light INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 704 of 2395

SEF594K

Component DescriptionNBEC0069The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature increases.

SEF012P

Engine coolant

temperature ÉC (ÉF)Voltage* V Resistance kW

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.2 0.68 - 1.00

90 (194) 0.9 0.236 - 0.260

*: These data are reference values and are measured between ECM terminal 70

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNBEC0070Malfunction is detected when an excessively high or low voltage

from the sensor is sent to ECM.

FAIL-SAFE MODENBEC0070S02When this malfunction is detected, the ECM enters fail-safe mode

and the MIL lights up.

Detected items Engine operating condition in fail-safe mode

Engine coolant tem-

perature sensor circuitEngine coolant temperature will be determined by ECM based on the time after turning ignition switch

ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided (CONSULT-II

display)

Just as ignition switch is turned ON or Start 40ÉC (104ÉF)

More than approx. 4 minutes after ignition ON or

Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR (ECTS) (CIRCUIT)

Component Description

EC-169

Page 710 of 2395

ECM Terminals and Reference Value=NBEC0651Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

91 R Throttle position sensor[Engine is running]

IWarm-up condition

IAccelerator pedal fully released0.15 - 0.85V

[Ignition switch ªONº]

IAccelerator pedal fully depressed3.5 - 4.7V

111 P/B Sensors' power supply[Ignition switch ªONº]Approximately 5V

58 B/P Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

On Board Diagnosis LogicNBEC0077Malfunction is detected when

(Malfunction A)an excessively low or high voltage from the sen-

sor is sent to ECM,

(Malfunction B)a high voltage from the sensor is sent to ECM

under light load driving conditions,

(Malfunction C)a low voltage from the sensor is sent to ECM

under heavy load driving conditions.

FAIL-SAFE MODENBEC0077S02When the malfunction A is detected, the ECM enters fail-safe mode

and the MIL lights up.

Detected items Engine operating condition in fail-safe mode

Throttle position sensor

circuitThrottle position will be determined based on the injected fuel amount and the engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

Possible CauseNBEC0430MALFUNCTION ANBEC0430S01IHarness or connectors

(The throttle position sensor circuit is open or shorted.)

IThrottle position sensor

MALFUNCTION BNBEC0430S02IHarness or connectors

(The throttle position sensor circuit is open or shorted.)

IThrottle position sensor

IFuel injector

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0120 THROTTLE POSITION SENSOR

ECM Terminals and Reference Value

EC-175

Page 829 of 2395

On Board Diagnosis LogicNBEC0169With the Air/Fuel Mixture Ratio Self-Learning Control, the actual

mixture ratio can be brought closely to the theoretical mixture ratio

based on the mixture ratio feedback signal from the heated oxygen

sensors 1 (front). The ECM calculates the necessary compensation

to correct the offset between the actual and the theoretical ratios.

In case the amount of the compensation value is extremely large

(The actual mixture ratio is too lean.), the ECM judges the condi-

tion as the fuel injection system malfunction and light up the MIL

(2 trip detection logic).

Sensor Input Signal to ECMECM func-

tionActuator

Heated oxygen sensors 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)Fuel injec-

tion controlInjectors

Malfunction is detected when fuel injection system does not oper-

ate properly, the amount of mixture ratio compensation is too large.

(The mixture ratio is too lean.)

Possible CauseNBEC0487IIntake air leaks

IHeated oxygen sensor 1 (front)

IInjectors

IExhaust gas leaks

IIncorrect fuel pressure

ILack of fuel

IMass air flow sensor

SEF968Y

DTC Confirmation ProcedureNBEC0170NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0170S011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Turn ignition switch ªONº and select ªSELF-LEARN CON-

TROLº in ªWORK SUPPORTº mode with CONSULT-II.

4) Clear the self-learning control coefficient by touching ªCLEARº.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Start engine again and let it idle for at least 10 minutes.

The 1st trip DTC P0171 or P0174 should be detected at this

stage, if a malfunction exists. If so, go to ªDiagnostic

Procedureº, EC-298.

7) If it is difficult to start engine at step 6, the fuel injection sys-

tem has a malfunction, too.

8) Crank engine while depressing accelerator pedal. If engine

starts, go to ªDiagnostic Procedureº, EC-298. If engine does

not start, check exhaust and intake air leak visually.

