INFINITI QX4 2001 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 861 of 2395

12 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Set voltmeter probes between ECM terminal 63 (HO2S1 bank 1 right signal) or 62 (HO2S1 bank 2 left signal) and

engine ground.

3. Check the following with engine speed held at 2,000 rpm constant under no load.

SEF967XA

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 REPLACE HEATED OXYGEN SENSOR 1 (FRONT)

1. Turn ignition switch ªOFFº.

2. Check heated oxygen sensor 1 (front) harness protector color.

SEF505Y

©Replace malfunctioning heated oxygen sensor 1 (front).

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

Diagnostic Procedure (Cont'd)

EC-326

Page 862 of 2395

14 CHECK MASS AIR FLOW SENSOR

With CONSULT-II

Check mass air flow sensor signal in ªDATA MONITORº mode with CONSULT-II.

2.0 - 6.0 g´m/sec: at idling

7.0 - 20.0 g´m/sec: at 2,500 rpm

With GST

Check mass air flow sensor signal in MODE 1 with GST.

2.0 - 6.0 g´m/sec: at idling

7.0 - 20.0 g´m/sec: at 2,500 rpm

OK or NG

OK©GO TO 15.

NG©Check connectors for rusted terminals or loose connections in the mass air flow sensor

circuit or engine grounds. Refer to EC-150.

15 CHECK SYMPTOM MATRIX CHART

Check items on the rough idle symptom in ªSymptom Matrix Chartº, EC-118.

OK or NG

OK©GO TO 16.

NG©Repair or replace.

16 ERASE THE 1ST TRIP DTC

Erase the 1st trip DTC from the ECM memory after performing the tests. Refer to EC-72.

Some tests may cause a 1st trip DTC to be set.

©GO TO 17.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

Diagnostic Procedure (Cont'd)

EC-327

Page 863 of 2395

SEF332I

Component DescriptionNBEC0185The knock sensor is attached to the cylinder block. It senses

engine knocking using a piezoelectric element. A knocking vibration

from the cylinder block is sensed as vibrational pressure. This

pressure is converted into a voltage signal and sent to the ECM.

Freeze frame data will not be stored in the ECM for the knock

sensor. The MIL will not light for knock sensor malfunction.

The knock sensor has one trip detection logic.

ECM Terminals and Reference ValueNBEC0663Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

93 W Knock sensor[Engine is running]

IIdle speedApproximately 2.5V

On Board Diagnosis LogicNBEC0187Malfunction is detected when an excessively low or high voltage

from the knock sensor is sent to ECM.

Possible CauseNBEC0491IHarness or connectors

(The knock sensor circuit is open or shorted.)

IKnock sensor

SEF058Y

DTC Confirmation ProcedureNBEC0188NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10V at idle.

DTC P0325 KNOCK SENSOR (KS)

Component Description

EC-328

Page 864 of 2395

WITH CONSULT-IINBEC0188S011) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II

2) Start engine and run it for at least 5 seconds at idle speed.

3) If DTC is detected, go to ªDiagnostic Procedureº, EC-331.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0325 KNOCK SENSOR (KS)

DTC Confirmation Procedure (Cont'd)

EC-329

Page 865 of 2395

Wiring DiagramNBEC0189

MEC958C

DTC P0325 KNOCK SENSOR (KS)

Wiring Diagram

EC-330

Page 866 of 2395

Diagnostic ProcedureNBEC0190

1 CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check resistance between ECM terminal 93 and engine ground.

NOTE:

It is necessary to use an ohmmeter which can measure more than 10 MW.

SEF321X

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 2.

2 CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect knock sensor harness connector.

2. Check harness continuity between ECM terminal 93 and knock sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F19, F116

IHarness for open or short between ECM and knock sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0325 KNOCK SENSOR (KS)

Diagnostic Procedure

EC-331

Page 867 of 2395

4 CHECK KNOCK SENSOR

Check resistance between knock sensor terminal 2 and ground.

NOTE:

It is necessary to use an ohmmeter which can measure more than 10 MW.

SEF976Y

CAUTION:

Do not use any knock sensors that have been dropped or physically damaged. Use only new ones.

OK or NG

OK©GO TO 8.

NG©Replace knock sensor.

5 RETIGHTEN GROUND SCREWS

Loose and retighten engine ground screws.

SEF959Y

©GO TO 6.

6 CHECK KNOCK SENSOR SHIELD CIRCUIT FOR OPEN AND SHORT

1. Disconnect harness connectors F19, F116.

2. Check harness continuity between harness connector F19 terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F19, F116

IHarness for open or short between harness connector F19 and engine ground

©Repair open circuit or short to power in harness or connectors.

DTC P0325 KNOCK SENSOR (KS)

Diagnostic Procedure (Cont'd)

EC-332

Page 868 of 2395

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION ENDGI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0325 KNOCK SENSOR (KS)

Diagnostic Procedure (Cont'd)

EC-333

Page 869 of 2395

SEF977Y

Component DescriptionNBEC0191The crankshaft position sensor (POS) is located on the oil pan

facing the gear teeth (cogs) of the signal plate (flywheel). It detects

the crankshaft position signal (1É signal).

