clutch INFINITI QX4 2001 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 192 of 2395

Wiring Diagram Ð AT Ð OVRCSVNBAT0200

MAT741A

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE

Wiring Diagram Ð AT Ð OVRCSV

AT-187

Page 193 of 2395

Diagnostic ProcedureNBAT0069

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 4 and ground.

SAT170J

Is resistance approx. 20 - 40W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove control valve assembly.

Refer to AT-273.

2. Check the following items:

IOverrun clutch solenoid valve

Refer to ªComponent Inspectionº, AT-189.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

3 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 4 and TCM harness connector terminal 20. Refer to wiring diagram Ð AT Ð

OVRCSV.

Continuity should exist.

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-185.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE

Diagnostic Procedure

AT-188

Page 194 of 2395

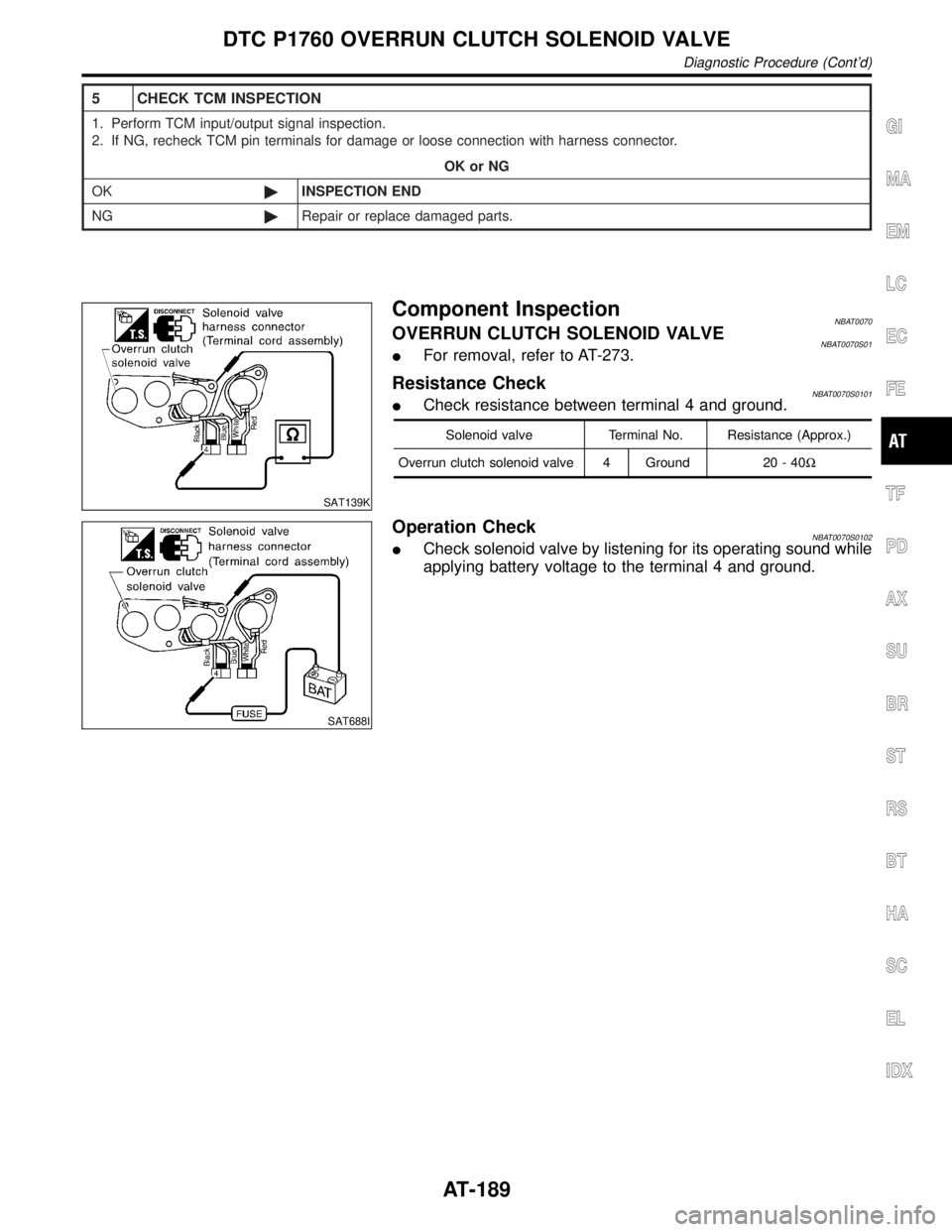

5 CHECK TCM INSPECTION

1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

SAT139K

Component InspectionNBAT0070OVERRUN CLUTCH SOLENOID VALVENBAT0070S01IFor removal, refer to AT-273.

