engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1800 of 2395

HEATER &

AIR CONDITIONER

SECTION

HA

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Precautions for Working with HFC-134a (R-134a) .....2

General Refrigerant Precautions .................................3

Precautions for Leak Detection Dye............................3

Identification .................................................................4

Precautions for Refrigerant Connection ......................4

Precautions for Servicing Compressor ........................6

Precautions for Service Equipment .............................7

Wiring Diagrams and Trouble Diagnoses....................9

PREPARATION.............................................................10

Special Service Tools ................................................10

HFC-134a (R-134a) Service Tools and

Equipment .................................................................. 11

DESCRIPTION...............................................................14

Refrigeration System .................................................14

V-6 Variable Displacement Compressor....................15

Component Layout ....................................................19

Introduction ................................................................20

Features .....................................................................20

Overview of Control System ......................................23

Control Operation ......................................................23

Discharge Air Flow.....................................................25

System Description ....................................................26

TROUBLE DIAGNOSES................................................27

Component Location..................................................27

Circuit Diagram (Without Navigation System) ...........30

Wiring Diagram - A/C, A - (Without Navigation

System) ......................................................................31

Circuit Diagram (With Navigation System) ................35

Wiring Diagram - A/C, A - (With Navigation

System) ......................................................................36

Auto Amp. Terminals and Reference Value...............40

Self-diagnosis ............................................................44

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................65Operational Check .....................................................66

A/C System ................................................................71

Mode Door Motor.......................................................75

Air Mix Door Motor ....................................................82

Intake Door Motor ......................................................87

Blower Motor..............................................................95

Magnet Clutch..........................................................104

Insufficient Cooling .................................................. 112

Insufficient Heating ..................................................121

Noise ........................................................................123

Self-diagnosis ..........................................................124

Memory Function .....................................................126

ECON (ECONOMY) Mode ......................................128

Ambient Sensor Circuit ............................................129

In-vehicle Sensor Circuit..........................................132

Sunload Sensor Circuit ............................................135

Intake Sensor Circuit ...............................................139

Air Mix Door Motor PBR Circuit ..............................141

Multiplex Communication Circuit .............................142

SERVICE PROCEDURE..............................................144

HFC-134a (R-134a) Service Procedure ..................144

Maintenance of Lubricant Quantity in

Compressor .............................................................146

Compressor .............................................................149

Compressor Clutch ..................................................150

Refrigerant Lines .....................................................154

Belt ...........................................................................159

Ventilation Air Filter ..................................................159

SERVICE DATA AND SPECIFICATIONS (SDS).......160

Compressor .............................................................160

Lubricant ..................................................................160

Refrigerant ...............................................................160

Engine Idling Speed (When A/C is ON) ..................160

Belt Tension .............................................................160

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

Page 1802 of 2395

ISuggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

IIf you choose to perform the repair, recover the refrigerant using onlydedicated equipment and con-

tainers. Do not recover contaminated refrigerant into your existing service equipment.If your facil-

ity does not have dedicated recovery equipment, you may contact a local refrigerant product retailer for

available service. This refrigerant must be disposed of in accordance with all federal and local regulations.

In addition, replacement of all refrigerant system components on the vehicle is recommended.

IIf the vehicle is within the warranty period, the air conditioner warranty is void. Please contact Nissan

Customer Affairs for further assistance.

General Refrigerant PrecautionsNBHA0003WARNING:

IDo not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

IAlways wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

IDo not store or heat refrigerant containers above 52ÉC (125ÉF).

IDo not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

IDo not intentionally drop, puncture, or incinerate refrigerant containers.

IKeep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

IRefrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

IDo not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional health and safety information may be obtained from refrigerant manu-

facturers.

Precautions for Leak Detection DyeNBHA0111IThe A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultravio-

let (UV) lamp is required to illuminate the dye when inspecting for leaks.

IAlways wear fluorescence enhancing UV safety glasses to protect your eyes and enhance the visibility of

the fluorescent dye.

IThe fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The

fluorescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector to

(J-41995) pin-point refrigerant leaks.

IFor your safety and your Customer's satisfaction, read and follow all manufacture's operating instructions

and precautions prior to performing the work.

