light INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 614 of 2395

RELATIONSHIP BETWEEN MIL, DTC, 1ST TRIP DTC AND DRIVING PATTERNS EXCEPT

FOR ªMISFIRE

SEF393S

*1: When the same malfunction is

detected in two consecutive trips,

MIL will light up.

*2: MIL will go off after vehicle is

driven 3 times (pattern B) without

any malfunctions.

*3: When the same malfunction is

detected in two consecutive trips,

the DTC and the freeze frame

data will be stored in ECM.*4: The DTC and the freeze frame

data will not be displayed any

longer after vehicle is driven 40

times (pattern A) without the same

malfunction.

(The DTC and the freeze frame

data still remain in ECM.)

*5: When a malfunction is detected

for the first time, the 1st trip DTCand the 1st trip freeze frame data

will be stored in ECM.

*6: 1st trip DTC will be cleared after

vehicle is driven once (pattern B)

without the same malfunction.

*7: When the same malfunction is

detected in the 2nd trip, the 1st

trip freeze frame data will be

cleared.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

OBD System Operation Chart (Cont'd)

EC-79

Page 620 of 2395

WORK SUPPORT MODE=NBEC0034S04

WORK ITEM CONDITION USAGE

TP SW/TP SEN IDLE POSI ADJIFOLLOW THE BASIC INSPECTION INSTRUCTION IN

THE SERVICE MANUAL.When adjusting the idle throttle

position

FUEL PRESSURE RELEASEIFUEL PUMP WILL STOP BY TOUCHING ªSTARTº

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure

from fuel line

IDLE AIR VOL LEARNITHE IDLE AIR VOLUME THAT KEEPS THE ENGINE

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM.When learning the idle air volume

SELF-LEARNING CONTITHE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL

COEFFICIENT.When clearing the coefficient of

self-learning control valve

EVAP SYSTEM CLOSE OPEN THE VACUUM CUT VALVE BYPASS VALVE AND

CLOSE THE EVAP CANISTER VENT CONTROL VALVE

IN ORDER TO MAKE EVAP SYSTEM CLOSE UNDER

THE FOLLOWING CONDITIONS.

IIGN SW ªONº

IENGINE NOT RUNNING

IAMBIENT TEMPERATURE IS ABOVE 0ÉC (32ÉF).

INO VACUUM AND NO HIGH PRESSURE IN EVAP

SYSTEM

ITANK FUEL TEMP. IS MORE THAN 0ÉC (32ÉF).

IWITHIN 10 MINUTES AFTER STARTING ªEVAP SYS-

TEM CLOSEº

IWHEN TRYING TO EXECUTE ªEVAP SYSTEM

CLOSEº UNDER THE CONDITION EXCEPT ABOVE,

CONSULT-II WILL DISCONTINUE IT AND DISPLAY

APPROPRIATE INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-II MAY DIS-

PLAY ªBATTERY VOLTAGE IS LOW. CHARGE

BATTERYº, EVEN IN USING CHARGED BATTERY.When detecting EVAP vapor leak

point of EVAP system

TARGET IGNITION TIMING ADJ*IIDLE CONDITIONIWhen adjusting target ignition

timing

After adjustment, confirm target

ignition timing with a timing

light.

IIf once the ªTARGET IDLE

RPM ADJº has been done, the

Idle Air Volume Learning proce-

dure will not be completed.

TARGET IDLE RPM ADJ*IIDLE CONDITION When setting target idle speed

*: This function is not necessary in the usual service procedure.

SELF-DIAGNOSTIC MODENBEC0034S05DTC and 1st Trip DTCNBEC0034S0501Regarding items of ªDTC and 1st trip DTCº, refer to ªTROUBLE

DIAGNOSIS Ð INDEXº (See EC-8.)

Freeze Frame Data and 1st Trip Freeze Frame DataNBEC0034S0502

Freeze frame data

item*1Description

DIAG TROUBLE

CODE

[PXXXX]IThe engine control component part/control system has a trouble code, it is displayed as ªPXXXXº.

(Refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-8.)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-85

Page 623 of 2395

![INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is](/img/42/57027/w960_57027-622.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is indicated.

EVAP SYS PRES [V]qIThe signal voltage of EVAP control sys-

tem pressure sensor is displayed.

ABSOL PRES/SE [V]qIThe signal voltage of the absolute pres-

sure sensor is displayed.

FUEL LEVEL SE [V]qIThe signal voltage of the fuel level sen-

sor is displayed.

START SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

starter signal.IAfter starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS

[ON/OFF]qqIIndicates idle position [ON/OFF] com-

puted by ECM according to the throttle

position sensor signal.

