window INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1437 of 2395

ENCODER AND LIMIT SWITCH CHECK=NBEL0221S01

1 CHECK DOOR WINDOW SLIDE MECHANISM

Check the following.

IObstacles in window, glass molding, etc.

IWorn or deformed glass molding

IDoor sash tilted too far inward or outward

IDoor window regulator

OK or NG

OK©GO TO 2.

NG©Remove obstacles or repair door window slide mechanism.

2 CHECK POWER SUPPLY TO LIMIT SWITCH

1. Disconnect front power window regulator LH or RH harness connector.

2. Check voltage between front power window main switch terminal 15 or front power window switch RH terminal 16 and

ground.

SEL725WA

OK or NG

OK©GO TO 3.

NG©Replace power window main switch or front power window switch RH.

3 CHECK LIMIT SWITCH OPERATION

1. Connect front power window regulator LH or RH harness connector.

2. Check voltage between front power window main switch terminal 15 or front power window switch RH terminal 16 and

ground during power window closing operation.

SEL726WA

OK or NG

OK©GO TO 5.

NG©GO TO 4.

POWER WINDOW

Trouble Diagnoses (Cont'd)

EL-252

Page 1438 of 2395

4 RESET LIMIT SWITCH

Reset limit switch. Refer to BT-19, ªFront Door Glass Limit Switch Resetº. Then check voltage between front power win-

dow main switch terminal 15 or front power window switch RH terminal 16 and ground during power window closing

operation at least ten times.

SEL726WA

OK or NG

OK©GO TO 5.

NG©Replace power window regulator motor.

5 CHECK ENCODER

Measure voltage between front power window main switch terminal 14 or front power window switch RH terminal 19 and

ground with oscilloscope when power window is in automatic closing operation.

SEL727WA

OK or NG

OK©Replace power window main switch.

NG©Replace power window regulator motor.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

POWER WINDOW

Trouble Diagnoses (Cont'd)

EL-253

Page 1450 of 2395

DOOR LOCK/UNLOCK SWITCH CHECK=NBEL0110S03

1 CHECK DOOR LOCK/UNLOCK SWITCH INPUT SIGNAL

1. Disconnect smart entrance control unit connector.

2. Check continuity between control unit terminal 23 or 35 and ground.

SEL309X

Refer to wiring diagram in EL-257.

OK or NG

OK©Door lock/unlock switch is OK.

NG©GO TO 2.

2 CHECK DOOR LOCK/UNLOCK SWITCH

1. Disconnect door lock/unlock switch connector.

2. Check continuity between each door lock/unlock switch terminals.

IPower window main switch (Door lock/unlock switch LH)

SEL310X

IDoor lock/unlock switch RH

SEL311X

OK or NG

OK©Check the following.

IGround circuit for door lock/unlock switch

IHarness for open or short between door lock/unlock switch and smart entrance control

unit connector

NG©Replace door lock/unlock switch.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

POWER DOOR LOCK

Trouble Diagnoses (Cont'd)

EL-265

Page 1468 of 2395

DOOR LOCK/UNLOCK SWITCH LH CHECK=NBEL0115S10

1 CHECK DOOR LOCK/UNLOCK SWITCH INPUT SIGNAL

1. Disconnect smart entrance control unit connector.

2. Check continuity between control unit terminal 23 or 35 and ground.

SEL309X

Refer to wiring diagram in EL-274.

OK or NG

OK©Door lock/unlock switch is OK.

NG©GO TO 2.

2 CHECK DOOR LOCK/UNLOCK SWITCH

1. Disconnect door lock/unlock switch connector.

2. Check continuity between each door lock/unlock switch terminals.

IPower window main switch (Door lock/unlock switch LH)

SEL310X

OK or NG

OK©Check the following.

IGround circuit for door lock/unlock switch

IHarness for open or short between door lock/unlock switch and smart entrance control

unit connector

NG©Replace door lock/unlock switch.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

MULTI-REMOTE CONTROL SYSTEM

Trouble Diagnoses (Cont'd)

EL-283

Page 1504 of 2395

DescriptionNBEL0124The following systems are controlled by the smart entrance control unit.

