change time INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1962 of 2395

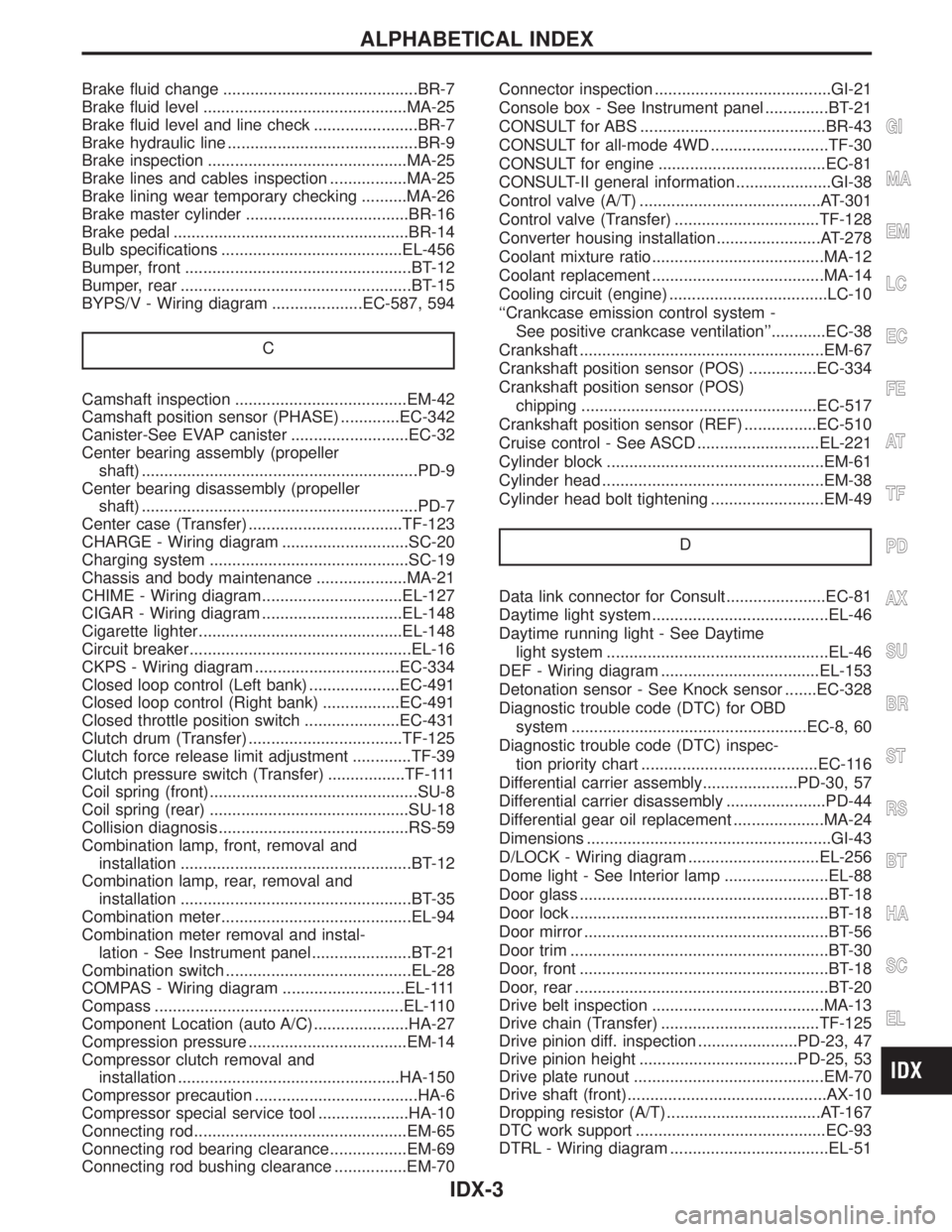

Brake fluid change ...........................................BR-7

Brake fluid level .............................................MA-25

Brake fluid level and line check .......................BR-7

Brake hydraulic line ..........................................BR-9

Brake inspection ............................................MA-25

Brake lines and cables inspection .................MA-25

Brake lining wear temporary checking ..........MA-26

Brake master cylinder ....................................BR-16

Brake pedal ....................................................BR-14

Bulb specifications ........................................EL-456

Bumper, front ..................................................BT-12

Bumper, rear ...................................................BT-15

BYPS/V - Wiring diagram ....................EC-587, 594

C

Camshaft inspection ......................................EM-42

Camshaft position sensor (PHASE) .............EC-342

Canister-See EVAP canister ..........................EC-32

Center bearing assembly (propeller

shaft) .............................................................PD-9

Center bearing disassembly (propeller

shaft) .............................................................PD-7

Center case (Transfer) ..................................TF-123

CHARGE - Wiring diagram ............................SC-20

Charging system ............................................SC-19

Chassis and body maintenance ....................MA-21

CHIME - Wiring diagram...............................EL-127

CIGAR - Wiring diagram ...............................EL-148

Cigarette lighter.............................................EL-148

Circuit breaker.................................................EL-16

CKPS - Wiring diagram ................................EC-334

Closed loop control (Left bank) ....................EC-491

Closed loop control (Right bank) .................EC-491

Closed throttle position switch .....................EC-431

Clutch drum (Transfer) ..................................TF-125

Clutch force release limit adjustment .............TF-39

Clutch pressure switch (Transfer) .................TF-111

