fuel INFINITI QX56 2007 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1207 of 3061

EC-124

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

5. Perform each diagnostic service according to each service pro-

cedure.

For further information, see the GST Operation Manual of

the tool maker.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003531628

Remarks:

l Specification data are reference values.

l Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in spite of the

ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the ECM according to the signals

input from the camshaft position sensor and other ignition timing related sensors.

SEF416S

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED• Run engine and compare CONSULT-II value with the tachometer indica-

tion.Almost the same speed as the

tachometer indication.

MAS A/F SE-B1 See EC-129

.

B/FUEL SCHDL See EC-129

.

A/F ALPHA-B1

A/F ALPHA-B2See EC-129

.

COOLAN TEMP/S • Engine: After warming up More than 70°C (158°F)

A/F SEN1 (B1)

A/F SEN1 (B2)• Engine: After warming up Maintaining engine speed at 2,000 rpm Fluctuates around 2.2 V

HO2S2 (B1)

HO2S2 (B2)• Revving engine from idle to 3,000 rpm quickly after the following conditions

are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and

at idle for 1 minute under no load0 - 0.3V ←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)• Revving engine from idle to 3,000 rpm quickly after the following conditions

are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and

at idle for 1 minute under no loadLEAN ←→ RICH

VHCL SPEED SE• Turn drive wheels and compare CONSULT-II value with the speedometer

indication.Almost the same speed as the

speedometer indication

BATTERY VOLT • Ignition switch: ON (Engine stopped) 11 - 14V

ACCEL SEN 1• Ignition switch: ON

(Engine stopped)Accelerator pedal: Fully released 0.5 - 1.0V

Accelerator pedal: Fully depressed 4.2 - 4.8V

ACCEL SEN 2*

1• Ignition switch: ON

(Engine stopped)Accelerator pedal: Fully released 0.5 - 1.0V

Accelerator pedal: Fully depressed 4.2 - 4.8V

THRTL SEN 1

THRTL SEN 2*

2

• Ignition switch: ON

(Engine stopped)

• Selector lever: DAccelerator pedal: Fully released More than 0.36V

Accelerator pedal: Fully depressed Less than 4.75V

EVAP SYS PRES • Ignition switch: ON Approx. 1.8 - 4.8V

START SIGNAL • Ignition switch: ON → START → ON OFF → ON → OFF

CLSD THL POS• Ignition switch: ON

(Engine stopped)Accelerator pedal: Fully released ON

Accelerator pedal: Slightly depressed OFF

Page 1208 of 3061

TROUBLE DIAGNOSIS

EC-125

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N POSI SW • Ignition switch: ONSelector lever: P or N ON

Selector lever: Except above OFF

PW/ST SIGNAL• Engine: After warming up, idle the

engineSteering wheel: Not being turned

(Forward direction)OFF

Steering wheel: Being turned ON

LOAD SIGNAL • Ignition switch: ONRear window defogger switch is ON

and/or lighting switch is in 2nd.ON

Rear window defogger switch is OFF

and lighting switch is OFF.OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW• Engine: After warming up, idle the

engineHeater fan control switch: ON ON

Heater fan control switch: OFF OFF

BRAKE SW • Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1

INJ PULSE-B2• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 2.0 - 2.8 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 10° - 20° BTDC

2,000 rpm 25° - 45° BTDC

CAL/LD VALUE• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 14% - 33%

2,500 rpm 12% - 25%

MASS AIRFLOW• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 3.0 - 9.0 g·m/s

2,500 rpm 9.0 - 28.0 g·m/s

PURG VOL C/V• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle

(Accelerator pedal: Not depressed

even slightly, after engine starting.)0%

2,000 rpm —

INT/V TIM (B1)

INT/V TIM (B2)• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 20°CA

INT/V SOL (B1)

INT/V SOL (B2)• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 0% - 2%

2,000 rpm Approx. 25% - 50%

AIR COND RLY• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor: Operates)ON

