clutch INFINITI QX4 2001 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 298 of 2395

SAT109B

d. Remove output shaft and parking gear as a unit from transmis-

sion case.

e. Remove parking gear from output shaft.

SAT033B

f. Remove needle bearing from transmission case.

SAT954A

23. Remove rear side clutch and gear components.

a. Remove front internal gear.

SAT110B

b. Remove bearing race from front internal gear.

SAT111B

c. Remove needle bearing from rear internal gear.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

AT-293

Page 299 of 2395

SAT951A

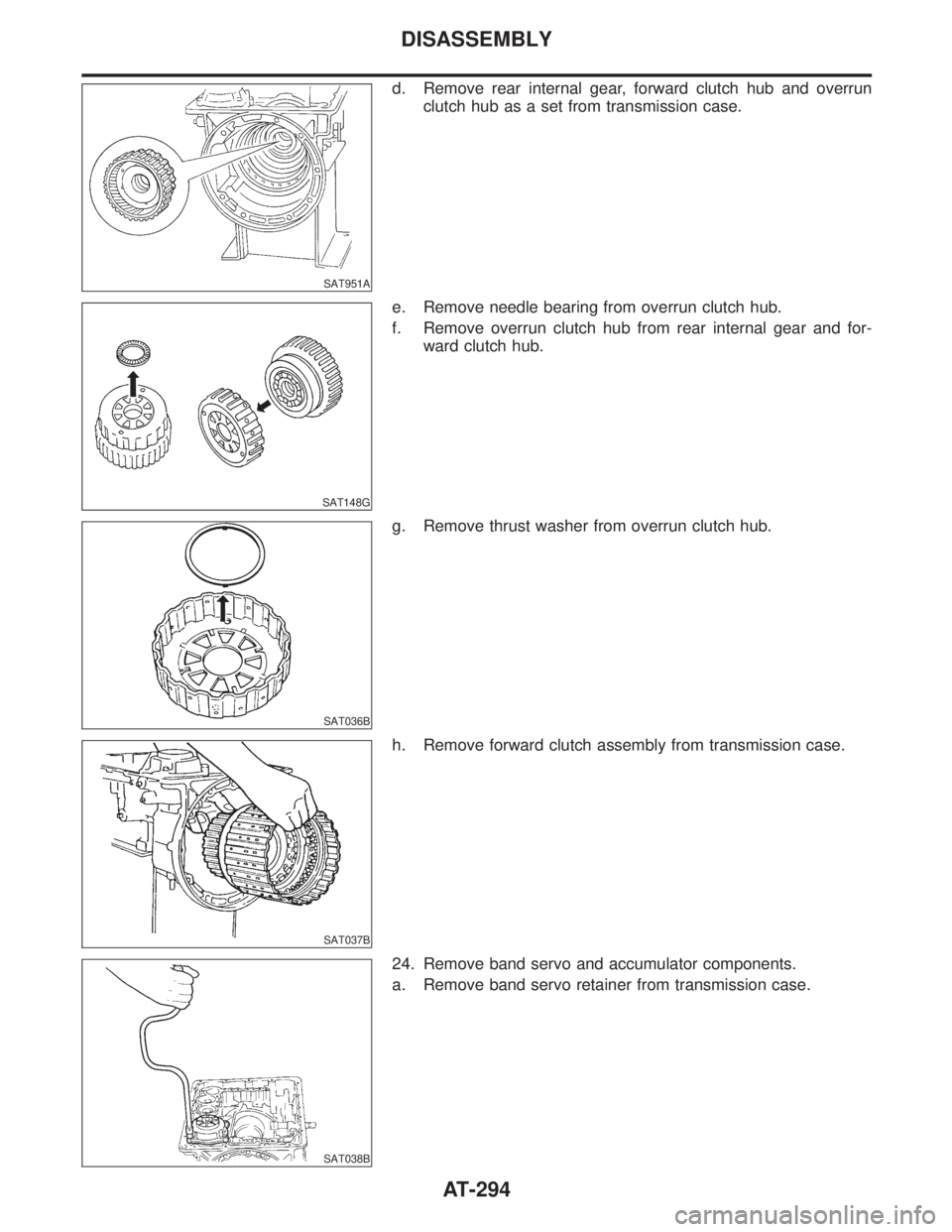

d. Remove rear internal gear, forward clutch hub and overrun

clutch hub as a set from transmission case.

