key INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2463 of 3061

HARNESS

PG-61

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

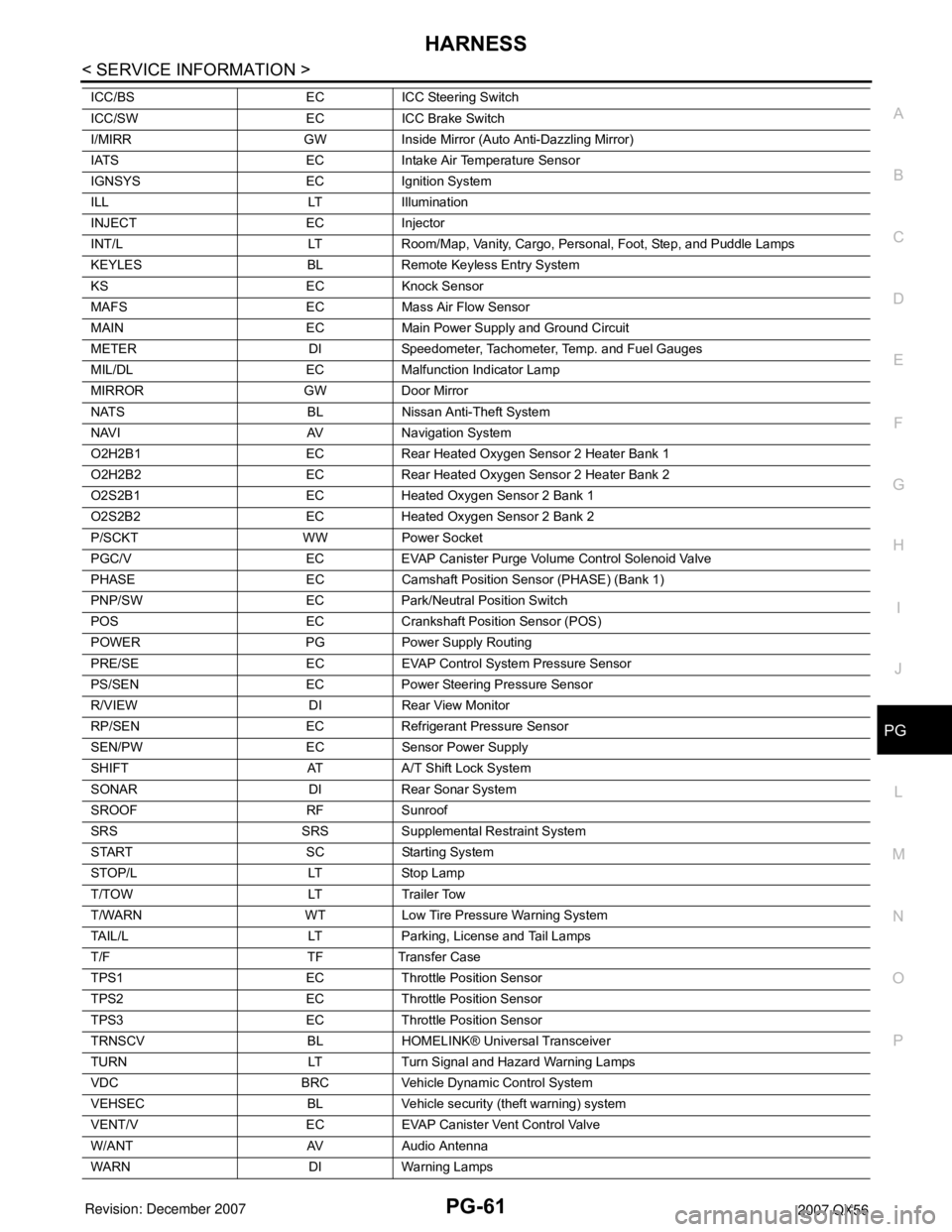

ICC/BS EC ICC Steering Switch

ICC/SW EC ICC Brake Switch

I/MIRR GW Inside Mirror (Auto Anti-Dazzling Mirror)

