INFINITI QX56 2007 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1821 of 3061

CAMSHAFTEM-51

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

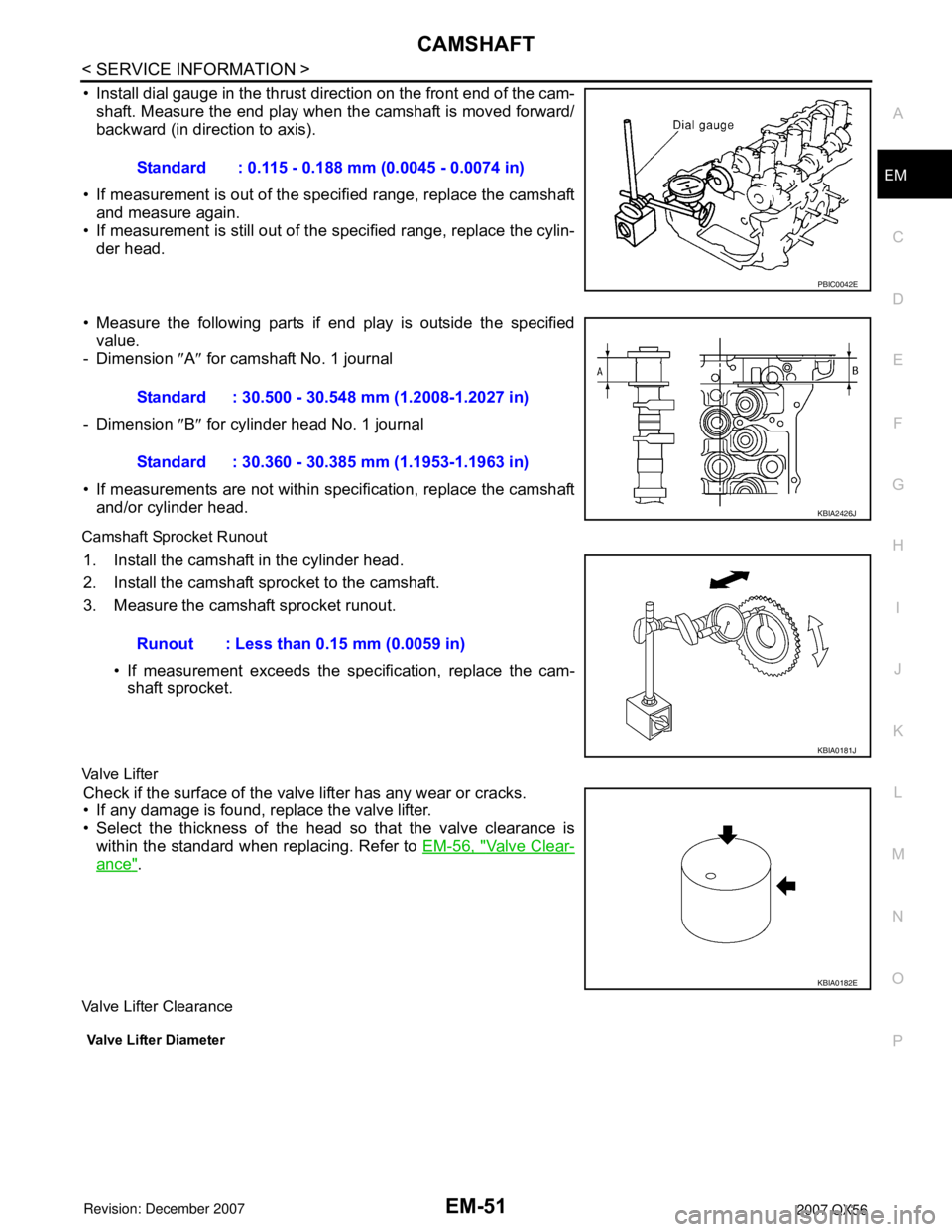

• Install dial gauge in the thrust direction on the front end of the cam-

shaft. Measure the end play when the camshaft is moved forward/

backward (in direction to axis).

