torque INFINITI QX56 2007 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1845 of 3061

ENGINE ASSEMBLY

EM-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

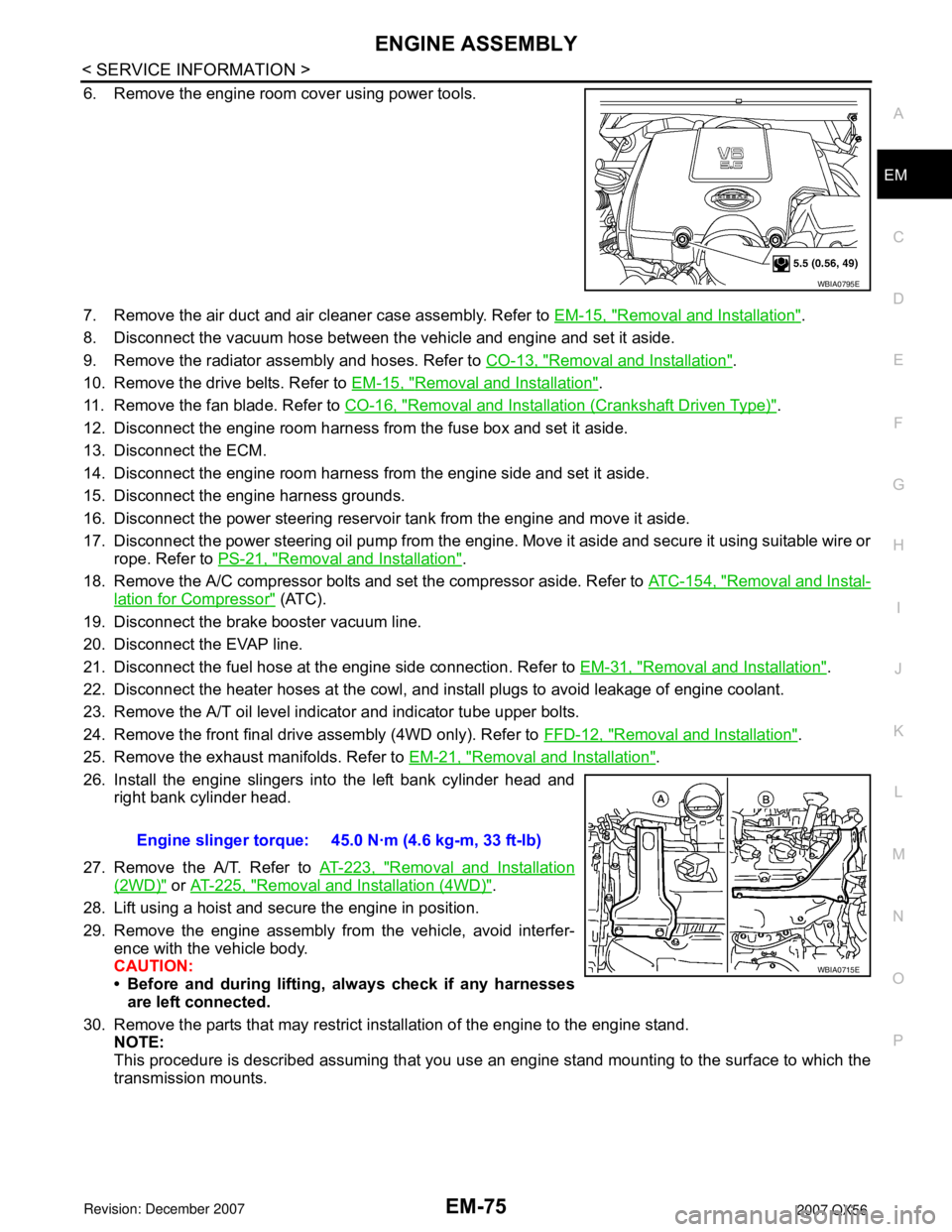

6. Remove the engine room cover using power tools.

7. Remove the air duct and air cleaner case assembly. Refer to EM-15, "

Removal and Installation".

