check engine INFINITI QX4 2001 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 403 of 2395

Removal and InstallationNBBR0016

SBR520E

InspectionNBBR0017Check brake pedal for following items.

IBrake pedal bend

IClevis pin deformation

ICrack of any welded portion

ICrack or deformation of clevis pin stopper

SBR463CC

AdjustmentNBBR0018Check brake pedal free height from metal panel.

H: Free height

Refer to SDS (BR-83).

D: Depressed height

Refer to SDS (BR-83).

Under force of 490 N (50 kg, 110 lb) with engine run-

ning

C

1,C2: Clearance between pedal stopper and

threaded end of stop lamp switch and ASCD switch

0.3 - 1.0 mm (0.012 - 0.039 in)

A: Pedal free play

1-3mm(0.04 - 0.12 in)

If necessary, adjust brake pedal free height.

BRAKE PEDAL AND BRACKET

Removal and Installation

BR-14

Page 404 of 2395

SBR824B

1. Loosen lock nut and adjust pedal free height by turning brake

booster input rod. Then tighten lock nut.

Make sure that tip of input rod stays inside.

2. Adjust clearance ªC

1º and ªC2º with stop lamp switch and

ASCD switch respectively. Then tighten lock nuts.

3. Check pedal free play.

Make sure that stop lamp is off when pedal is released.

4. Check brake pedal's depressed height while engine is running.

If depressed height is below specified value, check brake sys-

tem for leaks, accumulation of air or any damage to compo-

nents (master cylinder, wheel cylinder, etc.). Then make nec-

essary repairs.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

BRAKE PEDAL AND BRACKET

Adjustment (Cont'd)

BR-15

Page 408 of 2395

SBR002A

SBR365AA

On-vehicle ServiceNBBR0024OPERATING CHECKNBBR0024S011. Depress brake pedal several times with engine off. After

exhausting vacuum, make sure there is no change in pedal

stroke.

2. Depress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECKNBBR0024S021. Start engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. Booster is airtight if pedal

stroke is less each time.

2. Depress brake pedal while engine is running, and stop engine

with pedal depressed. The pedal stroke should not change

after holding pedal down for30 seconds.

SBR368DA

RemovalNBBR0025CAUTION:

IBe careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

IBe careful not to deform or bend brake pipes, during

removal of booster.

SBR208E

InspectionNBBR0026OUTPUT ROD LENGTH CHECKNBBR0026S011. Apply vacuum of þ66.7 kPa (þ500 mmHg, þ19.69 inHg) to

brake booster with a hand vacuum pump.

2. Add preload of 19.6 N (2.0 kg, 4.4 lb) to output rod.

3. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

BRAKE BOOSTER

On-vehicle Service

BR-19

Page 410 of 2395

SBR382D

Vacuum HoseNBBR0028

SBR225B

Removal and InstallationNBBR0029CAUTION:

When installing vacuum hoses, pay attention to the following

points.

IDo not apply any oil or lubricants to vacuum hose and

check valve.

IInsert vacuum tube into vacuum hose as shown.

SBR498A

IInstall check valve, paying attention to its direction.

InspectionNBBR0030HOSES AND CONNECTORSNBBR0030S01Check vacuum lines, connections and check valve for airtightness,

improper attachment chafing and deterioration.

SBR943A

CHECK VALVENBBR0030S02Check vacuum with a vacuum pump.

Connect to booster side Vacuum should exist.

Connect to engine side Vacuum should not exist.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

VACUUM PIPING

Vacuum Hose

BR-21

Page 420 of 2395

SBR042D

AdjustmentNBBR00471. Adjust clearance between shoe and drum as follows:

a. Release parking brake lever and loosen adjusting nut.

b. Depress brake pedal fully at least 10 times with engine run-

ning.

2. Pull control lever4-5notches. Then adjust control lever by

turning adjusting nut.

SBR073D

3. Pull control lever with specified amount of force. Check lever

stroke and ensure smooth operation.