• If measurement is out of the specified range, replace the camshaft and measure again.

• If measurement is still out of t he specified range, replace the cylin-

der head.

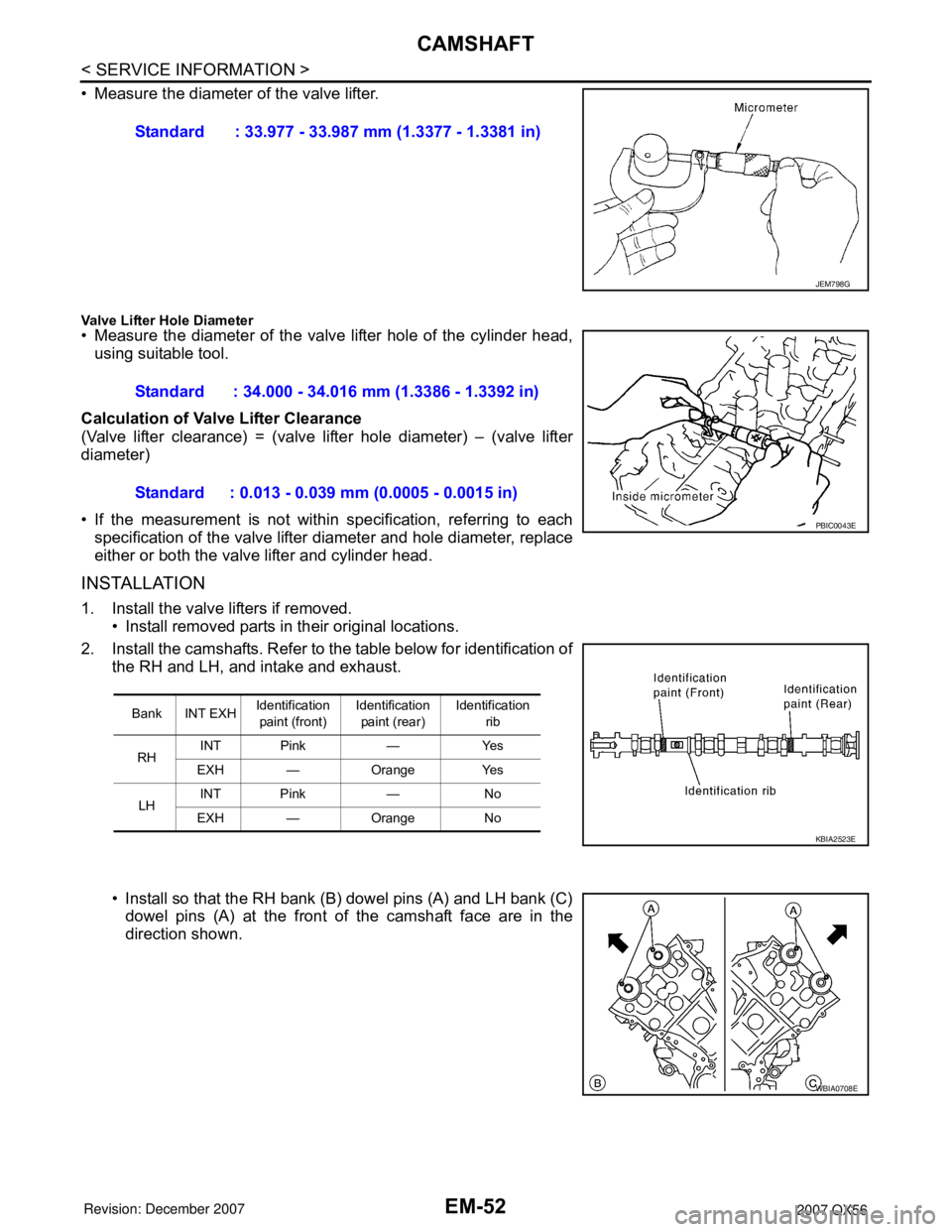

• Measure the following parts if end play is outside the specified value.

