check oil INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2592 of 3061

RSU-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532652

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Rear SuspensionINFOID:0000000003532653

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Page 2612 of 3061

RSU-22

< SERVICE INFORMATION >

REAR SUSPENSION ASSEMBLY

Rear Load Leveling Air Suspension System

On-Vehicle Inspection and ServiceINFOID:0000000003532670

Check all of the component mountings for any excessive looseness, or back lash. Check the components for

any excessive wear, damage, or abnormal conditions. Repair or replace the components as necessary.

SHOCK ABSORBER INSPECTION

• Check the shock absorbers for any air leaks or damage, and replace as necessary.

• Check the hoses for any air leaks or damage, and replace as necessary.

10. Shock absorber 11. Suspension arm 12. Lower rubber seat

13. Coil spring 14. Upper rubber seat 15. Rear suspension member

16. Spare tire bracket 17. Bound bumper

AWEIA0076ZZ

1. Rear load leveling air suspension

hose, RH2. Shock absorber, RH 3. Height sensor

4. Rear load leveling air suspension

hose, LH5. Shock absorber, LH 6. Rear load leveling air suspension

compressor assembly

⇐Front

Page 2618 of 3061

RSU-28

< SERVICE INFORMATION >

REAR SUSPENSION MEMBER

• Do not crimp or stretch the brake hose when repositioning the brake caliper out of the way.

• Do not press brake pedal while the brake caliper is removed.

7. Remove the spare tire.

8. Disconnect the two rear ABS sensor electrical connectors.

9. Remove the two rear drive shafts. Refer to RAX-7, "

Removal and Installation" .

10. Remove the rear final drive. Refer to RFD-14

.

11. Remove the EVAP canister bolt from the top of the rear suspension member.

12. Disconnect the parking brake cables from the brackets on the rear suspension member.

13. Set a suitable jack to support each of the rear lower links and the

coil spring tension.

14. Remove both of the rear lower link outer bolts and lower the jack to remove the rear coil springs.

15. Remove the two bolts to disconnect the seat belt latch anchor

from the rear suspension member.

16. Disconnect both of the connecting rods from the rear stabilizer

bar.

17. Set a suitable jack under the rear suspension member.

18. Remove the six rear suspension member bolts.

19. Slowly lower the jack to remove the rear suspension member,

suspension arm, front and rear lower links and stabilizer bar as

an assembly.

20. If necessary, remove the suspension arm, spare tire bracket,

height sensor, rear load leveling air suspension hoses, stabilizer

bar, knuckle, and front and rear lower links from the rear suspension member.

INSPECTION AFTER REMOVAL

Check the rear suspension member for deformation, cracks, and other damage and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• When raising the rear suspension member assembly, use the

locating pins to align the rear suspension member to the vehicle

body.

