engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1981 of 2395

SLC756A

CHECKING COOLING SYSTEM FOR LEAKSNBLC0016S04To check for leakage, apply pressure to the cooling system with a

tester.

Testing pressure:

157 kPa (1.6 kg/cm

2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator

damage.

Water Pump

REMOVAL AND INSTALLATIONNBLC0017CAUTION:

IWhen removing water pump assembly, be careful not to

get coolant on drive belt.

IWater pump cannot be disassembled and should be

replaced as a unit.

IAfter installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

SLC326B

SLC327B

REMOVALNBLC00181. Remove under cover.

2. Remove suspension member stay.

3. Drain coolant from radiator.

4. Remove radiator shrouds.

5. Remove drive belts.

6. Remove cooling fan.

7. Remove water drain plug on water pump side of cylinder block.

8. Remove chain tensioner cover and water pump cover.

ENGINE COOLING SYSTEM

System Check (Cont'd)

LC-12

Page 1982 of 2395

SLC328B

9. Pushing timing chain tensioner sleeve, apply a stopper pin so

it does not return. Then remove the chain tensioner assembly.

SLC941A

10. Remove the 3 water pump fixing bolts. Secure a gap between

water pump gear and timing chain, by turning crankshaft pul-

ley 20É backwards.

JLC357B

11. Put M8 bolts to two water pump fixing bolt holes.

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

Water Pump (Cont'd)

LC-13

Page 1983 of 2395

SLC116B

12. Tighten M8 bolts by turning half turn alternately until they reach

timing chain rear case.

IIn order to prevent damages to water pump or timing chain rear

case, do not tighten one bolt continuously. Always turn each

bolt half turn each time.

13. Lift up water pump and remove it.

IWhen lifting up water pump, do not allow water pump gear to

hit timing chain.

SLC943A

INSPECTIONNBLC00191. Check for badly rusted or corroded body assembly.

2. Check for rough operation due to excessive end play.

SLC244B

INSTALLATIONNBLC00201. Apply engine oil and coolant to O-rings as shown in the figure.

ENGINE COOLING SYSTEM

Water Pump (Cont'd)

LC-14

Page 1984 of 2395

SLC031B

2. Install water pump.

IDo not allow cylinder block to nip O-rings when installing

water pump.

SLC944A

3. Before installing, remove all traces of liquid gasket from mat-

ing surface of water pump cover and chain tensioner cover

using a scraper.

Also remove traces of liquid gasket from mating surface of

front cover.

SLC945AA

4. Apply a continuous bead of liquid gasket to mating surface of

chain tensioner cover and water pump cover.

SLC156B

5. Return the crankshaft pulley to its original position by turning

it 20É forward.

SLC961A

6. Install timing chain tensioner, then remove the stopper pin.

IWhen installing the timing chain tensioner, engine oil

should be applied to the oil hole and tensioner.

IAfter starting engine, let idle for three minutes, then rev

engine up to 3,000 rpm under no load to purge air from the

high-pressure chamber of the chain tensioners. The

engine may produce a rattling noise. This indicates that

air still remains in the chamber and is not a matter of

concern.

7. Reinstall any parts removed in reverse order of removal.

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

Water Pump (Cont'd)

LC-15

Page 1985 of 2395

Thermostat

REMOVAL AND INSTALLATIONNBLC0021

SLC329B

SLC962AA

1. Remove under cover.

2. Remove suspension member stay.

3. Drain coolant from radiator.

4. Remove drive belts.

5. Remove water drain plug on water pump side of cylinder block.

6. Disconnect lower radiator hose.

7. Remove water inlet and thermostat assembly.

IDo not disassemble water inlet and thermostat. Replace

them as a unit, if necessary.

SLC948A

8. Install thermostat with jiggle valve facing upward.

IAfter installation, run engine for a few minutes, and check

for leaks.

IBe careful not to spill coolant over engine compartment.

Use a rag to absorb coolant.

9. Reinstall any removed parts in reverse order of removal.

SLC949A

INSPECTIONNBLC00221. Check valve seating condition at ordinary room temperatures.