IWarning chime

IRear window defogger and door mirror defogger timer

IPower door lock

IMulti-remote control system

ITheft warning system

IInterior lamp timer

IElectric sunroof and power window timer

IHeadlamp battery saver

IBattery saver

For detailed description and wiring diagrams, refer to the relevant pages for the each system.

The smart entrance control unit receives data from the switches and sensors to control their corresponding

system relays and actuators.

INPUT/OUTPUTNBEL0124S01

System Input Output

Power door lockDoor lock and unlock switch LH and RH

Key switch (Insert)

Door switches

Door key cylinder switchesDoor lock actuator

Multi-remote controlKey switch (Insert)

Ignition switch (ACC)

Door switches

Front door unlock sensor LH

Door lock and unlock switch LH

Remote controller signalHorn relay

Headlamp relay (LH and RH)

Interior lamp

Multi-remote control relay

Door lock actuator

Warning chimeKey switch (Insert)

Ignition switch (ON)

Lighting switch (1st)

Seat belt switch

Front door switch LHWarning chime (located in smart entrance

control unit)

Rear window defogger and

door mirror defogger timerIgnition switch (ON)

Rear window defogger switchRear window defogger relay

Theft warningIgnition switch (ACC, ON)

Door switches

Hood switch

Glass hatch switch

Door key cylinder switches (lock/unlock)

Door unlock sensoresHorn relay

Headlamp relay (LH and RH)

Security indicator

Interior lamp timerDoor switches

Front door unlock sensor LH

Ignition switch (ON)

Key switch (Insert)Interior lamp

Electric sunroof and power

window timerFront door switches

Ignition switch (ON)Power window relay

Headlamp battery saver timerFront door switches

Ignition switch (ON)Headlamp battery saver control unit

Battery saverIgnition switch (ON)

Door switches

Driver's door unlock sensor

Key switch (Insert)Interior lamp

Luggage room lamp

Spot lamp

Vanity mirror illumination lamp

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

SMART ENTRANCE CONTROL UNIT

Description

EL-319

Page 1509 of 2395

Smart Entrance Control Unit Inspection TableNBEL0126

Terminal

No.Wire

colorConnections Operated conditionVoltage

(Approximate

values)