8. Disconnect the vacuum hose between the vehicle and engine and set it aside.

9. Remove the radiator assembly and hoses. Refer to CO-13, "

Removal and Installation".

10. Remove the drive belts. Refer to EM-15, "

Removal and Installation".

11. Remove the fan blade. Refer to CO-16, "

Removal and Installation (Crankshaft Driven Type)".

12. Disconnect the engine room harness from the fuse box and set it aside.

13. Disconnect the ECM.

14. Disconnect the engine room harness from the engine side and set it aside.

15. Disconnect the engine harness grounds.

16. Disconnect the power steering reservoir tank from the engine and move it aside.

17. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or

rope. Refer to PS-21, "

Removal and Installation".

18. Remove the A/C compressor bolts and set the compressor aside. Refer to ATC-154, "

Removal and Instal-

lation for Compressor" (ATC).

19. Disconnect the brake booster vacuum line.

20. Disconnect the EVAP line.

21. Disconnect the fuel hose at the engine side connection. Refer to EM-31, "

Removal and Installation".

22. Disconnect the heater hoses at the cowl, and install plugs to avoid leakage of engine coolant.

23. Remove the A/T oil level indicator and indicator tube upper bolts.

24. Remove the front final drive assembly (4WD only). Refer to FFD-12, "

Removal and Installation".

25. Remove the exhaust manifolds. Refer to EM-21, "

Removal and Installation".

26. Install the engine slingers into the left bank cylinder head and

right bank cylinder head.

27. Remove the A/T. Refer to AT-223, "

Removal and Installation

(2WD)" or AT-225, "Removal and Installation (4WD)".

28. Lift using a hoist and secure the engine in position.

29. Remove the engine assembly from the vehicle, avoid interfer-

ence with the vehicle body.

CAUTION:

• Before and during lifting, always check if any harnesses

are left connected.

30. Remove the parts that may restrict installation of the engine to the engine stand.

NOTE:

This procedure is described assuming that you use an engine stand mounting to the surface to which the

transmission mounts.

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Page 1852 of 3061

EM-82

< SERVICE INFORMATION >

CYLINDER BLOCK

ASSEMBLY

1. Fully air-blow the coolant and oil passages in the cylinder block, cylinder bore, and crankcase to remove

any foreign material.

CAUTION:

Use goggles to protect your eyes.

2. Install each plug to the cylinder block (only screw-type plugs are

shown).

• Apply liquid gasket.

Use Genuine Thread Sealant or equivalent. Refer to GI-45,

"Recommended Chemical Product and Sealant".

• Replace copper washers with new ones.

• Tighten each plug as specified below.

3. Install main bearings and thrust bearings.

a. Remove any dust, dirt, and oil on the bearing mating surfaces of

the cylinder block and main bearing caps.

b. Install thrust bearings to both sides of the No. 3 journal housing

on the cylinder block and main bearing caps

• Install thrust bearings with the oil groove facing the crankshaft

arm (outside).

• Install thrust bearings with a protrusion in the center on the

main bearing caps.

c. Install main bearings paying attention to the direction.

• Install the one with oil holes onto the cylinder block and the

one without oil holes onto the main bearing cap.

• Before installing bearings, apply engine oil to bearing surface

(inside). Do not apply oil to the back surface, but thoroughly

clean it.

• When installing, align the bearing stopper to the notch.

• Ensure the oil holes on the cylinder block and those on the

corresponding bearing are aligned.

4. Install pilot converter to the crankshaft using suitable tool.

5. Install crankshaft to the cylinder block.

• While turning crankshaft by hand, make sure it turns smoothly.

Part Washer Tightening torque

A Yes 53.9 N·m (5.5 kg-m, 40 ft-lb)

B No 19.6 N·m (2.0 kg-m, 15 ft-lb)

C Yes 62.7 N·m (6.4 kg-m, 46 ft-lb)

D Yes 62.7 N·m (6.4 kg-m, 46 ft-lb)

WBIA0419E

PBIC0093E

PBIC0094E

EMP0569D

Page 1866 of 3061

EM-96

< SERVICE INFORMATION >

CYLINDER BLOCK

• If measurement exceeds the limit, replace connecting rod assem-

bly.