LEIA0077E

LEIA0075E

LEIA0083E

Page 2619 of 3061

REAR SUSPENSION MEMBER

RSU-29

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

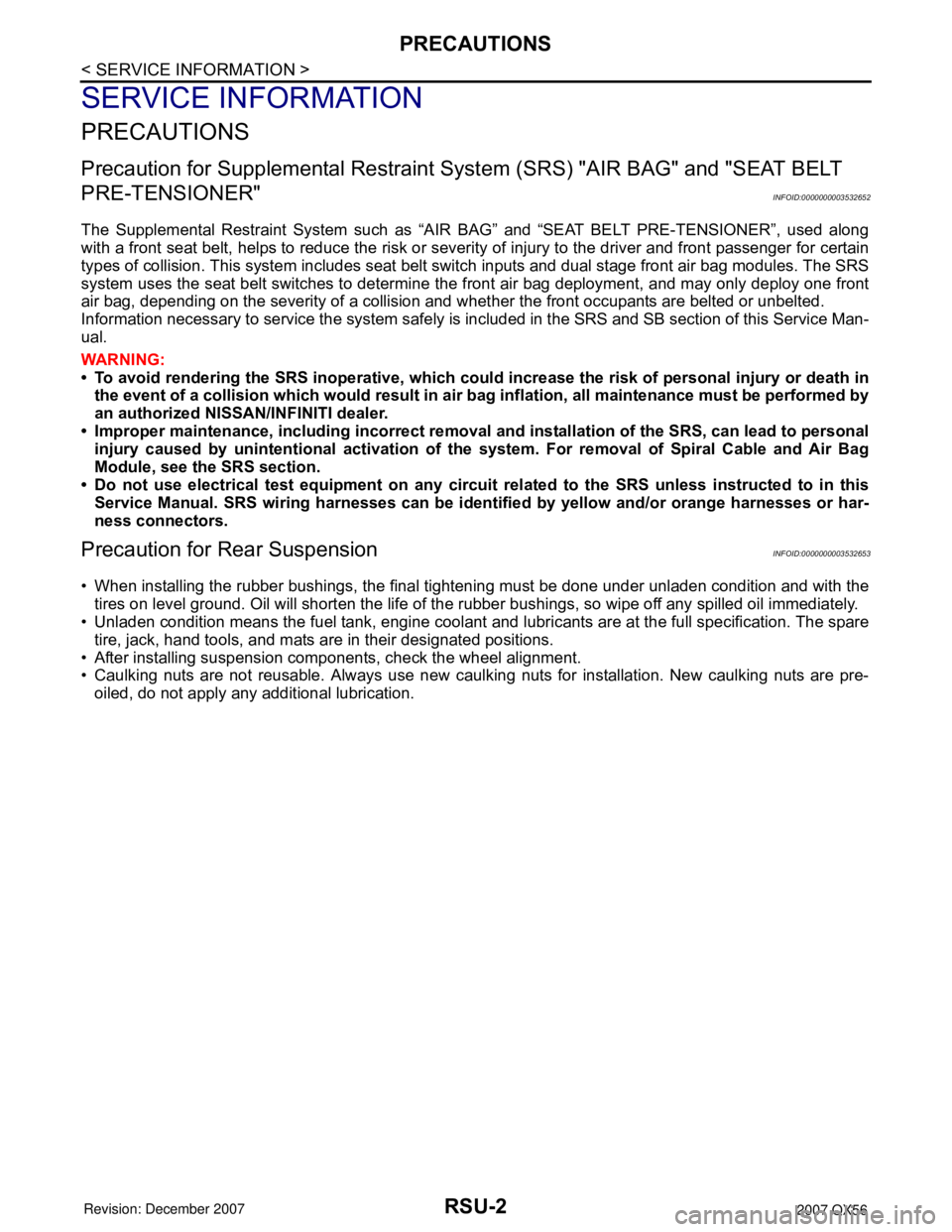

• When installing the upper and lower rubber seats for the rear coil

springs, the arrow embossed on the rubber seats must point out

toward the wheel and tire assembly.