FUEL PUMP RLY• For 1 second after turning ignition switch ON

• Engine running or crankingON

• Except above conditions OFF

VENT CONT/V • Ignition switch: ON OFF

THRTL RELAY • Ignition switch: ON ONMONITOR ITEM CONDITION SPECIFICATION

Page 1212 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-129

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000003531630

The specification (SP) value indicates the tolerance of the value that is displayed in “DATA MONITOR (SPEC)”

mode of CONSULT-II during normal operation of the Engine Control System. When the value in “DATA MONI-

TOR (SPEC)” mode is within the SP value, the Engine Control System is confirmed OK. When the value in

“DATA MONITOR (SPEC)” mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

• B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correc-

tion)

• A/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

• MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionINFOID:0000000003531631

• Vehicle driven distance: More than 5,000 km (3,107 miles)

• Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2 , 14.25 - 15.12 psi)

• Atmospheric temperature: 20 - 30°C (68 - 86°F)

• Engine coolant temperature: 75 - 95°C (167 - 203°F)

• Engine speed: Idle

• Transmission: Warmed-up

- After the engine is warmed up to normal operating temperature, drive vehicle until “ATF TEMP SE 1” (A/T

fluid temperature sensor signal) indicates more than 60°C (140°F).

• Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

Inspection ProcedureINFOID:0000000003531632

NOTE:

Perform “DATA MONITOR (SPEC)” mode in maximum scale display.

1. Perform EC-71, "

Basic Inspection" .

2. Confirm that the testing conditions indicated above are met.

3. Select “B/FUEL SCHDL”, “A/F ALPHA-B1”, “A/F ALPHA-B2”

and “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode with

CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to EC-130, "

Diagnosis Procedure" .

SEF601Z

Page 1215 of 3061

EC-132

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

3. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR

(SPEC)” mode, and make sure that the each indication is within

the SP value.

NOTE:

Check “A/F ALPHA-B1”, “A/F ALPHA-B2” for approximately 1

minute because they may fluctuate. It is NG if the indication is

out of the SP value even a little.

OK or NG

OK >> GO TO 17.

NG (Less than the SP value)>>GO TO 2.

NG (More than the SP value)>>GO TO 3.

2.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK >> GO TO 4.

NG (More than the SP value)>>GO TO 19.

3.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK >> GO TO 6.

NG (More than the SP value)>>GO TO 6.

NG (Less than the SP value)>>GO TO 25.

4.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Stop the engine.

2. Disconnect PCV hose, and then plug it.

3. Start engine.

4. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> GO TO 5.

NG >> GO TO 6.

5.CHANGE ENGINE OIL

1. Stop the engine.

2. Change engine oil.

NOTE:

This symptom may occur when a large amount of gasoline is mixed with engine oil because of driving

conditions (such as when engine oil temperature does not rise enough since a journey distance is too

short during winter). The symptom will not be detected after changing engine oil or changing driving con-

dition.

>>INSPECTION END

PBIB2369E

PBIB2332E

PBIB2332E

Page 1216 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-133

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

6.CHECK FUEL PRESSURE

Check fuel pressure. (Refer to EC-80, "

Fuel Pressure Check" .)

OK or NG

OK >> GO TO 9.

NG (Fuel pressure is too high)>>Replace fuel pressure regulator, refer to EC-80, "

Fuel Pressure Check" .

GO TO 8.

NG (Fuel pressure is too low)>>GO TO 7.

7.DETECT MALFUNCTIONING PART

1. Check the following.

- Clogged and bent fuel hose and fuel tube

- Clogged fuel filter

- Fuel pump and its circuit (Refer to EC-613

.)

2. If NG, repair or replace the malfunctioning part. (Refer to EC-80, "

Fuel Pressure Check" .)

If OK, replace fuel pressure regulator.

>> GO TO 8.

8.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG >> GO TO 9.