IATS EC Intake Air Temperature Sensor

IGNSYS EC Ignition System

ILL LT Illumination

INJECT EC Injector

INT/L LT Room/Map, Vanity, Cargo, Personal, Foot, Step, and Puddle Lamps

KEYLES BL Remote Keyless Entry System

KS EC Knock Sensor

MAFS EC Mass Air Flow Sensor

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp. and Fuel Gauges

MIL/DL EC Malfunction Indicator Lamp

MIRROR GW Door Mirror

NATS BL Nissan Anti-Theft System

NAVI AV Navigation System

O2H2B1 EC Rear Heated Oxygen Sensor 2 Heater Bank 1

O2H2B2 EC Rear Heated Oxygen Sensor 2 Heater Bank 2

O2S2B1 EC Heated Oxygen Sensor 2 Bank 1

O2S2B2 EC Heated Oxygen Sensor 2 Bank 2

P/SCKT WW Power Socket

PGC/V EC EVAP Canister Purge Volume Control Solenoid Valve

PHASE EC Camshaft Position Sensor (PHASE) (Bank 1)

PNP/SW EC Park/Neutral Position Switch

POS EC Crankshaft Position Sensor (POS)

POWER PG Power Supply Routing

PRE/SE EC EVAP Control System Pressure Sensor

PS/SEN EC Power Steering Pressure Sensor

R/VIEW DI Rear View Monitor

RP/SEN EC Refrigerant Pressure Sensor

SEN/PW EC Sensor Power Supply

SHIFT AT A/T Shift Lock System

SONAR DI Rear Sonar System

SROOF RF Sunroof

SRS SRS Supplemental Restraint System

START SC Starting System

STOP/L LT Stop Lamp

T/TOW LT Trailer Tow

T/WARN WT Low Tire Pressure Warning System

TAIL/L LT Parking, License and Tail Lamps

T/F TF Transfer Case

TPS1 EC Throttle Position Sensor

TPS2 EC Throttle Position Sensor

TPS3 EC Throttle Position Sensor

TRNSCV BL HOMELINK® Universal Transceiver

TURN LT Turn Signal and Hazard Warning Lamps

VDC BRC Vehicle Dynamic Control System

VEHSEC BL Vehicle security (theft warning) system

VENT/V EC EVAP Canister Vent Control Valve

W/ANT AV Audio Antenna

WARN DI Warning Lamps

Page 2501 of 3061

PS-10

< SERVICE INFORMATION >

STEERING COLUMN

STEERING COLUMN

Removal and InstallationINFOID:0000000003532827

CAUTION:

• Do not exert any load or impact in the axial direction immediately before or after column removal.

• Do not to move steering gear during removal of steering column assembly.

REMOVAL

1. Remove combination switch and spiral cable from steering column assembly. Refer to SRS-37, "Removal

and Installation" .

2. Remove the tilt motor and tilt sensor. Refer to PS-9, "

Removal and Installation" .

3. Remove steering column cover, ADP steering switch and ignition key finisher. Refer to IP-10, "

Removal

and Installation" .

1. Driver air bag module 2. Steering wheel 3. Steering wheel side cover

4. Combination switch and spiral cable 5. Steering column assembly 6. Collar

7. Hole cover seal 8. Clamp 9. Hole cover mounting plate

10. Hole cover 11. Upper joint 12. Upper shaft

13. Boot clamp 14. Lower joint shaft 15. Boot and clips (plastic)

WGIA0139E

Page 2504 of 3061

STEERING COLUMN

PS-13

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

Disassembly and AssemblyINFOID:0000000003532828

DISASSEMBLY

1. Remove mounting bolt from upper joint, then remove upper joint from steering column assembly.

2. Remove ignition switch tamper resistant self-shear screws with a drill or other suitable tool.

ASSEMBLY

Assembly is in the reverse order of disassembly.