Number of notches:6-8

4. Bend warning lamp switchplate to ensure:

IWarning lamp comes on when lever is lifted ªAº notches.

IWarning lamp goes out when lever is fully released.

Number of ªAº notches: 1 or less

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

PARKING BRAKE CONTROL

Adjustment

BR-31

Page 421 of 2395

PurposeNBBR0087The Anti-Lock Brake System (ABS) consists of electronic and hydraulic components. It allows for control of

braking force so locking of the wheels can be avoided.

1) Improves proper tracking performance through steering wheel operation.

2) Eases obstacle avoidance through steering wheel operation.

3) Improves vehicle stability.

OperationNBBR0088IWhen the vehicle speed is less than 10 km/h (6 MPH) this system does not work.

IThe Anti-Lock Brake System (ABS) has a self-test function. The system turns on the ABS warning lamp

for 1 second each time the ignition switch is turned ªONº. After the engine is started, the ABS warning lamp

turns off. The system performs a test the first time the vehicle reaches 6 km/h (4 MPH). A mechanical noise

may be heard as the ABS performs this self-test. This is a normal part of the self-test feature. If a mal-

function is found during this check, the ABS warning lamp will stay on.

IWhile driving, a mechanical noise may be heard during ABS operation. This is a normal condition.

ABS Hydraulic CircuitNBBR0089

SBR859D

1. Inlet solenoid valve

2. Outlet solenoid valve

3. Reservoir4. Pump

5. Motor

6. Inlet valve7. Outlet valve

8. Bypass check valve

9. Damper

DESCRIPTIONABS

Purpose

BR-32

Page 433 of 2395

SBR665E

CONSULT-II Inspection Procedure=NBBR0097SELF-DIAGNOSIS PROCEDURENBBR0097S011. Turn ignition switch OFF.

2. Connect CONSULT-II to data link connector.

3. Start engine.

4. Drive vehicle over 30 km/h (19 MPH) for at least one minute.

PBR455D

5. Stop vehicle with engine running and touch ªSTARTº on CON-

SULT-II screen.

SBR670E

6. Touch ªABSº.

SBR636E

7. Touch ªSELF-DIAG RESULTSº.

IThe screen shows the detected malfunction and how many

times the ignition switch has been turned ON since the mal-

function.

8. Make the necessary repairs following the diagnostic proce-

dures.

PBR950C

9. After the malfunctions are repaired, erase the self-diagnostic

results stored in the control unit by touching ªERASEº.

10. Check warning lamp for deactivation after driving vehicle over

30 km/h (19 MPH) for at least one minute.

11. Test the ABS in a safe area to verify that it functions properly.

NOTE:

ªSELF-DIAG RESULTSº screen shows the detected malfunction

and how many times the ignition switch has been turned since the

malfunction.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Inspection Procedure

BR-44

Page 441 of 2395

6 RECHECK BRAKE FLUID LEVEL

Check brake fluid level in reservoir tank again.

SBR451D

Is brake fluid filled between MAX and MIN lines on reservoir tank?

Ye s©GO TO 7.

No©Fill up brake fluid.

7 CHECK WARNING LAMP ACTIVATION

Check warning lamp activation.

SBR672E

Does warning lamp turn on when ignition switch is turned ON?

Ye s©GO TO 8.

No©Check fuse, warning lamp bulb and warning lamp circuit.

8 CHECK WARNING LAMP DEACTIVATION

Check warning lamp for deactivation after engine is started.

Does warning lamp turn off when engine is started?

Ye s©GO TO 9.

No©Go to Self-diagnosis (BR-41, 44).

9 DRIVE VEHICLE

Drive vehicle at speeds over 30 km/h (19 MPH) for at least one minute.

Does warning lamp remain off after vehicle has been driven at 30 km/h (19 MPH) for at least one minute?

Ye s©INSPECTION END

No©Go to Self-diagnosis (BR-41, 44).

