suspension INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1 of 3061

-1

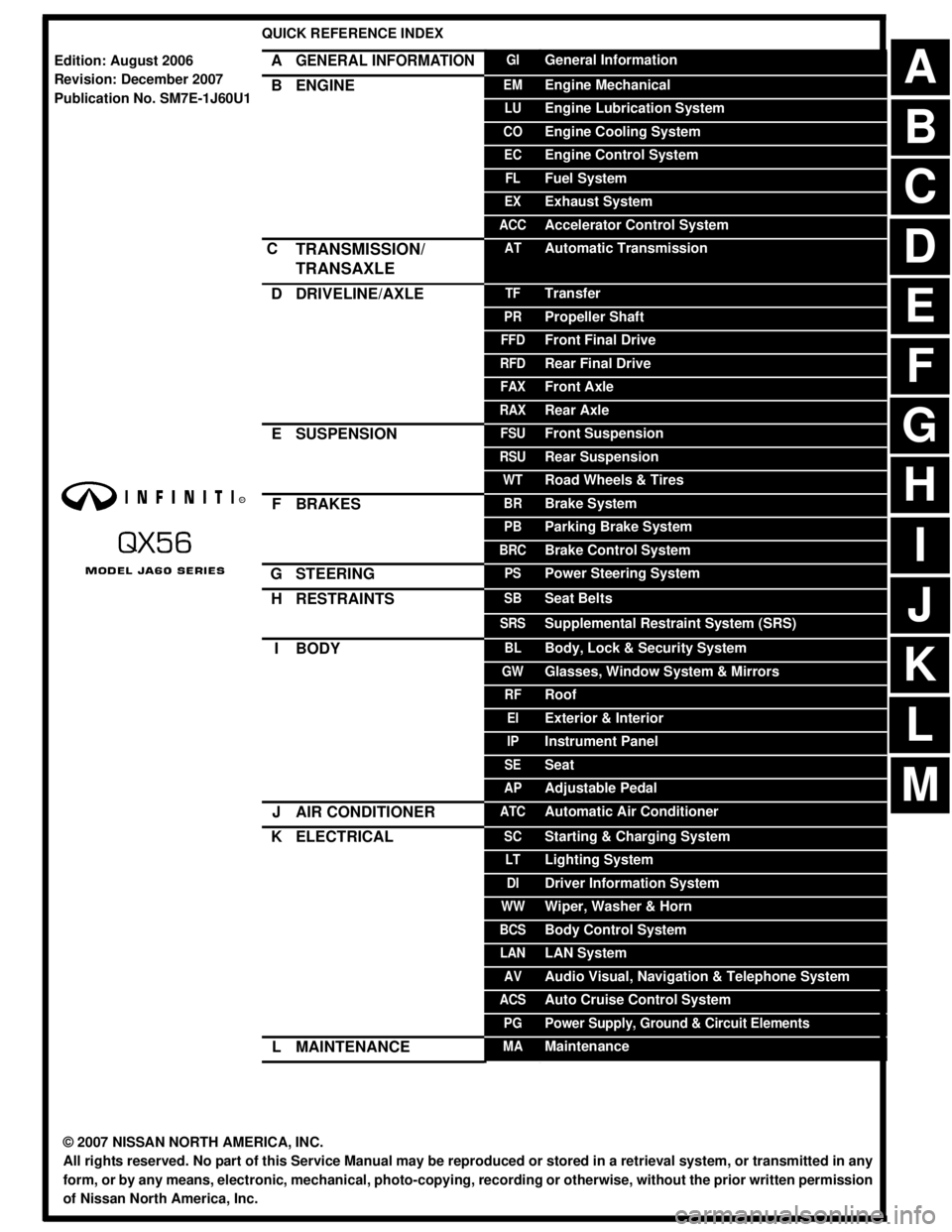

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLEATAutomatic Transmission

DDRIVELINE/AXLETFTransfer

PRPropeller Shaft

FFDFront Final Drive

RFDRear Final Drive

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

APAdjustable Pedal

JAIR CONDITIONERATCAutomatic Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: August 2006