CONNECTING ROD BEARING (BIG END)

• Install the connecting rod cap without the connecting rod bearing

installed. After tightening the connecting rod bolt to the specified

torque, measure the connecting rod large end inside diameter.

Refer to EM-78, "

Disassembly and Assembly".

• If measurement exceeds the standard, replace connecting rod.

CONNECTING ROD BUSHING OIL CLEARANCE (SMALL END)

Connecting Rod Inside Diameter (Small End)

• Measure inside diameter of bushing using suitable tool.

Piston Pin Diameter

• Measure diameter of piston pin using suitable tool.

Connecting Rod Bushing Oil Clearance (Small End)

SEM038F

Standard : 57.000 - 57.013 mm (2.2441 - 2.2446 in)

PBIC1641E

Standard : 22.000 - 22.006 mm (0.8661 - 0.8664 in)

PBIC0120E

Standard : 21.989 - 21.995 mm (0.8657 - 0.8659 in)

PBIC0117E

Page 1867 of 3061

CYLINDER BLOCK

EM-97

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

(Connecting rod small end oil clearance) = (Inside diameter of con-

necting rod small end) – (Piston pin diameter)

• If measured value exceeds the standard, replace the connecting

rod assembly and/or piston and piston pin assembly.

• If replacing the piston and piston pin assembly, refer to the Table

for Selective Fitting for Piston to select the piston corresponding to

the applicable bore grade of the cylinder block to be used. Refer to

EM-86, "

How to Select Piston and Bearing".

Factory installed parts grading:

• Only grade 0 is available.

Unit: mm (in)

CYLINDER BLOCK DISTORTION

• Remove any oil, scale, gasket, sealant and carbon deposits from the cylinder block surface.

CAUTION:

Do not allow any debris to enter the oil or coolant passages.

• Measure block upper face for distortion in six directions as shown.

• If measurement exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INSIDE DIAMETER

• Install the main bearing caps with the main bearings removed, and

tighten the bolts to the specified torque. Refer to EM-78, "

Disas-

sembly and Assembly".

• Measure inside diameter of main bearing housing.

• If out of the standard, replace cylinder block and main bearing

caps as an assembly.

NOTE:

These components must be replaced as a single unit, because

they were processed together.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder Bore Diameter

Standard : 0.005 - 0.017 mm (0.0002 - 0.0007 in)

KBIA2536E

Grade 0

Connecting rod bushing inside diameter22.000 - 22.006

(0.8661 - 0.8664)

Piston pin diameter21.989 - 21.995

(0.8657 - 0.8659)

Piston pin hole diameter21.993 - 21.999

(0.8659 - 0.8661)

KBIA2496E

Standard : 0.03 mm (0.0012 in)

Limit : 0.1 mm (0.004 in)

SEM123C

Standard : 68.944 - 68.968 mm (2.7143 - 2.7153 in)

PBIC1643E

Page 1869 of 3061

CYLINDER BLOCK

EM-99

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

1. Cylinder bore size is determined by adding piston-to-bore clearance to piston diameter “A”.

2. Install main bearing caps, and tighten them to the specified torque. Otherwise, cylinder bores may be dis-

torted in final assembly.

3. Cut the cylinder bores.

NOTE:

• When any cylinder needs boring, all other cylinders must also be bored.

• Do not cut too much out of cylinder bore at one time. Cut only 0.05 mm (0.0020 in) or so in diameter at a

time.

4. Hone cylinders to obtain the specified piston-to-bore clearance.

5. Measure finished cylinder bore for out-of-round and taper.

NOTE:

Measurement should be done after cylinder bore cools down.

CRANKSHAFT JOURNAL DIAMETER

• Measure diameter of crankshaft journals.

• If measurement is out of standard, measure the main bearing oil clearance. Then use the undersize bearing.

CRANKSHAFT PIN DIAMETER

• Measure diameter of crankshaft pin using suitable tool.

