fuse INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2419 of 3061

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

System DescriptionINFOID:0000000003533835

• IPDM E/R (Intelligent Power Distribution Module Engine Room) integrates the relay box and fuse block

which were originally placed in engine compartment. It controls integrated relays via IPDM E/R control cir-

cuits.

• IPDM E/R-integrated control circuits perform ON-OFF operation of relays, CAN communication control, etc.

• It controls operation of each electrical component via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R integrated relays can be removed.

SYSTEMS CONTROLLED BY IPDM E/R

1. Lamp control

Using CAN communication lines, it receives signals from the BCM and controls the following lamps:

• Headlamps (Hi, Lo)

• Parking lamps

• Tail and license lamps

• Front fog lamps

2. Wiper control

Using CAN communication lines, it receives signals from the BCM and controls the front wipers.

3. Rear window defogger relay control

Using CAN communication lines, it receives signals from the BCM and controls the rear window defogger

relay.

4. A/C compressor control

Using CAN communication lines, it receives signals from the ECM and controls the A/C compressor

(magnetic clutch).

5. Starter control

Using CAN communication lines, it receives signals from the BCM and controls the starter relay.

6. Cooling fan control

Using CAN communication lines, it receives signals from the ECM and controls the cooling fan relays.

7. Horn control

Using CAN communication lines, it receives signals from the BCM and controls the horn relay.

CAN COMMUNICATION LINE CONTROL

With CAN communication, by connecting each control unit using two communication lines (CAN L-line, CAN

H-line), it is possible to transmit a maximum amount of information with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

1. Fail-safe control

• When CAN communication with other control units is impossible, IPDM E/R performs fail-safe control.

After CAN communication returns to normal operation, it also returns to normal control.

• Operation of control parts by IPDM E/R during fail-safe mode is as follows:

Controlled system Fail-safe mode

Headlamp• With the ignition switch ON, the headlamp (low) is ON.

• With the ignition switch OFF, the headlamp (low) is OFF.

Tail and parking lamps• With the ignition switch ON, the tail and parking lamps are ON.

• With the ignition switch OFF, the tail and parking lamps are OFF.

Cooling fan• With the ignition switch ON, the cooling fan HI operates.

• With the ignition switch OFF, the cooling fan stops.

Front wiperUntil the ignition switch is turned off, the front wiper LO and HI remains in the same status it

was in just before fail−safe control was initiated.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C compressor OFF

Front fog lamps Front fog lamp relay OFF

Page 2424 of 3061

PG-22

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Terminal and Reference Value for IPDM E/R