2 G/B Rear window defogger relay OFF,ON (Ignition key is in ªONº position) 0V,12V

4 PU/W Theft warning horn/lamp relay When panic alarm is operated using remote controller 12V,0V

5 R/YHeadlamp battery saver control

unitWhen headlamp battery saver timer is operated 12V

7 P Multi-remote control relay When doors are locked using remote controller 12V,0V

8 R/B Interior lampWhen interior lamp is operated using remote controller.

(Lamp switch in ªDOORº position)0V,12V

10 G/R Power source (Fuse) Ð 12V

11 W/R Power source (C/B) Ð 12V

13 W/PU Driver door lock actuator

Door lock & unlock switchFree 0V

14 Y/B Passenger door lock actuator Unlocked 12V

15 L Door lock actuators Door lock & unlock switchFree 0V

Locked 12V

16 B Ground Ð Ð

17 R/W Battery saver (Interior lamp) Battery saver is not operate,Operate 12V,0V

19 LG/B Horn relayWhen doors are locked using remote controller with horn

chirp mode.12V,0V

21 G/W Ignition switch (ACC) ªACCº position 12V

22 B/P Seat belt buckle switch Unfasten,Fasten (Ignition key is in ªONº position) 0V,12V

23 BR Door lock & unlock switches Neutral,Locks 5V,0V

26 Y/R Rear door unlock sensors All doors are locked,One or more doors are unlocked 5V,0V

27 Y/B Hood open signal ON (Open),OFF (Closed) 0V,5V

28 R/L Rear and back door switches OFF (Closed),ON (Open) 5V,0V

29 G/R Driver door switch OFF (Closed),ON (Open) 5V,0V

30 LG Door key cylinder unlock switch OFF (Neutral),ON (Unlocked) 12V,0V

31 BR/Y Theft warning indicator Goes off,Illuminates 12V,0V

32 W/R Ignition key switch (Insert) key inserted,key removed from IGN key cylinder 12V,0V

33 W/B Ignition switch (ON) Ignition key is in ªONº position 12V

35 LG/R Door lock & unlock switches Neutral,Unlocks 5V,0V

36 Y/G Driver door unlock sensor Driver door: Locked,Unlocked 5V,0V

37 Y/L Passenger door unlock sensor Passenger door: Locked,Unlocked 5V,0V

38 L/W Glass hatch switch ON (Open),OFF (Closed) 0V,12V

39 OR Rear window defogger switch OFF,ON 5V,0V

40 Y Passenger door switch OFF (Closed),ON (Open) 5V,0V

41 Y Door key cylinder lock switch OFF (Neutral),ON (Locked) 5V,0V

42 G/B Back door key unlock switch OFF (Neutral),ON (Unlock) 5V,0V

SMART ENTRANCE CONTROL UNIT

Smart Entrance Control Unit Inspection Table

EL-324

Page 1561 of 2395

GPS ANTENNA CHECK=NBEL0184S11

1 CHECK VOLTAGE FOR GPS ANTENNA

1. Disconnect GPS feeder cable connector from IVCS unit.

2. Turn ignition switch ON.

3. Check voltage at IVCS unit GPS feeder cable terminal.

SEL106W

Does approx. 5V exist?

Ye s©Replace GPS antenna.

No©Replace IVCS unit.

AIR BAG DIAGNOSES SENSOR UNIT

COMMUNICATION CHECK

NBEL0184S12

1 AIR BAG OPERATION CHECK

Turn ignition switch ON and check air bag warning lamp operation. (For details, refer to RS-38.)

Does air bag warning lamp operate properly?

Ye s©Check harness connector connection between air bag diagnosis sensor unit and IVCS

unit.

No©Check supplemental restraint system. Refer to RS-29.

SMART ENTRANCE CONTROL UNIT COMMUNICATION

CHECK

NBEL0184S13

1 CHECK SMART ENTRANCE CONTROL UNIT OPERATION

Check the system related smart entrance control unit operation. (e.g.: power door lock, power window)

Does the system operate properly?

Ye s©Check harness for open or short between smart entrance control unit and IVCS unit.

No©Check smart entrance control unit. Refer to ªSMART ENTRANCE CONTROL UNITº in

the Service Manual. (EL-324)

INFINITI COMMUNICATOR (IVCS)

Trouble Diagnoses (Cont'd)