IA compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal

should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

IAlways remove and dye from the leak area after repairs are complete to avoid a misdiagnosis during a

future service.

IDo not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period

of time cannot be removed.

IDo not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

IDo not use more than one refrigerant dye bottle (1/4 ounce /7.4 cc) per A/C system.

ILeak detection dyes for R-134a and R12 A/C systems are different. Do not use R-134a leak detection dye

in R-12 A/C system or R-12 leak detector dye in R-134a A/C systems or A/C system damage may result.

IThe fluorescent properties of the dye will remain for over three (3) years unless a compressor failure

occurs.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

PRECAUTIONS

Precautions for Working with HFC-134a (R-134a) (Cont'd)

HA-3

Page 1805 of 2395

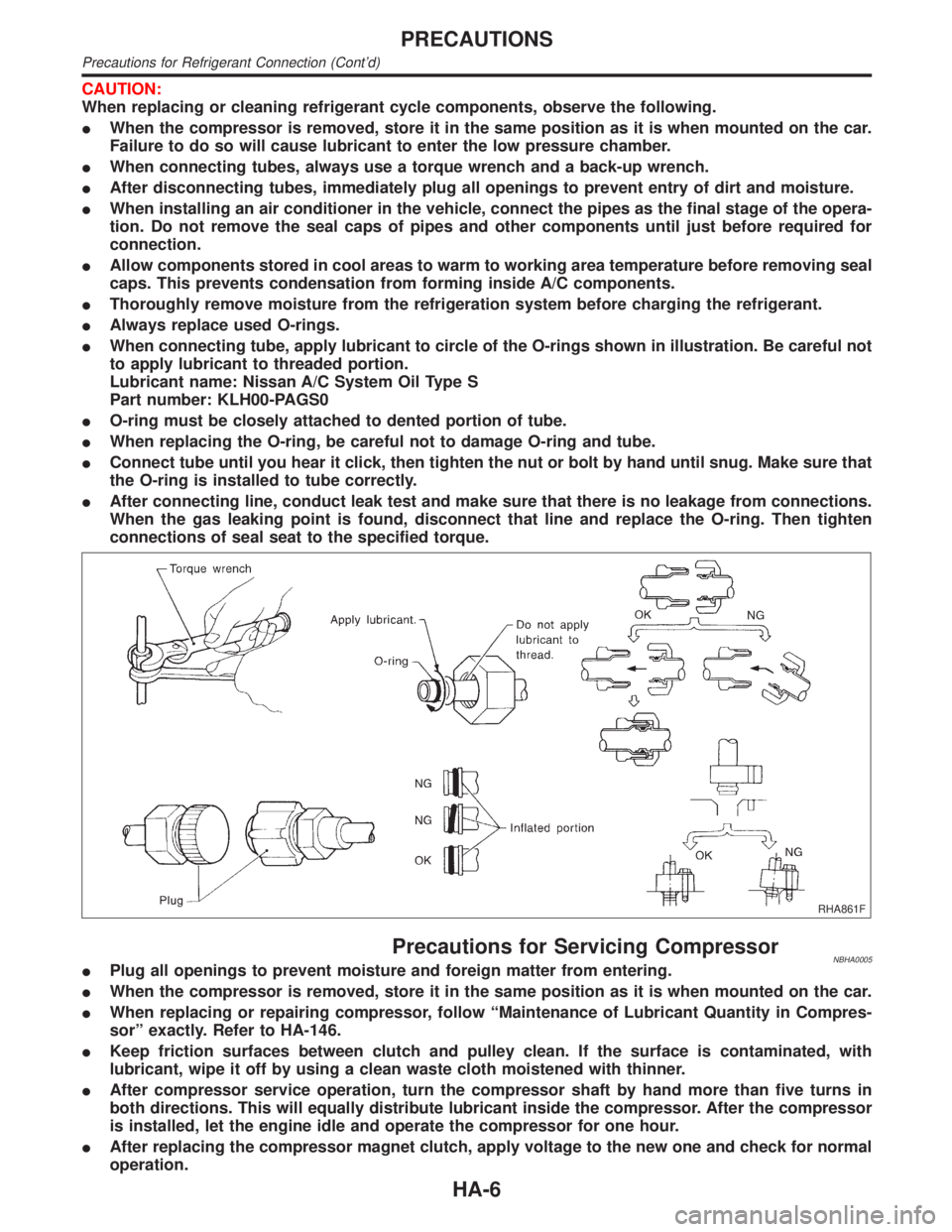

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

IWhen connecting tubes, always use a torque wrench and a back-up wrench.