INFOID:0000000003533840

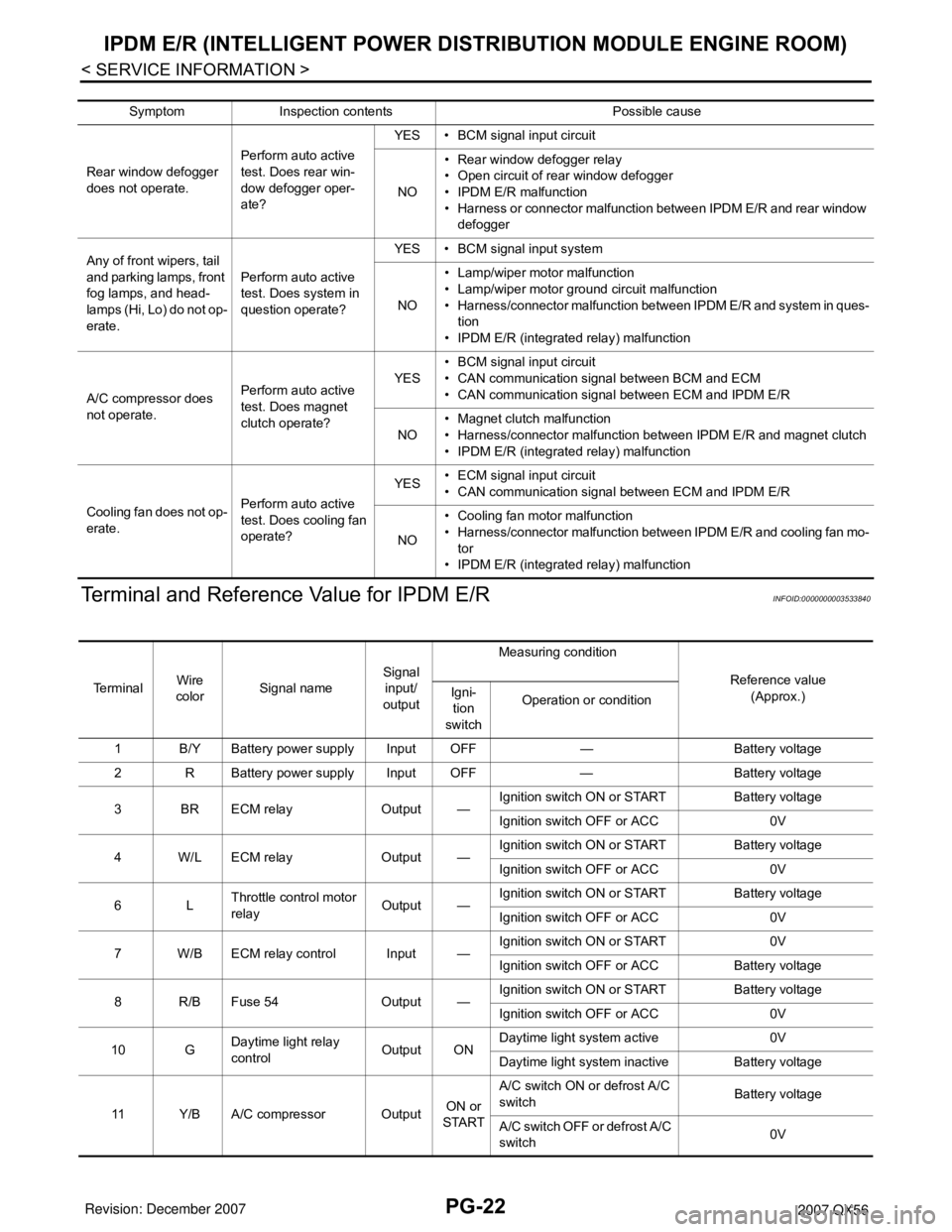

Symptom Inspection contents Possible cause

Rear window defogger

does not operate.Perform auto active

test. Does rear win-

dow defogger oper-

ate?YES • BCM signal input circuit

NO• Rear window defogger relay

• Open circuit of rear window defogger

•IPDM E/R malfunction

• Harness or connector malfunction between IPDM E/R and rear window

defogger

Any of front wipers, tail

and parking lamps, front

fog lamps, and head-

lamps (Hi, Lo) do not op-

erate.Perform auto active

test. Does system in

question operate?YES • BCM signal input system

NO• Lamp/wiper motor malfunction

• Lamp/wiper motor ground circuit malfunction

• Harness/connector malfunction between IPDM E/R and system in ques-

tion

• IPDM E/R (integrated relay) malfunction

A/C compressor does

not operate.Perform auto active

test. Does magnet

clutch operate?YES• BCM signal input circuit

• CAN communication signal between BCM and ECM

• CAN communication signal between ECM and IPDM E/R

NO• Magnet clutch malfunction

• Harness/connector malfunction between IPDM E/R and magnet clutch

• IPDM E/R (integrated relay) malfunction

Cooling fan does not op-

erate.Perform auto active

test. Does cooling fan

operate?YES• ECM signal input circuit

• CAN communication signal between ECM and IPDM E/R

NO• Cooling fan motor malfunction

• Harness/connector malfunction between IPDM E/R and cooling fan mo-

tor

• IPDM E/R (integrated relay) malfunction

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Igni-

tion

switchOperation or condition

1 B/Y Battery power supply Input OFF — Battery voltage

2 R Battery power supply Input OFF — Battery voltage

3 BR ECM relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

4 W/L ECM relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

6LThrottle control motor

relayOutput —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

7 W/B ECM relay control Input —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