Coil spring (front)..............................................SU-8

Coil spring (rear) ............................................SU-18

Collision diagnosis..........................................RS-59

Combination lamp, front, removal and

installation ...................................................BT-12

Combination lamp, rear, removal and

installation ...................................................BT-35

Combination meter..........................................EL-94

Combination meter removal and instal-

lation - See Instrument panel ......................BT-21

Combination switch .........................................EL-28

COMPAS - Wiring diagram ...........................EL-111

Compass .......................................................EL-110

Component Location (auto A/C).....................HA-27

Compression pressure ...................................EM-14

Compressor clutch removal and

installation .................................................HA-150

Compressor precaution ....................................HA-6

Compressor special service tool ....................HA-10

Connecting rod...............................................EM-65

Connecting rod bearing clearance.................EM-69

Connecting rod bushing clearance ................EM-70Connector inspection .......................................GI-21

Console box - See Instrument panel ..............BT-21

CONSULT for ABS .........................................BR-43

CONSULT for all-mode 4WD ..........................TF-30

CONSULT for engine .....................................EC-81

CONSULT-II general information .....................GI-38

Control valve (A/T) ........................................AT-301

Control valve (Transfer) ................................TF-128

Converter housing installation .......................AT-278

Coolant mixture ratio......................................MA-12

Coolant replacement ......................................MA-14

Cooling circuit (engine) ...................................LC-10

``Crankcase emission control system -

See positive crankcase ventilation''............EC-38

Crankshaft ......................................................EM-67

Crankshaft position sensor (POS) ...............EC-334

Crankshaft position sensor (POS)