It should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Standard

Valve opening temperature 76.5ÉC (170ÉF)

Valve lift More than 8.6 mm/90ÉC

(0.339 in/194ÉF)

ENGINE COOLING SYSTEM

Thermostat

LC-16

Page 1986 of 2395

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

Water Control Valve

REMOVAL AND INSTALLATIONNBLC0032

SLC330B

1. Water outlet housing

2. Water control valve

3. Water outlet4. Water hose

5. Cylinder block water outlet

6. Thermal transmitter7. Engine coolant temperature sen-

sor

1. Release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

2. Remove under cover.

3. Remove suspension member stay.

4. Drain coolant from radiator.

5. Remove engine cover.

6. Remove air duct with air cleaner assembly.

7. Disconnect wires, hoses, harness and so on.

8. Remove upper intake manifold corrector.

9. Remove intake manifold corrector support bolts.

10. Remove lower intake manifold corrector.

11. Disconnect injector harness connectors.

12. Remove injector tube.

13. Remove intake manifold.

14. Remove water outlet housing and water control valve.

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

Thermostat (Cont'd)

LC-17

Page 1987 of 2395

SLC334B

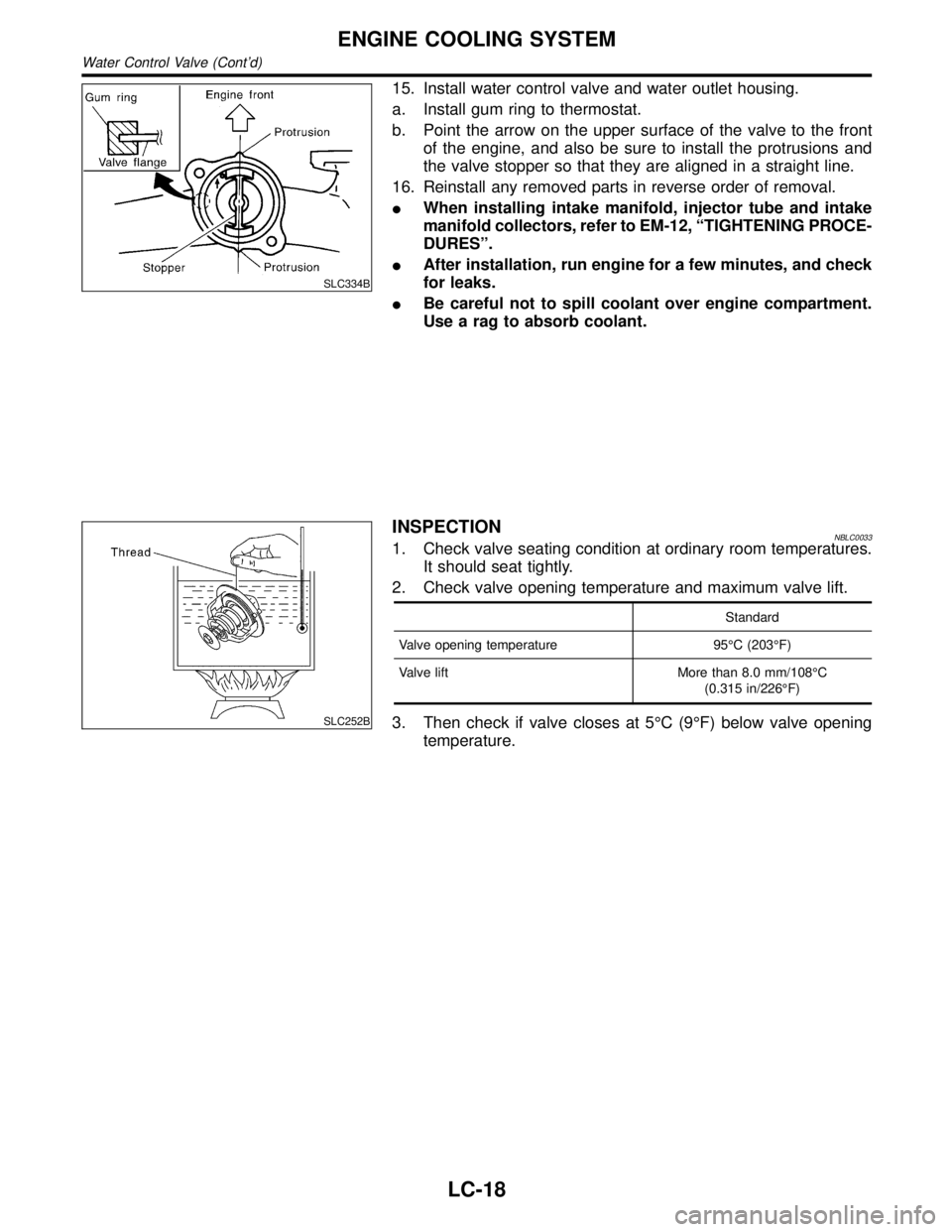

15. Install water control valve and water outlet housing.

a. Install gum ring to thermostat.

b. Point the arrow on the upper surface of the valve to the front