8 R/B Fuse 54 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

10 GDaytime light relay

controlOutput ONDaytime light system active 0V

Daytime light system inactive Battery voltage

11 Y/B A/C compressor OutputON or

STARTA/C switch ON or defrost A/C

switchBattery voltage

A/C switch OFF or defrost A/C

switch0V

Page 2425 of 3061

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

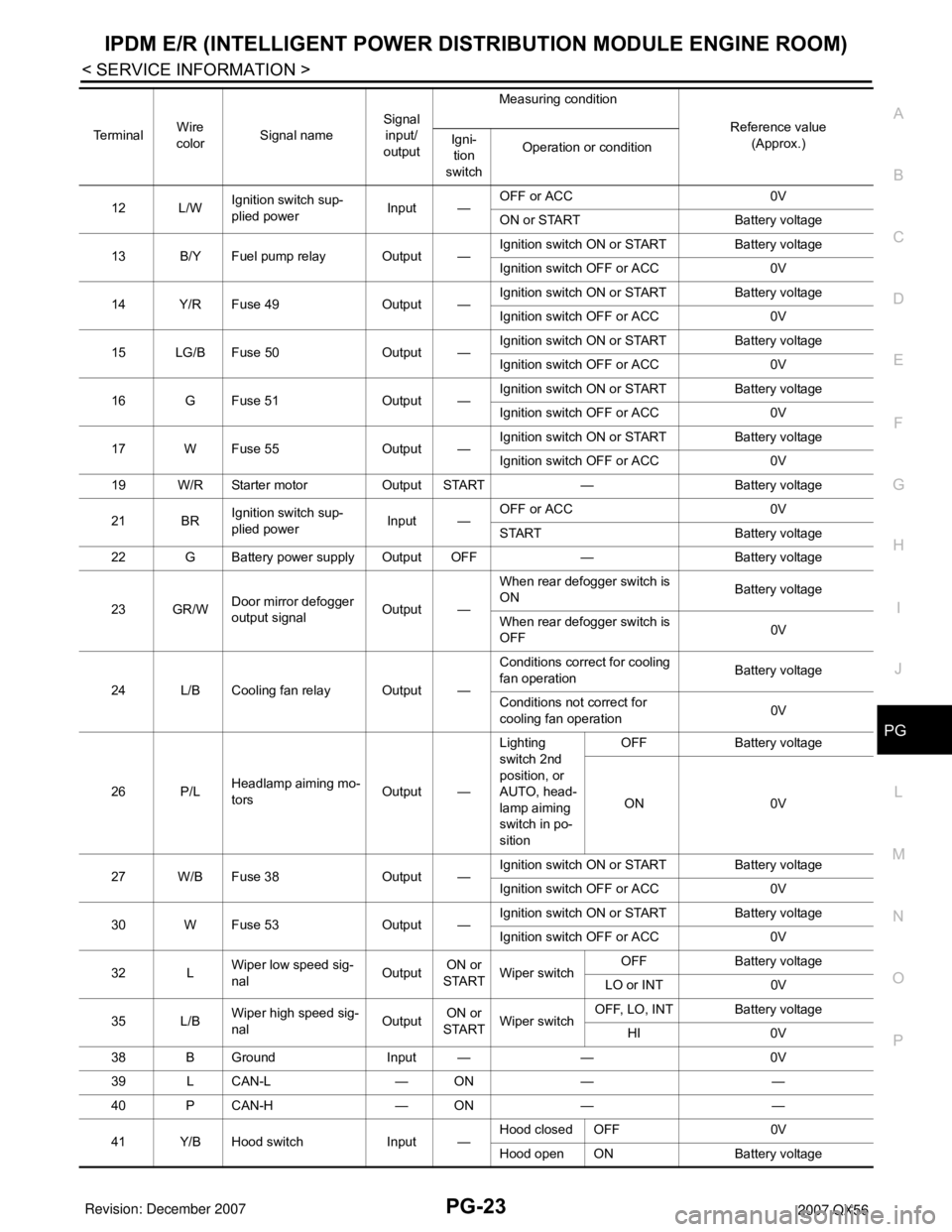

12 L/WIgnition switch sup-

plied powerInput —OFF or ACC 0V

ON or START Battery voltage

13 B/Y Fuel pump relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

14 Y/R Fuse 49 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

15 LG/B Fuse 50 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

16 G Fuse 51 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

17 W Fuse 55 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

19 W/R Starter motor Output START — Battery voltage

21 BRIgnition switch sup-

plied powerInput —OFF or ACC 0V

START Battery voltage

22 G Battery power supply Output OFF — Battery voltage

23 GR/WDoor mirror defogger

output signalOutput —When rear defogger switch is

ONBattery voltage

When rear defogger switch is

OFF0V

24 L/B Cooling fan relay Output —Conditions correct for cooling

fan operationBattery voltage

Conditions not correct for

cooling fan operation0V

26 P/LHeadlamp aiming mo-

torsOutput —Lighting

switch 2nd

position, or

AUTO, head-

lamp aiming

switch in po-

sitionOFF Battery voltage

ON 0V

27 W/B Fuse 38 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

30 W Fuse 53 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

32 LWiper low speed sig-

nalOutputON or

STARTWiper switchOFF Battery voltage

LO or INT 0V

35 L/BWiper high speed sig-

nalOutputON or

STARTWiper switchOFF, LO, INT Battery voltage

HI 0V

38 B Ground Input — — 0V

39 L CAN-L — ON — —

40 P CAN-H — ON — —

41 Y/B Hood switch Input —Hood closed OFF 0V

Hood open ON Battery voltage Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Igni-