chipping ....................................................EC-517

Crankshaft position sensor (REF) ................EC-510

Cruise control - See ASCD ...........................EL-221

Cylinder block ................................................EM-61

Cylinder head .................................................EM-38

Cylinder head bolt tightening .........................EM-49

D

Data link connector for Consult......................EC-81

Daytime light system.......................................EL-46

Daytime running light - See Daytime

light system .................................................EL-46

DEF - Wiring diagram ...................................EL-153

Detonation sensor - See Knock sensor .......EC-328

Diagnostic trouble code (DTC) for OBD

system ....................................................EC-8, 60

Diagnostic trouble code (DTC) inspec-

tion priority chart .......................................EC-116

Differential carrier assembly.....................PD-30, 57

Differential carrier disassembly ......................PD-44

Differential gear oil replacement ....................MA-24

Dimensions ......................................................GI-43

D/LOCK - Wiring diagram .............................EL-256

Dome light - See Interior lamp .......................EL-88

Door glass .......................................................BT-18

Door lock .........................................................BT-18

Door mirror ......................................................BT-56

Door trim .........................................................BT-30

Door, front .......................................................BT-18

Door, rear ........................................................BT-20

Drive belt inspection ......................................MA-13

Drive chain (Transfer) ...................................TF-125

Drive pinion diff. inspection ......................PD-23, 47

Drive pinion height ...................................PD-25, 53

Drive plate runout ..........................................EM-70

Drive shaft (front)............................................AX-10

Dropping resistor (A/T) ..................................AT-167

DTC work support ..........................................EC-93

DTRL - Wiring diagram ...................................EL-51

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

ALPHABETICAL INDEX

IDX-3

Page 1999 of 2395

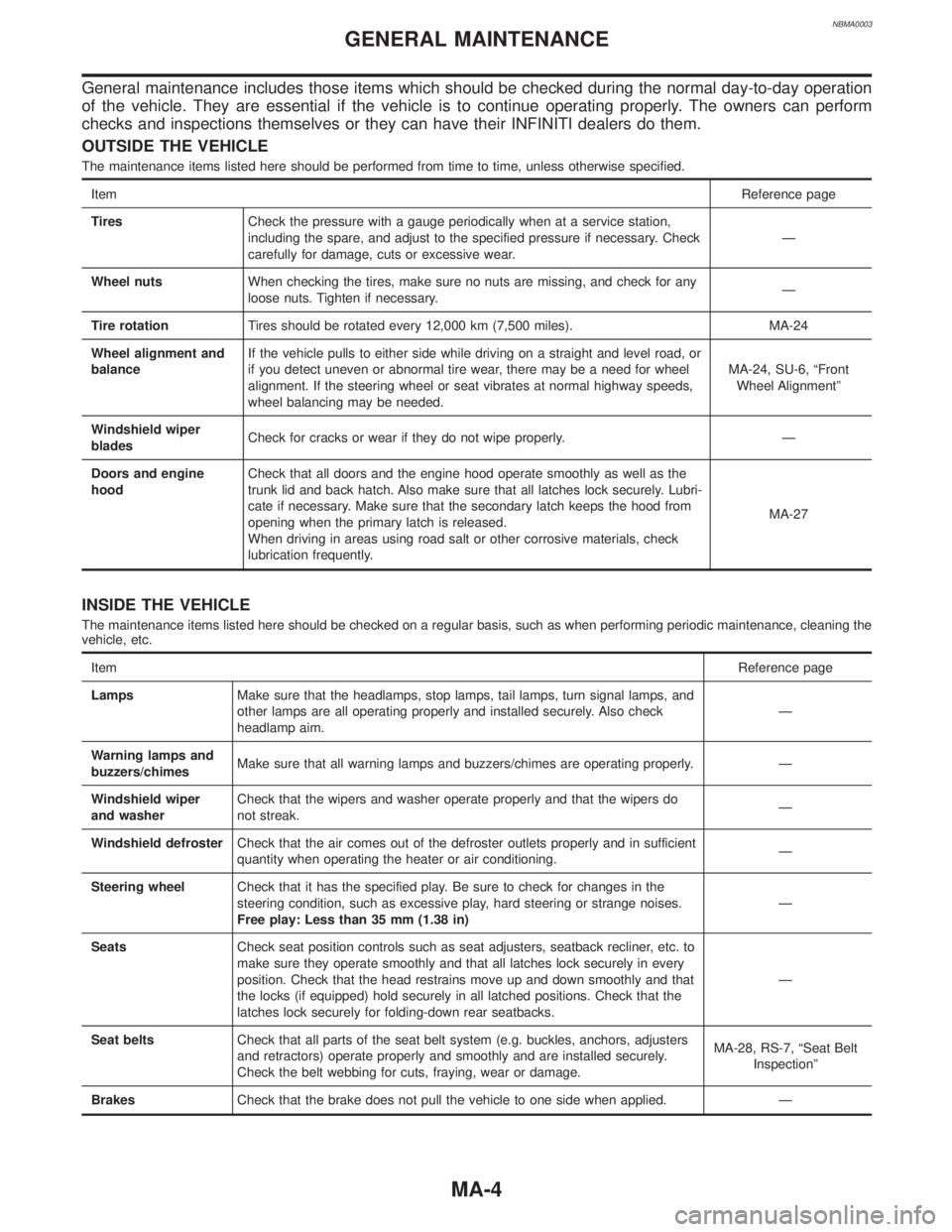

NBMA0003

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or they can have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

ItemReference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.Ð

Wheel nutsWhen checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.Ð

Tire rotationTires should be rotated every 12,000 km (7,500 miles). MA-24

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or

if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.MA-24, SU-6, ªFront

Wheel Alignmentº

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the

trunk lid and back hatch. Also make sure that all latches lock securely. Lubri-

cate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check

lubrication frequently.MA-27

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

ItemReference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.Ð

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly. Ð

Windshield wiper

and washerCheck that the wipers and washer operate properly and that the wipers do

not streak.Ð

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning.Ð

Steering wheelCheck that it has the specified play. Be sure to check for changes in the

steering condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.MA-28, RS-7, ªSeat Belt

Inspectionº

BrakesCheck that the brake does not pull the vehicle to one side when applied. Ð

GENERAL MAINTENANCE

MA-4

Page 2013 of 2395

SMA096D

Changing Engine OilNBMA0015WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine and wait for more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity

IAPI grade SG or SH, Energy ConservingI&IIorAPIgrade

SJ, Energy Conserving

IAPI Certification Mark

IILSAC grade GF-I & GF-II

ISee ªRECOMMENDED FLUIDS AND LUBRICANTSº, MA-11.