• Install new tamper resistant self-shear screws.

NOTE:

Any time the ignition switch has been removed and installed, the

keys must be re-registered in the BCM. Refer to CONSULT-II opera-

tion manual IVIS/NVIS.

INSPECTION AFTER ASSEMBLY

When the steering wheel does not turn smoothly, check the steering column as follows:

1. Check the column bearings for damage or unevenness. Lubricate with recommended multi-purpose

grease. Replace the steering column as an assembly, if necessary.

2. Check the column tube for deformation or breakage. Replace the steering column as an assembly, if nec-

essary.

1. Steering column assembly 2. Upper joint 3. Ignition switch

4. Tamper resistant self-shear screw

WGIA0091E

WGIA0009E

Page 2655 of 3061

BATTERY

SC-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

1. Turn off all loads on the vehicle electrical system. Clean or repair

as necessary.

2. Visually inspect the battery, battery terminals and cable ends

with ignition switch in “OFF” position.

NOTE:

The contact surface between the battery terminals, cable ends

and tester leads must be clean for a valid test. A poor connec-

tion will prevent testing and a “CHECK CONNECTION” mes-

sage will appear during the test procedures. If this occurs, clean

the battery post and terminals, reconnect them and restart the

test.

3. Connect the red tester lead clamp to the positive battery termi-

nal, and the black to the negative terminal.

4. The tester will turn on automatically. Using the arrow keys,

select “IN-VEHICLE” on the tester and then press the “ENTER”

key.

5. Locate the battery type and rating stamped or written on the top

case of the battery to be tested.

NOTE:

The battery rating will be either of the following:

•CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

•JIS: Japanese Industrial Standard.

When using the Battery Tester use the CCA rating only.

• The tester requires the CCA rating for the battery be entered

exactly as it is written or stamped on the battery.

• (U.S. market) Refer to the latest "Battery Testing" Technical

Service Bulletin (TSB) for a chart which contains these ratings

listed by vehicle.

• You must not use the JIS rating.

6. Using the arrow and “ENTER” keys alternately, select the battery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Only use CCA or JIS.

7. Press “ENTER” to begin the test. Diagnosis results are dis-

played on the tester. Refer to "DIAGNOSTIC RESULT ITEM

CHART".

SEL404X

SEL405X

WKIA4228E

SEL407X

Page 2683 of 3061

AUTOMATIC DRIVE POSITIONER

SE-11

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

AUTOMATIC DRIVE POSITIONER

Component Parts and Harness Connector LocationINFOID:0000000003533156

System DescriptionINFOID:0000000003533157

• Refer to Owner's Manual for Automatic Drive Positioner system operating instructions.

• The settings (ON/OFF) of the automatic sliding seat (entry/exiting operation) at entry/exit can be changed as

desired, using the display unit in the center of the instrument panel. The set content is transmitted by CAN

communication, from display control unit to driver seat control unit.

• Using CONSULT-ll, the seat slide amount at entry/exit setting can be changed.

1. A. Automatic drive positioner control

unit M33, M34

B. Pedal adjusting motor E109, E1102. A. Steering column

B. Key switch and key lock solenoid

M27

C. BCM M18, M19, M20 (view with

instrument panel removed)3. A. Door mirror remote control switch

D10

B. Seat memory switch D5

4. Pedal adjusting switch M96 5. A. Door mirrror LH D4, RH D107

B. Front door switch LH B86. A. A/T selector lever

B. A/T device (park position switch)

M203

7. A. Sliding motor LH P4 (driver seat

view), reclining motor LH P5, lifting

motor (front) P6, lifting motor (rear)

P7

B. Driver seat control unit P2, P3

C. Power seat switch LH P88. A. ADP steering switch M16

B.Tilt motor M68, M69

LIIA2726E

Page 2684 of 3061

SE-12

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

NOTE:

• Disconnecting the battery erases the stored memory.