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONABS

Preliminary Check (Cont'd)

BR-52

Page 461 of 2395

2 CHECK SYMPTOM

1. Apply brake.

2. Start engine.

Does the symptom appear only when engine is started?

Ye s©Carry out self-diagnosis. Refer to BR-41, 44.

No©Go to ª3. CHECK WARNING LAMP INDICATIONº in ª2. Unexpected Pedal Actionº,

BR-70.

NOTE:

ABS may operate and cause vibration under any of the following

conditions.

IApplying brake gradually when shifting or operating clutch.

ILow friction (slippery) road.

IHigh speed cornering.

IDriving over bumps and pot holes.

IEngine speed is over 5,000 rpm with vehicle stopped.

6. Warning Lamp Does Not Come On When

Ignition Switch Is Turned On

NBBR0112

1 INSPECTION START

Warning lamp circuit inspection

SBR673E

©GO TO 2.

2 CHECK FUSE

Check 10A fuse No. 8. For fuse layout, refer to EL-16, ªPOWER SUPPLY ROUTINGº.

Is fuse OK?

Ye s©GO TO 3.

No©Replace fuse.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

5. Pedal Vibration and Noise (Cont'd)

BR-72

Page 474 of 2395

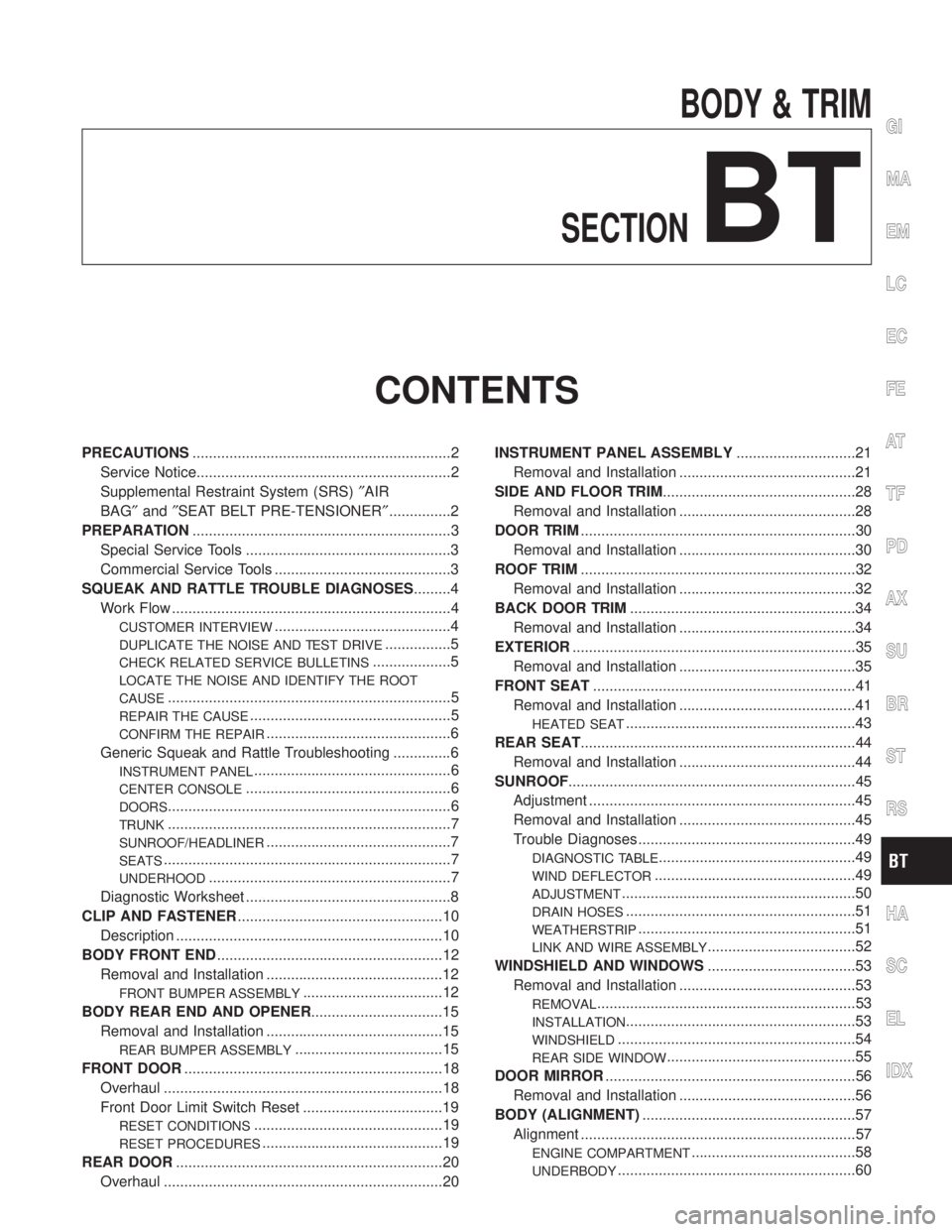

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS...............................................................2

Service Notice..............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools ...........................................3

SQUEAK AND RATTLE TROUBLE DIAGNOSES.........4

Work Flow ....................................................................4

CUSTOMER INTERVIEW...........................................4

DUPLICATE THE NOISE AND TEST DRIVE................5

CHECK RELATED SERVICE BULLETINS...................5

LOCATE THE NOISE AND IDENTIFY THE ROOT

CAUSE

.....................................................................5

REPAIR THE CAUSE.................................................5

CONFIRM THE REPAIR.............................................6

Generic Squeak and Rattle Troubleshooting ..............6

INSTRUMENT PANEL................................................6

CENTER CONSOLE..................................................6

DOORS.....................................................................6

TRUNK.....................................................................7

SUNROOF/HEADLINER.............................................7

SEATS......................................................................7

UNDERHOOD...........................................................7

Diagnostic Worksheet ..................................................8

CLIP AND FASTENER..................................................10

Description .................................................................10

BODY FRONT END.......................................................12

Removal and Installation ...........................................12

FRONT BUMPER ASSEMBLY..................................12

BODY REAR END AND OPENER................................15

Removal and Installation ...........................................15

REAR BUMPER ASSEMBLY....................................15

FRONT DOOR...............................................................18

Overhaul ....................................................................18