SAT148G

e. Remove needle bearing from overrun clutch hub.

f. Remove overrun clutch hub from rear internal gear and for-

ward clutch hub.

SAT036B

g. Remove thrust washer from overrun clutch hub.

SAT037B

h. Remove forward clutch assembly from transmission case.

SAT038B

24. Remove band servo and accumulator components.

a. Remove band servo retainer from transmission case.

DISASSEMBLY

AT-294

Page 307 of 2395

SAT194B

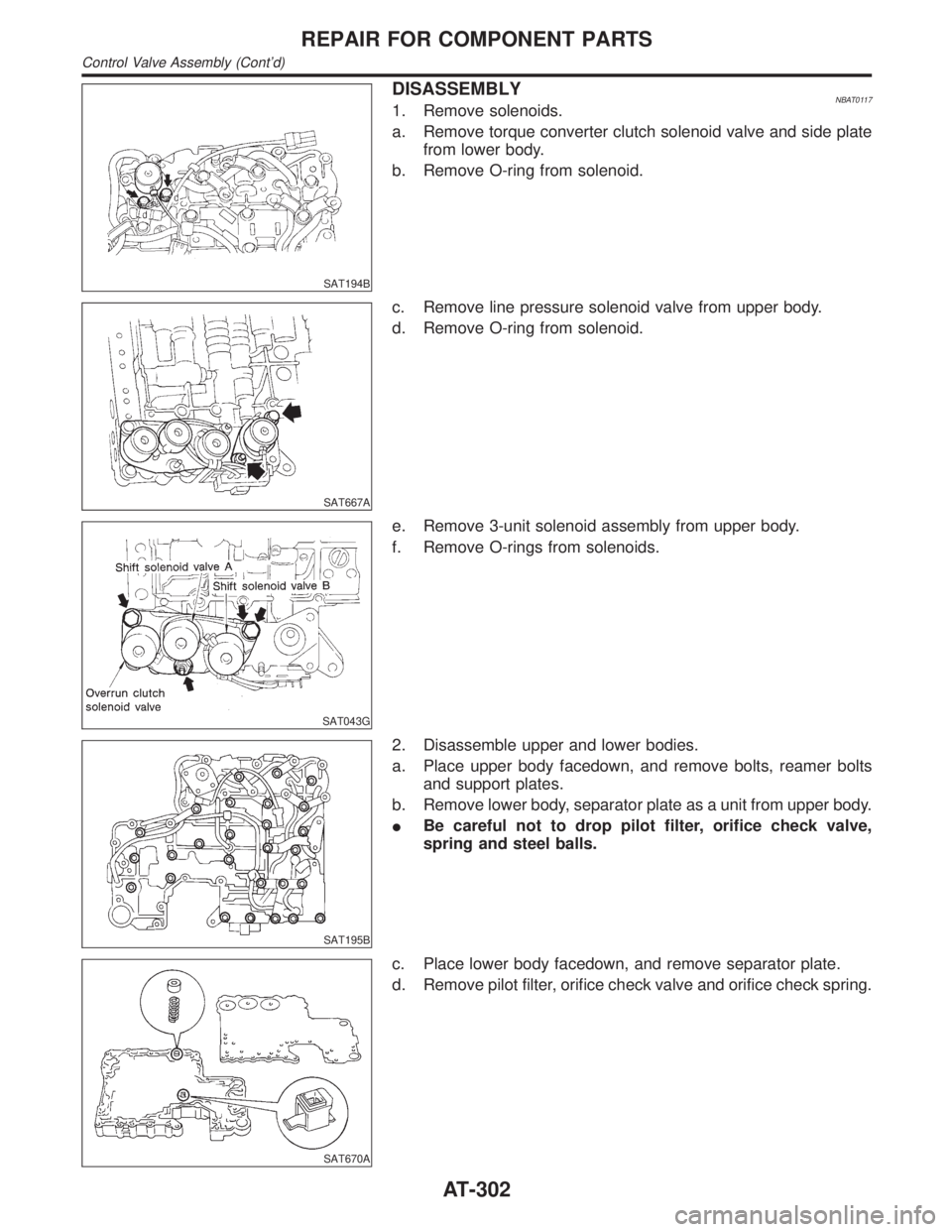

DISASSEMBLYNBAT01171. Remove solenoids.

a. Remove torque converter clutch solenoid valve and side plate

from lower body.

b. Remove O-ring from solenoid.