The sensor consists of a permanent magnet, core and coil.

When engine is running, the gap between the sensor and the gear

teeth (cogs) will periodically change. Permeability near the sensor

also changes.

Due to the permeability change, the magnetic flux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal and detects the crankshaft

position signal (1É signal).

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0492Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

Component Description

EC-334

Page 870 of 2395

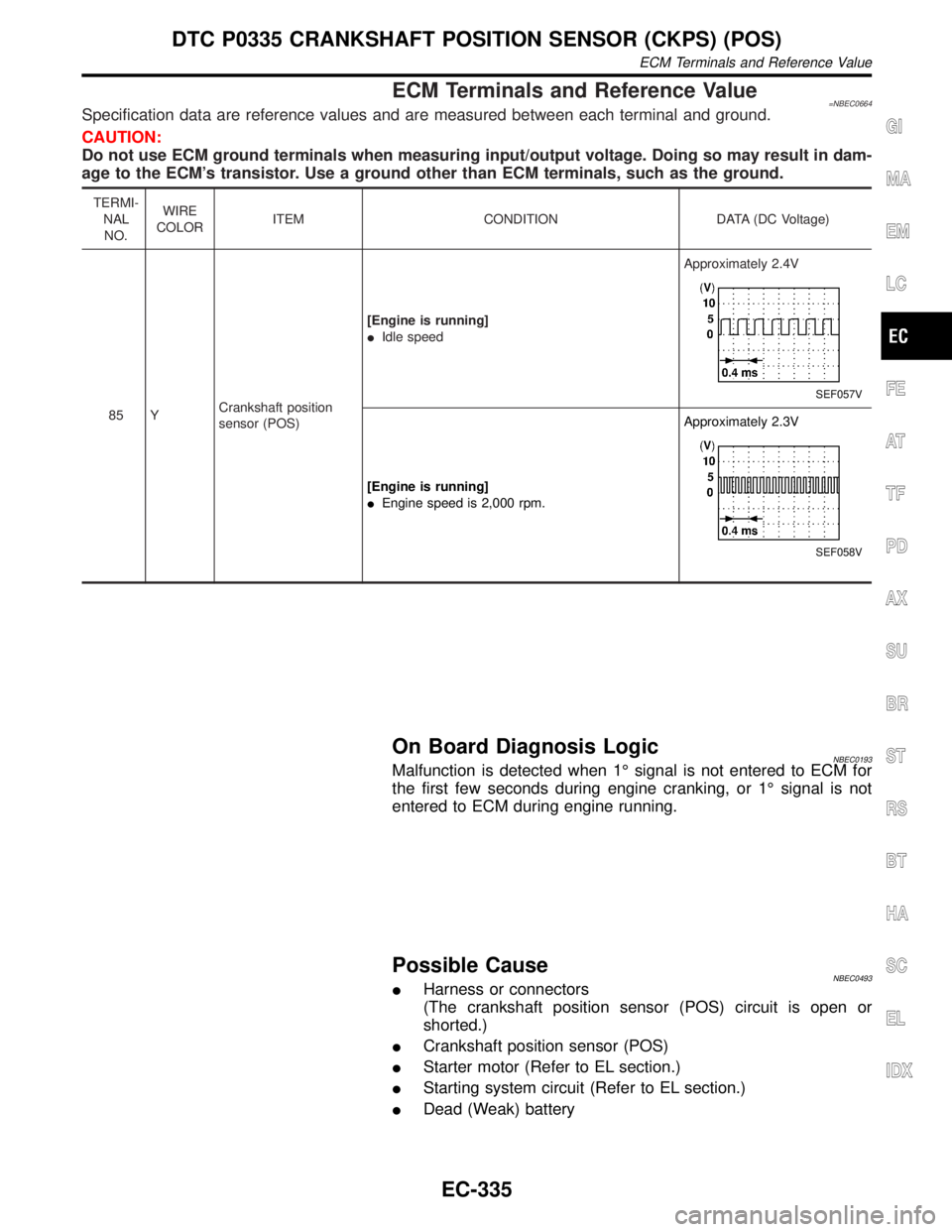

ECM Terminals and Reference Value=NBEC0664Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 YCrankshaft position

sensor (POS)[Engine is running]

IIdle speedApproximately 2.4V

SEF057V

[Engine is running]

IEngine speed is 2,000 rpm.Approximately 2.3V

SEF058V

On Board Diagnosis LogicNBEC0193Malfunction is detected when 1É signal is not entered to ECM for

the first few seconds during engine cranking, or 1É signal is not

entered to ECM during engine running.

Possible CauseNBEC0493IHarness or connectors

(The crankshaft position sensor (POS) circuit is open or

shorted.)

ICrankshaft position sensor (POS)

IStarter motor (Refer to EL section.)

IStarting system circuit (Refer to EL section.)

IDead (Weak) battery

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

ECM Terminals and Reference Value

EC-335