Revision: December 2007

Publication No. SM7E-1J60U1

B

D

© 2007 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America, Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 25 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-12

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

Outline of Laser Beam Aiming Adjustment ProcedureINFOID:0000000003533782

CAUTION:

• The laser beam aimin INFINITI QX56 2007 Factory Service Manual ACS-12

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

Outline of Laser Beam Aiming Adjustment ProcedureINFOID:0000000003533782

CAUTION:

• The laser beam aimin](/img/42/57029/w960_57029-24.png)

ACS-12

< SERVICE INFORMATION >[ICC]

LASER BEAM AIMING ADJUSTMENT

LASER BEAM AIMING ADJUSTMENT

Outline of Laser Beam Aiming Adjustment ProcedureINFOID:0000000003533782

CAUTION:

• The laser beam aiming adjustment cannot be performed without CONSULT-II.

• The laser beam aiming adjustment must be performed every time the ICC sensor is removed,

installed or has been moved as a result of a collision.

1. Prepare the vehicle and the work area.

2. Set up the ICC target board. For details, refer to Technical Service Bulletin.

3. Adjust the sensor following the procedure on CONSULT-II.

4. Check system operation after the adjustment.

PreparationINFOID:0000000003533783

• Place the vehicle on level ground. Shift the transmission into "P" position and release the parking brake.

• Adjust the tire pressure to the specified value.

• See that there is no load in the vehicle. Coolant, engine oil and fuel should be filled to correct level.

• Check that the vehicle suspension has been adjusted to the standard height by the load leveling rear air sus-

pension system. Refer to RSU-10, "

Basic Inspection" .

• Clean the sensor with a soft cloth.

Setting up the ICC Target BoardINFOID:0000000003533784

CAUTION:

Accuracy in setting up the ICC target board is essential for the laser beam aiming adjustment. For

details, refer to Technical Service Bulletin.

ADJUSTING HEIGHT OF THE TARGET

1. Attach a triangle scale as shown.Tool number : KV99110100 (J-45718)

LKIA0632E

WKIA1849E

Page 853 of 3061

BL-142

< SERVICE INFORMATION >

BODY REPAIR

6. 2nd crossmember assembly

7. Front upper link mounting bracket RH/LH

8. Panhard rod bracket reinforcement

9. Bound bumper bracket RH/LH

10. Front brake hose bracket RH/LH

11. Panhard rod reinforcement

12. 4th crossmember gusset RH/LH

13. 2nd cab mounting bracket RH/LH

14. 3rd cab mounting bracket RH/LH

15. 4th cab mounting reinforcement RH/LH

16. 4th cab mounting bracket RH/LH

17. Rear suspension mounting bracket RH/LH

18. Rear brake hose bracket

19. Rear shock absorber bracket assembly RH/LH

20. Rear bound bumper bracket RH/LH

21. Rear bracket bumper reinforcement RH/LH

22. Cab mounting bracket assembly RH/LH

23. 9th crossmember assembly

24. Exhaust bracket assembly

25. Canister bracket, LH

26. 7th crossmember reinforcement

27. 7th crossmember assembly

28. 6th crossmember assembly

29. 4th crossmember gusset RH/LH

30. 4th crossmember assembly

31. 3rd crossmember assembly

32. Frame assembly

Corrosion ProtectionINFOID:0000000003533007

DESCRIPTION

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrode position primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

PHOSPHATE COATING TREATMENT AND CATIONIC ELECTRODEPOSITION PRIMER

PIIA0093E

Page 902 of 3061

BR-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003532721

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

BR-18

, BR-24

BR-18

, BR-24

BR-18

, BR-24

BR-20

, BR-26

BR-20

, BR-26

BR-20

, BR-26

BR-20

, BR-26

BR-20

, BR-26

BR-20

, BR-26

BR-20

, BR-26

PR-3, "

NVH Troubleshooting Chart

"

FFD-6, "

NVH Troubleshooting Chart

", RFD-7, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

", RAX-4, "

NVH Troubleshooting Chart

"

FSU-4, "

NVH Troubleshooting Chart

", RSU-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

PROPELLER SHAFT

DIFFERENTIAL

DRIVESHAFT

SUSPENSION

TIRES AND ROAD WHEEL

STEERING

SymptomNoise××× ××××××

Shake××××××

Shimmy, Shudder××××××× ××××

Page 932 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-4

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

• If YES, GO TO 2.