of the engine, and also be sure to install the protrusions and

the valve stopper so that they are aligned in a straight line.

16. Reinstall any removed parts in reverse order of removal.

IWhen installing intake manifold, injector tube and intake

manifold collectors, refer to EM-12, ªTIGHTENING PROCE-

DURESº.

IAfter installation, run engine for a few minutes, and check

for leaks.

IBe careful not to spill coolant over engine compartment.

Use a rag to absorb coolant.

SLC252B

INSPECTIONNBLC00331. Check valve seating condition at ordinary room temperatures.

It should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Standard

Valve opening temperature 95ÉC (203ÉF)

Valve lift More than 8.0 mm/108ÉC

(0.315 in/226ÉF)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

ENGINE COOLING SYSTEM

Water Control Valve (Cont'd)

LC-18

Page 1988 of 2395

Radiator

REMOVAL AND INSTALLATION=NBLC00231. Remove under cover.

2. Remove suspension member stay.

3. Drain coolant from radiator.

4. Disconnect radiator upper and lower hoses.

5. Remove upper and lower radiator shroud.

6. Remove A/T oil cooler hoses.

7. Disconnect reservoir tank hose.

8. Remove radiator mounting bracket.

9. Remove radiator.

10. After repairing or replacing radiator, install any part removed in reverse order of removal.

When filling radiator with coolant, refer to MA-14, ªChanging Engine Coolantº.

