clutch INFINITI QX4 2001 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 324 of 2395

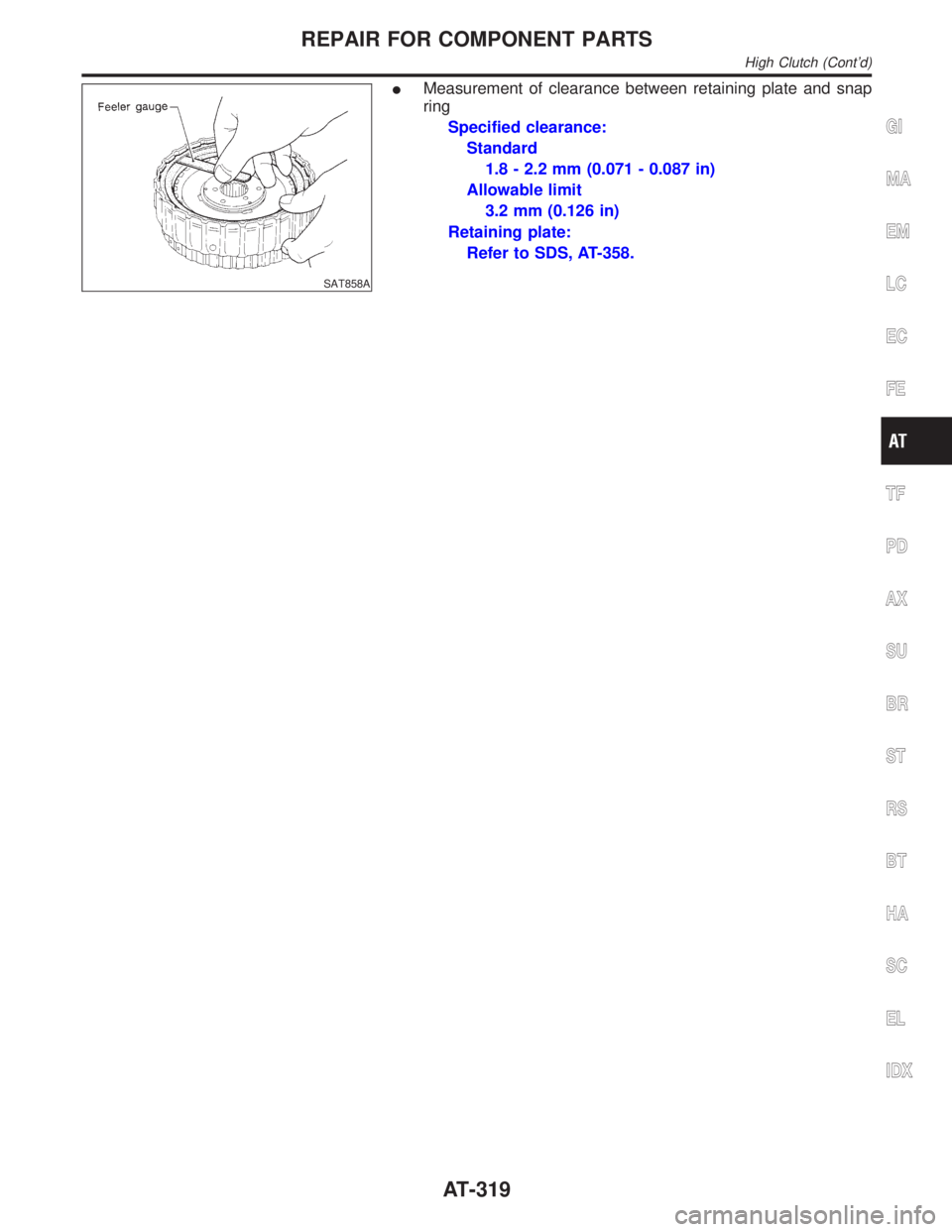

SAT858A

IMeasurement of clearance between retaining plate and snap

ring

Specified clearance:

Standard

1.8 - 2.2 mm (0.071 - 0.087 in)

Allowable limit

3.2 mm (0.126 in)

Retaining plate:

Refer to SDS, AT-358.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

High Clutch (Cont'd)