DTC P0171 (RIGHT, -B1), P0174 (LEFT, -B2) FUEL INJECTION SYSTEM

FUNCTION (LEAN)

On Board Diagnosis Logic

EC-294

Page 837 of 2395

On Board Diagnosis LogicNBEC0173With the Air/Fuel Mixture Ratio Self-Learning Control, the actual

mixture ratio can be brought closely to the theoretical mixture ratio

based on the mixture ratio feedback signal from the heated oxygen

sensors 1 (front). The ECM calculates the necessary compensation

to correct the offset between the actual and the theoretical ratios.

In case the amount of the compensation value is extremely large

(The actual mixture ratio is too rich.), the ECM judges the condi-

tion as the fuel injection system malfunction and light up the MIL

(2 trip detection logic).

Sensor Input Signal to ECMECM func-

tionActuator

Heated oxygen sensors 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)Fuel injec-

tion controlInjectors

Malfunction is detected when fuel injection system does not oper-

ate properly, the amount of mixture ratio compensation is too large.

(The mixture ratio is too rich.)

Possible CauseNBEC0488IHeated oxygen sensor 1 (front)

IInjectors

IExhaust gas leaks

IIncorrect fuel pressure

IMass air flow sensor

SEF968Y

DTC Confirmation ProcedureNBEC0174NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0174S011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Turn ignition switch ªONº and select ªSELF-LEARN CON-

TROLº in ªWORK SUPPORTº mode with CONSULT-II.

4) Clear the self-learning control coefficient by touching ªCLEARº.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Start engine again and let it idle for at least 10 minutes.

The 1st trip DTC P0172, P0175 should be detected at this

stage, if a malfunction exists. If so, go to ªDiagnostic

Procedureº, EC-306.

7) If it is difficult to start engine at step 6, the fuel injection sys-

tem has a malfunction, too.

8) Crank engine while depressing accelerator pedal.

If engine starts, go to ªDiagnostic Procedureº, EC-306. If

engine does not start, remove ignition plugs and check for

fouling, etc.

DTC P0172 (RIGHT, -B1), P0175 (LEFT, -B2) FUEL INJECTION SYSTEM

FUNCTION (RICH)

On Board Diagnosis Logic

EC-302

Page 849 of 2395

On Board Diagnosis LogicNBEC0610This diagnosis checks whether the engine coolant temperature is

extraordinary high, even when the load is not heavy.

When malfunction is detected, the malfunction indicator lamp (MIL)

will light up even in the first trip.

Malfunction is detected when engine coolant temperature is exces-

sively high under normal engine speed.

Possible CauseNBEC0611IThermostat

IImproper ignition timing

IEngine coolant temperature sensor

IBlocked radiator

IBlocked front end (Improper fitting of nose mask)

ICrushed vehicle frontal area (Vehicle frontal is collided but not

repaired)

IBlocked air passage by improper installation of front fog lamp

or fog lamps.

IImproper mixture ratio of coolant

IDamaged bumper

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-319.

Overall Function CheckNBEC0612Use this procedure to check the overall function of the coolant

overtemperature enrichment protection check, a DTC might not be

confirmed.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high-pressure fluid escaping from

the radiator.

Wrap a thick cloth around the cap. Carefully remove the cap

by turning it a quarter turn to allow built-up pressure to

escape. Then turn the cap all the way off.