- Dimension ″A ″ for camshaft No. 1 journal

- Dimension ″B ″ for cylinder head No. 1 journal

• If measurements are not within specification, replace the camshaft and/or cylinder head.

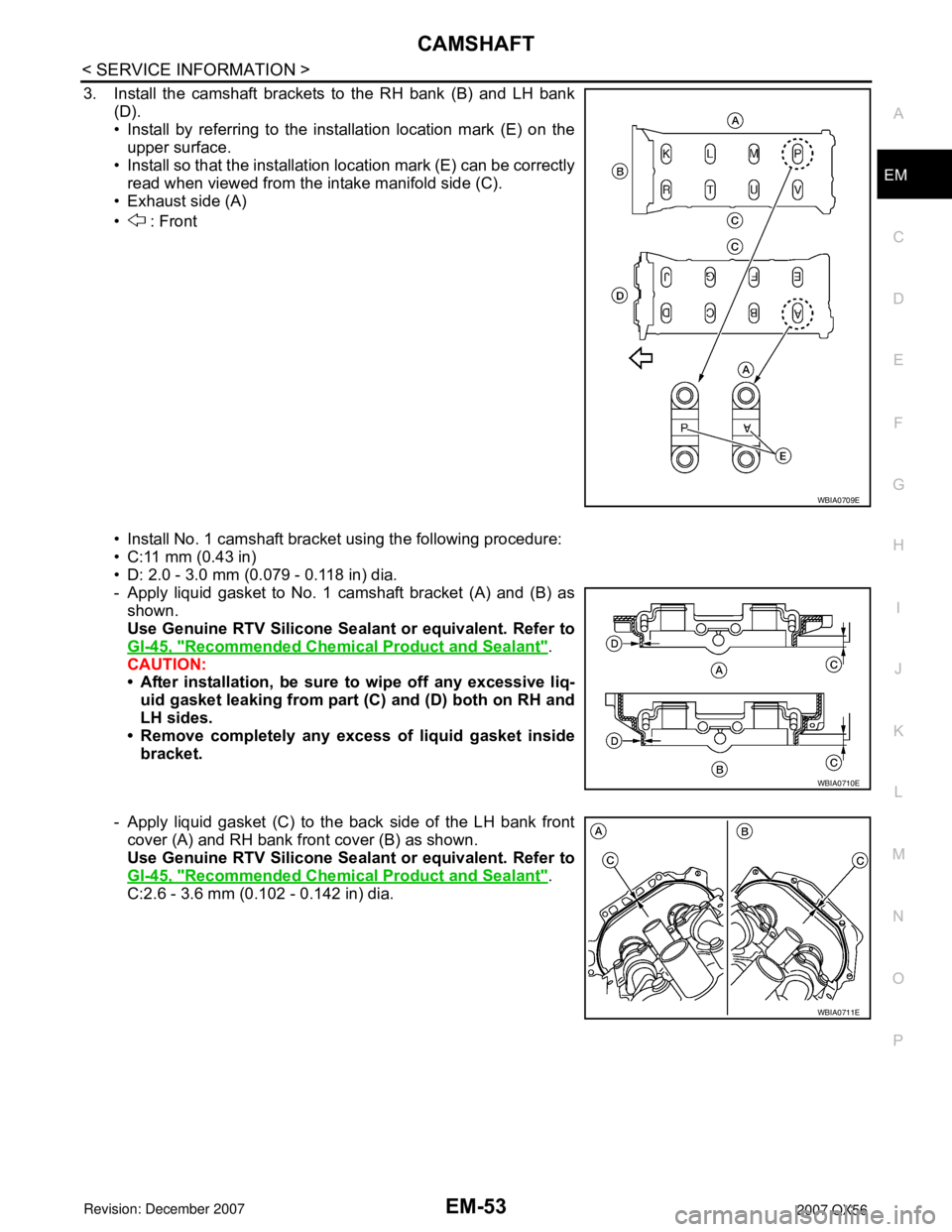

Camshaft Sprocket Runout

1. Install the camshaft in the cylinder head.

2. Install the camshaft sprocket to the camshaft.

3. Measure the camshaft sprocket runout.

• If measurement exceeds the s pecification, replace the cam-

shaft sprocket.