CLSD THL/P SW

[ON/OFF]qIIndicates mechanical contact [ON/OFF]

condition of the closed throttle position

switch.

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the

park/neutral position (PNP) switch sig-

nal.

PW/ST SIGNAL

[ON/OFF]qqI[ON/OFF] condition of the power steer-

ing oil pressure switch determined by

the power steering oil pressure signal is

indicated.

LOAD SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

electrical load signal and/or lighting

switch.

ON ... rear defogger is operating and/or

lighting switch is on.

OFF ... rear defogger is not operating

and lighting switch is not on.

IGNITION SW

[ON/OFF]qIIndicates [ON/OFF] condition from igni-

tion switch.

SWRL CONT S/V

[ON/OFF]qIThe control condition of the swirl con-

trol valve control solenoid valve (deter-

mined by ECM according to the input

signals) is indicated.

ION ... Swirl control valve is closed.

OFF ... Swirl control valve is opened.

INJ PULSE-B1

[msec]q

IIndicates the actual fuel injection pulse

width compensated by ECM according

to the input signals.IWhen the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

[msec]

B/FUEL SCHDL

[msec]qIªBase fuel scheduleº indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board

correction.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-88

Page 626 of 2395

![INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running](/img/42/57027/w960_57027-625.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running, specifi-

cation range is indicated.

IThis data also includes the data for

the air-fuel ratio learning control. A/F ALPHA-B2 [%]q

NOTE:

IAny monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

IRegarding R50 model, ªB1º indicates bank 1 and ªB2º indicates bank 2.

ACTIVE TEST MODENBEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor

IGNITION TIMINGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial ignition timing

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

IIACV-AAC valve

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IA/C switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

VIAS SOL VALVEIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

SWIRL CONT

S O L VA LV EIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

PURG VOL

CONT/VIEngine: After warming up, run

engine at 1,500 rpm.

IChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

ISolenoid valve

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-91

Page 649 of 2395

28 CHECK IGNITION TIMING

1. Start engine and warm it up to normal operating temperature.

2. Check ignition timing at idle using a timing light.

SEF572X

Ignition timing:

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 36.

NG©GO TO 29.

29 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 27.

NG©1. Repair the timing chain installation.

2. GO TO 22.

30 CHECK IGNITION TIMING

1. Start engine and let it idle.

2. Check ignition timing at idle using a timing light.

SEF572X

Ignition timing:

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 36.