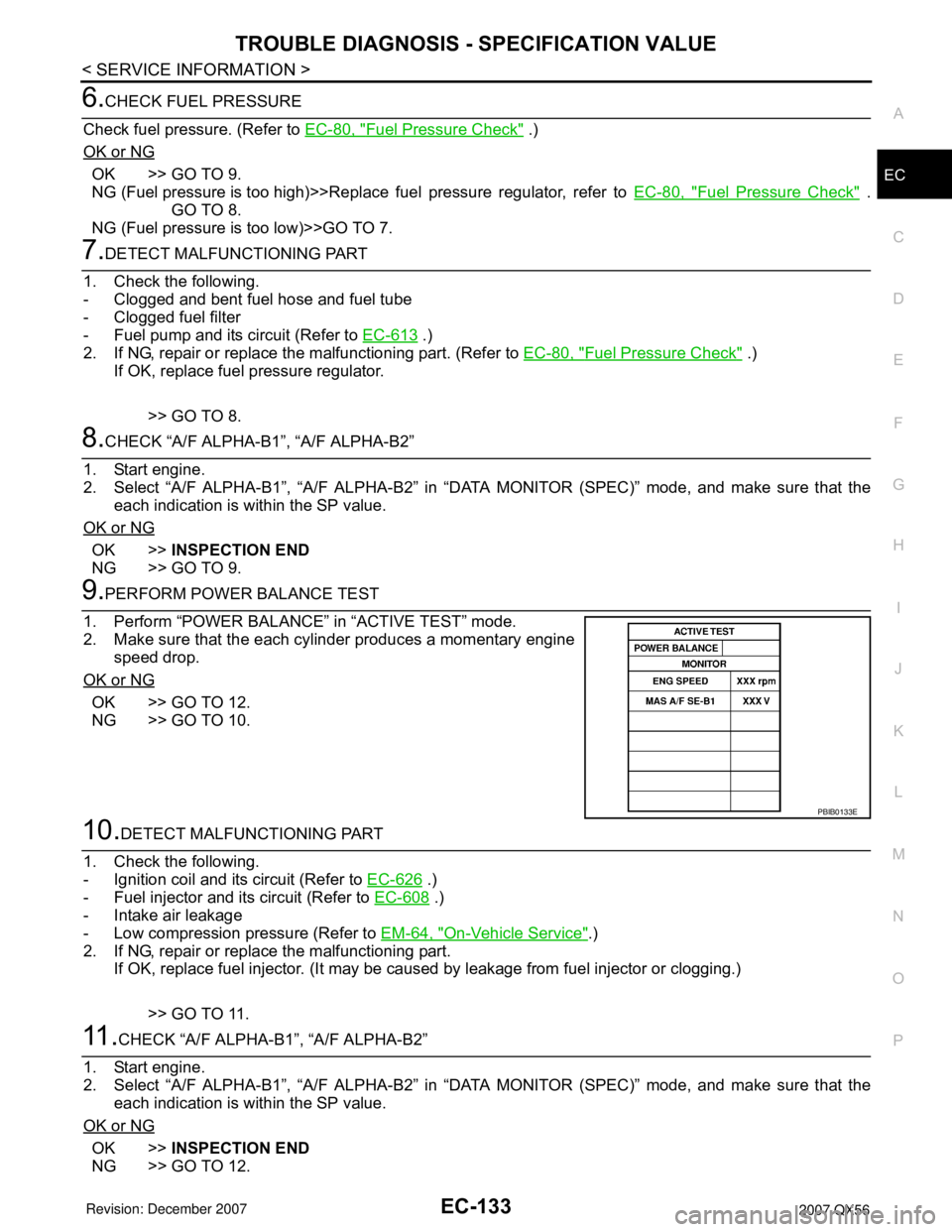

9.PERFORM POWER BALANCE TEST

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode.

2. Make sure that the each cylinder produces a momentary engine

speed drop.

OK or NG

OK >> GO TO 12.

NG >> GO TO 10.

