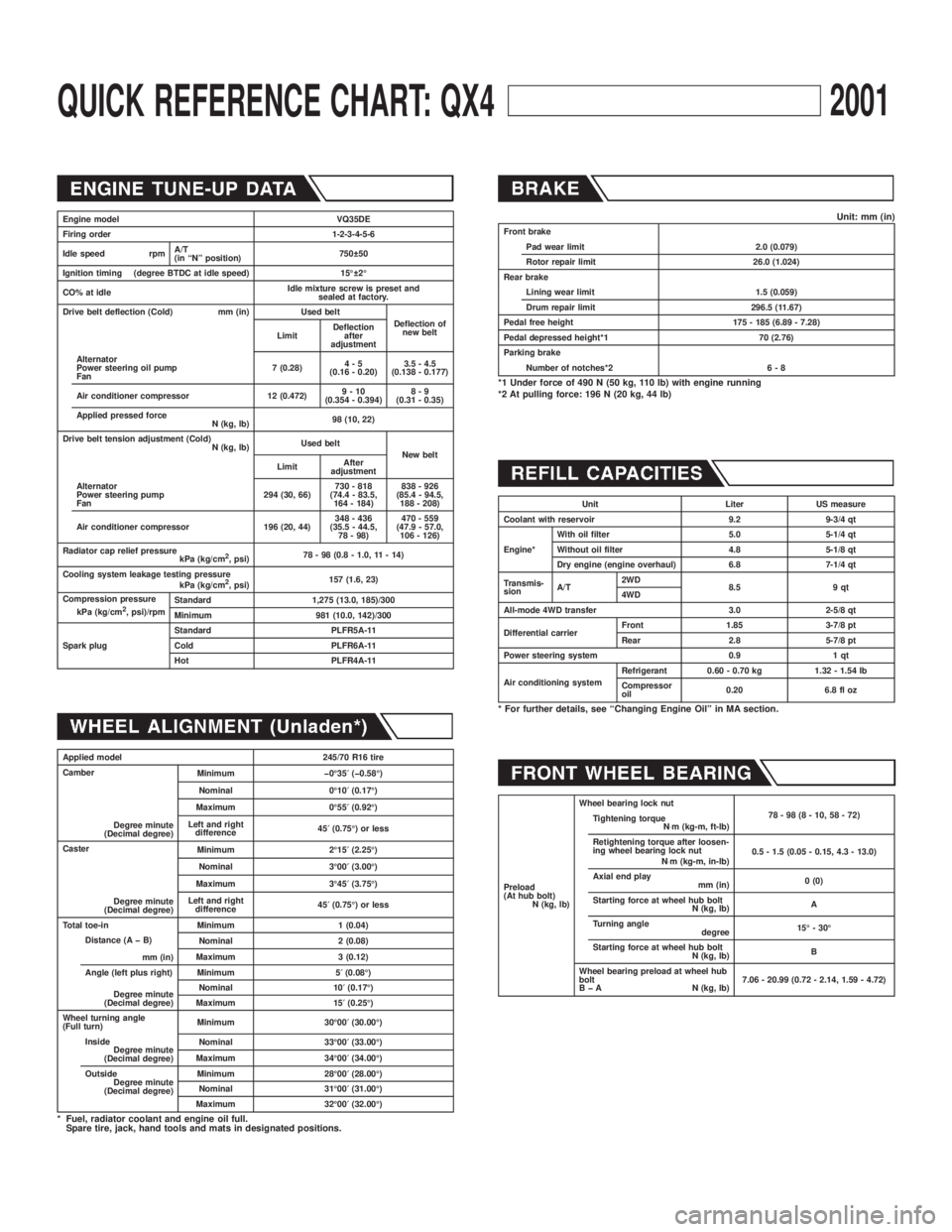

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)