SAT667A

c. Remove line pressure solenoid valve from upper body.

d. Remove O-ring from solenoid.

SAT043G

e. Remove 3-unit solenoid assembly from upper body.

f. Remove O-rings from solenoids.

SAT195B

2. Disassemble upper and lower bodies.

a. Place upper body facedown, and remove bolts, reamer bolts

and support plates.

b. Remove lower body, separator plate as a unit from upper body.

IBe careful not to drop pilot filter, orifice check valve,

spring and steel balls.

SAT670A

c. Place lower body facedown, and remove separator plate.

d. Remove pilot filter, orifice check valve and orifice check spring.

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-302

Page 309 of 2395

SAT676A

Pilot FilterNBAT0118S03ICheck to make sure that filter is not clogged or damaged.

SAT149G

Torque Converter Clutch Solenoid ValveNBAT0118S04ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-152.

Line Pressure Solenoid ValveNBAT0118S05ICheck that filter is not clogged or damaged.

IMeasure resistance. Refer to ªComponent Inspectionº, AT-167.

SAT095B

3-Unit Solenoid Assembly (Overrun Clutch Solenoid

Valve and Shift Solenoid Valves A and B)

NBAT0118S06IMeasure resistance of each solenoid. Refer to ªComponent

Inspectionº, AT-171, AT-175 and AT-189.

SAT096BA

A/T Fluid Temperature Sensor and SwitchNBAT0118S07IMeasure resistance. Refer to ªComponent Inspectionº, AT-110

and AT-264.

SAT671A

ASSEMBLYNBAT01191. Install upper and lower bodies.

a. Place oil circuit of upper body face up. Install steel balls in their

proper positions.

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-304

Page 311 of 2395

SAT199BA

g. Install and temporarily tighten bolts and tube brackets in their

proper locations.

Bolt length and location:

Bolt symbol a b c d

Bolt length mm (in) 70 (2.76) 50 (1.97) 33 (1.30) 27 (1.06)

SAT200B

2. Install solenoids.

a. Attach O-ring and install torque converter clutch solenoid valve

and side plates onto lower body.

SAT150G

b. Attach O-rings and install 3-unit solenoids assembly onto

upper body.

c. Attach O-ring and install line pressure solenoid valve onto

upper body.