Front Door Limit Switch Reset ..................................19

RESET CONDITIONS..............................................19

RESET PROCEDURES............................................19

REAR DOOR.................................................................20

Overhaul ....................................................................20INSTRUMENT PANEL ASSEMBLY.............................21

Removal and Installation ...........................................21

SIDE AND FLOOR TRIM...............................................28

Removal and Installation ...........................................28

DOOR TRIM...................................................................30

Removal and Installation ...........................................30

ROOF TRIM...................................................................32

Removal and Installation ...........................................32

BACK DOOR TRIM.......................................................34

Removal and Installation ...........................................34

EXTERIOR.....................................................................35

Removal and Installation ...........................................35

FRONT SEAT................................................................41

Removal and Installation ...........................................41

HEATED SEAT........................................................43

REAR SEAT...................................................................44

Removal and Installation ...........................................44

SUNROOF......................................................................45

Adjustment .................................................................45

Removal and Installation ...........................................45

Trouble Diagnoses.....................................................49

DIAGNOSTIC TABLE................................................49

WIND DEFLECTOR.................................................49

ADJUSTMENT.........................................................50

DRAIN HOSES........................................................51

WEATHERSTRIP.....................................................51

LINK AND WIRE ASSEMBLY....................................52

WINDSHIELD AND WINDOWS....................................53

Removal and Installation ...........................................53

REMOVAL...............................................................53

INSTALLATION........................................................53

WINDSHIELD..........................................................54

REAR SIDE WINDOW..............................................55

DOOR MIRROR.............................................................56

Removal and Installation ...........................................56

BODY (ALIGNMENT)....................................................57

Alignment ...................................................................57

ENGINE COMPARTMENT........................................58

UNDERBODY..........................................................60

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX