check engine INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 198 of 2395

Diagnostic ProcedureNBAT0173

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 6.

2 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªFLUID TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT614J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING ITEM

Check the following items:

IHarness for short to ground or short to power or open between TCM, ECM and terminal cord assembly (Main harness)

IGround circuit for ECM.

Refer to EC-174, ªWiring Diagramº.

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

Diagnostic Procedure

AT-193

Page 199 of 2395

4 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assmebly.

3. Check resistance between terminals 8 and 9 when A/T is cold [20ÉC (68ÉF)].

SAT697I

Is resistance approx. 2.5 kW?

Ye s©GO TO 7.

No©GO TO 5.

5 DETECT MALFUNCTIONING ITEM

1. Remove oil pan.

2. Check the following items:

IA/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-110.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

6 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT518J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

Diagnostic Procedure (Cont'd)

AT-194

Page 200 of 2395

7 CHECK TCM POWER SOURCE STEP 1

1. Turn ignition switch to ON position.

(Do not start engine.)

2. Check voltage between TCM terminals 10, 19, 28 and ground.

SAT611J

OK or NG

OK©GO TO 8.

NG©GO TO 9.

8 CHECK TCM POWER SOURCE STEP 2

1. Turn ignition switch to OFF position.

2. Check voltage between TCM terminal 28 and ground.

SAT612JC

OK or NG

OK©GO TO 10.

NG©GO TO 9.

9 DETECT MALFUNCTIONING ITEM

Check the following items:

IHarness for short or open between ignition switch and TCM terminals 10, 19 and 28 (Main harness)

IIgnition switch and 10A or 7.5A fuse [No. 18 or 24, located in the fuse block (J/B)]

Refer to EL-9, ªSchematicº.

OK or NG

OK©GO TO 10.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

Diagnostic Procedure (Cont'd)

AT-195

Page 202 of 2395

DescriptionNBAT0071The vehicle speed sensor´MTR is built into the speedometer

assembly. The sensor functions as an auxiliary device to the revo-

lution sensor when it is malfunctioning. The TCM will then use a

signal sent from the vehicle speed sensor´MTR.

TCM TERMINALS AND REFERENCE VALUENBAT0071S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

40 W/LVehicle speed

sensor

When moving vehicle at 2 to 3 km/h (1 to 2

MPH) for1m(3ft)ormore.Voltage varies

between less

than 1V and

more than

4.5V

ON BOARD DIAGNOSIS LOGICNBAT0071S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: VHCL SPEED SEN´MTR

TCM does not receive the proper voltage

signal from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

IVehicle speed sensor

: 2nd judgement flicker

SAT014K

SAT971J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0071S01CAUTION:

IAlways drive vehicle at a safe speed.

IIf conducting this ªDTC CONFIRMATION PROCEDUREº

again, always turn ignition switch ªOFFº and wait at least

5 seconds before continuing.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªA/Tº with CONSULT-II.

2) Start engine and accelerate vehicle from 0 to 25 km/h (0 to 6

MPH).

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC VEHICLE SPEED SENSOR´MTR

Description

AT-197

Page 205 of 2395

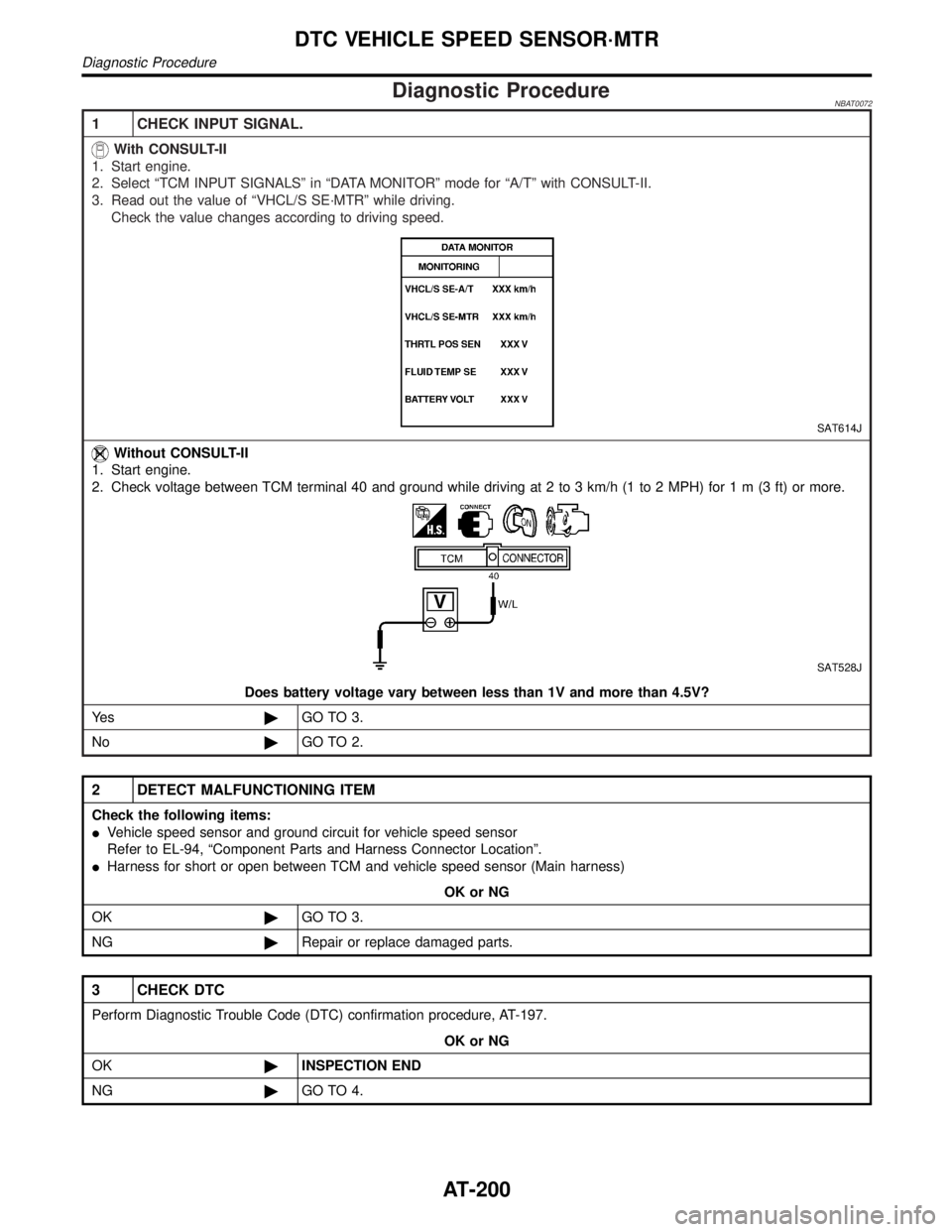

Diagnostic ProcedureNBAT0072

1 CHECK INPUT SIGNAL.

With CONSULT-II

1. Start engine.

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªVHCL/S SE´MTRº while driving.

Check the value changes according to driving speed.

SAT614J

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 40 and ground while driving at 2 to 3 km/h (1 to 2 MPH) for1m(3ft)ormore.

SAT528J

Does battery voltage vary between less than 1V and more than 4.5V?

Ye s©GO TO 3.

No©GO TO 2.

2 DETECT MALFUNCTIONING ITEM

Check the following items:

IVehicle speed sensor and ground circuit for vehicle speed sensor

Refer to EL-94, ªComponent Parts and Harness Connector Locationº.

IHarness for short or open between TCM and vehicle speed sensor (Main harness)

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

3 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-197.

OK or NG

OK©INSPECTION END

NG©GO TO 4.

DTC VEHICLE SPEED SENSOR´MTR

Diagnostic Procedure

AT-200

Page 207 of 2395

SAT136K

DescriptionNBAT0224The turbine revolution sensor detects input shaft rpm (revolutions

per minute). It is located on the input side of the automatic trans-

mission. The vehicle speed sensor A/T (Revolution sensor) is

located on the output side of the automatic transmission. With the

two sensors, input and output shaft rpms are accurately detected.

The result is optimal shift timing during deceleration and improved

shifting.

TCM TERMINALS AND REFERENCE VALUENBAT0224S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

38 WTurbine revolution

sensor

(Measure in AC

range)

When engine is running at 1,000 rpm1.2V

Voltage rises

gradually in

response to

engine speed.

42 BThrottle position

sensor (Ground)

Ð0V

ON BOARD DIAGNOSIS LOGICNBAT0224S02

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: TURBINE REV

TCM does not receive the proper voltage

signal from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

ITurbine revolution sensor

: 10th judgement flicker

DTC TURBINE REVOLUTION SENSOR

Description

AT-202

Page 210 of 2395

Diagnostic ProcedureNBAT0226

1 CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªTURBINE REVº. Check the value changes according to engine speed.

SAT740J

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 38 and ground. (Measure in AC range.)

SAT140K

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING ITEM

Check harness for short or open between TCM and turbine revolution sensor.

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

3 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-203.

OK or NG

OK©INSPECTION END

NG©GO TO 4.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC TURBINE REVOLUTION SENSOR

Diagnostic Procedure

AT-205

Page 212 of 2395

DescriptionNBAT0228The ECM and TCM provide mutual communication in relation to

engine output control signal (ignition timing retard signal) during

rapid standing starts/acceleration. With this consistent real-time

control, the shifting feel is substantially improved.

TCM TERMINALS AND REFERENCE VALUENBAT0228S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

33 G/R LAN

ÐÐ

*: This terminal is connected to the ECM.

ON BOARD DIAGNOSIS LOGICNBAT0228S02

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: A/T COMM LINE

The ECM-A/T communication line is

open or shorted.IHarness or connector

: 12th judgement flicker

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC A/T COMMUNICATION LINE

Description

AT-207

Page 215 of 2395

Diagnostic ProcedureNBAT0230

1 CHECK CIRCUIT BETWEEN TCM AND ECM

1. Turn ignition switch to OFF position.

2. Check continuity between TCM terminal 33 and ECM terminal 114.

SAT640JA

OK or NG

OK©GO TO 2.

NG©Repair or replace harness and connector between TCM and ECM.

2 CHECK DTC WITH ECM STEP 1

Perform self-diagnosis for engine control. Refer to EC-74, ªDESCRIPTIONº.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 CHECK DTC WITH ECM STEP 2

Check ECM. Refer to EC-440 and EC-603, ªSystem Descriptionº and ªComponent Descriptionº.

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-208.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

5 CHECK TCM INSPECTION

If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

DTC A/T COMMUNICATION LINE

Diagnostic Procedure

AT-210

Page 216 of 2395

SAT574J

DescriptionNBAT0207The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the A/T.

ON BOARD DIAGNOSIS LOGICNBAT0207S01

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: CONTROL UNIT (RAM)

: CONTROL UNIT (ROM)TCM memory (RAM) or (ROM) is mal-

functioning.TCM

SAT014K

SAT971J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0207S02NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for A/T with CONSULT-II.

2) Start engine.

3) Run engine for at least 2 seconds at idle speed.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC CONTROL UNIT (RAM), CONTROL UNIT (ROM)

Description

AT-211