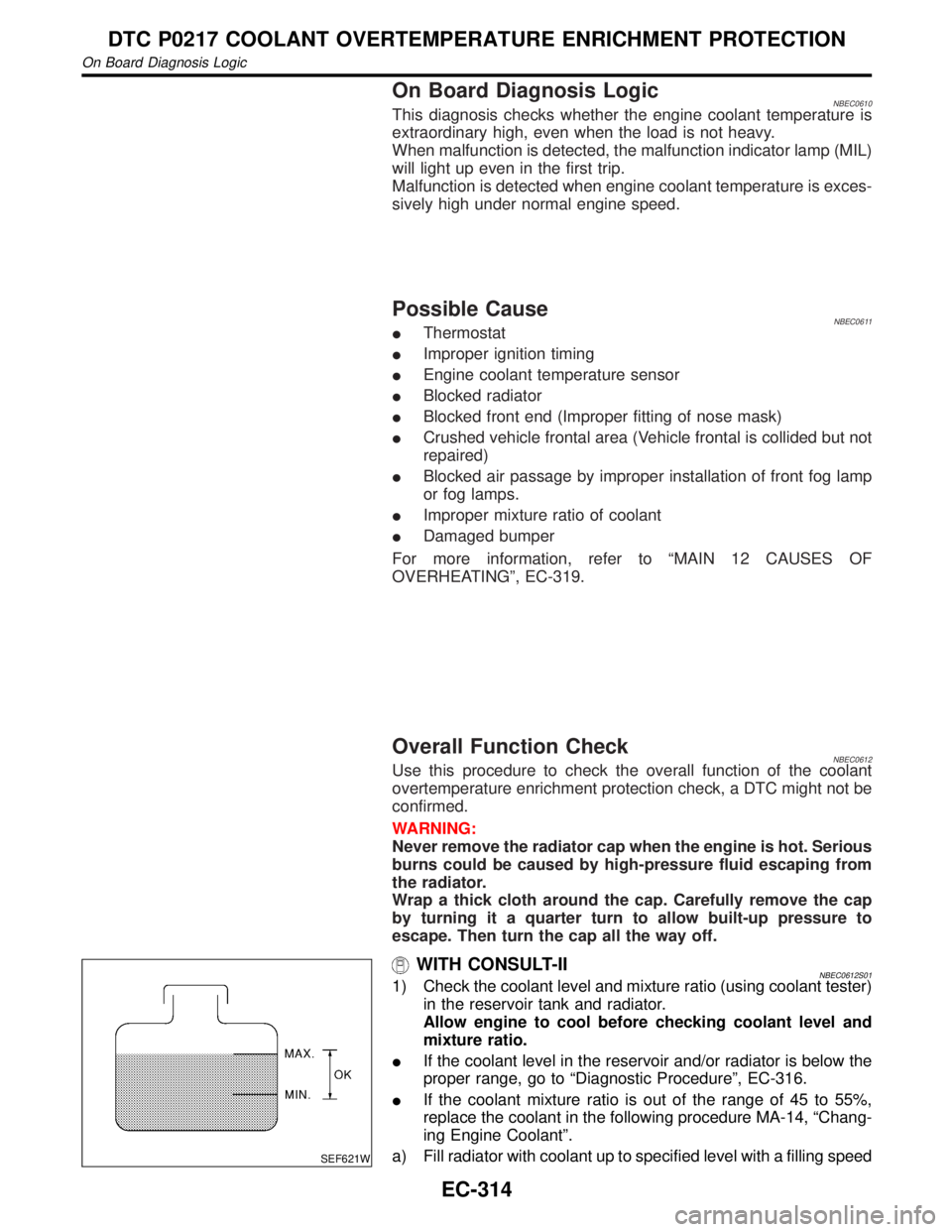

SEF621W

WITH CONSULT-IINBEC0612S011) Check the coolant level and mixture ratio (using coolant tester)

in the reservoir tank and radiator.

Allow engine to cool before checking coolant level and

mixture ratio.

IIf the coolant level in the reservoir and/or radiator is below the

proper range, go to ªDiagnostic Procedureº, EC-316.

IIf the coolant mixture ratio is out of the range of 45 to 55%,

replace the coolant in the following procedure MA-14, ªChang-

ing Engine Coolantº.

a) Fill radiator with coolant up to specified level with a filling speed

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

On Board Diagnosis Logic

EC-314

Page 855 of 2395

On Board Diagnosis LogicNBEC0182When a misfire occurs, engine speed will fluctuate. If the engine

speed fluctuates enough to cause the CKP sensor signal to vary,

ECM can determine that a misfire is occurring.

Sensor Input Signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the first trip that a misfire condition occurs that can dam-

age the three way catalyst (TWC) due to overheating, the MIL

will blink.

When a misfire condition occurs, the ECM monitors the CKP

sensor signal every 200 engine revolutions for a change.

When the misfire condition decreases to a level that will not

damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC

on a second trip, the MIL will blink.

When the misfire condition decreases to a level that will not

damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC,

the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will

affect vehicle emissions), the MIL will only light when the mis-

fire is detected on a second trip. During this condition, the ECM

monitors the CKP sensor signal every 1,000 engine revolu-

tions.

A misfire malfunction can be detected on any one cylinder or

on multiple cylinders.