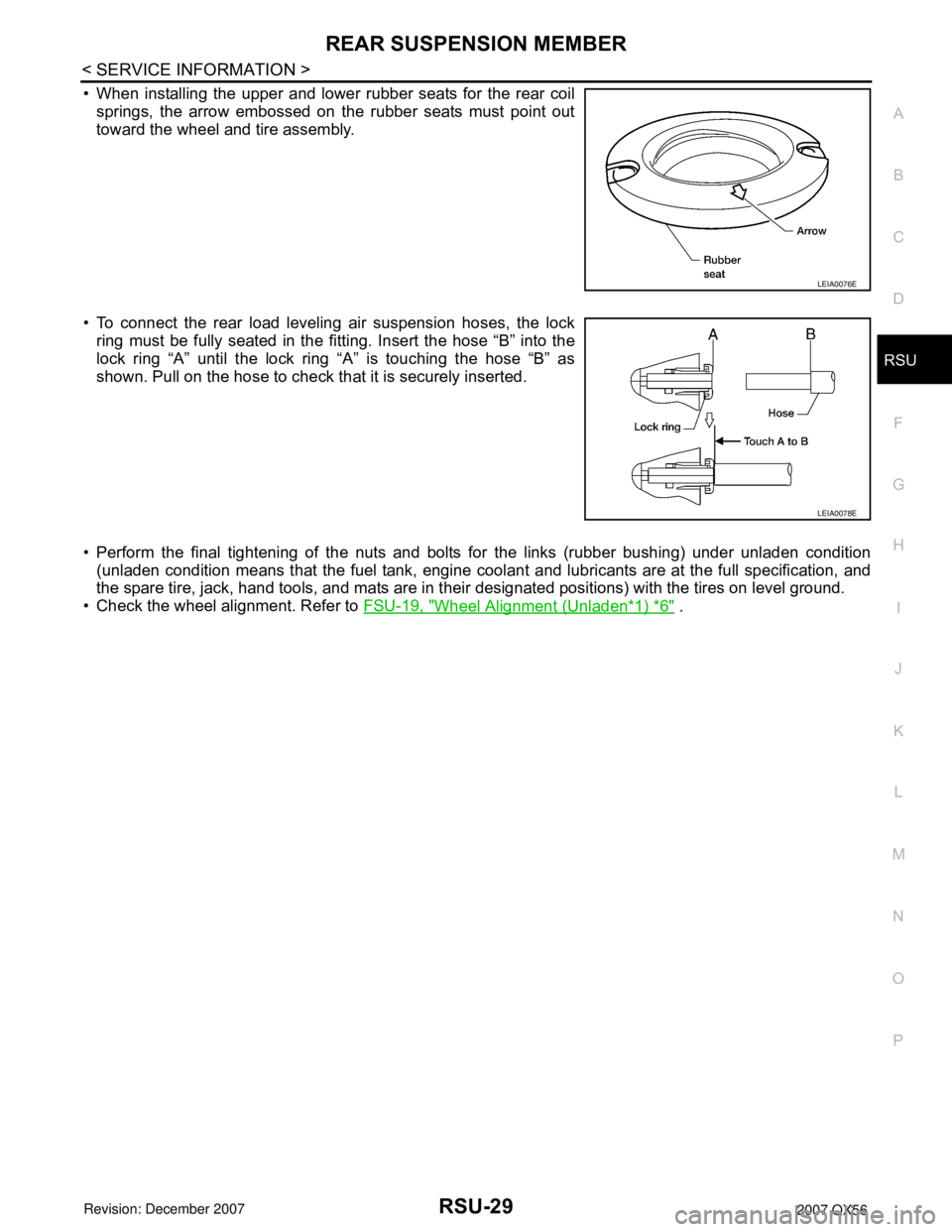

• To connect the rear load leveling air suspension hoses, the lock

ring must be fully seated in the fitting. Insert the hose “B” into the

lock ring “A” until the lock ring “A” is touching the hose “B” as

shown. Pull on the hose to check that it is securely inserted.

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition

(unladen condition means that the fuel tank, engine coolant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in their designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to FSU-19, "

Wheel Alignment (Unladen*1) *6" .