EL-376

Page 1642 of 2395

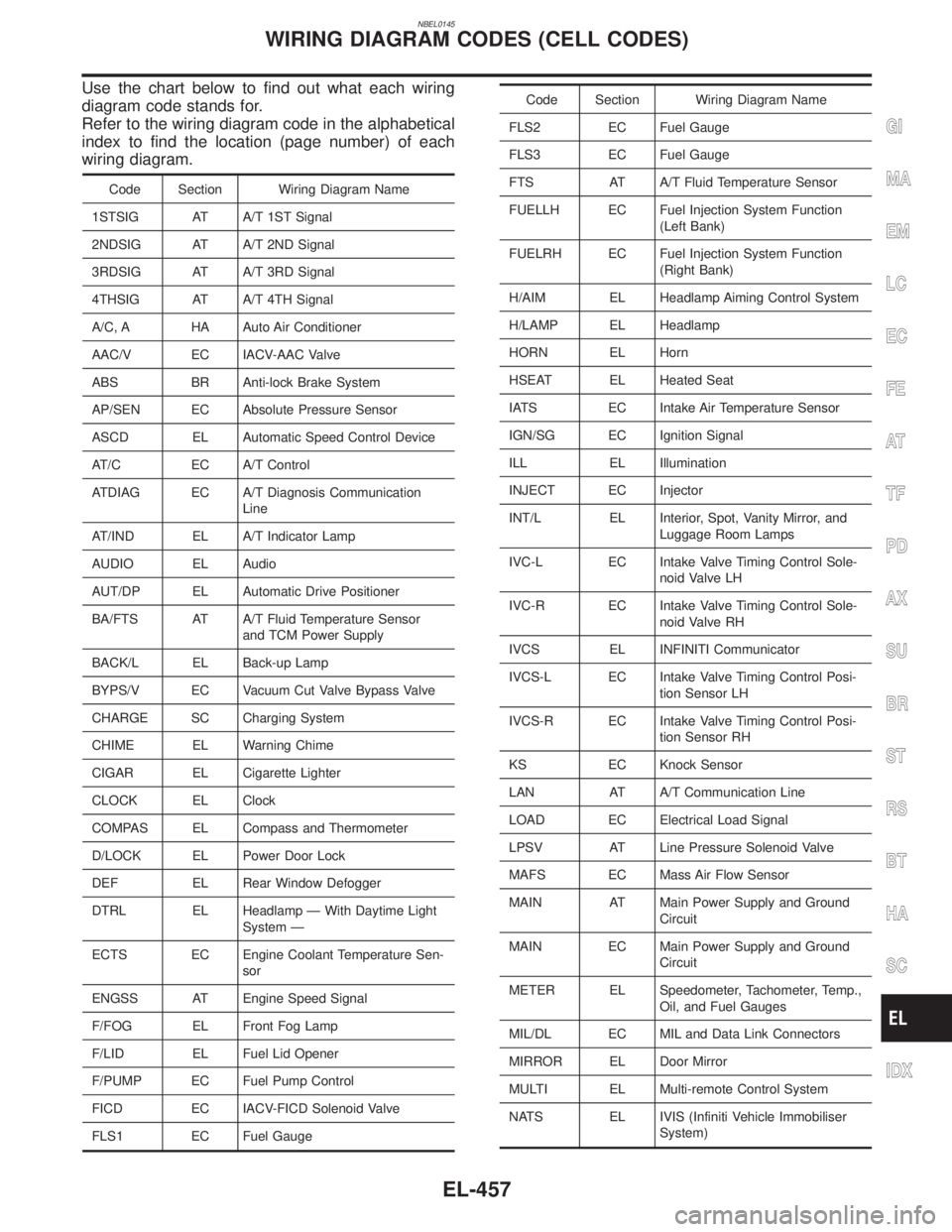

NBEL0145

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

1STSIG AT A/T 1ST Signal

2NDSIG AT A/T 2ND Signal

3RDSIG AT A/T 3RD Signal

4THSIG AT A/T 4TH Signal

A/C, A HA Auto Air Conditioner

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

AP/SEN EC Absolute Pressure Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

ATDIAG EC A/T Diagnosis Communication

Line

AT/IND EL A/T Indicator Lamp

AUDIO EL Audio

AUT/DP EL Automatic Drive Positioner

BA/FTS AT A/T Fluid Temperature Sensor

and TCM Power Supply

BACK/L EL Back-up Lamp

BYPS/V EC Vacuum Cut Valve Bypass Valve

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CLOCK EL Clock

COMPAS EL Compass and Thermometer

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DTRL EL Headlamp Ð With Daytime Light

System Ð

ECTS EC Engine Coolant Temperature Sen-

sor

ENGSS AT Engine Speed Signal

F/FOG EL Front Fog Lamp

F/LID EL Fuel Lid Opener

F/PUMP EC Fuel Pump Control

FICD EC IACV-FICD Solenoid Valve

FLS1 EC Fuel Gauge

Code Section Wiring Diagram Name

FLS2 EC Fuel Gauge

FLS3 EC Fuel Gauge

FTS AT A/T Fluid Temperature Sensor

FUELLH EC Fuel Injection System Function

(Left Bank)

FUELRH EC Fuel Injection System Function

(Right Bank)

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HORN EL Horn

HSEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior, Spot, Vanity Mirror, and