Oil capacity (Approximately):

Unit:(US qt, Imp qt)

Drain and refillWith oil filter change 5.0 (5-1/4, 4-3/8)

Without oil filter change 4.8 (5-1/8, 4-1/4)

Dry engine (engine overhaul) 6.8 (7-1/4, 6)

CAUTION:

IBe sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

JMA122D

5. Warm up engine and check area around drain plug and oil fil-

ter for oil leakage.

6. Stop engine and wait for more than 10 minutes.

7. Check oil level.

SMA097D

Changing Oil FilterNBMA00161. Remove oil filter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

The filter is a full-flow cartridge type and is provided with a relief

valve.

Refer to LC-7, ªOil Filterº.

ENGINE MAINTENANCE

Changing Engine Oil

MA-18

Page 2015 of 2395

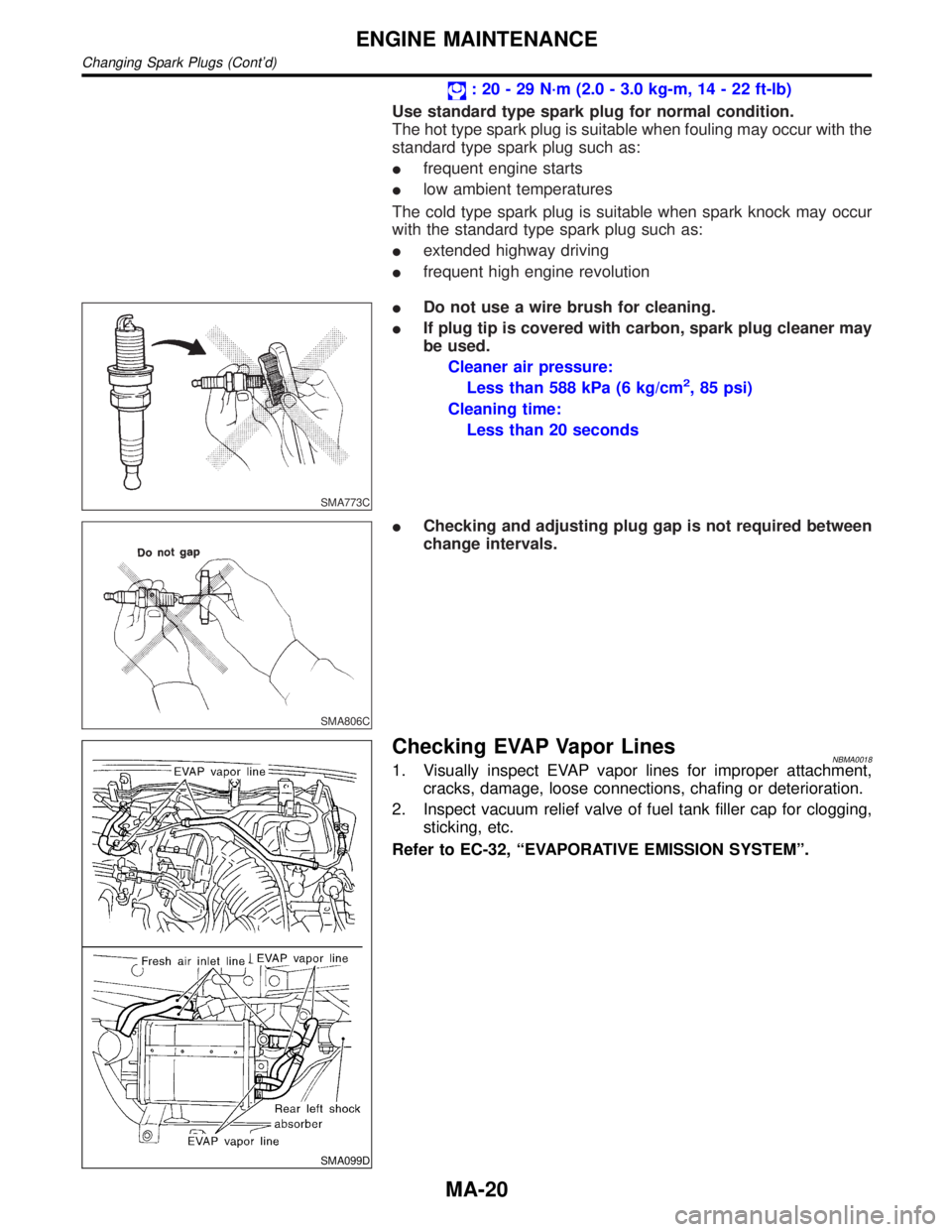

: 20 - 29 N´m (2.0 - 3.0 kg-m, 14 - 22 ft-lb)

Use standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling may occur with the

standard type spark plug such as:

Ifrequent engine starts

Ilow ambient temperatures

The cold type spark plug is suitable when spark knock may occur

with the standard type spark plug such as:

Iextended highway driving

Ifrequent high engine revolution

SMA773C

IDo not use a wire brush for cleaning.