3. Tighten all bolts.

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-306

Page 319 of 2395

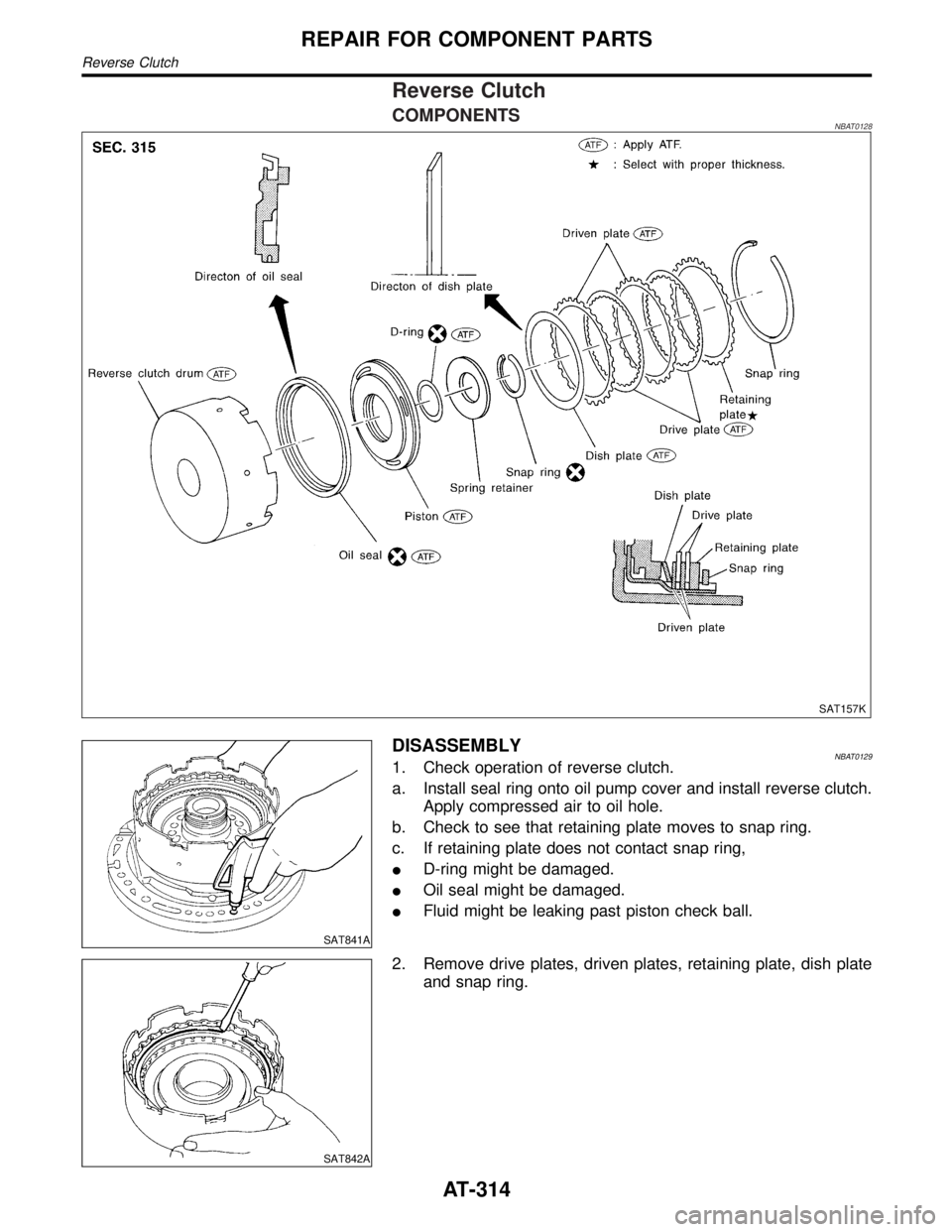

Reverse Clutch

COMPONENTSNBAT0128

SAT157K

SAT841A

DISASSEMBLYNBAT01291. Check operation of reverse clutch.

a. Install seal ring onto oil pump cover and install reverse clutch.

Apply compressed air to oil hole.

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring,

ID-ring might be damaged.

IOil seal might be damaged.

IFluid might be leaking past piston check ball.

SAT842A

2. Remove drive plates, driven plates, retaining plate, dish plate

and snap ring.

REPAIR FOR COMPONENT PARTS

Reverse Clutch

AT-314

Page 320 of 2395

SAT524G

3. Remove snap ring from clutch drum while compressing clutch

springs.

IDo not expand snap ring excessively.

4. Remove spring retainer.

SAT844A

5. Install seal ring onto oil pump cover and install reverse clutch

drum. While holding piston, gradually apply compressed air to

oil hole until piston is removed.

IDo not apply compressed air abruptly.