• If measurement is out of standard, measure connecting rod bear-

ing oil clearance. Then use undersize bearing.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

• Measure dimensions at four different points as shown on each

journal and pin.

• Out-of-roundness is indicated by the difference in dimension

between ″X″ and ″Y″ at ″A″ and ″B″.

• Taper is indicated by the difference in dimension between ″A″ and

″B″ at ″X″ and ″Y″.

• If measured value exceeds the standard, correct or replace crankshaft.

• If corrected, measure the bearing oil clearance of the corrected journal or pin. Then select the main bearing

or connecting rod bearing. Rebored size calculation: D = A +B - C

where,

D: Bored diameter

A: Piston diameter as measured

B: Piston - to - bore clearance (standard value)

C: Honing allowance 0.02 mm (0.0008 in)

Standard : 63.940 - 63.964 mm (2.5173 - 2.5183 in)

Standard : 53.956 - 53.974 mm (2.1243 - 2.1250 in)

PBIC0127E

Limit

Out-of-round (Difference between ″X″ and ″Y″)

: 0.002 mm (0.0001 in)

Taper (Difference between ″A″ and ″B″)

: 0.002 mm (0.0001 in)

PBIC1685E

Page 1870 of 3061

EM-100

< SERVICE INFORMATION >

CYLINDER BLOCK

CRANKSHAFT RUNOUT

• Place a V-block on a precise flat table to support the journals on

both ends of the crankshaft.

• Measure at No. 3 journal using suitable tool.

• While rotating crankshaft, read the movement of the pointer.

• Half of the movement shows the runout.

• If measurement exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method of Measurement

• Install connecting rod bearings to the connecting rod and cap. Tighten connecting rod bolts to the specified

torque. Refer to EM-78, "

Disassembly and Assembly".

Measure inside diameter of connecting rod bearing.

(Oil clearance) = (Inside diameter of connecting rod bearing) –

(Crankshaft pin diameter)

• If clearance cannot be adjusted within the standard, grind crank-

shaft pin and use undersized bearing. Refer to EM-86, "

How to

Select Piston and Bearing".

Method of Using Plastigage

• Remove oil and dust on the crankshaft pin and surfaces of each

bearing completely.

• Cut a plastigage slightly shorter than the bearing width, and place

it in the crankshaft axial direction, avoiding oil holes.

• Install the connecting rod bearings to the connecting rod and con-

necting rod bearing cap, and tighten the connecting rod bolts to the

specified torque.

CAUTION:

Do not rotate crankshaft with plastigage installed.

• Remove the connecting rod bearing cap and bearings. Measure

the plastigage width using the scale on the plastigage bag.

NOTE:

The procedure when the measured value exceeds the repair limit is the same as that described in “Method

of Measurement”.

MAIN BEARING OIL CLEARANCE

Method of Measurement

• Install the main bearings to the cylinder block and main bearing

cap. Measure the main bearing inside diameter with the bearing

cap bolts tightened to the specified torque. Refer to EM-78, "

Disas-

sembly and Assembly".

(Oil clearance) = (Inside diameter of main bearing) – (Crankshaft

journal diameter)Limit : Less than 0.05 mm (0.002 in)

PBIC0129E

Standard : 0.020 - 0.039 mm (0.0008 - 0.0015 in)

Limit : 0.055 mm (0.0022 in)

PBIC1642E

KBIA2550E

Standard:

No. 1 and 5 journals

: 0.001 - 0.011 mm (0.00004 - 0.0004 in)

No. 2, 3 and 4 journals

PBIC1644E

Page 1871 of 3061

CYLINDER BLOCK

EM-101

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

• If measured value exceeds the repair limit, select main bearings referring to the main bearing inside diame-

ter and crankshaft journal diameter, so that the oil clearance satisfies the standard. Refer to EM-86, "

How to

Select Piston and Bearing".