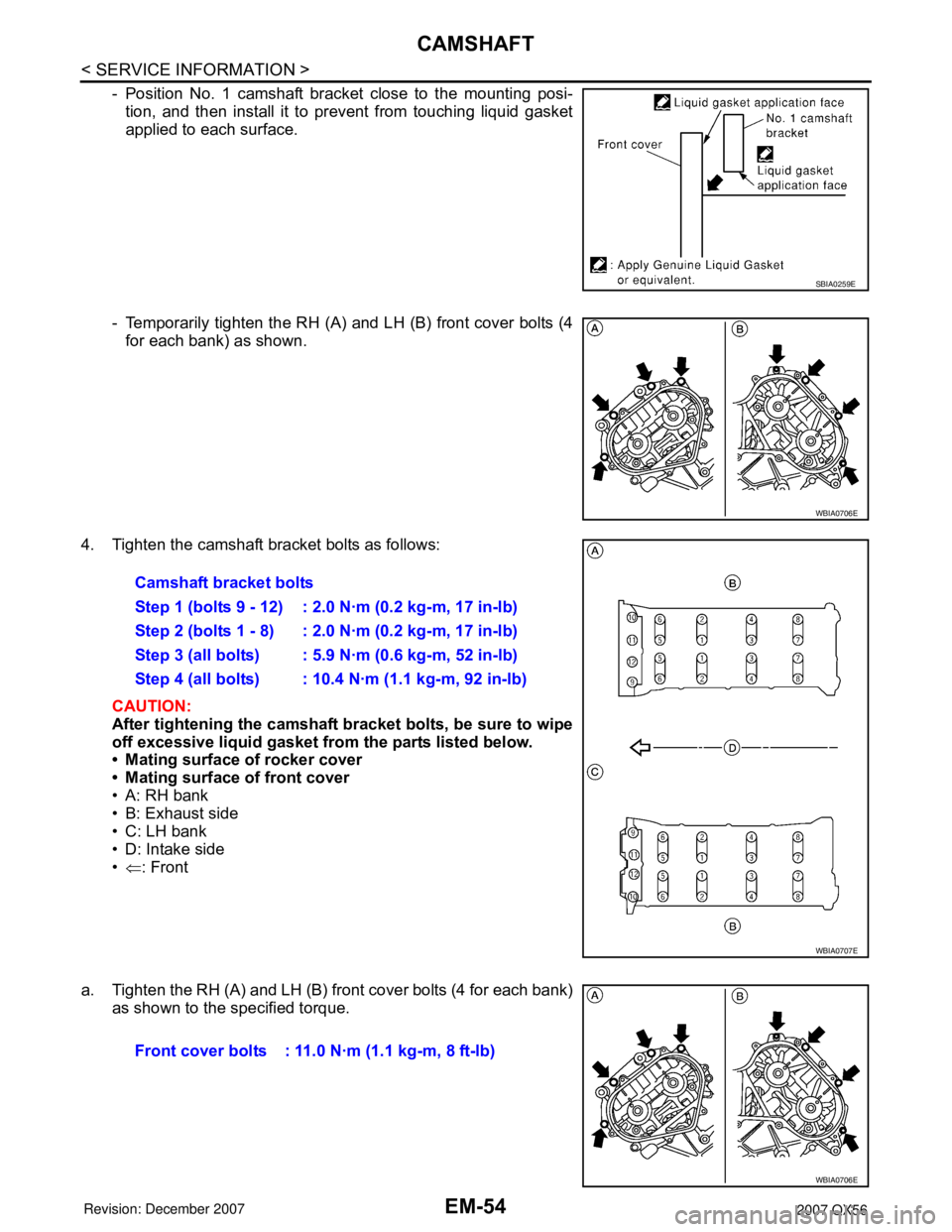

Valve Lifter

Check if the surface of the valve lifter has any wear or cracks.