• If NO, GO TO 5.

2. Is there any indication other than indications relating to CAN communication system in the self-diagn INFINITI QX56 2007 Factory Service Manual BRC-4

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

• If YES, GO TO 2.

• If NO, GO TO 5.

2. Is there any indication other than indications relating to CAN communication system in the self-diagn](/img/42/57029/w960_57029-931.png)

BRC-4

< SERVICE INFORMATION >[VDC/TCS/ABS]

PRECAUTIONS

• If YES, GO TO 2.

• If NO, GO TO 5.

2. Is there any indication other than indications relating to CAN communication system in the self-diagnosis

results?

• If YES, GO TO 3.

• If NO, GO TO 4.

3. Based on self-diagnosis results unrelated to CAN communication, carry out the inspection.

4. Malfunctions may be detected in self-diagnosis depending on control units carrying out CAN communica-

tion. Therefor, erase the self-diagnosis results.

5. Diagnose CAN communication system. Refer to LAN-7

.

Precaution for Brake ControlINFOID:0000000003532764

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting vehicle, the brake pedal may vibrate or a motor operating noise may be heard from engine

compartment. This is a normal status of operation check.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check booster operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near control module, ABS function may have a malfunction or

error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits or improper wiring.

• If the following components are replaced with non-genuine components or modified, the VDC OFF indicator

lamp and SLIP indicator lamp may turn on or the VDC system may not operate properly. Components

related to suspension (shock absorbers, struts, springs, bushings, etc.), tires, wheels (exclude specified

size), components related to brake system (pads, rotors, calipers, etc.), components related to engine (muf-

fler, ECM, etc.), components related to body reinforcement (roll bar, tower bar, etc.).

• Driving with broken or excessively worn suspension components, tires or brake system components may

cause the VDC OFF indicator lamp and the SLIP indicator lamp to turn on, and the VDC system may not

operate properly.

• When the TCS or VDC is activated by sudden acceleration or sudden turn, some noise may occur. The

noise is a result of the normal operation of the TCS and VDC.

• When driving on roads which have extreme slopes (such as mountainous roads) or high banks (such as

sharp curves on a freeway), the VDC may not operate normally, or the VDC warning lamp and the SLIP indi-

cator lamp may turn on. This is not a problem if normal operation can be resumed after restarting the engine.

• Sudden turns (such as spin turns, acceleration turns), drifting, etc. with VDC turned off may cause the yaw

rate/side/decel G sensor to indicate a problem. This is not a problem if normal operation can be resumed

after restarting the engine.

Precaution for CAN SystemINFOID:0000000003532765

• Do not apply voltage of 7.0V or higher to terminal to be measured.

• Maximum open terminal voltage of tester in use must be less than 7.0V.

• Before checking harnesses, turn ignition switch OFF and disconnect battery negative cable.

Page 982 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-54

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angle Sensor Neutral PositionINFOID:0000000003532809

After removing/installing or replacing ABS INFINITI QX56 2007 Factory Service Manual BRC-54

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angle Sensor Neutral PositionINFOID:0000000003532809

After removing/installing or replacing ABS](/img/42/57029/w960_57029-981.png)

BRC-54

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angle Sensor Neutral PositionINFOID:0000000003532809

After removing/installing or replacing ABS actuator and electric unit (control unit), steering angle sensor, steer-

ing and suspension components which affect wheel alignment or after adjusting wheel alignment, be sure to

adjust neutral position of steering angle sensor before running vehicle.

NOTE:

Adjustment of steering angle sensor neutral position requires CONSULT-II.

1. Stop vehicle with front wheels in straight-ahead position.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector on vehicle, and turn ignition switch ON (do not

start engine).

3. Touch “START (NISSAN BASED VHCL)”, “ABS”, “WORK SUP-

PORT” and “ST ANGLE SENSOR ADJUSTMENT” on CON-

SULT-II screen in this order.

4. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle

sensor.

5. After approximately 10 seconds, touch “END”. (After approxi-

mately 60 seconds, it ends automatically.)

6. Turn ignition switch OFF, then turn it ON again.

7. Run vehicle with front wheels in straight-ahead position, then

stop.

8. Select “DATA MONITOR”, “SELECTION FROM MENU”, and

“STR ANGLE SIG” on CONSULT-II screen. Then check that

“STR ANGLE SIG” is within 0±3.5 deg. If value is more than specification, repeat steps 1 to 5.

9. Erase memory of ABS actuator and electric unit (control unit) and ECM.

10. Turn ignition switch to OFF.

Calibration of Decel G SensorINFOID:0000000003532810

After removing/installing or replacing ABS actuator and electric unit (control unit), yaw rate/side/decel G sen-

sor, steering and suspension components which affect wheel alignment or after adjusting wheel alignment, be

sure to calibrate the decel G sensor before running vehicle.

NOTE:

Calibration of decel G sensor requires CONSULT-II.

1. Stop vehicle with front wheels in straight-ahead position.

CAUTION:

• The work should be done on a level area with an unloaded vehicle.

• Keep all the tires inflated to the correct pressures. Adjust the tire pressure to the specified pres-

sure value.

2. Connect CONSULT-II with CONSULT-II CONVERTER to data link connector on vehicle, and turn ignition

switch ON (do not start engine).

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

3. Touch “START (NISSAN BASED VHCL)”, "ABS", "WORK SUPPORT" and "DECEL G SEN CALIBRA-

TION" on CONSULT-II screen in this order. Refer to BRC-26, "

CONSULT-II Function (ABS)".

BBIA0369E

WFIA0239E

Page 1179 of 3061

EC-96

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

1. EVAP canister purge volume control

solenoid valve (view with engine

cover removed)2. EVAP service port (view with engine

cover removed)3. Crankshaft position sensor (POS)

(view from under the vehicle)

4. Engine oil pan (view from under the

vehicle)5. Condenser-1 6. Brake fluid reservoir

7. EVAP canister (view with fuel tank

removed)8. EVAP control system pressure sen-

sor (view with fuel tank removed)9. EVAP canister vent control valve

(view with fuel tank removed)

10. Rear suspension member (view with

fuel tank removed)11. Refrigerant pressure sensor (view

with hood open)12. Intake valve timing control position

sensor (bank 2) (view with engine

cover and intake air duct removed)