AT-319

Page 325 of 2395

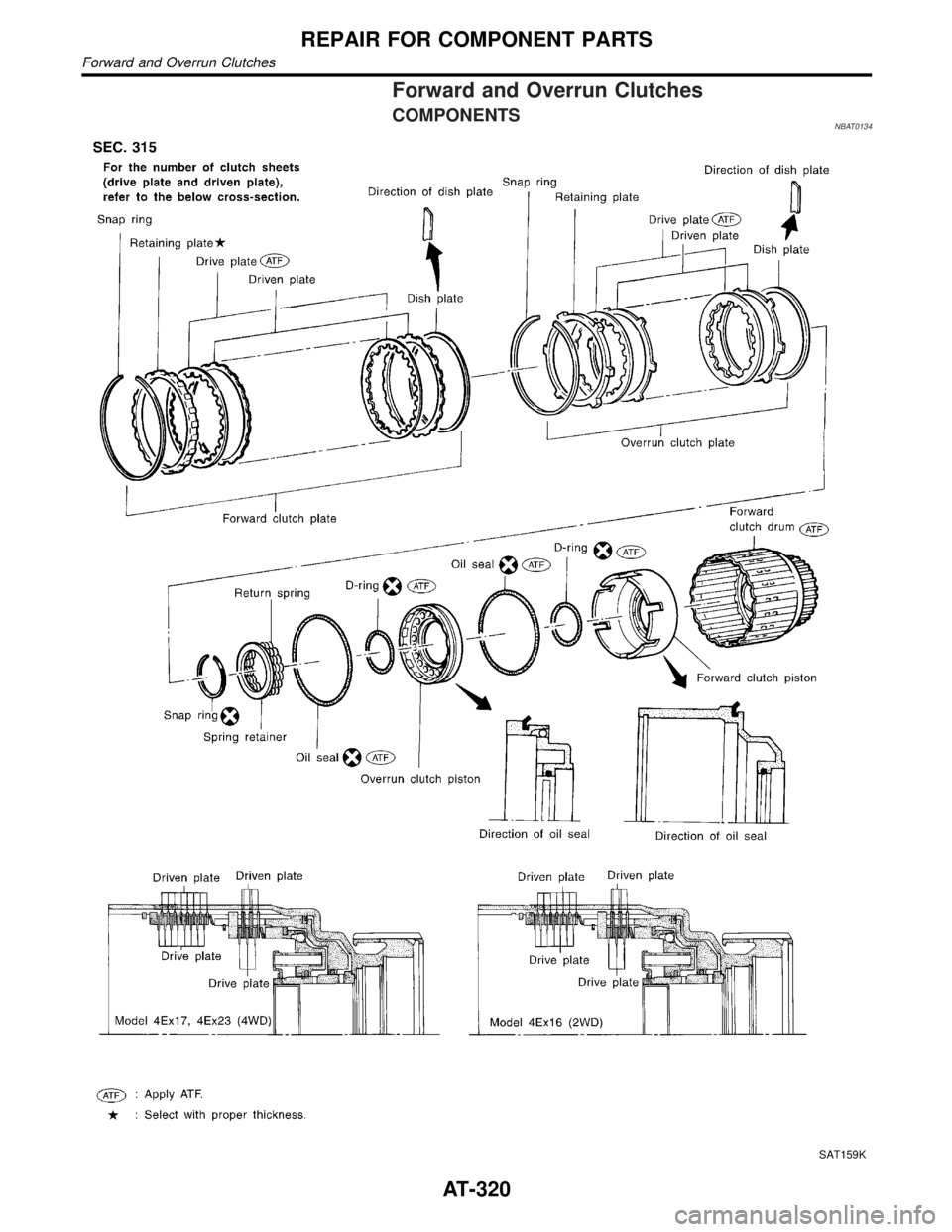

Forward and Overrun Clutches

COMPONENTSNBAT0134

SAT159K

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches

AT-320

Page 326 of 2395

SAT860A

DISASSEMBLY AND ASSEMBLYNBAT0135Forward and overrun clutches are serviced essentially the same

way as reverse clutch is serviced. However, note the following

exceptions.

ICheck of forward clutch operation

SAT861A

ICheck of overrun clutch operation

SAT865A

IRemoval of forward clutch drum

Remove forward clutch drum from transmission case by hold-

ing snap ring.