• After connecting the battery, insert the key into the ignition cylinder and turn the front door switch LH ON (open)→OFF (close)→ON

(open), the entry/exiting function becomes possible.

• After Exiting operation is carried out, return operation can be operated.

NOTE:

During automatic operation, if the ignition switch is turned ON→START, the automatic operation is suspended. When the ignition switch

returns to ON, it resumes.

FA I L - S A F E M O D E

When any manual and automatic operations are not performed, if any motor operations of seats or pedals are

detected for T2 or more, status is judged “Output error”.

CANCEL OF FAIL-SAFE MODE

The mode is cancelled when the A/T selector lever is shifted to P position from any other position.

NOTE:

The front seat LH position and pedal adjustment functions (see the following table) operate simultaneously in

the order of priority.

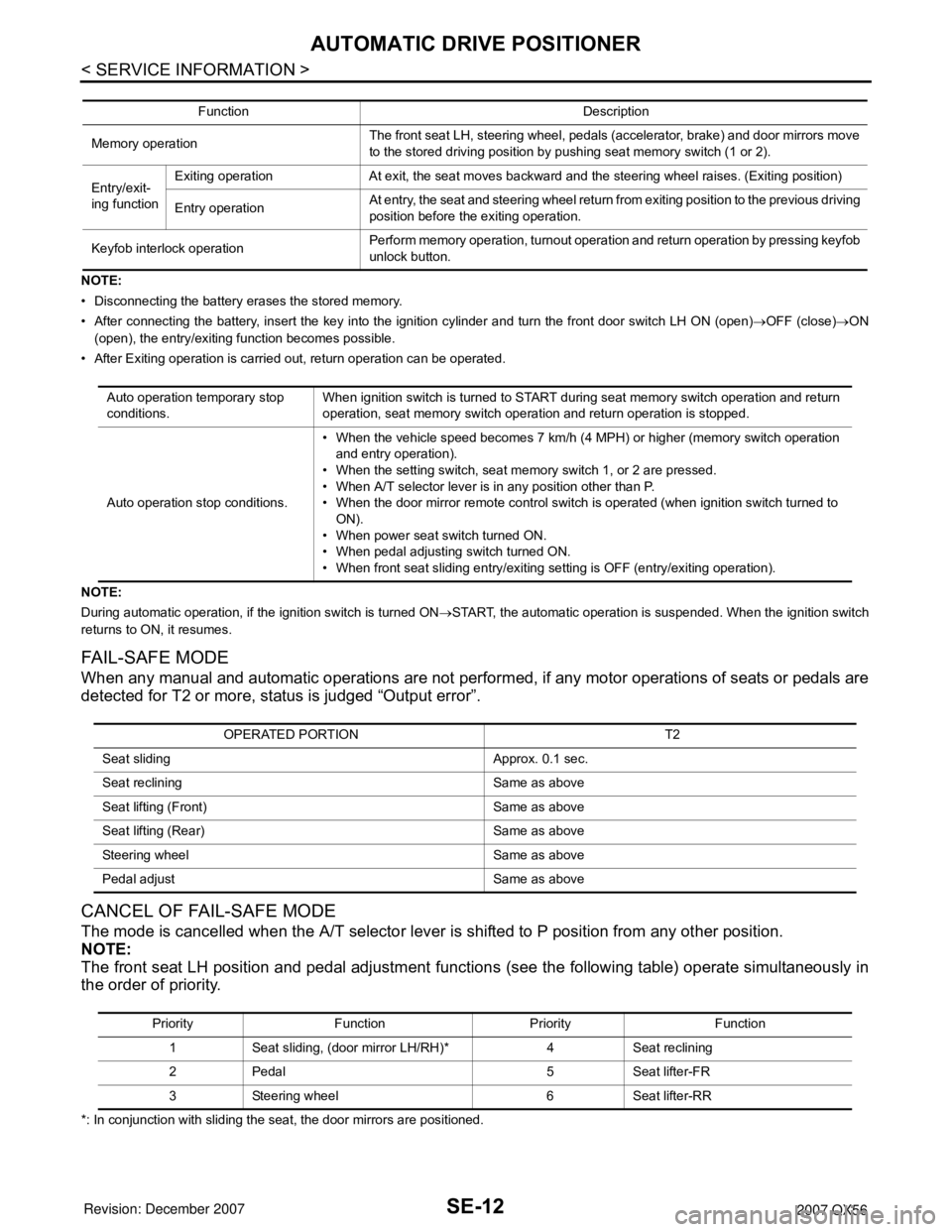

*: In conjunction with sliding the seat, the door mirrors are positioned.Function Description

Memory operation The front seat LH, steering wheel, pedals (accelerator, brake) and door mirrors move

to the stored driving position by pushing seat memory switch (1 or 2).

Entry/exit-

ing functionExiting operation At exit, the seat moves backward and the steering wheel raises. (Exiting position)

Entry operationAt entry, the seat and steering wheel return from exiting position to the previous driving

position before the exiting operation.

Keyfob interlock operationPerform memory operation, turnout operation and return operation by pressing keyfob

unlock button.

Auto operation temporary stop

conditions.When ignition switch is turned to START during seat memory switch operation and return

operation, seat memory switch operation and return operation is stopped.

Auto operation stop conditions.• When the vehicle speed becomes 7 km/h (4 MPH) or higher (memory switch operation

and entry operation).

• When the setting switch, seat memory switch 1, or 2 are pressed.

• When A/T selector lever is in any position other than P.