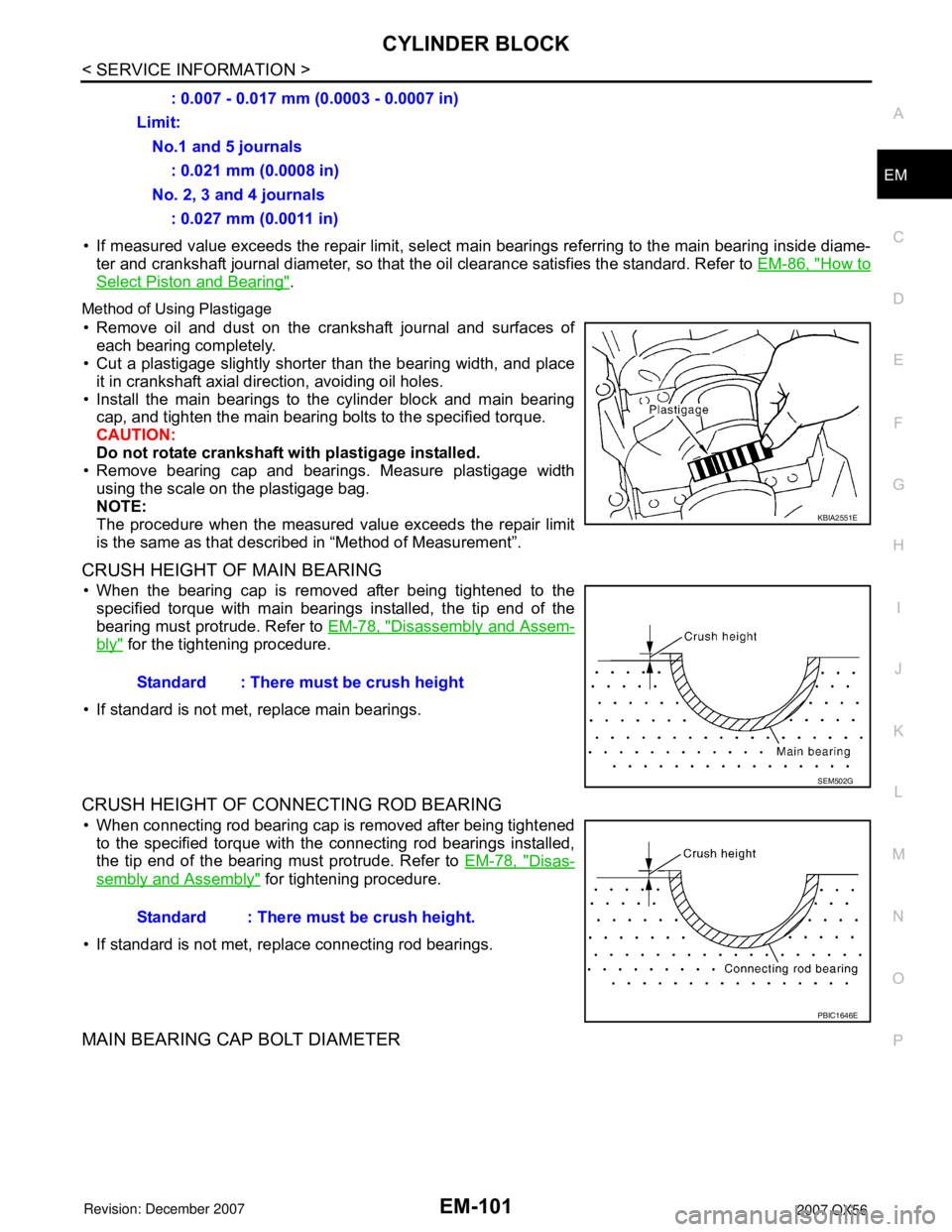

Method of Using Plastigage

• Remove oil and dust on the crankshaft journal and surfaces of

each bearing completely.

• Cut a plastigage slightly shorter than the bearing width, and place

it in crankshaft axial direction, avoiding oil holes.

• Install the main bearings to the cylinder block and main bearing

cap, and tighten the main bearing bolts to the specified torque.

CAUTION:

Do not rotate crankshaft with plastigage installed.

• Remove bearing cap and bearings. Measure plastigage width

using the scale on the plastigage bag.