SAT862A

IRemoval of forward clutch and overrun clutch pistons

a) While holding overrun clutch piston, gradually apply com-

pressed air to oil hole.

SAT863A

b) Remove overrun clutch from forward clutch.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-321

Page 327 of 2395

SAT526G

IRemoval and installation of return springs

SAT829A

IInspection of forward clutch and overrun clutch return springs

Inspection standard:

Refer to SDS, AT-357.

SAT845A

IInspection of forward clutch drive plates

Thickness of drive plate:

Standard

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

1.40 mm (0.0551 in)

SAT845A

IInspection of overrun clutch drive plates

Thickness of drive plate:

Standard

1.90 - 2.05 mm (0.0748 - 0.0807 in)

Wear limit

1.80 mm (0.0709 in)

SAT866A

IInstallation of forward clutch piston and overrun clutch piston

a) Install forward clutch piston by turning it slowly and evenly.

IApply ATF to inner surface of clutch drum.

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-322

Page 328 of 2395

SAT867A

IAlign notch in forward clutch piston with groove in for-

ward clutch drum.

SAT868A

b) Install overrun clutch by turning it slowly and evenly.

IApply ATF to inner surface of forward clutch piston.

SAT869A

IMeasurement of clearance between retaining plate and snap

ring of overrun clutch

Specified clearance:

Standard

1.0 - 1.4 mm (0.039 - 0.055 in)

Allowable limit

2.0 mm (0.079 in)

Retaining plate:

Refer to SDS, AT-359.

SAT870A

IMeasurement of clearance between retaining plate and snap

ring of forward clutch

Specified clearance:

Standard

0.35 - 0.75 mm (0.0138 - 0.0295 in)

Allowable limit

Model 4EX16 (2WD)

2.15 mm (0.0846 in)

Model 4EX17, 4EX23 (4WD)

2.35 mm (0.0925 in)

Retaining plate:

Refer to SDS, AT-359.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Forward and Overrun Clutches (Cont'd)