LEIA0076E

LEIA0078E

Page 2626 of 3061

RSU-36

< SERVICE INFORMATION >

REAR LOWER LINK & COIL SPRING

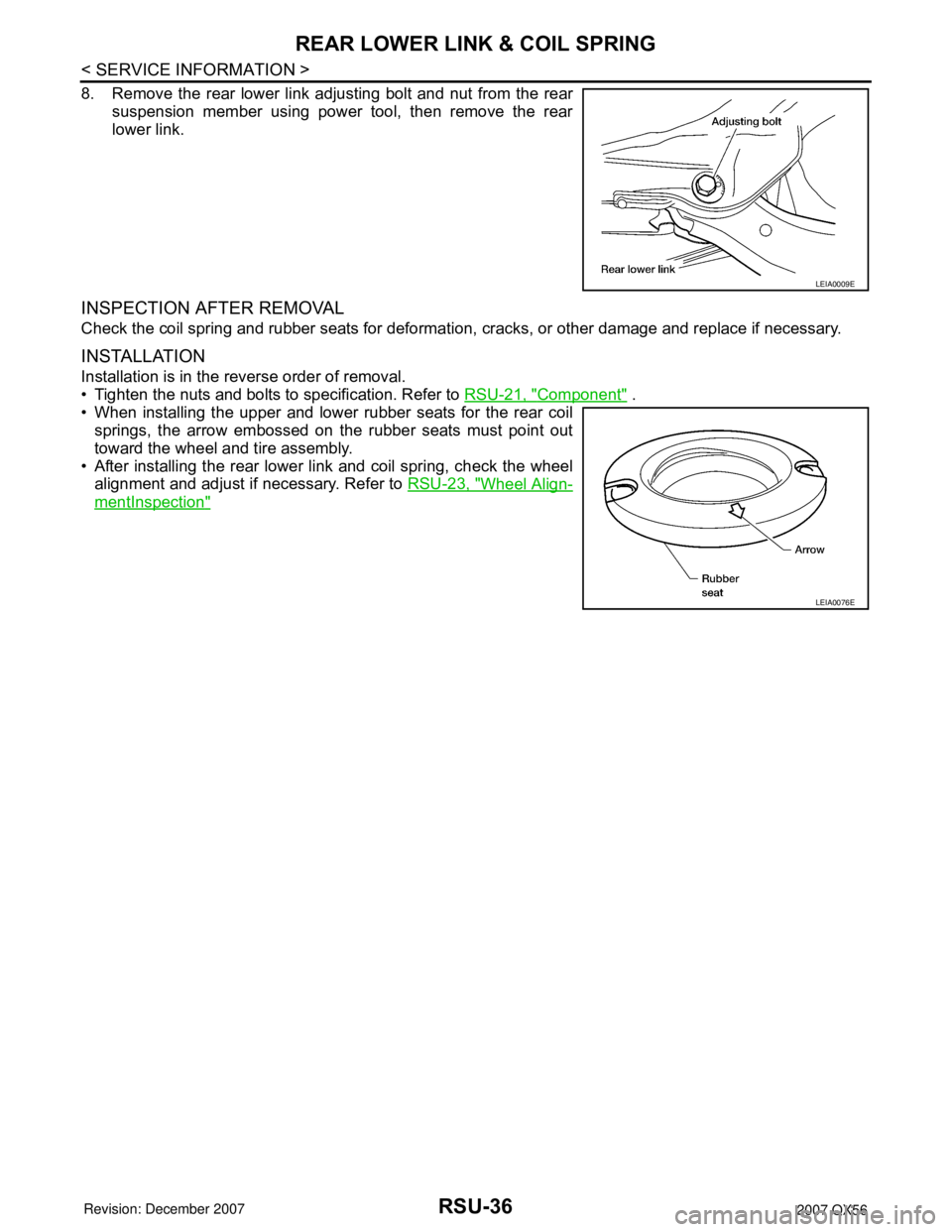

8. Remove the rear lower link adjusting bolt and nut from the rear

suspension member using power tool, then remove the rear

lower link.

INSPECTION AFTER REMOVAL

Check the coil spring and rubber seats for deformation, cracks, or other damage and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-21, "

Component" .

• When installing the upper and lower rubber seats for the rear coil

springs, the arrow embossed on the rubber seats must point out

toward the wheel and tire assembly.

• After installing the rear lower link and coil spring, check the wheel

alignment and adjust if necessary. Refer to RSU-23, "

Wheel Align-

mentInspection"

LEIA0009E

LEIA0076E

Page 2636 of 3061

SB-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532841

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Seat Belt ServiceINFOID:0000000003532842

CAUTION:

• Before removing the seat belt pre-tensioner assembly, turn the ignition switch OFF, disconnect both

battery cables and wait at least 3 minutes.

• After replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-ten-

sioner assembly connector, make sure entire SRS operates properly. Refer to SRS-20, "

SRS Opera-

tion Check".

• Do not disassemble buckle or seat belt assembly.

• Do not reuse seat belt anchor bolts after removal. Replace with new ones.

• Replace anchor bolts if they are deformed or worn out.

• Never oil tongue and buckle.