• If any damage is found, replace the valve lifter.

• Select the thickness of the head so that the valve clearance is within the standard when replacing. Refer to EM-56, "

Valve Clear-

ance".

Valve Lifter Clearance

Valve Lifter Diameter

Standard : 0.115 - 0.188 mm (0.0045 - 0.0074 in)

PBIC0042E

Standard : 30.500 - 30.548 mm (1.2008-1.2027 in)

Standard : 30.360 - 30.385 mm (1.1953-1.1963 in)

KBIA2426J

Runout : Less than 0.15 mm (0.0059 in)

KBIA0181J

KBIA0182E

Page 1822 of 3061

EM-52

< SERVICE INFORMATION >

CAMSHAFT

• Measure the diameter of the valve lifter.

Valve Lifter Hole Diameter• Measure the diameter of the valve lifter hole of the cylinder head,using suitable tool.

Calculation of Valve Lifter Clearance

(Valve lifter clearance) = (valve lifter hole diameter) – (valve lifter

diameter)

• If the measurement is not within specification, referring to each specification of the valve lifter diameter and hole diameter, replace

either or both the valve lifter and cylinder head.

INSTALLATION

1. Install the valve lifters if removed. • Install removed parts in their original locations.

2. Install the camshafts. Refer to the table below for identification of the RH and LH, and intake and exhaust.

• Install so that the RH bank (B) dowel pins (A) and LH bank (C)dowel pins (A) at the front of the camshaft face are in the

direction shown.Standard : 33.977 - 33.987 mm (1.3377 - 1.3381 in)

JEM798G

Standard : 34.000 - 34.016 mm (1.3386 - 1.3392 in)

Standard : 0.013 - 0.039 mm (0.0005 - 0.0015 in)

PBIC0043E

Bank INT EXH

Identification

paint (front) Identification

paint (rear) Identification

rib

RH INT Pink — Yes

EXH — Orange Yes

LH INT Pink — No

EXH — Orange No

KBIA2523E

WBIA0708E

Page 1823 of 3061

CAMSHAFTEM-53

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

3. Install the camshaft brackets to the RH bank (B) and LH bank

(D).

• Install by referring to the installation location mark (E) on theupper surface.

• Install so that the installation location mark (E) can be correctly read when viewed from the intake manifold side (C).

• Exhaust side (A)

• : Front

• Install No. 1 camshaft bracket using the following procedure:

• C:11 mm (0.43 in)

• D: 2.0 - 3.0 mm (0.079 - 0.118 in) dia.

- Apply liquid gasket to No. 1 camshaft bracket (A) and (B) as

shown.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-45, "

Recommended Chemical Product and Sealant".

CAUTION:

• After installation, be sure to wipe off any excessive liq-

uid gasket leaking from part (C) and (D) both on RH and

LH sides.

• Remove completely any excess of liquid gasket inside

bracket.

- Apply liquid gasket (C) to the back side of the LH bank front cover (A) and RH bank front cover (B) as shown.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-45, "

Recommended Chemical Product and Sealant".

C:2.6 - 3.6 mm (0.102 - 0.142 in) dia.

WBIA0709E

WBIA0710E

WBIA0711E

Page 1824 of 3061

EM-54

< SERVICE INFORMATION >

CAMSHAFT

- Position No. 1 camshaft bracket close to the mounting posi-

tion, and then install it to prevent from touching liquid gasket

applied to each surface.

- Temporarily tighten the RH (A) and LH (B) front cover bolts (4 for each bank) as shown.