10.DETECT MALFUNCTIONING PART

1. Check the following.

- Ignition coil and its circuit (Refer to EC-626

.)

- Fuel injector and its circuit (Refer to EC-608

.)

- Intake air leakage

- Low compression pressure (Refer to EM-64, "

On-Vehicle Service".)

2. If NG, repair or replace the malfunctioning part.

If OK, replace fuel injector. (It may be caused by leakage from fuel injector or clogging.)

>> GO TO 11.

11 .CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG >> GO TO 12.

PBIB0133E

Page 1217 of 3061

EC-134

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

12.CHECK A/F SENSOR 1 FUNCTION

Perform all DTC Confirmation Procedure related with A/F sensor 1.

• For DTC P0130, P0150, refer to EC-225, "

DTC Confirmation Procedure" .

• For DTC P0131, P0151, refer to EC-234, "

DTC Confirmation Procedure" .

• For DTC P0132, P0132, refer to EC-242, "

DTC Confirmation Procedure" .

• For DTC P0133, P0153, refer to EC-250, "

DTC Confirmation Procedure" .

• For DTC P2A00, P2A03, refer to EC-588, "

DTC Confirmation Procedure" .

OK or NG

OK >> GO TO 15.

NG >> GO TO 13.

13.CHECK A/F SENSOR 1 CIRCUIT

Perform Diagnostic Procedure according to corresponding DTC.

>> GO TO 14.

14.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG >> GO TO 15.

15.DISCONNECT AND RECONNECT ECM HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect ECM harness connector. Check pin terminal and connector for damage, and then reconnect it.

>> GO TO 16.

16.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG >> Detect malfunctioning part according to EC-90, "

Symptom Matrix Chart" .

17.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG (More than the SP value)>>GO TO 18.

NG (Less than the SP value)>>GO TO 25.

18.DETECT MALFUNCTIONING PART

1. Check for the cause of large engine friction. Refer to the following.

- Engine oil level is too high

- Engine oil viscosity

- Belt tension of power steering, alternator, A/C compressor, etc. is excessive

- Noise from engine

PBIB2332E

Page 1218 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-135

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

- Noise from transmission, etc.

2. Check for the cause of insufficient combustion. Refer to the following.

- Valve clearance malfunction

- Intake valve timing control function malfunction

- Camshaft sprocket installation malfunction, etc.

>> Repair or replace malfunctioning part, and then GO TO 30.

19.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

OK or NG

OK >> GO TO 21.

NG >> Repair or replace malfunctioning part, and then GO TO 20.

20.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG (“B/FUEL SCHDL” is more, “A/F ALPHA-B1”, “A/F ALPHA-B2” are less than the SP value)>>GO TO 21.

21.DISCONNECT AND RECONNECT MASS AIR FLOW SENSOR HARNESS CONNECTOR

1. Stop the engine.

2. Disconnect mass air flow sensor harness connector. Check pin terminal and connector for damage and

then reconnect it again.

>> GO TO 22.

22.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >> 1. Detect malfunctioning part of mass air flow sensor circuit and repair it. Refer to EC-194 .

2. GO TO 29.

NG >> GO TO 23.

