fuse INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2087 of 3061

GW-68

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

REAR WINDOW DEFOGGER

Component Parts and Harness Connector LocationINFOID:0000000003533066

System DescriptionINFOID:0000000003533067

The rear window defogger system is controlled by BCM (body control module) and IPDM E/R (intelligent

power distribution module engine room).

The rear window defogger operates only for approximately 15 minutes.

Power is supplied at all times

• through 15A fuses (No. 43, 46, and 47 located in the IPDM E/R)

• to rear window defogger relay and heated mirror relay (located in the IPDM E/R)

• through 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch turned to ON or START position, power is supplied

• through ignition switch

• to rear window defogger relay (located in the IPDM E/R)

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to front air control terminal 14.

Ground is supplied

• to BCM terminal 67

• to front air control terminal 1

• through body grounds M57, M61 and M79

1. A. Steering column

B. BCM M18, M20 (view with instru-

ment panel removed)2. Front air control M49, M50 3. A. Rear window defogger ground

connector D604

B. Rear window defogger connector

D406

4. IPDM E/R, E120, E122, E124 5. Door mirror LH (door mirror defog-

ger) D4

Door mirror RH (door mirror defog-

ger) D107

LIIA2716E

Page 2095 of 3061

GW-76

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

1. Turn ignition switch OFF.

2. Disconnect BCM and front air control.

3. Check continuity between BCM connector M18 terminal 9 and

front air control connector M49 terminal 11.

4. Check continuity between BCM connector M18 terminal 9 and

ground

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM.

2. Turn ignition switch ON.

3. Check voltage between BCM connector M18 terminal 9 and

ground.

OK or NG

OK >> Replace front air control. Refer to ATC-123, "Removal

and Installation" .

NG >> Replace BCM. Refer to BCS-24, "

BCM" .

Rear Window Defogger Circuit InspectionINFOID:0000000003533078

1.CHECK FUSES

Check if any of the following fuses in IPDM E/R are blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK REAR WINDOW DEFOGGER POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger.

3. Turn ignition switch ON.

4. Check voltage between rear window defogger connector D406

terminal + and ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.9 - 11 : Continuity should exist.

9 - Ground : Continuity should not exist.

LIIA2035E

9 - Ground : Approx. 5

WIIA0523E

COMPONENT PARTS AMPERE FUSE NO.

IPDM E/R 15A 46

IPDM E/R 15A 47

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

D406 + GroundRear window defogger

switch ON. Battery voltage

Rear window defogger

switch OFF.0

LIIA0655E

Page 2096 of 3061

REAR WINDOW DEFOGGER

GW-77

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

3.CHECK REAR WINDOW DEFOGGER GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear window defogger connector

D604 terminal - and ground.

OK or NG

OK >> Check filament. Refer to GW-80, "Filament Check".

• If filament is OK.

Check the condition of the harness and the connector.

• If filament is NG.

Repair filament.

NG >> Repair or replace harness.

4.CHECK REAR WINDOW DEFOGGER RELAY OUTPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R connector E124 terminal 60

and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R".

NG >> Repair or replace harness.

Door Mirror Defogger Power Supply Circuit InspectionINFOID:0000000003533079

1.CHECK FUSE

Check if any of the following fuses in fuse block (J/B) are blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT 2

Check voltage between IPDM E/R connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Replace IPDM E/R. Refer to PG-28, "

Removal and Installation of IPDM E/R".

3.CHECK DOOR MIRROR DEFOGGER CIRCUIT- - Ground : Continuity should exist.

LIIA0409E

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

E124 60 GroundRear window defogger

switch ON Battery voltage

Rear window defogger

switch OFF0

LIIA2190E

COMPONENT PARTS AMPERE FUSE NO.