• When the door mirror remote control switch is operated (when ignition switch turned to

ON).

• When power seat switch turned ON.

• When pedal adjusting switch turned ON.

• When front seat sliding entry/exiting setting is OFF (entry/exiting operation).

OPERATED PORTION T2

Seat sliding Approx. 0.1 sec.

Seat reclining Same as above

Seat lifting (Front) Same as above

Seat lifting (Rear) Same as above

Steering wheel Same as above

Pedal adjust Same as above

Priority Function Priority Function

1 Seat sliding, (door mirror LH/RH)* 4 Seat reclining

2 Pedal 5 Seat lifter-FR

3 Steering wheel 6 Seat lifter-RR

Page 2698 of 3061

SE-26

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

13 L/B Front lifting switch DOWN signalON (front lifting switch DOWN op-

eration)0

Other than above Battery voltage

14 G/W Rear lifting switch DOWN signalON (rear lifting switch DOWN op-

eration)0

Other than above Battery voltage

15 L/YPedal adjusting switch BACK-

WARD signalON (pedal adjusting switch BACK-

WARD operation) 0

Other than above Battery voltage

16 W Seat sensor power Ignition switch ON 5

17 W UART LINE (TX)Pedal adjusting switch ON (FOR-

WARD or BACKWARD operation)

19 P CAN-L — —

21 L/RA/T device (park position switch)

signalA/T selector lever in P position 0

A/T selector lever in other than P

position with ignition key in ignition

cylinderBattery voltage

24 Y/G Seat sliding motor sensor signalON (seat sliding motor operation)

Other than above 0 or 5

25 LG Front lifting motor sensor signalON (front lifting motor operation)

Other than above. 0 or 5

26 P/BSeat sliding switch FORWARD

signalON (seat sliding switch FOR-

WARD operation)0

Other than above Battery voltage

27 G/BSeat reclining switch FORWARD

signalON (seat reclining switch FOR-

WARD operation)0

Other than above Battery voltage

28 Y/B Front lifting switch UP signalON (front lifting switch UP opera-

tion)0

Other than above Battery voltage Te r m i n a lWire

ColorItem ConditionVoltage (V)

(Approx.)