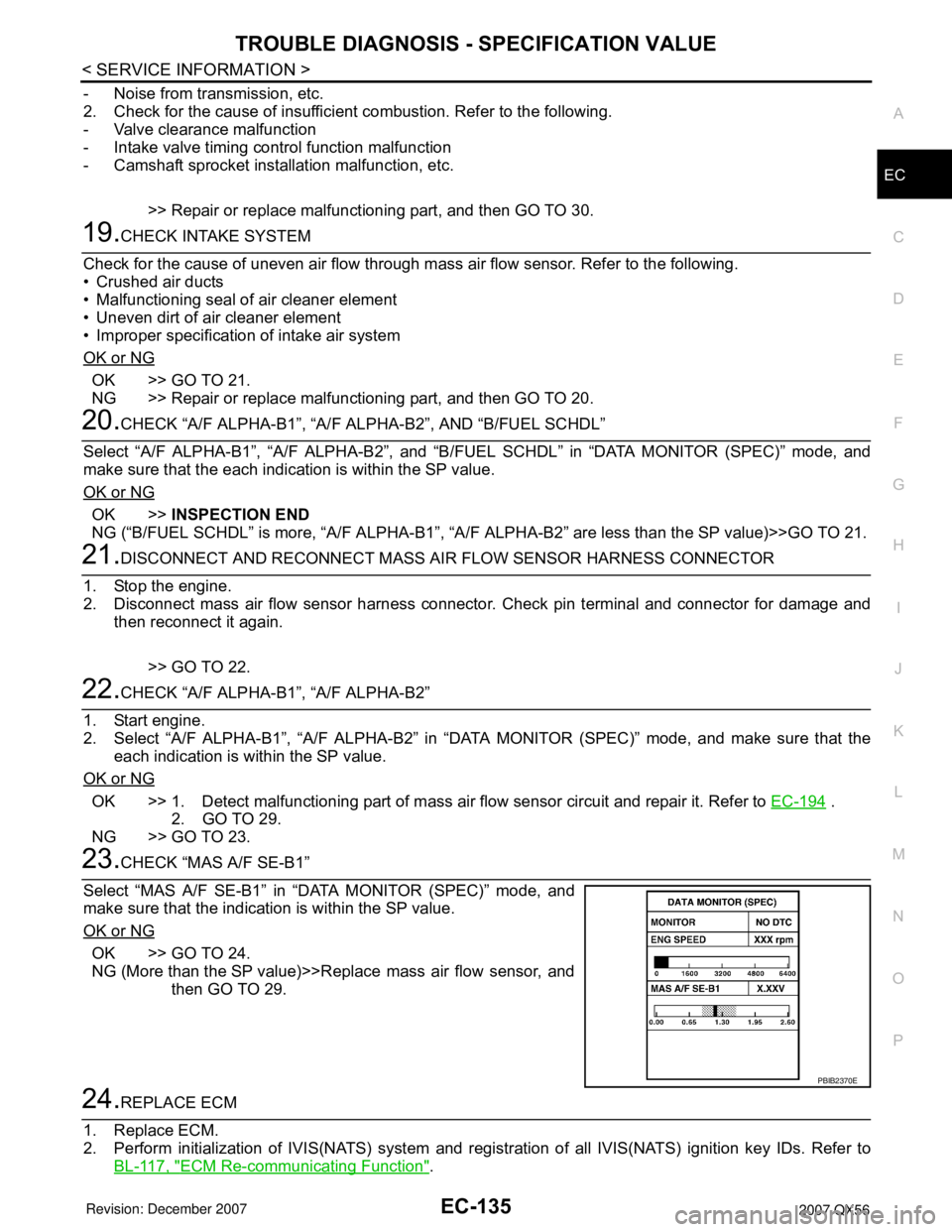

23.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK >> GO TO 24.

NG (More than the SP value)>>Replace mass air flow sensor, and

then GO TO 29.

24.REPLACE ECM

1. Replace ECM.

2. Perform initialization of IVIS(NATS) system and registration of all IVIS(NATS) ignition key IDs. Refer to

BL-117, "

ECM Re-communicating Function".

PBIB2370E

Page 1219 of 3061

EC-136

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

3. Perform EC-77, "VIN Registration" .

4. Perform EC-77, "

Accelerator Pedal Released Position Learning" .

5. Perform EC-77, "

Throttle Valve Closed Position Learning" .

6. Perform EC-78, "

Idle Air Volume Learning" .

>> GO TO 29.

25.CHECK INTAKE SYSTEM

Check for the cause of uneven air flow through mass air flow sensor. Refer to the following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system

OK or NG

OK >> GO TO 27.

NG >> Repair or replace malfunctioning part, and then GO TO 26.

26.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and make sure that the indication is within the

SP value.