AT-323

Page 329 of 2395

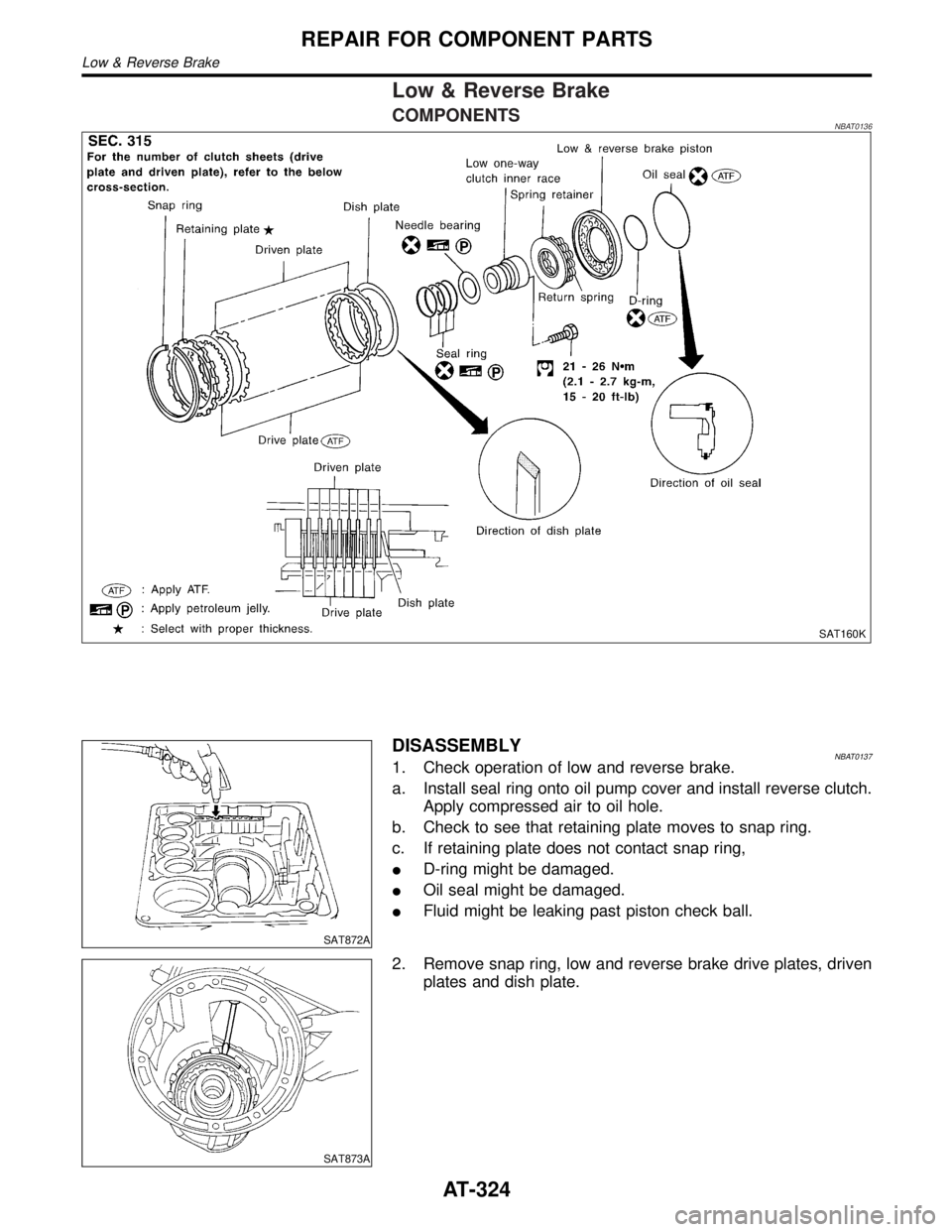

Low & Reverse Brake

COMPONENTSNBAT0136

SAT160K

SAT872A

DISASSEMBLYNBAT01371. Check operation of low and reverse brake.

a. Install seal ring onto oil pump cover and install reverse clutch.

Apply compressed air to oil hole.

b. Check to see that retaining plate moves to snap ring.

c. If retaining plate does not contact snap ring,

ID-ring might be damaged.

IOil seal might be damaged.

IFluid might be leaking past piston check ball.

SAT873A

2. Remove snap ring, low and reverse brake drive plates, driven

plates and dish plate.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake

AT-324

Page 330 of 2395

SAT382I

3. Remove low one-way clutch inner race, spring retainer and

return spring from transmission case.

4. Remove seal rings from low one-way clutch inner race.

5. Remove needle bearing from low one-way clutch inner race.

SAT876A

6. Remove low and reverse brake piston using compressed air.

7. Remove oil seal and D-ring from piston.

INSPECTIONNBAT0138Low and Reverse Brake Snap Ring and Spring RetainerNBAT0138S01ICheck for deformation, or damage.

SAT829A

Low and Reverse Brake Return SpringsNBAT0138S02ICheck for deformation or damage. Also measure free length

and outside diameter.

Inspection standard:

Refer to SDS, AT-357.

SAT845A

Low and Reverse Brake Drive PlatesNBAT0138S03ICheck facing for burns, cracks or damage.

IMeasure thickness of facing.

Thickness of drive plate:

Standard value

Model 4EX16 (2WD)

1.90 - 2.05 mm (0.075 - 0.081 in)

Model 4EX17, 4EX23 (4WD)

1.52 - 1.67 mm (0.0598 - 0.0657 in)

Wear limit

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-325

Page 331 of 2395

1.40 mm (0.0551 in)

IIf not within wear limit, replace.