Luggage Room Lamps

IVC-L EC Intake Valve Timing Control Sole-

noid Valve LH

IVC-R EC Intake Valve Timing Control Sole-

noid Valve RH

IVCS EL INFINITI Communicator

IVCS-L EC Intake Valve Timing Control Posi-

tion Sensor LH

IVCS-R EC Intake Valve Timing Control Posi-

tion Sensor RH

KS EC Knock Sensor

LAN AT A/T Communication Line

LOAD EC Electrical Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground

Circuit

MAIN EC Main Power Supply and Ground

Circuit

METER EL Speedometer, Tachometer, Temp.,

Oil, and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL IVIS (Infiniti Vehicle Immobiliser

System)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WIRING DIAGRAM CODES (CELL CODES)

EL-457

Page 1643 of 2395

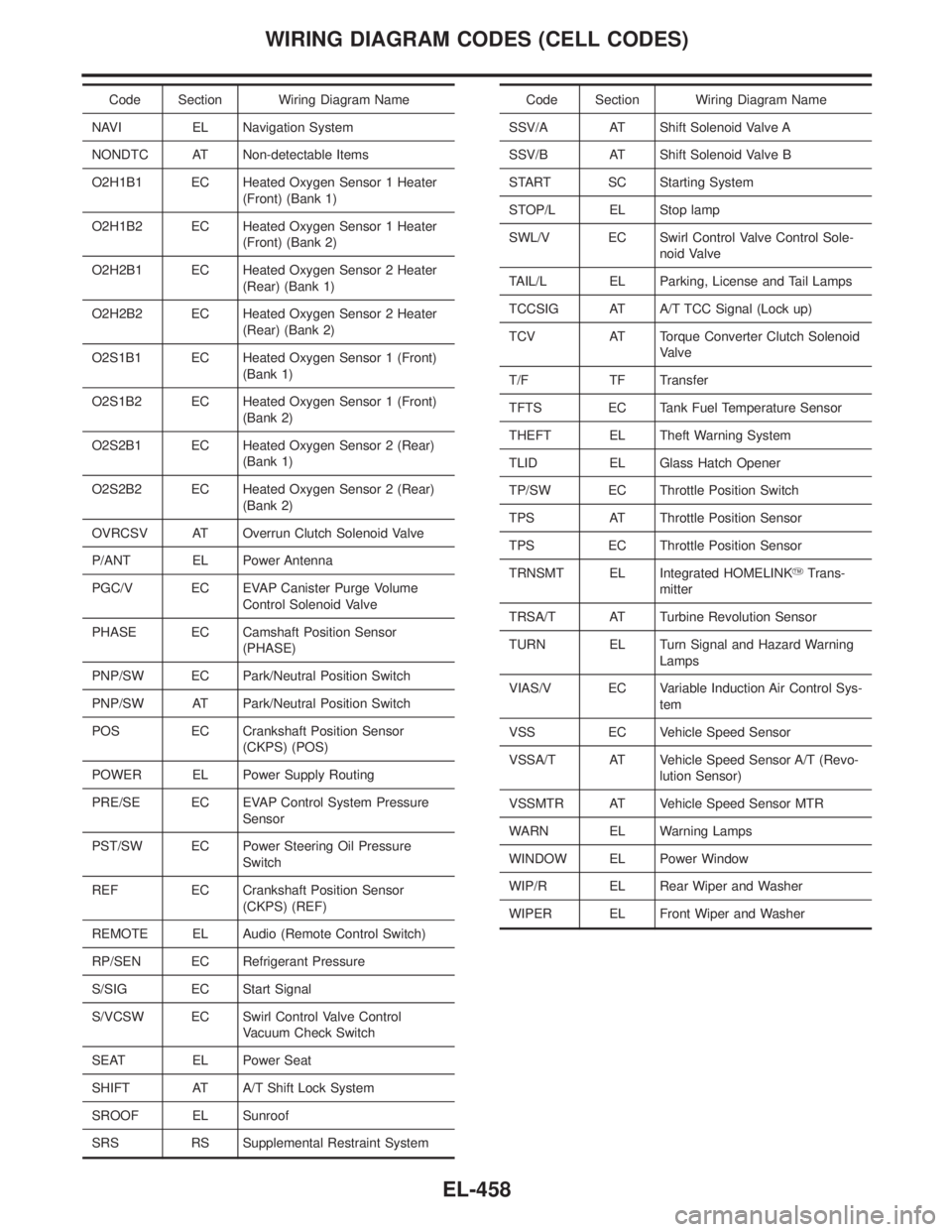

Code Section Wiring Diagram Name

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 1)

O2H1B2 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 2)

O2H2B1 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 1)

O2H2B2 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 2)

O2S1B1 EC Heated Oxygen Sensor 1 (Front)

(Bank 1)

O2S1B2 EC Heated Oxygen Sensor 1 (Front)

(Bank 2)

O2S2B1 EC Heated Oxygen Sensor 2 (Rear)

(Bank 1)

O2S2B2 EC Heated Oxygen Sensor 2 (Rear)

(Bank 2)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume

Control Solenoid Valve

PHASE EC Camshaft Position Sensor

(PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor

(CKPS) (POS)

POWER EL Power Supply Routing

PRE/SE EC EVAP Control System Pressure

Sensor

PST/SW EC Power Steering Oil Pressure

Switch

REF EC Crankshaft Position Sensor

(CKPS) (REF)

REMOTE EL Audio (Remote Control Switch)

RP/SEN EC Refrigerant Pressure

S/SIG EC Start Signal

S/VCSW EC Swirl Control Valve Control

Vacuum Check Switch

SEAT EL Power Seat

SHIFT AT A/T Shift Lock System

SROOF EL Sunroof

SRS RS Supplemental Restraint SystemCode Section Wiring Diagram Name

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop lamp

SWL/V EC Swirl Control Valve Control Sole-

noid Valve

TAIL/L EL Parking, License and Tail Lamps

TCCSIG AT A/T TCC Signal (Lock up)

TCV AT Torque Converter Clutch Solenoid

Valve

T/F TF Transfer

TFTS EC Tank Fuel Temperature Sensor

THEFT EL Theft Warning System