IPDM E/R 15A 43

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

E120 23 GroundRear window defogger

switch ON Battery voltage

Rear window defogger

switch OFF0

LIIA0977E

Page 2108 of 3061

IDX-4

ALPHABETICAL INDEX

Duct and grilles .............................................. ATC-170

DVD - Wiring Diagram ....................................... AV-75

DVD Entertainment System ............................... AV-72

DVD Player ........................................................ AV-73

E

ECM input/output signal ..................... EC-109

, EC-133

ECM power supply ............................. EC-150, EC-475

ECM relay ........................................................ EC-150

ECM/PW - Wiring diagram ............................... EC-476

ECTS - Wiring diagram .................................... EC-220

Electric sunroof .................................................. RF-10

Electric throttle control actuator ......... EC-595, EC-606

Electrical load signal circuit .............................. EC-657

Electrical units location ...................................... PG-65

Electronic ignition (EI) system ........................... EC-27

Engine control circuit diagram ......................... EC-107

Engine control component parts location ........... EC-98

Engine control module (ECM) .......................... EC-479

Engine control system diagram ......................... EC-24

Engine coolant .................................................. CO-10

Engine coolant temperature sensor (ECTS) ... EC-218,

EC-231

Engine fail-safe system ...................................... EC-93

Engine oil ............................................................. LU-8

Engine oil filter replacement ............................. MA-17

Engine oil precautions .......................................... GI-7

Engine oil replacement ..................................... MA-17

Engine removal ................................................. EM-74

Engine room cover ............................................ EM-12

Engine serial number .......................................... GI-50

ETC1 - Wiring diagram .................................... EC-596

ETC2 - Wiring diagram .................................... EC-591

ETC3 - Wiring diagram .................................... EC-602

EVAP canister .................................................... EC-36

EVAP canister purge volume control solenoid valve ....

EC-395

, EC-403

EVAP canister vent control valve ....... EC-410, EC-417

EVAP control system (small leak) diagnosis .. EC-387,

EC-441

, EC-449

EVAP control system pressure sensor .... EC-424, EC-

427, EC-433

EVAP control system purge flow monitoring diagnosis

EC-382

EVAP vapor lines inspection ............................. MA-20

Evaporative emission (EVAP) system ............... EC-33

Evaporator ..................................................... ATC-186

Exhaust manifold .............................................. EM-21

Exhaust system ................................................... EX-3

Exhaust system inspection .................................. EX-3

Expansion valve ............................................. ATC-188

F

F/FOG - Wiring diagram ..................................... LT-56

F/PUMP - Wiring diagram ................................ EC-666

Final drive pre-inspection ................................. FFD-15

Final drive removal and installation .. FFD-12, RFD-13

Flow charts .......................................................... GI-27

Fluid temperature sensor (A/T) ........................ AT-123

Fluids ................................................................ MA-11

Fluorescent leak detector .............................. ATC-189

Fog lamp, front ................................................... LT-54

Fog lamp, front, removal and installation ........... LT-62

Foot lamp ......................................................... LT-111

Freeze frame data ............................... EC-55, EC-121

Front brake solenoid valve ................. AT-139, AT-141

Front bumper ...................................................... EI-13

Front case (Transfer) .......................... TF-149, TF-176

Front combination lamp removal and installation LT-25

Front door ............................. BL-117, BL-121, GW-62

Front Door Trim ................................................... EI-32

Front drive shaft (Transfer) ................. TF-149, TF-176

Front fog lamp .................................................... LT-54

Front fog lamp removal and installation ............. LT-62

Front passenger air bag .................................. SRS-43

Front seat ........................................................... SE-89

Front seat belt ...................................................... SB-3

Front seat belt pre-tensioner ............... SRS-3, SRS-50

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-124

FTTS - Wiring diagram ...................... EC-334, EC-339

Fuel cut control (at no load high engine speed) EC-28

Fuel filter replacement ......................................... FL-5

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) .......... EC-311, EC-322

Fuel injection system (Bank 2) .......... EC-311, EC-322

Fuel injector .................................................... EC-659

Fuel injector and fuel tube ................................. EM-31

Fuel level sensor ................. EC-458, EC-460, EC-462

Fuel line inspection .............................................. FL-4

Fuel precautions ................................................... GI-5

Fuel pressure check .......................................... EC-82

Fuel pressure release ....................................... EC-82

Fuel pump ....................................................... EC-665

Fuel pump and gauge .......................................... FL-5

Fuel system .......................................................... FL-4

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor ........... EC-332, EC-338