NG©GO TO 31.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-114

Page 652 of 2395

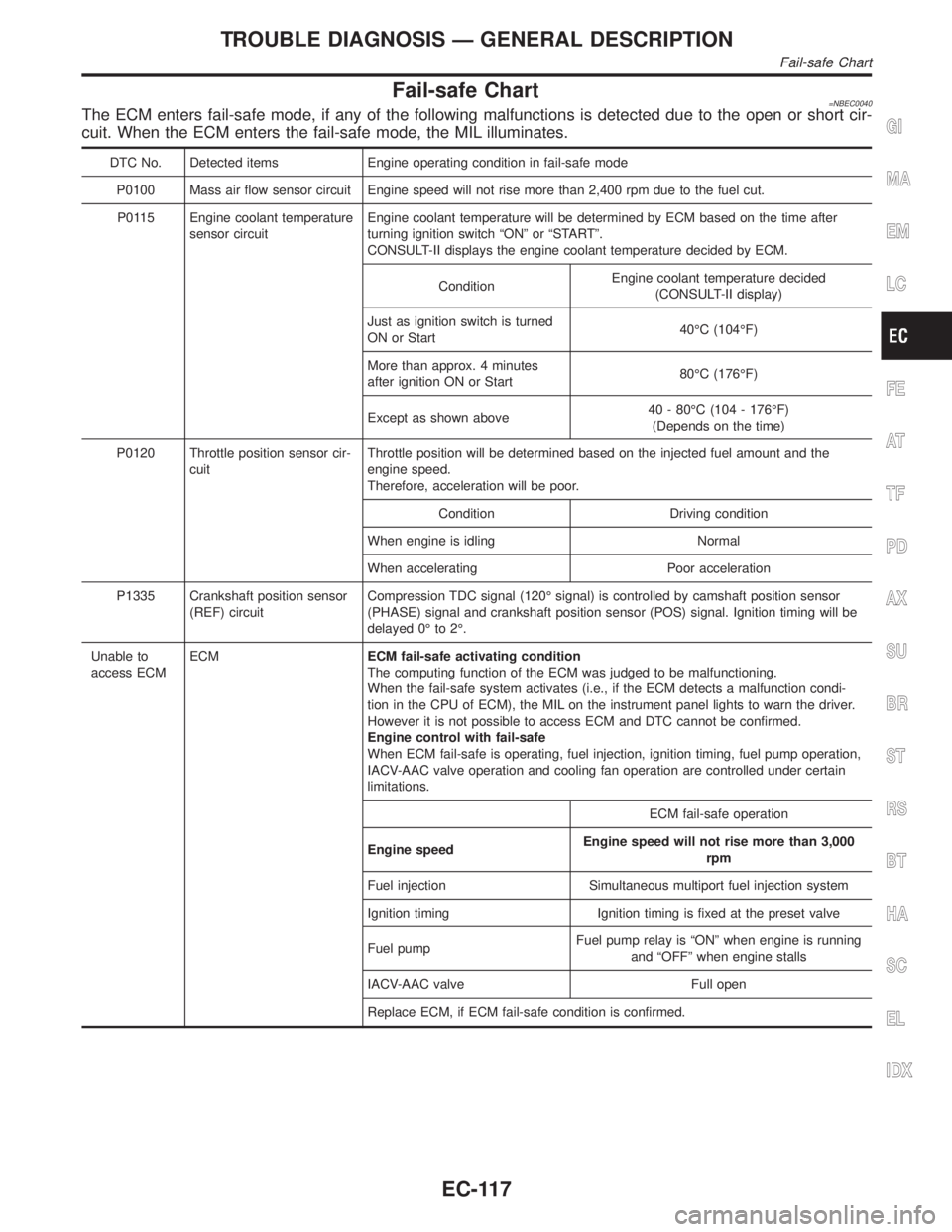

Fail-safe Chart=NBEC0040The ECM enters fail-safe mode, if any of the following malfunctions is detected due to the open or short cir-

cuit. When the ECM enters the fail-safe mode, the MIL illuminates.

DTC No. Detected items Engine operating condition in fail-safe mode

P0100 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0115 Engine coolant temperature

sensor circuitEngine coolant temperature will be determined by ECM based on the time after

turning ignition switch ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-II display)

Just as ignition switch is turned

ON or Start40ÉC (104ÉF)

More than approx. 4 minutes

after ignition ON or Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

P0120 Throttle position sensor cir-

cuitThrottle position will be determined based on the injected fuel amount and the

engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

P1335 Crankshaft position sensor

(REF) circuitCompression TDC signal (120É signal) is controlled by camshaft position sensor

(PHASE) signal and crankshaft position sensor (POS) signal. Ignition timing will be

delayed 0É to 2É.

Unable to

access ECMECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates (i.e., if the ECM detects a malfunction condi-

tion in the CPU of ECM), the MIL on the instrument panel lights to warn the driver.

However it is not possible to access ECM and DTC cannot be confirmed.

Engine control with fail-safe

When ECM fail-safe is operating, fuel injection, ignition timing, fuel pump operation,

IACV-AAC valve operation and cooling fan operation are controlled under certain

limitations.

ECM fail-safe operation

Engine speedEngine speed will not rise more than 3,000

rpm

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset valve

Fuel pumpFuel pump relay is ªONº when engine is running

and ªOFFº when engine stalls

IACV-AAC valve Full open

Replace ECM, if ECM fail-safe condition is confirmed.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Fail-safe Chart

EC-117

Page 657 of 2395

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

IVIS (INFINITI Vehicle Immobilizer System Ð

NATS)11EC-74 or EL

section

1 - 6: The numbers refer to the order of inspection.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0042Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in

spite of the ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the ECM

according to the signals input from the camshaft position sensor and other ignition timing related sensors.

IIf the real-time diagnosis results are NG and the on board diagnostic system results are OK when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as

the CONSULT-II value.

POS COUNTIEngine: Running 179 - 181

MAS A/F SE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 1.2 - 1.8V

2,500 rpm 1.6 - 2.2V

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

HO2S1 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S1 MNTR (B1)