Resistance CheckNBAT0070S0101ICheck resistance between terminal 4 and ground.

Solenoid valve Terminal No. Resistance (Approx.)

Overrun clutch solenoid valve 4 Ground 20 - 40W

SAT688I

Operation CheckNBAT0070S0102ICheck solenoid valve by listening for its operating sound while

applying battery voltage to the terminal 4 and ground.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE

Diagnostic Procedure (Cont'd)

AT-189

Page 229 of 2395

3 CHECK A/T FLUID LEVEL

Check A/T fluid level again.

SAT638A

OK or NG

OK©GO TO 4.

NG©Refill ATF.

4 CHECK A/T FLUID CONDITION

1. Remove oil pan.

2. Check A/T fluid condition.

SAT171B

OK or NG

OK©GO TO 5.

NG©1. Disassemble A/T.

2. Check the following items:

IForward clutch assembly

IOverrun clutch assembly

IReverse clutch assembly

5 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR SYMPTOMS

4. In ªNº Position, Vehicle Moves (Cont'd)

AT-224

Page 232 of 2395

6. Vehicle Does Not Creep Backward In ªRº

Position

=NBAT0078SYMPTOM:

Vehicle does not creep backward when selecting ªRº position.

1 CHECK A/T FLUID LEVEL

Check A/T fluid level again.

SAT638A

OK or NG

OK©GO TO 2.

NG©Refill ATF.

2 CHECK STALL TEST

Check stall revolution with selector lever in ª1º and ªRº positions.

Refer to AT-356.

SAT493G

OK or NG

OK©GO TO 3.

OK in ª1º position, NG in

ªRº position©1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-273.

2. Check the following items:

IValves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot

valve and pilot filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

NG in both ª1º and ªRº

positions©GO TO 6.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position

AT-227

Page 234 of 2395

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-273.

2. Check the following items:

IValves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

ITorque converter

IReverse clutch assembly

IHigh clutch assembly

ILow & reverse brake assembly

ILow one-way clutch

©Repair or replace damaged parts.GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

6. Vehicle Does Not Creep Backward In ªRº Position (Cont'd)

AT-229

Page 237 of 2395

6 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to ªON-VEHICLE SERVICEº, AT-273.

2. Check the following items:

IValves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot filter)

ILine pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

IOil pump assembly

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

ILow & reverse brake assembly

ITorque converter

©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position (Cont'd)

AT-232

Page 240 of 2395

7 CHECK SYMPTOM

Check again.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

8 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly.

Refer to AT-273.

2. Check the following items:

IShift valve A

IShift valve B

IShift solenoid valve A

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following items:

IForward clutch assembly

IForward one-way clutch

ILow one-way clutch

IHigh clutch assembly

ITorque converter

IOil pump assembly

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

8. Vehicle Cannot Be Started From D1(Cont'd)

AT-235

Page 246 of 2395

7 DETECT MALFUNCTIONING ITEM

1. Remove control valve Assembly. Refer to AT-273.

2. Check the following items:

IShift valve B

IShift solenoid valve B

IPilot valve

IPilot filter

3. Disassemble A/T.

4. Check the following items:

IServo piston assembly

IHigh clutch assembly

IOil pump assembly

OK or NG

OK©GO TO 6.

NG©Repair or replace damaged parts.GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

10. A/T Does Not Shift: D2®D3(Cont'd)

AT-241

Page 248 of 2395

3 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-174, ªDescriptionº.

SAT142K

OK or NG

OK©GO TO 4.

NG©Repair or replace throttle position sensor.

4 CHECK A/T FLUID CONDITION

1. Remove oil pan.

2. Check A/T fluid condition.

SAT171B

OK or NG

OK©GO TO 5.

NG©GO TO 7.

5 DETECT MALFUNCTIONING ITEM

1. Remove control valve Assembly. Refer to AT-273.

2. Check the following items:

IShift valve B

IOverrun clutch control valve

IShift solenoid valve B

IPilot valve

IPilot filter

OK or NG

OK©GO TO 6.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

11. A/T Does Not Shift: D3®D4(Cont'd)

AT-243