Fuel tank vacuum relief valve ........................... EC-36

FUELB1 - Wiring diagram ................. EC-313, EC-324

FUELB2 - Wiring diagram ................. EC-315, EC-326

Fuse ...................................................... PG-17, PG-77

Fuse and fusible link box .................................. PG-77

Fuse block ......................................................... PG-76

Fusible link ............................................ PG-17, PG-77

G

Garage jack and safety stand ............................. GI-42

Gauges ................................................................. DI-5

Generator .......................................................... SC-17

Generic scan tool (GST) ................................. EC-131

Glass ...................................... GW-11, GW-62, GW-65

Glove box lamp ................................................ LT-131

GPS antenna ..................................................... AV-82

Page 2123 of 3061

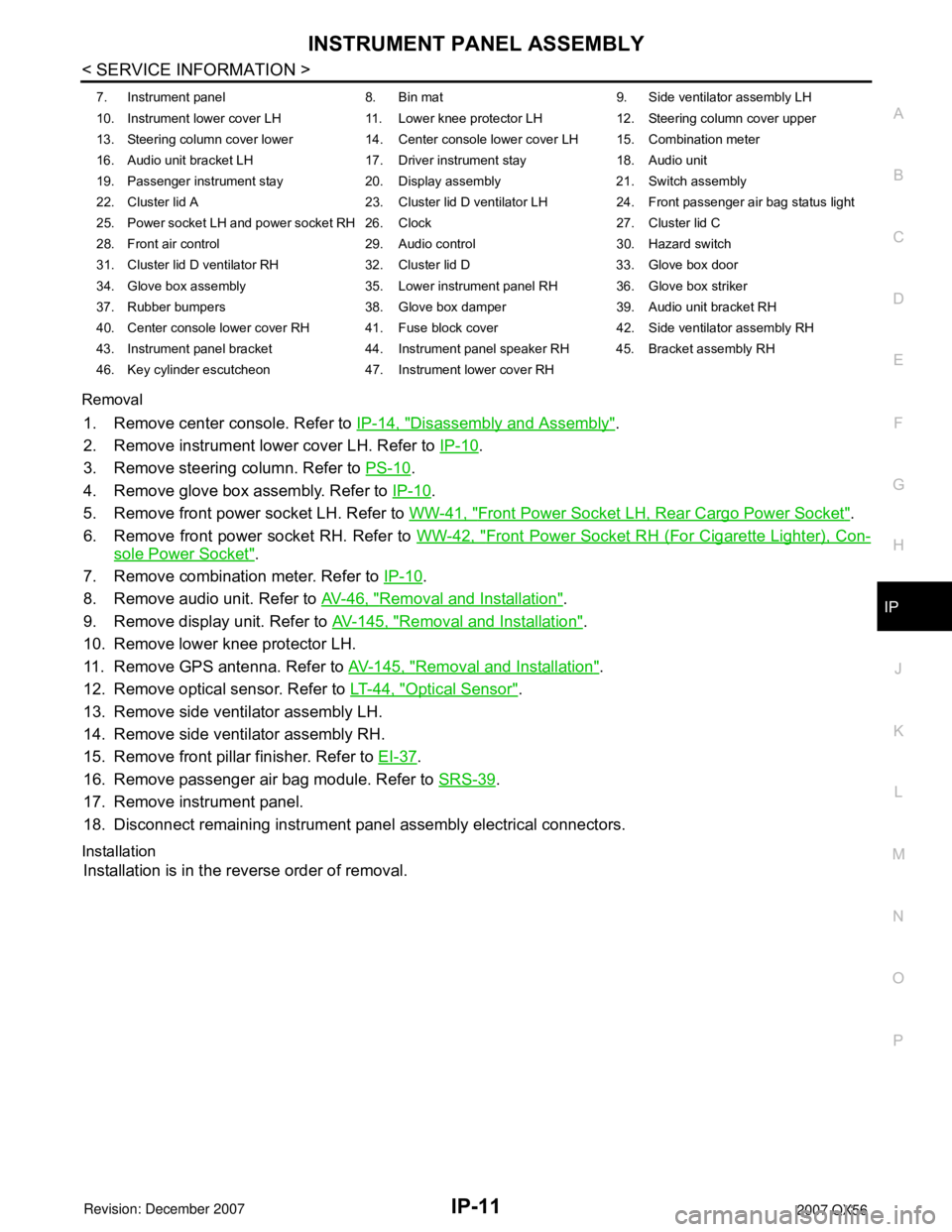

INSTRUMENT PANEL ASSEMBLY

IP-11

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

P Removal

1. Remove center console. Refer to IP-14, "Disassembly and Assembly".

2. Remove instrument lower cover LH. Refer to IP-10

.