6. Remove D-ring and oil seal from piston.

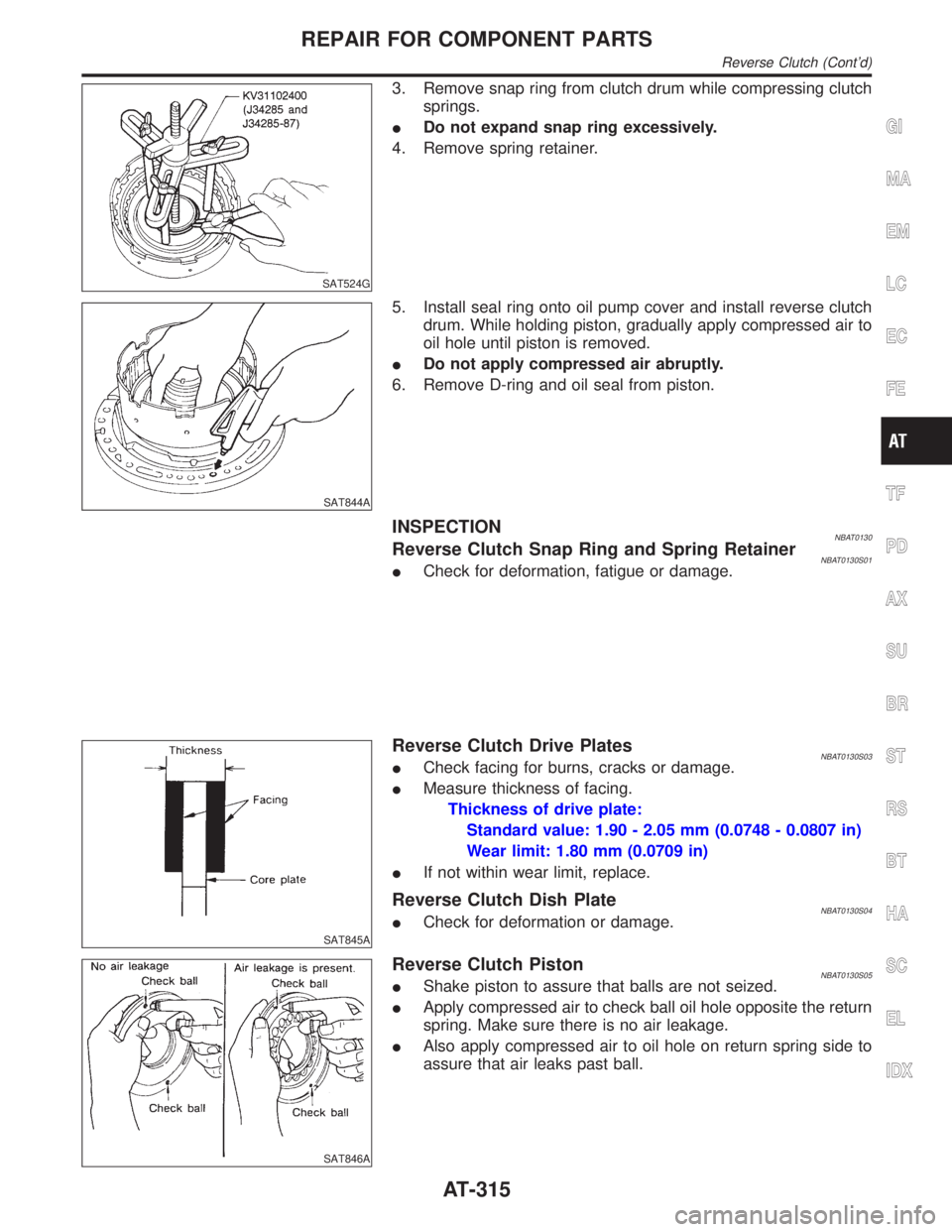

INSPECTIONNBAT0130Reverse Clutch Snap Ring and Spring RetainerNBAT0130S01ICheck for deformation, fatigue or damage.

SAT845A

Reverse Clutch Drive PlatesNBAT0130S03ICheck facing for burns, cracks or damage.

IMeasure thickness of facing.

Thickness of drive plate:

Standard value: 1.90 - 2.05 mm (0.0748 - 0.0807 in)

Wear limit: 1.80 mm (0.0709 in)

IIf not within wear limit, replace.

Reverse Clutch Dish PlateNBAT0130S04ICheck for deformation or damage.

SAT846A

Reverse Clutch PistonNBAT0130S05IShake piston to assure that balls are not seized.

IApply compressed air to check ball oil hole opposite the return

spring. Make sure there is no air leakage.

IAlso apply compressed air to oil hole on return spring side to

assure that air leaks past ball.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-315

Page 321 of 2395

SAT847A

ASSEMBLYNBAT01311. Install D-ring and oil seal on piston.

IApply ATF to both parts.

SAT848A

2. Install piston assembly by turning it slowly and evenly.

IApply ATF to inner surface of drum.

3. Install spring retainer.

SAT524G

4. Install snap ring while compressing clutch springs.

SAT850A

IDo not align snap ring gap with spring retainer stopper.