SLC331B

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

Radiator

LC-19

Page 1989 of 2395

SLC066B

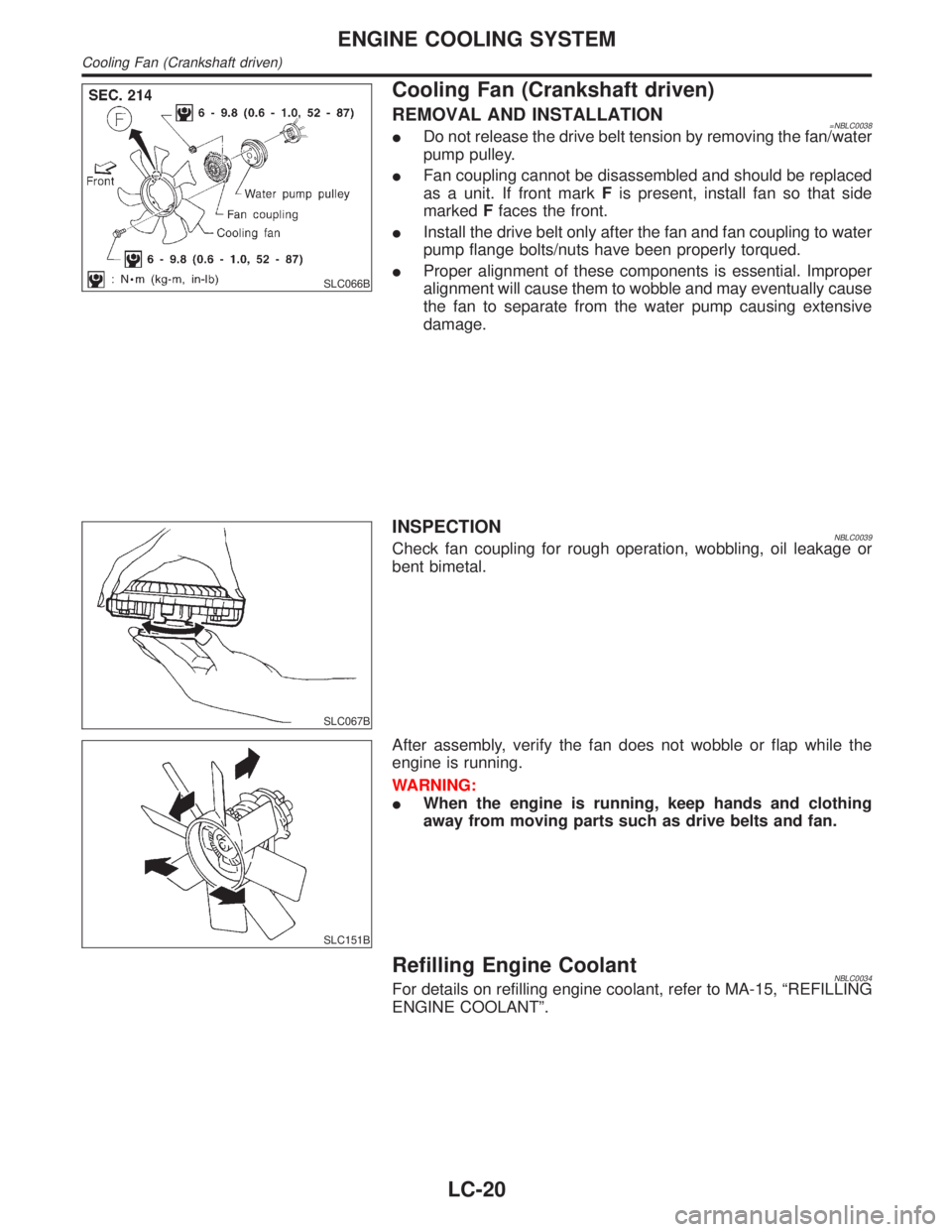

Cooling Fan (Crankshaft driven)

REMOVAL AND INSTALLATION=NBLC0038IDo not release the drive belt tension by removing the fan/water

pump pulley.

IFan coupling cannot be disassembled and should be replaced

as a unit. If front markFis present, install fan so that side

markedFfaces the front.

IInstall the drive belt only after the fan and fan coupling to water

pump flange bolts/nuts have been properly torqued.

IProper alignment of these components is essential. Improper

alignment will cause them to wobble and may eventually cause

the fan to separate from the water pump causing extensive

damage.

SLC067B

INSPECTIONNBLC0039Check fan coupling for rough operation, wobbling, oil leakage or

bent bimetal.

SLC151B

After assembly, verify the fan does not wobble or flap while the

engine is running.

WARNING:

IWhen the engine is running, keep hands and clothing

away from moving parts such as drive belts and fan.

Refilling Engine CoolantNBLC0034For details on refilling engine coolant, refer to MA-15, ªREFILLING

ENGINE COOLANTº.

ENGINE COOLING SYSTEM

Cooling Fan (Crankshaft driven)

LC-20

Page 1990 of 2395

Radiator (Aluminum type)

PREPARATIONNBLC0025

SLC882AB

SLC655CB

1. Attach the spacer to the tip of the radiator plate pliers A. Spacer

specification: 1.5 mm (0.059 in) thick x 18 mm (0.71 in) wide

x 8.5 mm (0.335 in) long.

2. Make sure that when radiator plate pliers A are closed dimen-

sion H¢¢is approx. 7.6 mm (0.299 in).

3. Adjust dimension H¢¢with the spacer, if necessary.

SLC903-A

DISASSEMBLYNBLC00261. Remove tank with Tool.

SLC893

IGrip the crimped edge and bend it upwards so that Tool slips

off.

Do not bend excessively.

GI

MA

EM

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEM

Radiator (Aluminum type)

LC-21