IAfter disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

IWhen installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

IAllow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

IThoroughly remove moisture from the refrigeration system before charging the refrigerant.

IAlways replace used O-rings.

IWhen connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

IO-ring must be closely attached to dented portion of tube.

IWhen replacing the O-ring, be careful not to damage O-ring and tube.

IConnect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

IAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

RHA861F

Precautions for Servicing CompressorNBHA0005IPlug all openings to prevent moisture and foreign matter from entering.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

IWhen replacing or repairing compressor, follow ªMaintenance of Lubricant Quantity in Compres-

sorº exactly. Refer to HA-146.

IKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

IAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

IAfter replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-6

Page 1814 of 2395

V-6 Variable Displacement Compressor

GENERAL INFORMATION=NBHA00861. The V-6 variable compressor differs from previous units. The vent temperatures of the V-6 variable com-

press do not drop too far below 5ÉC (41ÉF) when:

Ievaporator intake air temperature is less than 20ÉC (68ÉF)

Iengine is running at speeds less than 1,500 rpm.

This is because the V-6 compressor provides a means of ªcapacityº control.

2. The V-6 variable compressor provides refrigerant control under varying conditions. During cold winters, it

may not produce high refrigerant pressure discharge (compared to previous units) when used with air

conditioning systems.

3. A ªclankingº sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the V-6 compressor, the clutch remains engaged unless: the system main

switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are low or when

the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.5 to 1.8 kg/cm

2, 21 to 26 psi) under varying conditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

V-6 Variable Displacement Compressor

HA-15

Page 1821 of 2395

Fan Speed ControlNBHA0014S0804Blower speed is automatically controlled based on temperature setting, ambient temperature, in-vehicle

temperature, intake temperature, amount of sunload and air mix door position.

With FAN switch set to ªAUTOº, the blower motor starts to gradually increase air flow volume.

When engine coolant temperature is low, the blower motor operation is delayed to prevent cool air from flow-

ing.

Intake Door ControlNBHA0014S0805The intake doors are automatically controlled by: The temperature setting, ambient temperature, in-vehicle

temperature, intake temperature, amount of sunload and ON-OFF operation of the compressor.

Outlet Door ControlNBHA0014S0806The outlet door is automatically controlled by: The temperature setting, ambient temperature, in-vehicle

temperature, intake temperature and amount of sunload.

Magnet Clutch ControlNBHA0014S0807The ECM controls compressor operation using input signals from the throttle position sensor and auto ampli-

fier.

Self-diagnostic SystemNBHA0014S0808The self-diagnostic system is built into the auto amplifier (LCU) to quickly locate the cause of problems.

DESCRIPTION

Features (Cont'd)