SAT842A

5. Install drive plates, driven plates, retaining plate and dish plate.

6. Install snap ring.

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-316

Page 322 of 2395

SAT852A

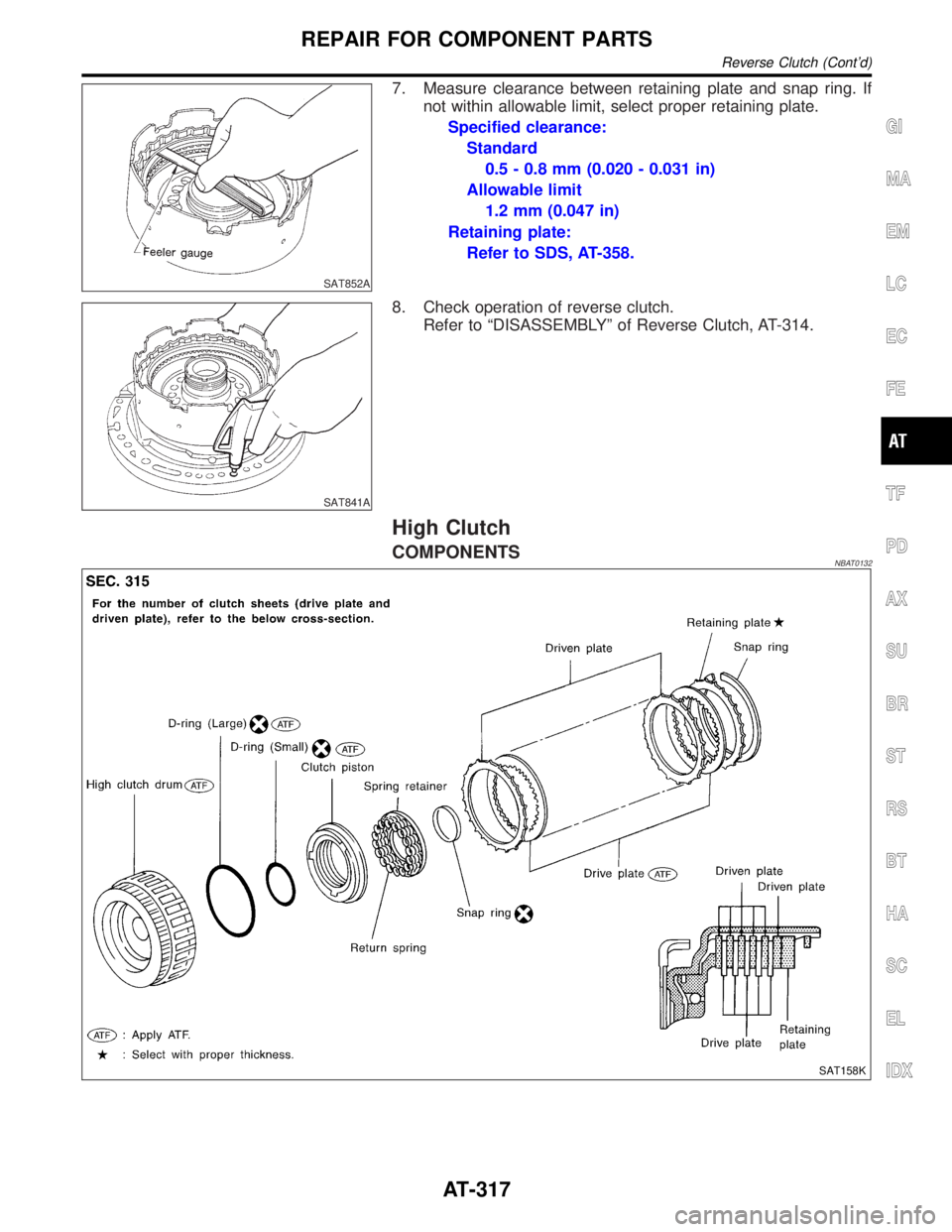

7. Measure clearance between retaining plate and snap ring. If

not within allowable limit, select proper retaining plate.

Specified clearance:

Standard

0.5 - 0.8 mm (0.020 - 0.031 in)

Allowable limit

1.2 mm (0.047 in)

Retaining plate:

Refer to SDS, AT-358.

SAT841A

8. Check operation of reverse clutch.

Refer to ªDISASSEMBLYº of Reverse Clutch, AT-314.

High Clutch

COMPONENTSNBAT0132

SAT158K

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Reverse Clutch (Cont'd)

AT-317

Page 323 of 2395

SAT853A

DISASSEMBLY AND ASSEMBLYNBAT0133Service procedures for high clutch are essentially the same as

those for reverse clutch, with the following exception:

SAT854A

ICheck of high clutch operation

SAT525G

IRemoval and installation of return spring

SAT829A

IInspection of high clutch return springs

Inspection standard:

Refer to SDS, AT-357.

SAT845A

IInspection of high clutch drive plate

Thickness of drive plate:

Standard

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

1.40 mm (0.0551 in)

REPAIR FOR COMPONENT PARTS

High Clutch (Cont'd)

AT-318