Malfunction is detected when multiple cylinders misfire, No. 1 cyl-

inder misfires, No. 2 cylinder misfires, No. 3 cylinder misfires, No.

4 cylinder misfires, No. 5 cylinder misfires and No. 6 cylinder

misfires.

Possible CauseNBEC0490IImproper spark plug

IInsufficient compression

IIncorrect fuel pressure

IThe injector circuit is open or shorted

IInjectors

IIntake air leak

IThe ignition secondary circuit is open or shorted

ILack of fuel

IDrive plate or flywheel

IHeated oxygen sensor 1 (front)

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

On Board Diagnosis Logic

EC-320

Page 863 of 2395

SEF332I

Component DescriptionNBEC0185The knock sensor is attached to the cylinder block. It senses

engine knocking using a piezoelectric element. A knocking vibration

from the cylinder block is sensed as vibrational pressure. This

pressure is converted into a voltage signal and sent to the ECM.

Freeze frame data will not be stored in the ECM for the knock

sensor. The MIL will not light for knock sensor malfunction.

The knock sensor has one trip detection logic.

ECM Terminals and Reference ValueNBEC0663Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

93 W Knock sensor[Engine is running]

IIdle speedApproximately 2.5V

On Board Diagnosis LogicNBEC0187Malfunction is detected when an excessively low or high voltage

from the knock sensor is sent to ECM.

Possible CauseNBEC0491IHarness or connectors

(The knock sensor circuit is open or shorted.)

IKnock sensor

SEF058Y

DTC Confirmation ProcedureNBEC0188NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10V at idle.

DTC P0325 KNOCK SENSOR (KS)