OK or NG

OK >>INSPECTION END

NG (Less than the SP value)>>GO TO 27.

27.CHECK “MAS A/F SE-B1”

Select “MAS A/F SE-B1” in “DATA MONITOR (SPEC)” mode, and

make sure that the indication is within the SP value.

OK or NG

OK >> GO TO 28.

NG (Less than the SP value)>>Replace mass air flow sensor, and

then GO TO 30.

28.CHECK INTAKE SYSTEM

Check for the cause of air leak after the mass air flow sensor. Refer to the following.

• Disconnection, looseness, and cracks in air duct

• Looseness of oil filler cap

• Disconnection of oil level gauge

• Open stuck, breakage, hose disconnection, or cracks of PCV valve

• Disconnection or cracks of EVAP purge hose, open stuck of EVAP canister purge volume control solenoid

valve

• Malfunctioning seal of rocker cover gasket

• Disconnection, looseness, or cracks of hoses, such as vacuum hose, connecting to intake air system parts

• Malfunctioning seal of intake air system, etc.

>> GO TO 30.

29.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”, AND “B/FUEL SCHDL”

Select “A/F ALPHA-B1”, “A/F ALPHA-B2”, and “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and

make sure that the each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG >> Detect malfunctioning part according to EC-90, "

Symptom Matrix Chart" .

PBIB2370E

Page 1220 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-137

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

30.CHECK “B/FUEL SCHDL”

Select “B/FUEL SCHDL” in “DATA MONITOR (SPEC)” mode, and then make sure that the indication is within

the SP value.

OK or NG

OK >>INSPECTION END

NG >> Detect malfunctioning part according to EC-90, "

Symptom Matrix Chart" .

Page 1246 of 3061

DTC P0031, P0032, P0051, P0052 A/F SENSOR 1 HEATER

EC-163

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0031, P0032, P0051, P0052 A/F SENSOR 1 HEATER

DescriptionINFOID:0000000003531656

SYSTEM DESCRIPTION

The ECM performs ON/OFF duty control of the A/F sensor 1 heater corresponding to the engine operating

condition to keep the temperature of A/F sensor 1 element at the specified range.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003531657

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000003531658

DTC Confirmation ProcedureINFOID:0000000003531659

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is between 10.5V and 16V at

idle.

WITH CONSULT-II

1. Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

2. Start engine and let it idle for at least 10 seconds.

3. If 1st trip DTC is detected, go to EC-167, "

Diagnosis Procedure".

Sensor Input Signal to ECM ECM function Actuator

Camshaft position sensor (PHASE)

Crankshaft position sensor (POS)Engine speed

Air fuel ratio (A/F) sensor 1

heater controlAir fuel ratio (A/F) sensor 1

heater

Mass air flow sensor Amount of intake air

MONITOR ITEM CONDITION SPECIFICATION

A/F S1 HTR (B1)

A/F S1 HTR (B2)• Engine: After warming up, idle the engine 4 - 100%

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0031

0031

(Bank 1)

Air fuel ratio (A/F) sensor

1 heater control circuit lowThe current amperage in the air fuel ratio (A/F) sen-

sor 1 heater circuit is out of the normal range.

(An excessively low voltage signal is sent to ECM

through the air fuel ratio (A/F) sensor 1 heater.)• Harness or connectors

(The A/F sensor 1 heater circuit is

open or shorted.)

• A/F sensor 1 heater P0051

0051

(Bank 2)

P0032

0032

(Bank 1)Air fuel ratio (A/F) sensor

1 heater control circuit

highThe current amperage in the air fuel ratio (A/F) sen-

sor 1 heater circuit is out of the normal range.

(An excessively high voltage signal is sent to ECM

through the air fuel ratio (A/F) sensor 1 heater.)• Harness or connectors

(The A/F sensor 1 heater circuit is

shorted.)

• A/F sensor 1 heater P0052

0052

(Bank 2)

SEF058Y