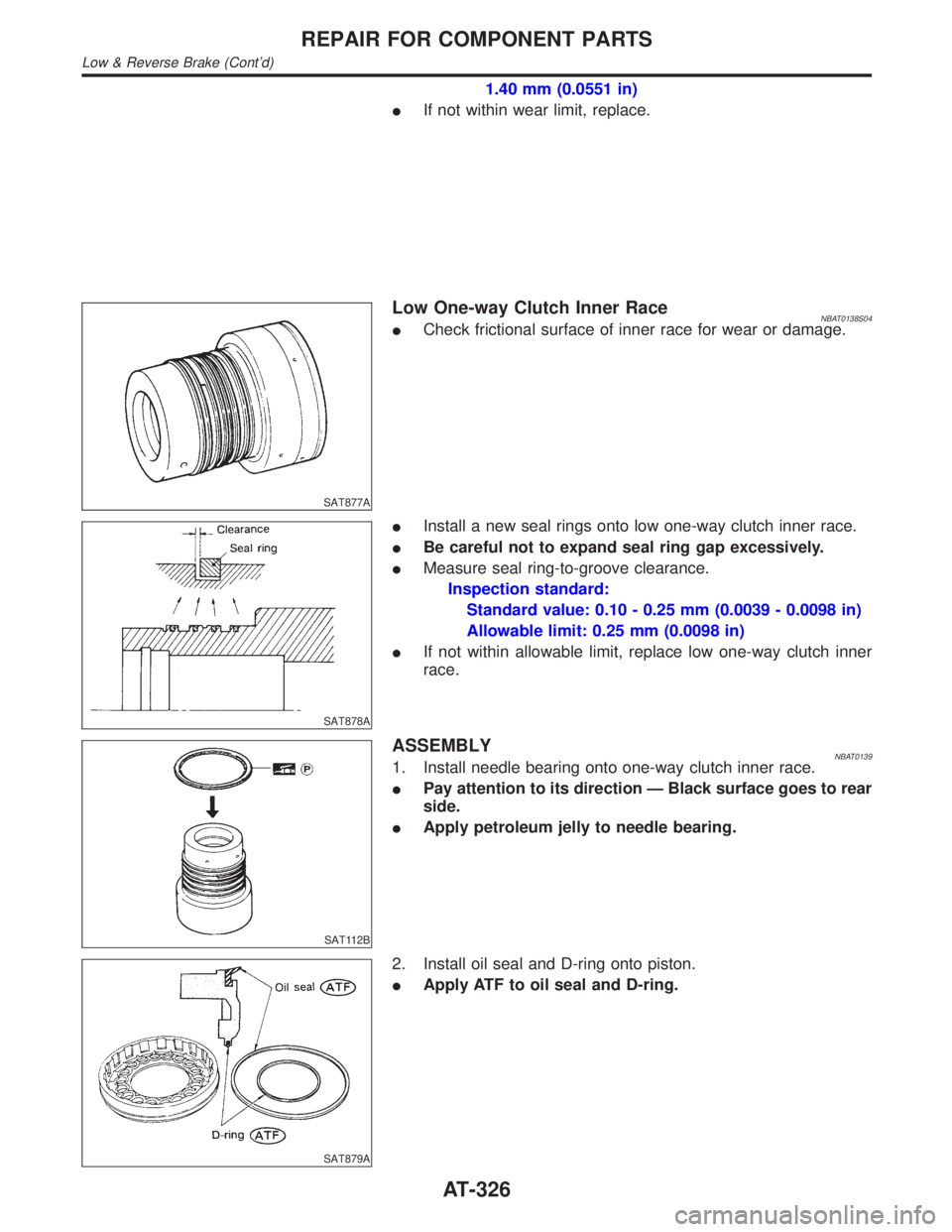

SAT877A

Low One-way Clutch Inner RaceNBAT0138S04ICheck frictional surface of inner race for wear or damage.

SAT878A

IInstall a new seal rings onto low one-way clutch inner race.

IBe careful not to expand seal ring gap excessively.

IMeasure seal ring-to-groove clearance.

Inspection standard:

Standard value: 0.10 - 0.25 mm (0.0039 - 0.0098 in)

Allowable limit: 0.25 mm (0.0098 in)

IIf not within allowable limit, replace low one-way clutch inner

race.

SAT112B

ASSEMBLYNBAT01391. Install needle bearing onto one-way clutch inner race.

IPay attention to its direction Ð Black surface goes to rear

side.

IApply petroleum jelly to needle bearing.

SAT879A

2. Install oil seal and D-ring onto piston.

IApply ATF to oil seal and D-ring.