• If any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

• If webbing is cut, frayed, or damaged, replace seat belt assembly.

• When replacing seat belt assembly, use a genuine NISSAN seat belt assembly.

AFTER A COLLISION

WARNING:

• Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

• NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

• The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

• The seat belt was damaged in an accident. (i.e., torn webbing, bent retractor or guide, etc.)

• The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for damage

or distortion and repair as necessary before installing a new seat belt assembly.

• Anchor bolts are deformed or worn out.

• The seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

Page 2675 of 3061

PRECAUTIONS

SE-3

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003533149

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for WorkINFOID:0000000003533150

• When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and keep them.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After re-installation is completed, be sure to check that each part works normally.

• Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the

fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

• Do not use organic solvent such as thinner, benzene, alcohol, or gasoline.

• For genuine leather seats, use a genuine leather seat cleaner.

Page 2806 of 3061

SRS-36

< SERVICE INFORMATION >

DRIVER AIR BAG MODULE

• Replace the air bag module if it has been dropped or sus-

tained an impact.

• Do not allow oil, grease or water to come in contact with the

air bag module.

INSTALLATION

Installation is in the reverse order of removal.

• If driver air bag module is being replaced due to deployment, spiral cable must also be replaced. Refer to

SRS-37

.

• For removal/installation of the direct-connect SRS connectors, refer to SRS-6, "

Direct-connect SRS Compo-

nent Connectors" .

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-

20, "SRS Operation Check" .

SBF814E

Page 2840 of 3061

TF-18

< SERVICE INFORMATION >

ALL-MODE 4WD SYSTEM

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different oper-

ating conditions.

• The line pressure switch turns ON when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch turns ON when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

TRANSFER FLUID TEMPERATURE SENSOR

The transfer temperature sensor detects the transfer fluid temperature and sends a signal to the transfer con-

trol unit.

TRANSFER CONTROL UNIT

• Transfer control unit controls transfer control device by input signals of each sensor and each switch.

• Self-diagnosis can be done.

TRANSFER CONTROL DEVICE

The transfer control device changes the state of transfer assembly between 2WD, AUTO, 4H⇔4LO with the

2WD, AUTO, 4H and 4LO signals of 4WD shift switch.

NOTE:

• To shift between 4H⇔4LO, stop the vehicle, depress the brake pedal and shift the transmission selector to

the "N" position. Depress and turn the 4WD shift switch. The shift switch will not shift to the desired mode if

the transmission is not in "N" or the vehicle is moving. The 4LO indicator lamp will be lit when the 4LO is

engaged.

• Actuator motor and actuator position switch are integrated.

4WD SHIFT SWITCH AND INDICATOR LAMP

4WD Shift Switch

The 4WD shift switch allows selection from 2WD, AUTO, 4H or 4LO.

4WD Shift Indicator Lamp

• Displays driving conditions selected by 4WD shift switch with 2WD, AUTO and 4H indicators while engine is

running. (When 4WD warning lamp is turned on, all 4WD shift indicator lamps are turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4LO Indicator Lamp

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns ON or FLASH when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF for approximately 1

second after the engine starts if system is normal.

4WD Warning Lamp Indication

Condition Content 4WD warning lamp

During self-diagnosis Indicates the malfunction position by number of flickers. Flickers at malfunction mode.

Lamp check*Checks the lamp by turning ON during engine starting. After

engine starts, it turns OFF if there are no malfunctions.ON

Malfunction in 4WD system*Turns ON to indicate malfunction. When ignition switch is

turned to “OFF” or the malfunction is corrected, it turns OFF.ON

When vehicle is driven with different

diameters of front and rear tiresFlickers once every 2 seconds.

Turns OFF when ignition switch is “OFF”.Flickers once every 2 sec-

onds.

Page 2866 of 3061

![INFINITI QX56 2007 Factory Service Manual TF-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

CAUTION:

• If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

• If “V INFINITI QX56 2007 Factory Service Manual TF-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

CAUTION:

• If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

• If “V](/img/42/57029/w960_57029-2865.png)

TF-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

CAUTION:

• If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communication

line.