PIIA4814E

PIIA3277E

SIIA0691J

Page 2706 of 3061

![INFINITI QX56 2007 Factory Service Manual SE-34

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

Monitor item [OPERATION or UNIT] Contents

SLIDE SW-FR “ON/OFF� INFINITI QX56 2007 Factory Service Manual SE-34

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

Monitor item [OPERATION or UNIT] Contents

SLIDE SW-FR “ON/OFF�](/img/42/57029/w960_57029-2705.png)

SE-34

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

Monitor item [OPERATION or UNIT] Contents

SLIDE SW-FR “ON/OFF” ON/OFF status judged from the sliding switch (FR) signal is displayed.

SLIDE SW-RR “ON/OFF” ON/OFF status judged from the sliding switch (RR) signal is displayed.

RECLN SW-FR “ON/OFF” ON/OFF status judged from the reclining switch (FR) signal is displayed.

RECLN SW-RR “ON/OFF” ON/OFF status judged from the reclining switch (RR) signal is displayed.

LIFT FR SW-UP “ON/OFF” ON/OFF status judged from the FR lifter switch (UP) signal is displayed.

LIFT FR SW-DN “ON/OFF” ON/OFF status judged from the FR lifter switch (DOWN) signal is displayed.

LIFT RR SW-UP “ON/OFF” ON/OFF status judged from the RR lifter switch (UP) signal is displayed.

LIFT RR SW-DN “ON/OFF” ON/OFF status judged from the RR lifter switch (DOWN) signal is displayed.

MIR CON SW-UP “ON/OFF”ON/OFF status judged from the door mirror remote control switch (UP) signal is dis-

played.

MIR CON SW-DN “ON/OFF”ON/OFF status judged from the door mirror remote control switch (DOWN) signal

is displayed.

MIR CON SW-RH “ON/OFF”ON/OFF status judged from the door mirror remote control switch (RIGHT) signal

is displayed.

MIR CON SW-LH “ON/OFF”ON/OFF status judged from the door mirror remote control switch (LEFT) signal is

displayed.

MIR CHNG SW-R “ON/OFF”ON/OFF status judged from the door mirror remote control switch (switching to

RIGHT) signal is displayed.

MIR CHNG SW-L “ON/OFF”ON/OFF status judged from the door mirror remote control switch (switching to

LEFT) signal is displayed.

SET SW “ON/OFF” ON/OFF status judged from the setting switch signal is displayed.

TILT SW-UP “ON/OFF” ON/OFF status judged from the tilt adjusting switch (UP) signal is displayed.

PEDAL SW-FR “ON/OFF” ON/OFF status judged from the pedal adjusting switch (FR) signal is displayed.

PEDAL SW-RR “ON/OFF” ON/OFF status judged from the pedal adjusting switch (RR) signal is displayed.

MEMORY SW1 “ON/OFF” ON/OFF status judged from the seat memory switch 1 signal is displayed.

MEMORY SW2 “ON/OFF” ON/OFF status judged from the seat memory switch 2 signal is displayed.

DETENT SW “ON/OFF”The A/T selector lever position “OFF (P position) / ON (other than P position)”

judged from the park position switch signal is displayed.

STARTER SW “ON/OFF”Ignition key switch ON (START, ON) /OFF (ignition switch IGN, ACC, or OFF) sta-

tus judged from the ignition switch signal is displayed.

SLIDE PULSE —Value (32768) when battery connects is as standard. If it moves BACKWARD, the

value increases. If it moves FORWARD, the value decreases.

RECLN PULSE —Value (32768) when battery connects is as standard. If it moves BACKWARD, the

value increases. If it moves FORWARD, the value decreases.

LIFT FR PULSE —Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

LIFT RR PULSE —Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

MIR/SEN RH R-L “V” Voltage output from RH door mirror sensor (LH/RH) is displayed.

MIR/SEN RH U-D “V” Voltage output from RH door mirror sensor (UP/DOWN) is displayed.

MIR/SEN LH R-L “V” Voltage output from LH door mirror sensor (LH/RH) is displayed.