NOTE:

The procedure when the measured value exceeds the repair limit

is the same as that described in “Method of Measurement”.

CRUSH HEIGHT OF MAIN BEARING

• When the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of the

bearing must protrude. Refer to EM-78, "

Disassembly and Assem-

bly" for the tightening procedure.

• If standard is not met, replace main bearings.

CRUSH HEIGHT OF CONNECTING ROD BEARING

• When connecting rod bearing cap is removed after being tightened

to the specified torque with the connecting rod bearings installed,

the tip end of the bearing must protrude. Refer to EM-78, "

Disas-

sembly and Assembly" for tightening procedure.

• If standard is not met, replace connecting rod bearings.

MAIN BEARING CAP BOLT DIAMETER

: 0.007 - 0.017 mm (0.0003 - 0.0007 in)

Limit:

No.1 and 5 journals

: 0.021 mm (0.0008 in)

No. 2, 3 and 4 journals

: 0.027 mm (0.0011 in)

KBIA2551E

Standard : There must be crush height

SEM502G

Standard : There must be crush height.

PBIC1646E

Page 1886 of 3061

EX-4

< SERVICE INFORMATION >

EXHAUST SYSTEM

Remove exhaust system components using power tool.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Always replace exhaust gaskets with new ones when reassembling.

• Before installing a new heated oxygen sensor, clean and lube the exhaust tube threads using Tool.

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; replace with a new one.

• Do not over-torque the heated oxygen sensor. Doing so may damage the heated oxygen sensor,

resulting in the MIL coming on.

• If any mounting insulator is badly deformed, repair or replace it. If deposits such as mud pile up on

the mounting insulators, clean and inspect them.

• Temporarily tighten the nuts on the exhaust manifold side and the bolts on the vehicle side. Check

each part for interference with other components, and then tighten the nuts and bolts to specifica-

tion.

INSPECTION AFTER INSTALLATION

• With the engine running, check exhaust tube joints for gas leakage and unusual noises.

• Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue

stress. Improper installation could result in excessive noise and vibration. Tool number

A : — (J-43897-18)

B : — (J-43897-12)