3. Remove steering column. Refer to PS-10

.

4. Remove glove box assembly. Refer to IP-10

.

5. Remove front power socket LH. Refer to WW-41, "

Front Power Socket LH, Rear Cargo Power Socket".

6. Remove front power socket RH. Refer to WW-42, "

Front Power Socket RH (For Cigarette Lighter), Con-

sole Power Socket".

7. Remove combination meter. Refer to IP-10

.

8. Remove audio unit. Refer to AV-46, "

Removal and Installation".

9. Remove display unit. Refer to AV-145, "

Removal and Installation".

10. Remove lower knee protector LH.

11. Remove GPS antenna. Refer to AV-145, "

Removal and Installation".

12. Remove optical sensor. Refer to LT-44, "

Optical Sensor".

13. Remove side ventilator assembly LH.

14. Remove side ventilator assembly RH.

15. Remove front pillar finisher. Refer to EI-37

.

16. Remove passenger air bag module. Refer to SRS-39

.

17. Remove instrument panel.

18. Disconnect remaining instrument panel assembly electrical connectors.

Installation

Installation is in the reverse order of removal.

7. Instrument panel 8. Bin mat 9. Side ventilator assembly LH

10. Instrument lower cover LH 11. Lower knee protector LH 12. Steering column cover upper

13. Steering column cover lower 14. Center console lower cover LH 15. Combination meter

16. Audio unit bracket LH 17. Driver instrument stay 18. Audio unit

19. Passenger instrument stay 20. Display assembly 21. Switch assembly

22. Cluster lid A 23. Cluster lid D ventilator LH 24. Front passenger air bag status light

25. Power socket LH and power socket RH 26. Clock 27. Cluster lid C

28. Front air control 29. Audio control 30. Hazard switch

31. Cluster lid D ventilator RH 32. Cluster lid D 33. Glove box door

34. Glove box assembly 35. Lower instrument panel RH 36. Glove box striker

37. Rubber bumpers 38. Glove box damper 39. Audio unit bracket RH

40. Center console lower cover RH 41. Fuse block cover 42. Side ventilator assembly RH

43. Instrument panel bracket 44. Instrument panel speaker RH 45. Bracket assembly RH

46. Key cylinder escutcheon 47. Instrument lower cover RH

Page 2127 of 3061

INSTRUMENT PANEL ASSEMBLY

IP-15

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

P Disassembly

1. Remove damper clip from glove box.

2. Remove glove box pins and glove box.

3. Remove glove box striker screws, using power tool and remove glove box striker.

4. Remove fuse block cover.

5. Remove glove box damper screws and remove glove box damper.

Assembly

Assembly is in the reverse order of disassembly.

CENTER CONSOLE

1. Glove box damper 2. Lower instrument panel RH 3. Clips

4. Rubber stoppers 5. Glove box pins 6. Glove box

7. Glove box striker 8. Fuse block cover 9. Glove box assembly

WIIA0301E

Page 2138 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-7

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000003533611

“U1000” or “U1001” is in INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-7

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000003533611

“U1000” or “U1001” is in](/img/42/57029/w960_57029-2137.png)

TROUBLE DIAGNOSIS

LAN-7

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

TROUBLE DIAGNOSIS

Condition of Error DetectionINFOID:0000000003533611

“U1000” or “U1001” is indicated on SELF-DIAG RESULTS on CONSULT-II if CAN communication signal is not

transmitted or received between units for 2 seconds or more.

CAN COMMUNICATION SYSTEM ERROR

• CAN communication line open (CAN-H, CAN-L, or both)

• CAN communication line short (ground, between CAN communication lines, other harnesses)

• Error of CAN communication control circuit of the unit connected to CAN communication line

WHEN INDICATED “U1000” OR “U1001” IS INDICATED EVEN THOUGH CAN COMMUNICATION

SYSTEM IS NORMAL

• CONSULT-II CONVERTER not connected: Error may be detected by the self-diagnosis when not using

CONSULT-II CONVERTER (Depending on the control unit which carries out CAN communication).

• Removal/installation of parts: Error may be detected when removing and installing CAN communication unit

and related parts while turning the ignition switch ON. (A DTC except for CAN communication may be

detected.)