BBIA0783E

Page 1890 of 3061

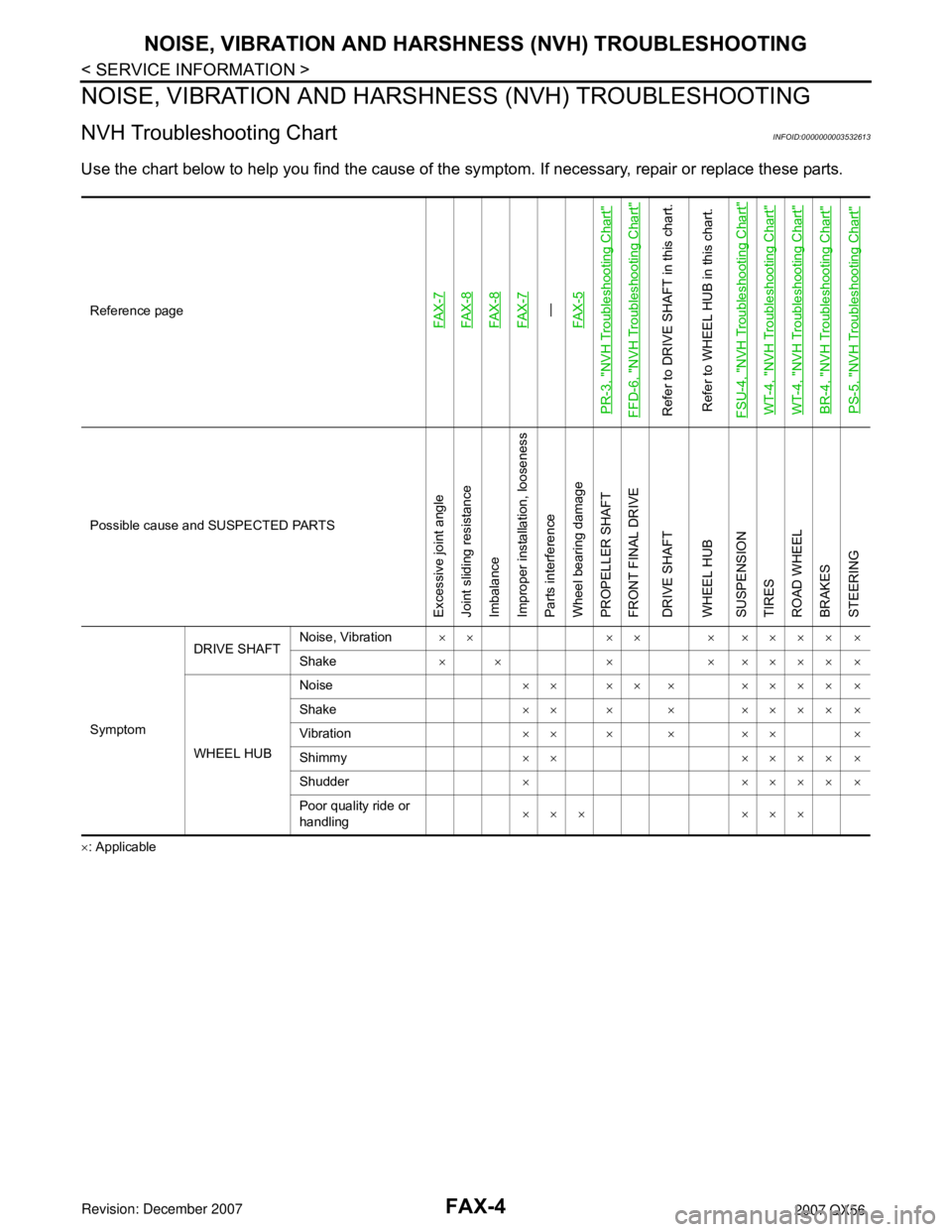

FAX-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003532613

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

FAX-7FAX-8FAX-8FAX-7—

FAX-5

PR-3, "

NVH Troubleshooting Chart

"

FFD-6, "

NVH Troubleshooting Chart

"

Refer to DRIVE SHAFT in this chart.

Refer to WHEEL HUB in this chart.

FSU-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

BR-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

PROPELLER SHAFT

FRONT FINAL DRIVE

DRIVE SHAFT

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration×× ×× × ×××× ×

Shake× × × × ×××× ×

WHEEL HUBNoise×× ×× × ×××× ×

Shake×× × × ×××× ×

Vibration×× × × ×× ×

Shimmy×× ×××× ×

Shudder× ×××× ×

Poor quality ride or

handling××× ×××

Page 1905 of 3061

FFD-6

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003532587

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

FFD-13FFD-13FFD-13FFD-13FFD-13FFD-7

PR-3, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

FSU-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

BR-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Incorrect backlash

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

FRONT AXLE

FRONT SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom Noise××××××××××××××