HO2S1 MNTR (B2)LEAN+,RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

HO2S2 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN+,RICH

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-122

Page 658 of 2395

MONITOR ITEM CONDITION SPECIFICATION

VHCL SPEED SEITurn drive wheels and compare speedometer indication with the CON-

SULT-II valueAlmost the same speed as

the CONSULT-II value

BATTERY VOLTIIgnition switch: ON (Engine stopped) 11 - 14V

THRTL POS SENIEngine: After warming up, idle

the engineThrottle valve: fully closed 0.15 - 0.85V

IEngine: After warming up

IIgnition switch: ON

(Engine stopped)Throttle valve: fully opened 3.5 - 4.7V

START SIGNALIIgnition switch: ON,START,ON OFF,ON,OFF

CLSD THL POS

CLSD THL/P SWIEngine: After warming up, idle

the engineThrottle valve: Idle position ON

Throttle valve: Slightly open OFF

AIR COND SIGIEngine: After warming up, idle

the engineAir conditioner switch: ªOFFº OFF

Air conditioner switch: ªONº

(Compressor operates.)ON

P/N POSI SWIIgnition switch: ONShift lever: ªPº or ªNº ON

Except above OFF

PW/ST SIGNALIEngine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is turned ON

IGNITION SWIIgnition switch: ON,OFF,ON ON,OFF,ON

INJ PULSE-B2

INJ PULSE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2.4 - 3.2 msec

2,000 rpm 1.9 - 2.8 msec

B/FUEL SCHDLIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2.0 - 3.2 msec

2,000 rpm 1.4 - 2.6 msec

IGN TIMINGIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 15ɱ5É BTDC

2,000 rpm More than 25É BTDC

IACV-AAC/VIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2 - 10 step

2,000 rpm Ð

PURG VOL C/VIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 0 %

2,000 rpm Ð

A/F ALPHA-B2

A/F ALPHA-B1IEngine: After warming upMaintaining engine speed at 2,000

rpm54 - 155%

EVAP SYS PRESIIgnition switch: ON Approx. 3.4V

AIR COND RLYIAir conditioner switch: OFF,ON OFF,ON

FUEL PUMP RLYIIgnition switch is turned to ON (Operates for 5 seconds)