Component Description

EC-328

Page 962 of 2395

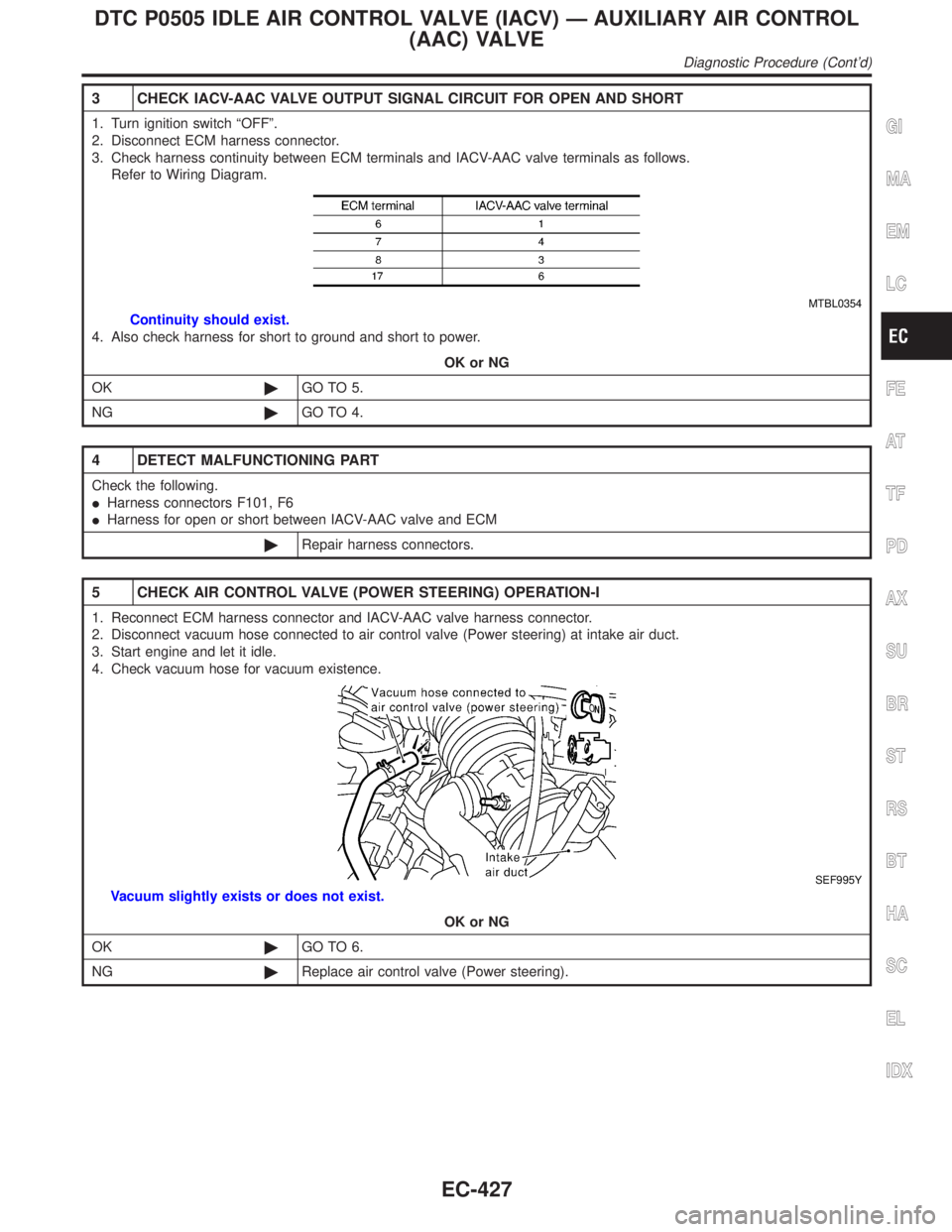

3 CHECK IACV-AAC VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals and IACV-AAC valve terminals as follows.

Refer to Wiring Diagram.

MTBL0354

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F101, F6

IHarness for open or short between IACV-AAC valve and ECM

©Repair harness connectors.

5 CHECK AIR CONTROL VALVE (POWER STEERING) OPERATION-I

1. Reconnect ECM harness connector and IACV-AAC valve harness connector.

2. Disconnect vacuum hose connected to air control valve (Power steering) at intake air duct.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence.

SEF995Y

Vacuum slightly exists or does not exist.

OK or NG

OK©GO TO 6.

NG©Replace air control valve (Power steering).

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Diagnostic Procedure (Cont'd)

EC-427

Page 966 of 2395

SEF505V

Component DescriptionNBEC0256A closed throttle position switch and wide open throttle position

switch are built into the throttle position sensor unit. The wide open

throttle position switch is used only for A/T control.

When the throttle valve is in the closed position, the closed throttle

position switch sends a voltage signal to the ECM. The ECM only

uses this signal to open or close the EVAP canister purge volume

control solenoid valve when the throttle position sensor is malfunc-

tioning.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0257Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CLSD THL/P SWIEngine: After warming up, idle

the engineThrottle valve: Idle position ON

Throttle valve: Slightly open OFF

ECM Terminals and Reference ValueNBEC0671Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

56 OR/LThrottle position switch

(Closed position)[Engine is running]

IAccelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IAccelerator pedal depressedApproximately 0V

On Board Diagnosis LogicNBEC0259Malfunction is detected when battery voltage from the closed

throttle position switch is sent to ECM with the throttle valve

opened.

Possible CauseNBEC0516IHarness or connectors

(The closed throttle position switch circuit is shorted.)

IClosed throttle position switch

IThrottle position sensor

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Component Description

EC-431

Page 967 of 2395

SEF197Y

SEF198Y

DTC Confirmation ProcedureNBEC0260CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0260S011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº, wait at least 10 seconds and then

start engine.

3) Select ªCLSD THL/P SWº in ªDATA MONITORº mode.

If ªCLSD THL/P SWº is not available, go to step 5.

4) Check the signal under the following conditions.

Condition Signal indication

Throttle valve: Idle position ON

Throttle valve: Slightly open OFF

If the result is NG, go to ªDiagnostic Procedureº, EC-435.

If OK, go to following step.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Drive the vehicle for at least 5 consecutive seconds under the

following condition.

THRTL POS SEN More than 2.5V

VHCL SPEED SE More than 5 km/h (3 MPH)

Selector lever Suitable position

Driving locationDriving vehicle uphill (Increased engine load)

will help maintain the driving conditions

required for this test.

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-435.

SEF345X

Overall Function CheckNBEC0261Use this procedure to check the overall function of the closed

throttle position switch circuit. During this check, a 1st trip DTC

might not be confirmed.

WITH GSTNBEC0261S011) Start engine and warm it up to normal operating temperature.

2) Check the voltage between ECM terminal 56 (Closed throttle

position switch signal) and ground under the following condi-

tions.

At idle: Battery voltage

DTC P0510 CLOSED THROTTLE POSITION SWITCH

DTC Confirmation Procedure

EC-432