IIf plug tip is covered with carbon, spark plug cleaner may

be used.

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time:

Less than 20 seconds

SMA806C

IChecking and adjusting plug gap is not required between

change intervals.

SMA099D

Checking EVAP Vapor LinesNBMA00181. Visually inspect EVAP vapor lines for improper attachment,

cracks, damage, loose connections, chafing or deterioration.

2. Inspect vacuum relief valve of fuel tank filler cap for clogging,

sticking, etc.

Refer to EC-32, ªEVAPORATIVE EMISSION SYSTEMº.

ENGINE MAINTENANCE

Changing Spark Plugs (Cont'd)

MA-20

Page 2060 of 2395

SPD560

15. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Install side oil seal.

Tool number: KV38100200 (J26233)

SPD513

16. Measure ring gear to drive pinion backlash with a dial indica-

tor.

Ring gear-to-drive pinion backlash:

0.10 - 0.15 mm (0.0039 - 0.0059 in)

IIf backlash is too small, decrease thickness of right shim and

increase thickness of left shim by the same amount.

If backlash is too great, reverse the above procedure.

Never change the total amount of shims as it will change the

bearing preload.

SPD664

17. Check total preload with Tool.

When checking preload, turn drive pinion in both direc-

tions several times to set bearing rollers.

Tool number: ST3127S000 (J25765-A)

Total preload:

P

1+ [0.3 - 1.5 N´m (3 - 15 kg-cm, 2.6 - 13.0 in-lb)]

P

1: Drive pinion preload

SPD561

IIf preload is too great, remove the same amount of shim from

each side.

IIf preload is too small, add the same amount of shim to each

side.

Never add or remove a different number of shims for each side

as it will change ring gear to drive pinion backlash.

18. Recheck ring gear to drive pinion backlash because increase

or decrease in thickness of shims will cause change of ring

gear-to-pinion backlash.

SPD524

19. Check runout of ring gear with a dial indicator.

Runout limit:

0.05 mm (0.0020 in)

IIf backlash varies excessively in different places, the variance

may have resulted from foreign matter caught between the ring

gear and the differential case.

IIf the backlash varies greatly when the runout of the ring gear

is within a specified range, the hypoid gear set or differential

case should be replaced.

20. Check tooth contact. Refer to ªTOOTH CONTACTº, PD-29.

21. Install rear cover and gasket.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Assembly (Cont'd)

PD-35

Page 2119 of 2395

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II=NBRS0040S03From User Mode to Diagnosis ModeNBRS0040S0301After selecting ªAIR BAGº on the ªSELECT SYSTEMº screen, User mode automatically changes to Diagno-

sis mode.

SRS803

From Diagnosis Mode to User ModeNBRS0040S0302To return to User mode from Diagnosis mode, touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears, Diagnosis mode automatically changes to User mode.

SRS804

HOW TO CHANGE SELF-DIAGNOSIS MODE WITHOUT CONSULT-IINBRS0040S04From User Mode to Diagnosis ModeNBRS0040S0401Diagnosis mode activates only when a malfunction is detected, by turning ignition switch as follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

SRS will not enter Diagnosis mode, if no malfunction is detected.

From Diagnosis Mode to User ModeNBRS0040S0402After a malfunction is repaired, switch the ignition ªOFFº for at least one second, then back ªONº. Diagnosis

mode is returned to User mode.

If switching Diagnosis mode to User mode is required while malfunction is being detected, by turning ignition

switch as follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn ignition switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

HOW TO ERASE SELF-DIAGNOSIS RESULTSNBRS0040S05With CONSULT-IINBRS0040S0501IªSELF-DIAG [CURRENT]º

A current Self-diagnosis result is displayed on the CONSULT-II screen in real time.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses Introduction (Cont'd)

RS-30

Page 2275 of 2395

SMT968D

1. Current CLUTCH FORCE RELEASE LIMIT value ª0.3 kg-mº

appears under ªCONDITION SETTINGº on CONSULT-II dis-

play.

2. Touch ª1.2º on the display.

SMT969D

3. Display changes to ªNOW ADJUSTINGº in a short time.

SMT970D

4. When clutch force release limit value is set to ª1.2 kg-mº, cur-

rent value ª0.3 kg-mº shown on display will be replaced by ª1.2

kg-mº and ªADJUSTING COMPLETEº will appear at the same

time. Clutch force release limit value setting is now complete.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-40