HA-22

Page 1826 of 2395

Component LocationNBHA0033ENGINE COMPARTMENTNBHA0033S01

SHA281FA

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Component Location

HA-27

Page 1840 of 2395

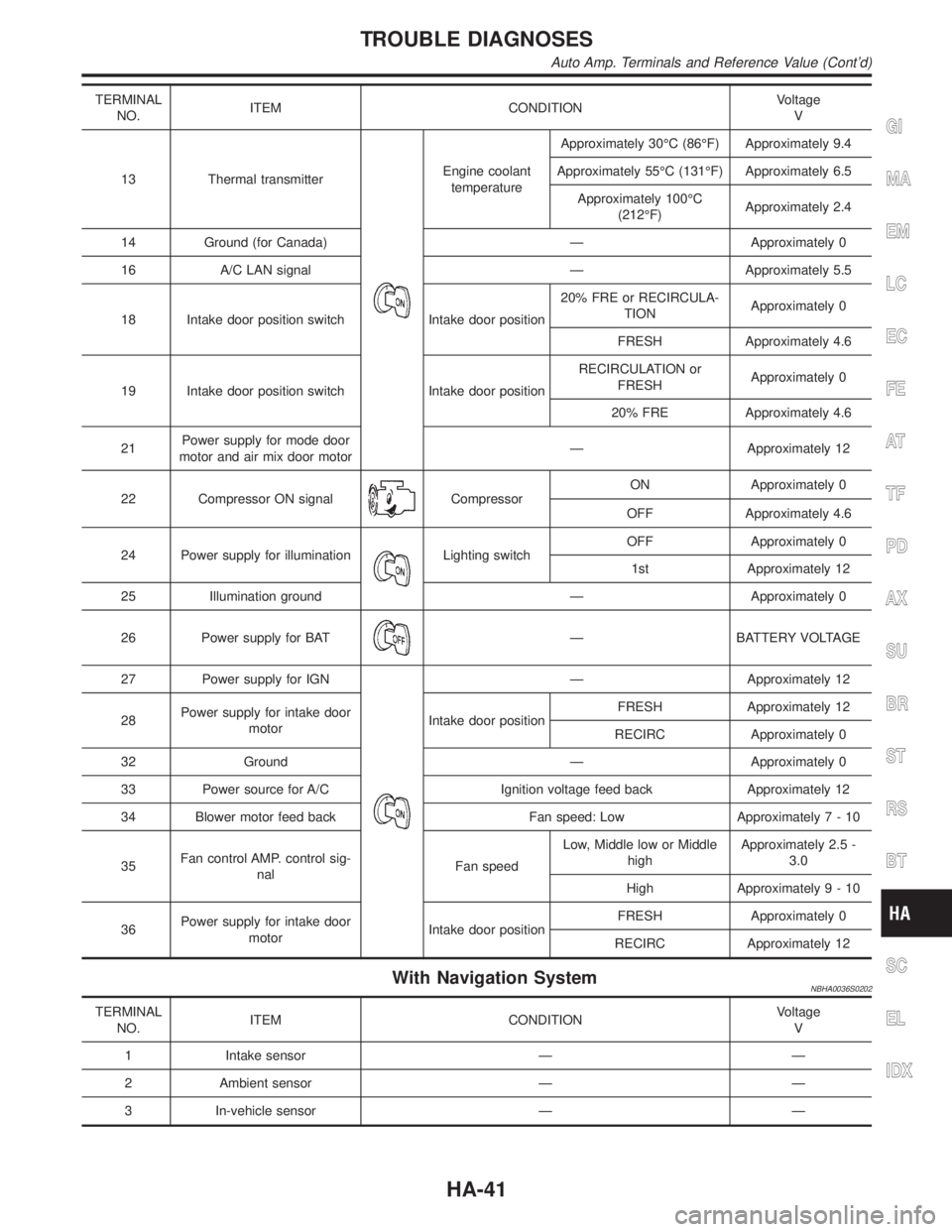

TERMINAL

NO.ITEM CONDITIONVoltage

V

13 Thermal transmitter

Engine coolant

temperatureApproximately 30ÉC (86ÉF) Approximately 9.4

Approximately 55ÉC (131ÉF) Approximately 6.5

Approximately 100ÉC

(212ÉF)Approximately 2.4

14 Ground (for Canada) Ð Approximately 0

16 A/C LAN signal Ð Approximately 5.5

18 Intake door position switch Intake door position20% FRE or RECIRCULA-

TIONApproximately 0

FRESH Approximately 4.6

19 Intake door position switch Intake door positionRECIRCULATION or

FRESHApproximately 0

20% FRE Approximately 4.6

21Power supply for mode door

motor and air mix door motorÐ Approximately 12

22 Compressor ON signal

CompressorON Approximately 0

OFF Approximately 4.6

24 Power supply for illumination

Lighting switchOFF Approximately 0

1st Approximately 12

25 Illumination ground Ð Approximately 0

26 Power supply for BAT

Ð BATTERY VOLTAGE

27 Power supply for IGN

Ð Approximately 12

28Power supply for intake door

motorIntake door positionFRESH Approximately 12

RECIRC Approximately 0

32 Ground Ð Approximately 0

33 Power source for A/C Ignition voltage feed back Approximately 12

34 Blower motor feed back Fan speed: Low Approximately7-10

35Fan control AMP. control sig-

nalFan speedLow, Middle low or Middle

highApproximately 2.5 -

3.0

High Approximately9-10

36Power supply for intake door

motorIntake door positionFRESH Approximately 0

RECIRC Approximately 12

With Navigation SystemNBHA0036S0202

TERMINAL

NO.ITEM CONDITIONVoltage

V

1 Intake sensor Ð Ð

2 Ambient sensor Ð Ð

3 In-vehicle sensor Ð Ð

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Auto Amp. Terminals and Reference Value (Cont'd)

HA-41

Page 1841 of 2395

TERMINAL

NO.ITEM CONDITIONVoltage

V

6 Intake door position switch