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-326

Page 332 of 2395

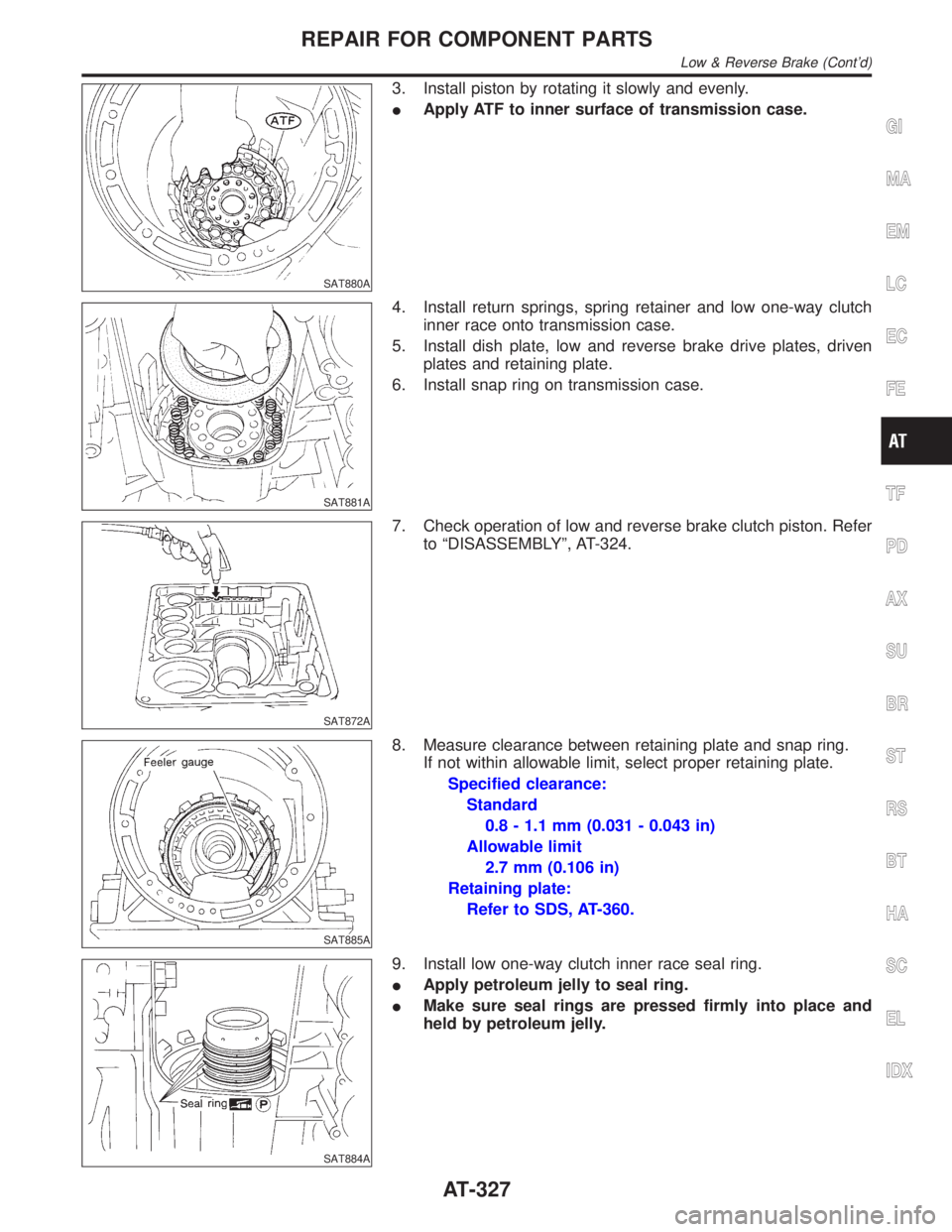

SAT880A

3. Install piston by rotating it slowly and evenly.

IApply ATF to inner surface of transmission case.

SAT881A

4. Install return springs, spring retainer and low one-way clutch

inner race onto transmission case.

5. Install dish plate, low and reverse brake drive plates, driven

plates and retaining plate.

6. Install snap ring on transmission case.

SAT872A

7. Check operation of low and reverse brake clutch piston. Refer

to ªDISASSEMBLYº, AT-324.

SAT885A

8. Measure clearance between retaining plate and snap ring.

If not within allowable limit, select proper retaining plate.

Specified clearance:

Standard

0.8 - 1.1 mm (0.031 - 0.043 in)

Allowable limit

2.7 mm (0.106 in)

Retaining plate:

Refer to SDS, AT-360.

SAT884A

9. Install low one-way clutch inner race seal ring.

IApply petroleum jelly to seal ring.