• If “VHCL SPEED SEN·AT [P1808]”, “ABS OP SIG [P1830]”, “VDC OP SIG [P1831]” or “TCS OP SIG [P1832]” is displayed, first

perform the trouble diagnosis for ABS system.

• If “VHCL SPEED SEN·AT [P1808]”, is displayed, first perform the trouble diagnosis for A/T system.

NOTE:

• If "SHIFT ACT POSI SW [P1818]" or “SHIFT ACT CIR [P1819]” is displayed, first erase self-diagnostic results. ("SHIFT ACT POSI SW

[P1818]" or “SHIFT ACT CIR [P1819]” may be displayed after installing transfer control unit or transfer assembly.)

• If “CL PRES SW [P1827]” or “LINE PRES SW [P1828]” is displayed only while driving in reverse, check the continuity of “R” position

on A/T PNP switch. When there is nothing wrong with the electrical system, check the hydraulic system.

How to Erase Self-diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

SHIFT ACT CIR

[P1819]• Transfer control device actuator circuit is shorted or open. (Mal-

functions are detected when transfer shift relay circuit is open/

shorted or relay monitor circuit is open/shorted.)

• Malfunction occurs in transfer control device drive circuit.

• Malfunction is detected in transfer shut off relay.TF-72, "Transfer Control Device"

Malfunction is detected in transfer shut off relay.TF-51, "Power Supply Circuit for

Transfer Control Unit"

ENGINE SPEED SIG

[P1820]• Malfunction is detected in engine speed signal that is output from

ECM through CAN communication.

• Improper signal is input while driving.TF-76, "Engine Speed Signal

(ECM)"

DUTY SOLENOID

[P1822]• Proper voltage is not applied to clutch pressure solenoid valve

due to open or short circuit.TF-76, "Clutch Pressure Sole-

noid"

2-4WD SOLENOID

[P1823]• Proper voltage is not applied to 2-4WD solenoid valve due to open

or short circuit.TF-80, "2-4WD Solenoid"

MOTOR RELAY

[P1824]• Motor does not operate properly due to open or short circuit in

transfer motor or motor relay.TF-84, "Transfer Motor"

OIL TEMP SEN

[P1826]• Signal voltage from fluid temperature sensor is abnormally high

(Transfer fluid temperature is abnormally low) while driving.TF-90, "Transfer Fluid Tempera-

ture"

CLUTCH PRES SW

[P1827]• Improper signal from clutch pressure switch is input due to open or

short circuit.

• Malfunction occurs in clutch pressure switch or hydraulic circuit.TF-92, "Clutch Pressure Switch"

LINE PRES SW

[P1828]• Improper signal from line pressure switch is input due to open or

short circuit.

• Malfunction occurs in line pressure switch or hydraulic circuit.TF-94, "Line Pressure Switch"

THROTTLE POSI SEN

[P1829]• Malfunction is detected in accelerator pedal position signal that is

output from ECM through CAN communication.

• Signal voltage from accelerator pedal position sensor is abnormal-

ly high or low.TF-97, "Throttle Position Signal

(ECM)"

ABS OP SIG

[P1830]• Malfunction is detected in ABS operation signal that is output from

ABS actuator and electric unit (control unit) through CAN commu-

nication.TF-97, "ABS Operation Signal

(ABS)"

VDC OP SIG

[P1831]• Malfunction is detected in VDC operation signal that is output from

ABS actuator and electric unit (control unit) through CAN commu-

nication.TF-98, "VDC Operation Signal

(ABS)"

TCS OP SIG

[P1832]• Malfunction is detected in TCS operation signal that is output from

ABS through CAN communication.TF-98, "TCS Operation Signal

(ABS)"

CAN COMM CIRCUIT

[U1000]• Malfunction has been detected from CAN communication line.TF-99, "CAN Communication

Line"

NO DTC IS DETECTED.

FURTHER TESTING MAY

BE REQUIRED.• No NG item has been detected. — Items (CONSULT-II screen

terms)Diagnostic item is detected when... Check item