Intake door positionRECIRCULATION Approximately 4.6

FRESH or 20% FRESH Approximately 0

7Multiplex communication sig-

nal

(AMP,NAVI)ÐÐ

8Multiplex communication sig-

nal

(NAVI,AMP)ÐÐ

9 Sensor ground

Ð Approximately 0

10 Sunload sensor Ð Ð

11 Thermal transmitter

Engine coolant

temperatureApproximately 30ÉC (86ÉF) Approximately 9.4

Approximately 55ÉC (131ÉF) Approximately 6.5

Approximately 100ÉC

(212ÉF)Approximately 2.4

Approximately 110ÉC

(230ÉF)Approximately 1.9

14 A/C LAN signal Ð Approximately 5.5

17 ECM signalCompressor: ON Approximately 0

Compressor: OFF Approximately 4.6

18 Intake door position switch Intake door positionFRESH Approximately 4.6

RECIRCULATION or 20%

FRESHApproximately 0

19 Intake door position switch Intake door position20% FRESH Approximately 4.6

RECIRCULATION or

FRESHApproximately 0

20Multiplex communication sig-

nal (CLK)ÐÐ

21 Power supply for door motor

Ð Approximately 12

22 Compressor ON signalCompressor: ON Approximately 0

Compressor: OFF Approximately 4.6

24 Power supply for BAT Ð BATTERY VOLTAGE

TROUBLE DIAGNOSES

Auto Amp. Terminals and Reference Value (Cont'd)

HA-42

Page 1843 of 2395

Self-diagnosis=NBHA0021INTRODUCTION AND GENERAL DESCRIPTIONNBHA0021S01The self-diagnostic system diagnoses sensors, door motors, blower motor, etc. by system line. Refer to appli-

cable sections (items) for details. Shifting from normal control to the self-diagnostic system is accomplished

by starting the engine (turning the ignition switch from ªOFFº to ªONº) and pressing ª

º switch for at least

5 seconds. The ª

º switch must be pressed within 10 seconds after starting the engine (ignition switch is

turned ªONº). This system will be canceled by either pressing

(AUTO) switch or turning the ignition switch

ªOFFº. Shifting from one step to another is accomplished by means of pushing

(HOT) or(COLD) switch,

as required.

Additionally shifting from STEP 5 to AUXILIARY MECHANISM is accomplished by means of pushing

(fan)

UP switch.