IMake sure seal rings are pressed firmly into place and

held by petroleum jelly.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REPAIR FOR COMPONENT PARTS

Low & Reverse Brake (Cont'd)

AT-327

Page 333 of 2395

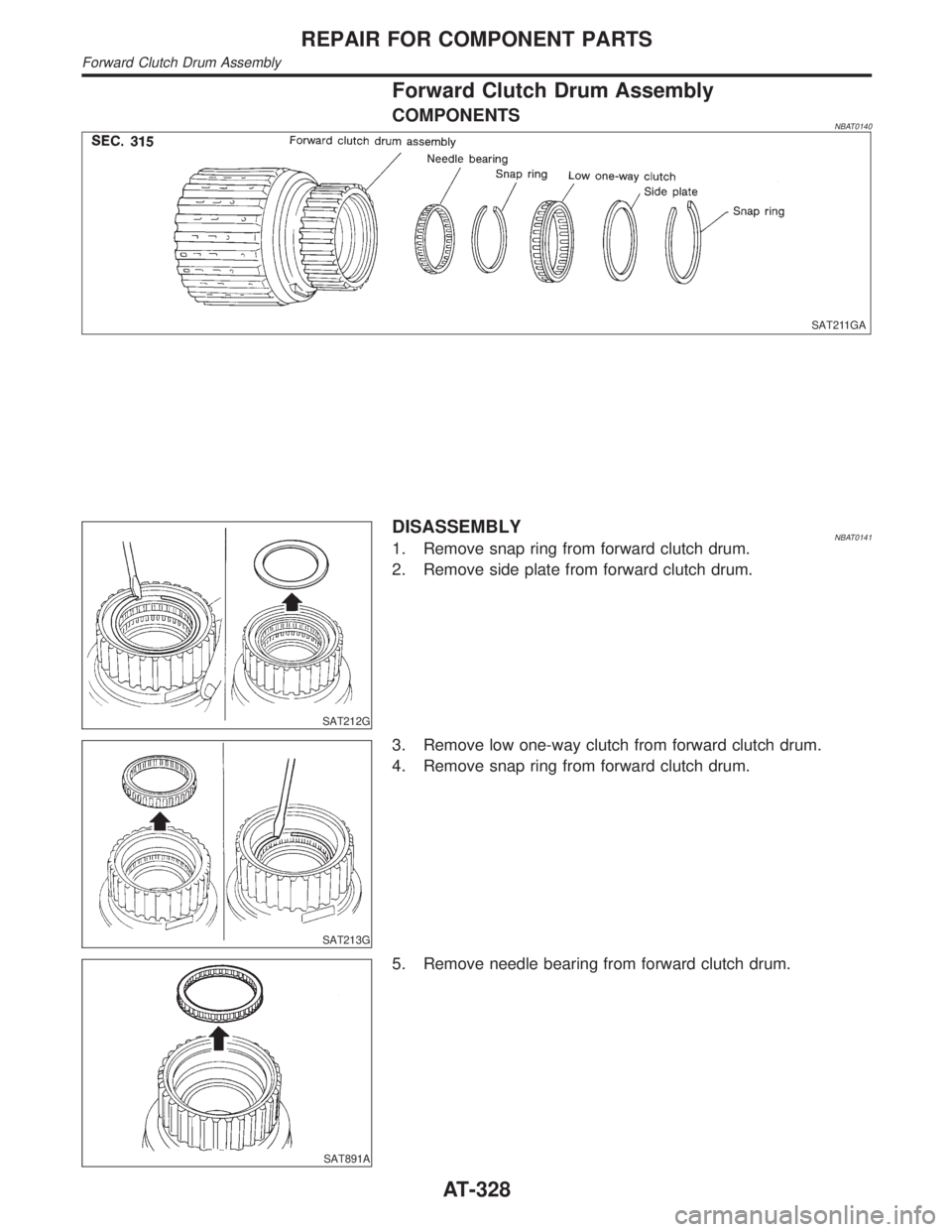

Forward Clutch Drum Assembly

COMPONENTSNBAT0140

SAT211GA

SAT212G

DISASSEMBLYNBAT01411. Remove snap ring from forward clutch drum.

2. Remove side plate from forward clutch drum.

SAT213G

3. Remove low one-way clutch from forward clutch drum.

4. Remove snap ring from forward clutch drum.

SAT891A

5. Remove needle bearing from forward clutch drum.

REPAIR FOR COMPONENT PARTS

Forward Clutch Drum Assembly

AT-328