IEngine running and crankingON

Except as shown above OFF

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-123

Page 671 of 2395

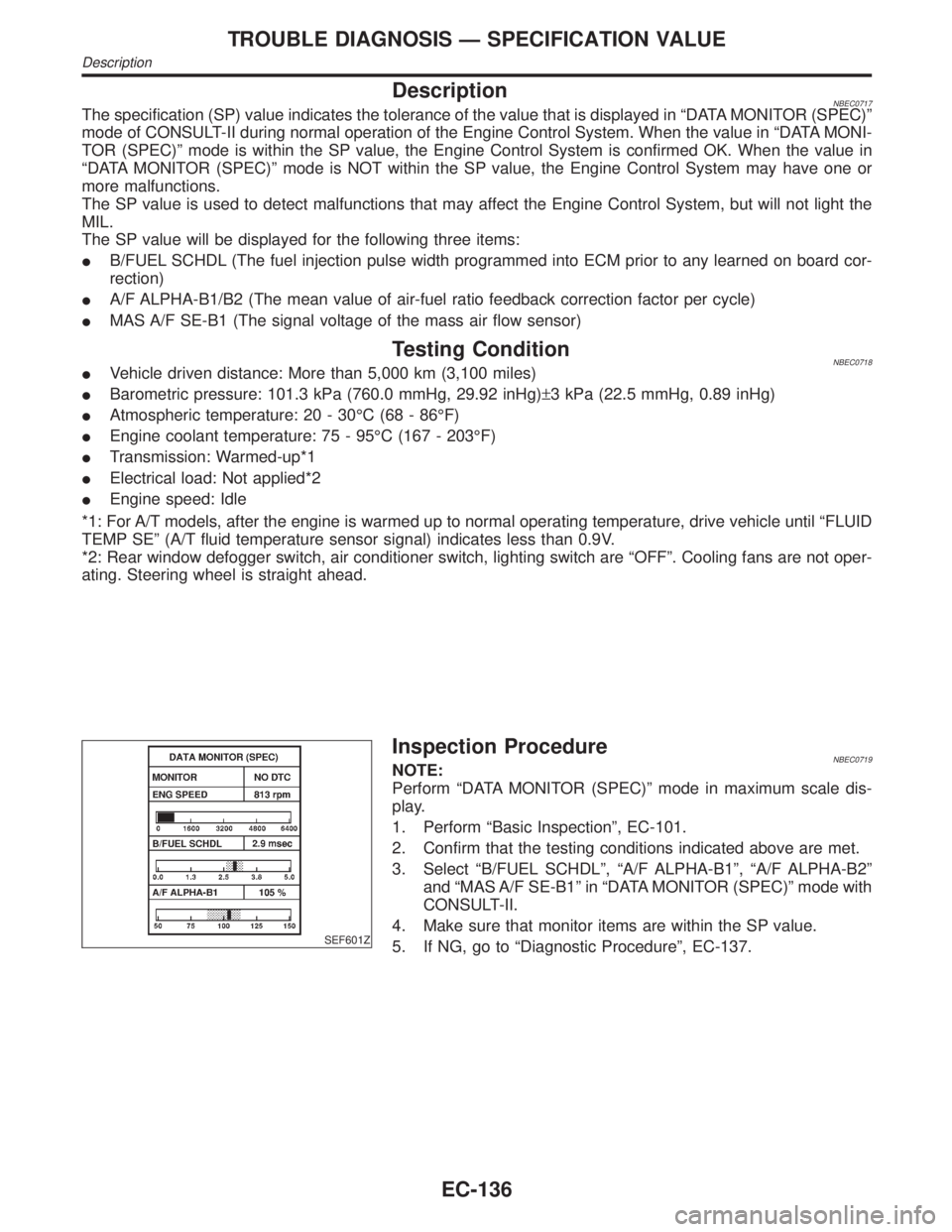

DescriptionNBEC0717The specification (SP) value indicates the tolerance of the value that is displayed in ªDATA MONITOR (SPEC)º

mode of CONSULT-II during normal operation of the Engine Control System. When the value in ªDATA MONI-

TOR (SPEC)º mode is within the SP value, the Engine Control System is confirmed OK. When the value in

ªDATA MONITOR (SPEC)º mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

IB/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board cor-

rection)

IA/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

IMAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionNBEC0718IVehicle driven distance: More than 5,000 km (3,100 miles)

IBarometric pressure: 101.3 kPa (760.0 mmHg, 29.92 inHg)±3 kPa (22.5 mmHg, 0.89 inHg)

IAtmospheric temperature: 20 - 30ÉC (68 - 86ÉF)

IEngine coolant temperature: 75 - 95ÉC (167 - 203ÉF)

ITransmission: Warmed-up*1

IElectrical load: Not applied*2

IEngine speed: Idle

*1: For A/T models, after the engine is warmed up to normal operating temperature, drive vehicle until ªFLUID

TEMP SEº (A/T fluid temperature sensor signal) indicates less than 0.9V.

*2: Rear window defogger switch, air conditioner switch, lighting switch are ªOFFº. Cooling fans are not oper-

ating. Steering wheel is straight ahead.

SEF601Z

Inspection ProcedureNBEC0719NOTE:

Perform ªDATA MONITOR (SPEC)º mode in maximum scale dis-

play.

1. Perform ªBasic Inspectionº, EC-101.

2. Confirm that the testing conditions indicated above are met.

3. Select ªB/FUEL SCHDLº, ªA/F ALPHA-B1º, ªA/F ALPHA-B2º

and ªMAS A/F SE-B1º in ªDATA MONITOR (SPEC)º mode with

CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to ªDiagnostic Procedureº, EC-137.

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUE

Description

EC-136

Page 686 of 2395

On Board Diagnosis LogicNBEC0053Malfunction is detected when

(Malfunction A)an excessively high voltage from the sensor is

sent to ECM when engine is not running,

(Malfunction B)an excessively low voltage from the sensor is sent

to ECM when engine is running,

(Malfunction C)a high voltage from the sensor is sent to ECM

under light load driving condition,

(Malfunction D)a low voltage from the sensor is sent to ECM

under heavy load driving condition,

(Malfunction E)a voltage from the sensor is constantly approx.

1.0V when engine is running.

FAIL-SAFE MODENBEC0053S02When the malfunction B is detected, the ECM enters fail-safe mode

and the MIL lights up.

Detected items Engine operating condition in fail-safe mode

Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

Possible CauseNBEC0426MALFUNCTION A OR CNBEC0426S01IHarness or connectors

(The sensor circuit is open or shorted.)

IMass air flow sensor

MALFUNCTION B, D OR ENBEC0426S02IHarness or connectors

(The sensor circuit is open or shorted.)

IIntake air leaks

IMass air flow sensor

DTC Confirmation ProcedureNBEC0054Perform ªPROCEDURE FOR MALFUNCTION Aº first.

If the 1st trip DTC cannot be confirmed, perform ªPROCE-

DURE FOR MALFUNCTION B AND Eº.

If there is no problem on ªPROCEDURE FOR MALFUNCTION

B AND Eº, perform ªPROCEDURE FOR MALFUNCTION Cº.

If there is no problem on ªPROCEDURE FOR MALFUNCTION

Cº, perform ªPROCEDURE FOR MALFUNCTION Dº.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0100 MASS AIR FLOW SENSOR (MAFS)

On Board Diagnosis Logic

EC-151