Without Navigation SystemNBHA0021S0101

RHA453GA

TROUBLE DIAGNOSES

Self-diagnosis

HA-44

Page 1844 of 2395

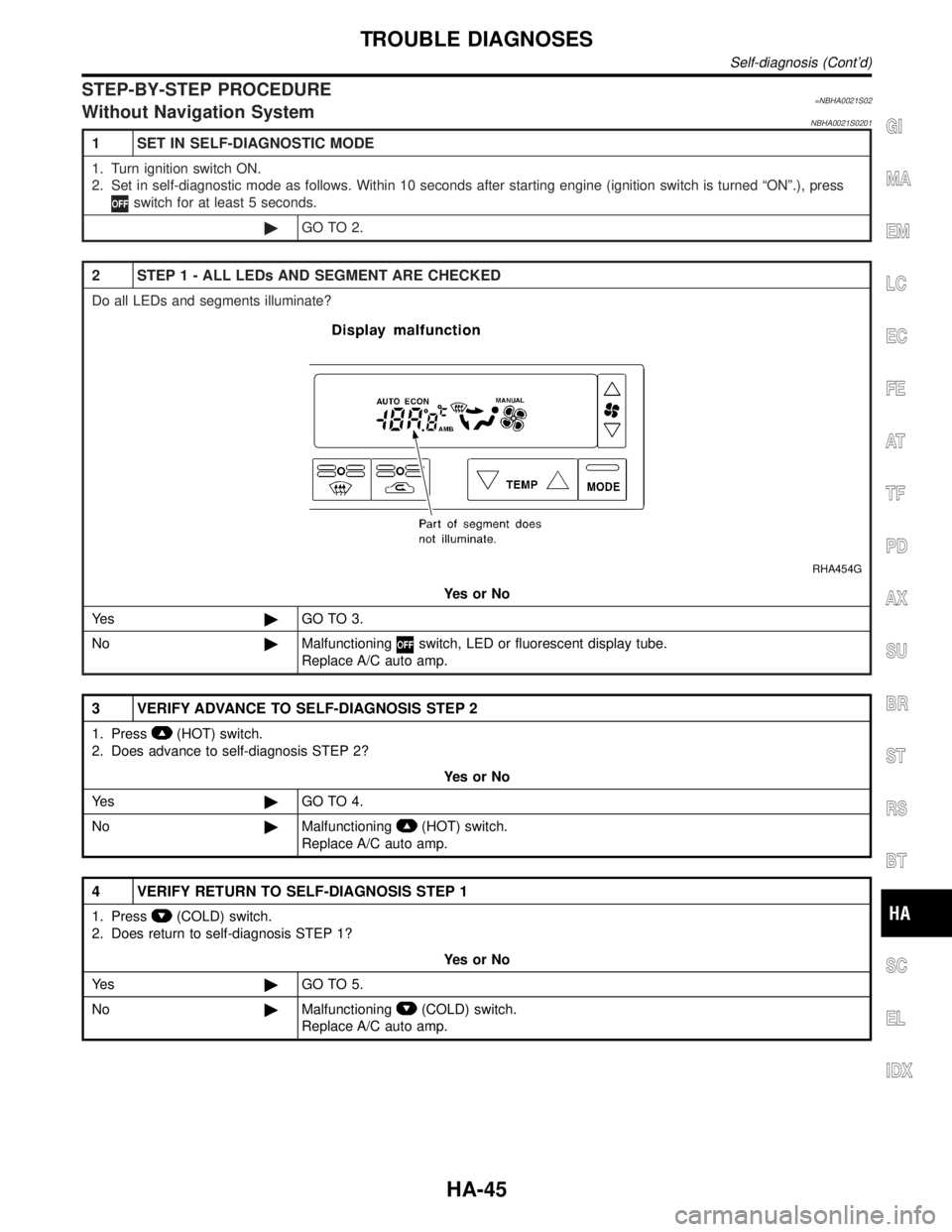

STEP-BY-STEP PROCEDURE=NBHA0021S02Without Navigation SystemNBHA0021S0201

1 SET IN SELF-DIAGNOSTIC MODE

1. Turn ignition switch ON.

2. Set in self-diagnostic mode as follows. Within 10 seconds after starting engine (ignition switch is turned ªONº.), press

switch for at least 5 seconds.

©GO TO 2.

2 STEP 1 - ALL LEDs AND SEGMENT ARE CHECKED

Do all LEDs and segments illuminate?

RHA454G

YesorNo

Ye s©GO TO 3.

No©Malfunctioning

switch, LED or fluorescent display tube.

Replace A/C auto amp.

3 VERIFY ADVANCE TO SELF-DIAGNOSIS STEP 2

1. Press(HOT) switch.

2. Does advance to self-diagnosis STEP 2?

YesorNo

Ye s©GO TO 4.

No©Malfunctioning

(HOT) switch.

Replace A/C auto amp.

4 VERIFY RETURN TO SELF-DIAGNOSIS STEP 1

1. Press(COLD) switch.

2. Does return to self-diagnosis STEP 1?

YesorNo

Ye s©GO TO 5.

No©Malfunctioning

(COLD) switch.

Replace A/C auto amp.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

HA-45