Page 1947 of 3061

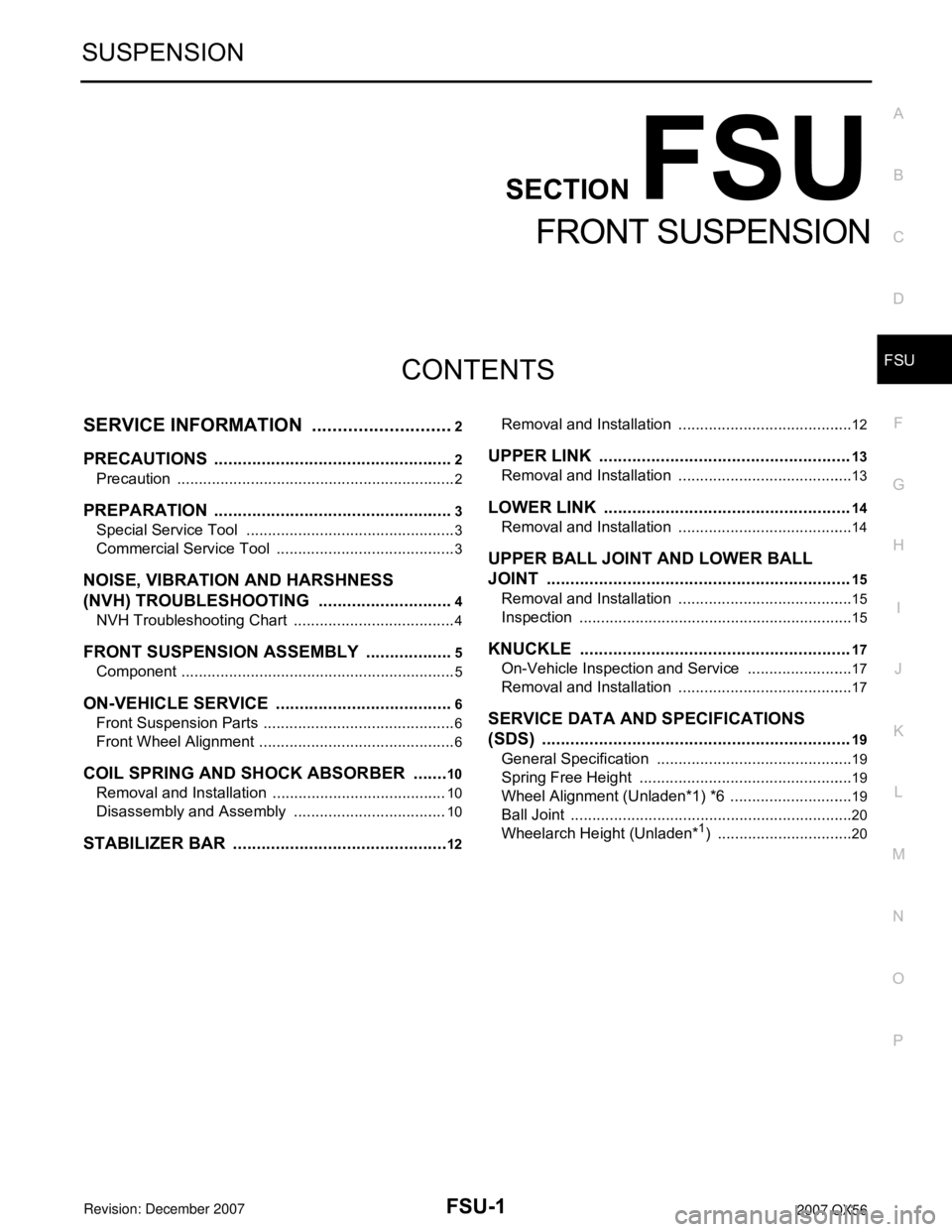

FSU-1

SUSPENSION

C

D

F

G

H

I

J

K

L

M

SECTION FSU

A

B

FSU

N

O

PCONTENTS

FRONT SUSPENSION

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution .................................................................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ......................................4

FRONT SUSPENSION ASSEMBLY ...................5

Component ................................................................5

ON-VEHICLE SERVICE ......................................6

Front Suspension Parts .............................................6

Front Wheel Alignment ..............................................6

COIL SPRING AND SHOCK ABSORBER ........10

Removal and Installation .........................................10

Disassembly and Assembly ....................................10

STABILIZER BAR ..............................................12

Removal and Installation .........................................12

UPPER LINK .....................................................13

Removal and Installation .........................................13

LOWER LINK ....................................................14

Removal and Installation .........................................14

UPPER BALL JOINT AND LOWER BALL

JOINT ................................................................

15

Removal and Installation .........................................15

Inspection ................................................................15

KNUCKLE .........................................................17

On-Vehicle Inspection and Service .........................17

Removal and Installation .........................................17

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

19

General Specification ..............................................19

Spring Free Height ..................................................19

Wheel Alignment (Unladen*1) *6 .............................19

Ball Joint ..................................................................20

Wheelarch Height (Unladen*1) ................................20