TLID EL Glass Hatch Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TRNSMT EL Integrated HOMELINKYTrans-

mitter

TRSA/T AT Turbine Revolution Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VIAS/V EC Variable Induction Air Control Sys-

tem

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revo-

lution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-458

Page 1772 of 2395

The second method is to put the suspect component into a freezer

long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair

or replace the component.

SGI844

WATER INTRUSIONNBGI0004S0205The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water

intrusion on an electrical part. This can be simulated by soaking the

car or running it through a car wash.

Do not spray water directly on any electrical components.

SGI845

ELECTRICAL LOADNBGI0004S0206The incident may be electrical load sensitive. Perform diagnosis

with all accessories (including A/C, rear window defogger, radio,

fog lamps) turned on.

COLD OR HOT START UPNBGI0004S0207On some occasions an electrical incident may occur only when the

car is started cold. Or it may occur when the car is restarted hot

shortly after being turned off. In these cases you may have to keep

the car overnight to make a proper diagnosis.

Circuit InspectionNBGI0004S03INTRODUCTIONNBGI0004S0302In general, testing electrical circuits is an easy task if it is

approached in a logical and organized method. Before beginning

it is important to have all available information on the system to be

tested. Also, get a thorough understanding of system operation.

Then you will be able to use the appropriate equipment and follow

the correct test procedure.

You may have to simulate vehicle vibrations while testing electrical

components.Gently shakethe wiring harness or electrical com-

ponent to do this.

OPEN A circuit is open when there is no continuity through a section of

the circuit.

SHORT There are two types of shorts.

ISHORT CIRCUIT When a circuit contacts another circuit

and causes the normal resistance to

change.

ISHORT TO GROUND When a circuit contacts a ground

source and grounds the circuit.

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Incident Simulation Tests (Cont'd)

GI-27