• Fuse blown out (removed): CAN communication of the unit may cease.

• Voltage drop: Error may be detected if voltage drops due to discharged battery when turning the ignition

switch ON (Depending on the control unit which carries out CAN communication).

• Error may be detected if the power supply circuit of the control unit, which carries out CAN communication,

malfunctions (Depending on the control unit which carries out CAN communication).

• Error may be detected if reprogramming is not completed normally.

NOTE:

CAN communication system is normal if “U1000” or “U1001” is indicated on SELF-DIAG RESULTS of CON-

SULT-II under the above conditions. Erase the memory of the self-diagnosis of each unit.

Symptom When Error Occurs in CAN Communication SystemINFOID:0000000003533612

In CAN communication system, multiple units mutually transmit and receive signals. Each unit cannot transmit

and receive signals if any error occurs on CAN communication line. Under this condition, multiple control units

related to the root cause malfunction or go into fail-safe mode.

ERROR EXAMPLE

NOTE:

• Each vehicle differs in symptom of each unit under fail-safe mode and CAN communication line wiring.

• Refer to LAN-37, "

Abbreviation List" for the unit abbreviation.

Example: TCM branch line open circuit

SKIB8738E

Page 2207 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-76

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 5.

NG >> Replace the ECM and/or the IPDM E/R.

5.CHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in INFINITI QX56 2007 Factory Service Manual LAN-76

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 5.

NG >> Replace the ECM and/or the IPDM E/R.

5.CHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in](/img/42/57029/w960_57029-2206.png)

LAN-76

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 5.

NG >> Replace the ECM and/or the IPDM E/R.

5.CHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in the “Symptom (Results from interview with

customer)” are reproduced.

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF

2. Disconnect the battery cable from the negative terminal.

3. Disconnect all the unit connectors on CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace unit whose connector was disconnected.

IPDM E/R

Resistance (Ω)

Te r m i n a l N o .

39 40 Approx. 108 – 132

Page 2211 of 3061

LT-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003533330

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

General precautions for service operationsINFOID:0000000003533331

• Never work with wet hands.

• Xenon headlamp includes high voltage generating part. Be sure to

disconnect battery negative cable (negative terminal) or power

fuse before removing, installing, or touching the xenon headlamp

(including lamp bulb).

• Turn the lighting switch OFF before disconnecting and connecting

the connector.

• When turning the xenon headlamp on and while it is illuminated,

never touch the harness, bulb, and socket of the headlamp.

• When checking the headlamp on/off operation, check it on vehicle

and with the power connected to the vehicle-side connector.

• Do not touch the headlamp bulb glass surface with bare hands or

allow oil or grease to get on it. Do not touch the headlamp bulb just after the headlamp is turned off, because

it is very hot.

• Install the xenon headlamp bulb socket correctly. If it is installed

improperly, high-voltage leak or corona discharge may occur that

can melt the bulb, connector, and housing. Do not illuminate the

xenon headlamp bulb out of the headlamp housing. Doing so can

cause fire and harm your eyes.

• When the bulb has burned out, wrap it in a thick vinyl bag and dis-

card. Do not break the bulb.

• Leaving the bulb removed from the headlamp housing for a long

period of time can deteriorate the performance of the lens and

reflector (dirt, clouding). Always prepare a new bulb and have it on

hand when replacing the bulb.

• Do not use organic solvent (paint thinner or gasoline) to clean

lamps and to remove old sealant.

WKIA0460E

EL-3422D

Page 2212 of 3061

HEADLAMP (FOR USA)

LT-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

HEADLAMP (FOR USA)

Component Parts and Harness Connector LocationINFOID:0000000003533332

System DescriptionINFOID:0000000003533333

Control of the headlamp system operation is dependent upon the position of the combination switch (lighting

switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives input

requesting the headlamps (and tail lamps) illuminate. This input is communicated to the IPDM E/R (intelligent

power distribution module engine room) across the CAN communication lines. The CPU (central processing

unit) of the IPDM E/R controls the headlamp high and headlamp low relay coils. When energized, these relays

direct power to the respective headlamps, which then illuminate.

OUTLINE

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to headlamp high relay, located in the IPDM E/R,

• to headlamp low relay, located in the IPDM E/R,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R, and

• through 10A fuse (No. 59, located in the fuse and relay box)

WKIA3463E