MIR/SEN LH U-D “V” Voltage output from LH door mirror sensor (UP/DOWN) is displayed.

PEDAL SEN “V”The pedal position (voltage) judged from the pedal adjust sensor signal is dis-

played.

Page 2707 of 3061

AUTOMATIC DRIVE POSITIONER

SE-35

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

If active test is performed, reset seat memory and automatic drive positioner seat memory after performing

work.

DISPLAY ITEM LIST

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)INFOID:0000000003533171

1.SELF-DIAGNOSTIC RESULT CHECK

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

1. Connect to CONSULT-II, and select “AUTO DRIVE POS.” on the “SELECT DIAG SYSTEM” screen.

2. Select “SELF-DIAG RESULTS” on "SELECT DIAG MODE" screen.

3. Check display content in self-diagnostic results.

Contents displayed

No malfunction>>Inspection End.

Malfunction in CAN communication system>>After printing the monitor items, go to “CAN System”. Refer to

LAN-3, "

Precaution When Using CONSULT-II".

Symptom ChartINFOID:0000000003533172

Test item Description

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

SEAT RECLINING The reclining motor is activated by receiving the drive signal.

SEAT LIFTER FR The lifting motor (front) is activated by receiving the drive signal.

SEAT LIFTER RR The lifting motor (rear) is activated by receiving the drive signal.

PEDAL MOTOR The pedal adjust motor is activated by receiving the drive signal.

MEMORY SW INDCTR The memory switch indicator is lit by receiving the drive signal.

MIRROR MOTOR RHThe RH mirror motor moves the mirror UP/DOWN and LEFT/RIGHT by receiving the drive

signal.

MIRROR MOTOR LHThe LH mirror motor moves the mirror UP/DOWN and LEFT/RIGHT by receiving the drive

signal.

CONSULT-II display code Diagnosis item

U1000INITIAL DIAG

TRANSMIT DIAG

BCM

METER/M&A

ECM

I-KEY

Symptom Diagnoses / service procedure Refer to page

Only setting change function cannot be set with display.1. Preliminary checkSE-30

2. CAN communication inspection using CONSULT-II (self-

diagnosis)SE-35

3. If the above systems are normal, check display system.AV- 7 3

Page 2709 of 3061

AUTOMATIC DRIVE POSITIONER

SE-37

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

Sliding Motor Circuit InspectionINFOID:0000000003533173

1.CHECK SEAT SLIDING MECHANISM

Check the following.

• Operation malfunction caused by sliding rail deformation, pinched harness or other foreign materials

• Operation malfunction caused by foreign materials adhered to the sliding motor LH or sliding rail connector

rod

• Operation malfunction and interference with other parts by poor installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

2.CHECK FUNCTION

With CONSULT-II

Check operation with “SEAT SLIDE” in ACTIVE TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Sliding motor circuit is OK.

NG >> GO TO 3.

3.CHECK SLIDING MOTOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and sliding motor LH.

3. Check continuity between driver seat control unit connector P3

terminals 35, 42 and sliding motor connector P4 terminals 4, 6.

4. Check continuity between driver seat control unit connector P3

terminals 35, 42 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

The entry/exiting does not operate when door is opened

and closed.

(The entry/exiting operates with key switch)1. Front door switch circuit inspectionSE-72

2. If all the above systems are normal, replace the BCM.BCS-24

Door mirror system does not operate (only manual oper-

ation).1.Door mirror remote control switch ground circuit inspectionSE-65

Door mirror system does not operate (only automatic op-

eration).1. Door mirror sensor power supply and ground circuit in-

spectionSE-69

Seat system does not operate (only manual operation). 1. Power seat switch ground circuit inspectionSE-60

Symptom Diagnoses / service procedure Refer to page

Test item Description

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

PIIA0265E

35 - 6 : Continuity should exist.

42 - 4 : Continuity should exist.

35 - Ground : Continuity should not exist.

42 - Ground : Continuity should not exist.

LIIA0696E