Page 1891 of 3061

WHEEL HUB

FAX-5

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

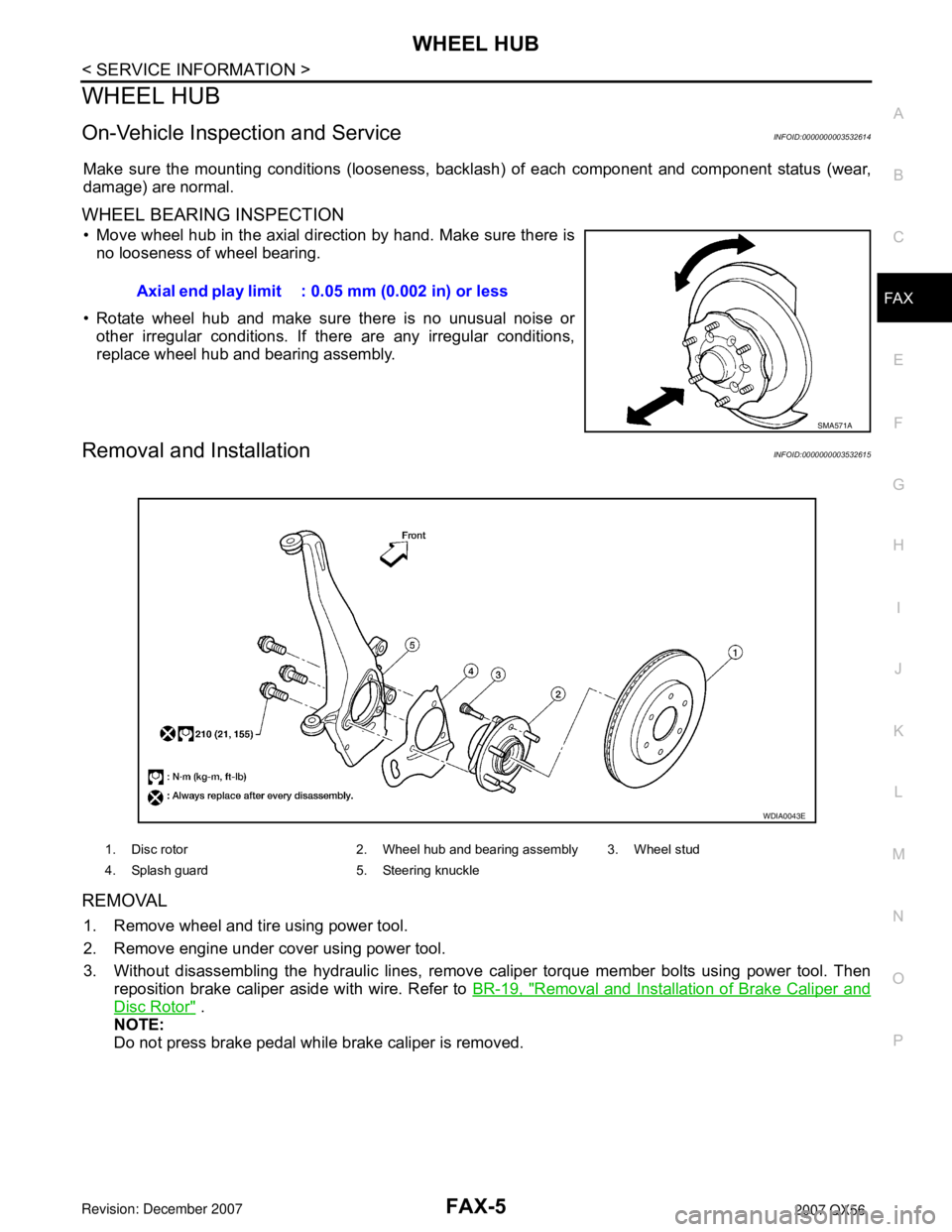

WHEEL HUB

On-Vehicle Inspection and ServiceINFOID:0000000003532614

Make sure the mounting conditions (looseness, backlash) of each component and component status (wear,

damage) are normal.

WHEEL BEARING INSPECTION

• Move wheel hub in the axial direction by hand. Make sure there is

no looseness of wheel bearing.

• Rotate wheel hub and make sure there is no unusual noise or

other irregular conditions. If there are any irregular conditions,

replace wheel hub and bearing assembly.

Removal and InstallationINFOID:0000000003532615

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Without disassembling the hydraulic lines, remove caliper torque member bolts using power tool. Then

reposition brake caliper aside with wire. Refer to BR-19, "

Removal and Installation of Brake Caliper and

Disc Rotor" .

NOTE:

Do not press brake pedal while brake caliper is removed.Axial end play limit : 0.05 mm (0.002 in) or less

SMA571A

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle

WDIA0043E

Page 1901 of 3061

FFD-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Servicing Front Final DriveINFOID:0000000003532584

• Before starting diagnosis of the vehicle, understand the symptoms well. Perform correct and systematic

operations.

• Check for the correct installation status prior to removal or disassembly. When matching marks are required,

be certain they do not interfere with the function of the parts they are applied to.

• Overhaul should be done in a clean work area, a dust proof area is recommended.

• Before disassembly, completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

• Always use shop paper for cleaning the inside of components.

• Avoid using cotton gloves or a shop cloth to prevent the entering of lint.

• Check appearance of the disassembled parts for damage, deformation, and abnormal wear. Replace them

with new ones if necessary.

• Gaskets, seals and O-rings should be replaced any time the unit is disassembled.

• Clean and flush the parts sufficiently and blow them dry.

• Be careful not to damage sliding surfaces and mating surfaces.

• When applying sealant, remove the old sealant from the mating surface; then remove any moisture, oil, and

foreign materials from the application and mating surfaces.

• In principle, tighten nuts or bolts gradually in several steps working diagonally from inside to outside. If a

tightening sequence is specified, observe it.

• During assembly, observe the specified tightening torque.

• Add new differential gear oil, petroleum jelly, or multi-purpose grease, as specified.