tion

switchOperation or condition

Page 2427 of 3061

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

*1: When horn reminder is ON

*2: L/W is for U.S.A.

*3: Y is for Canada61 BR Fuse 32 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Igni-

tion

switchOperation or condition

Page 2428 of 3061

PG-26

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R Terminal Arrangement

INFOID:0000000003533841

IPDM E/R Power/Ground Circuit InspectionINFOID:0000000003533842

1.FUSE AND FUSIBLE LINK INSPECTION

Check that the following fusible links or IPDM E/R fuses are not blown.

WKIA5845E

Page 2429 of 3061

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-27

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

OK or NG

OK >> GO TO 2.

NG >> Replace fuse or fusible link.

2.POWER CIRCUIT INSPECTION

1. Disconnect IPDM E/R harness connector E118.

2. Check voltage between IPDM E/R harness connector E118 terminals 1, 2 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace IPDM E/R power circuit harness.

3.GROUND CIRCUIT INSPECTION

1. Disconnect IPDM E/R harness connectors E122 and E124.

2. Check continuity between IPDM E/R harness connector E122

terminal 38, and E124 terminal 59 and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or replace IPDM E/R ground circuit harness.

Inspection with CONSULT-II (Self-Diagnosis)INFOID:0000000003533843

CAUTION:

If a CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on which control unit(s) carry out CAN communication.

1.SELF-DIAGNOSIS RESULT CHECK

1. Connect CONSULT-II and select "IPDM E/R" on the Diagnosis System Selection screen.

2. Select "SELF-DIAG RESULTS" on the diagnosis mode selection screen.

3. Check display content in self-diagnosis results.

NOTE:

The Details for Display for the Period are as follows:

• CRNT: Error currently detected by IPDM E/R.

Terminal No. Signal name Fuse, fusible link No.

1, 2 Battery power a, c, d

Battery voltage should exist.

SKIA1987E

Continuity should exist.

WKIA1453E

CONSULT-II DisplayCONSULT-II

display codeTIME

Details of diagnosis result

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING MAY BE REQUIRED.——— No malfunction

CAN COMM CIRC U1000 X XAny of items listed below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

Page 2475 of 3061

FUSE BLOCK - JUNCTION BOX (J/B)

PG-73

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

FUSE BLOCK - JUNCTION BOX (J/B)

Terminal ArrangementINFOID:0000000003533853

AWMIA0896GB

Page 2476 of 3061

PG-74

< SERVICE INFORMATION >

FUSE AND FUSIBLE LINK BOX

FUSE AND FUSIBLE LINK BOX

Terminal ArrangementINFOID:0000000003533854

WKIA4691E

Page 2477 of 3061

FUSE AND RELAY BOX

PG-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

FUSE AND RELAY BOX

Terminal ArrangementINFOID:0000000003533855

WKIA5846E

Page 2542 of 3061

RF-10

< SERVICE INFORMATION >

SUNROOF

SUNROOF

Component Parts and Harness Connector LocationINFOID:0000000003533095

System DescriptionINFOID:0000000003533096

OUTLINE

Electric sunroof system consists of

• Front door switches

• Sunroof switch

• Sunroof motor assembly

• BCM (body control module)

BCM supplies power to the sunroof motor. Sunroof operation depends on sunroof switch condition.

OPERATION

Power is supplied at all times

• through 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70 and

• through BCM terminal 69

• to sunroof motor assembly terminal 5.

With ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to sunroof motor assembly terminal 7

• through grounds M57, M61 and M79.

TILT UP OPERATION

When the tilt switch is operated for tilt up, ground is supplied

• to sunroof motor assembly terminal 4

LIIA2398E

1. Sunroof switch R104 2. Steering column 3. BCM M18, M19, M20

4. Sunroof motor harness connector R4 5. Sunroof motor assembly 6. Front door switch

LH B8

RH 108