4. Tighten the camshaft bracket bolts as follows: CAUTION:

After tightening the camshaft br acket bolts, be sure to wipe

off excessive liquid gasket from the parts listed below.

• Mating surface of rocker cover

• Mating surface of front cover

• A: RH bank

• B: Exhaust side

• C: LH bank

• D: Intake side

• ⇐ : Front

a. Tighten the RH (A) and LH (B) front cover bolts (4 for each bank) as shown to the specified torque.

SBIA0259E

WBIA0706E

Camshaft bracket bolts

Step 1 (bolts 9 - 12) : 2.0 N·m (0.2 kg-m, 17 in-lb)

Step 2 (bolts 1 - 8) : 2.0 N·m (0.2 kg-m, 17 in-lb)

Step 3 (all bolts) : 5.9 N·m (0.6 kg-m, 52 in-lb)

Step 4 (all bolts) : 10.4 N·m (1.1 kg-m, 92 in-lb)

WBIA0707E

Front cover bolts : 11.0 N·m (1.1 kg-m, 8 ft-lb)

WBIA0706E

Page 1825 of 3061

CAMSHAFTEM-55

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

5. Install the camshaft sprockets using the following procedure:

• A: LH bank shown

a. Install the camshaft sprockets aligning them with the matching marks painted on the timing chain (B) and the camshaft sprock-

ets (C) before removal. Align the camshaft sprocket key groove

with the dowel pin on the camshaft front edge at the same time.

Then temporarily tighten camshaft sprocket bolts.

• Install the intake camshaft sprocket (VTC) (A) and exhaust

camshaft sprockets (B) by select ively using the groove of the

dowel pin according to the bank. (Common part used for both

exhaust banks.)

NOTE:

Use the groove marked "R" for RH bank and "L" for LH bank.

b. Lock the hexagonal part of the camshaft in the same way as for removal, and tighten the camshaft sprocket bolts.

c. Check again that the timing alignment mark on the timing chain and on each sprocket are aligned.

6. Install the chain tensioner using the following procedure: NOTE:

LH is shown.

a. Install the chain tensioner. • Compress the plunger and hold it using a stopper pin wheninstalling.

• Loosen the slack guide side timing chain by rotating the cam- shaft hexagonal part if mounting space is small.

b. Remove the stopper pin and release the plunger, and then apply tension to the timing chain.

c. Install the chain tensioner cover onto the front cover. • Apply liquid gasket as shown.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-45, "

Recommended Chemical Product and Sealant".

7. Check and adjust valve clearances. Refer to EM-56, "

Va l v e

Clearance".

8. Installation of the remaining components is in the reverse order of removal.

Inspection after InstallationINFOID:0000000003531535

INSPECTION OF CAMSHAFT SPROCKET (INT) OIL GROOVE

CAUTION:

• Perform this inspection only when DTC P0011 is de tected in self-diagnostic results of CONSULT II

and it is directed according to inspect ion procedure of EC section. Refer to EC-159, "

Component

Inspection".

• Check when engine is cold so as to pr event burns from any splashing engine oil.

1. Check engine oil level. Refer to LU-8, "

Inspection".

AWBIA0152ZZ

AWBIA0151ZZ

Chain tensioner bolts : 6.9 N·m (0.70 kg-m, 61 in-lb)

Tensioner cover bolts : 9.0 N·m (0.92 kg-m, 80 in-lb)KBIA2479E

KBIA2547E

Page 1826 of 3061

EM-56

< SERVICE INFORMATION >

CAMSHAFT

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release fuel pressure. Refer to EC-80, "

Fuel Pressure Check".

b. Disconnect ignition coil and injector harness connectors if practical.

3. Remove IVT control solenoid valve.

4. Crank engine, and then make sure that engine oil comes out from IVT control cover oil hole. End cranking

after checking.

WARNING:

Be careful not to touch rotating parts (drive be lts, idler pulley, and crankshaft pulley, etc.).

CAUTION:

• Engine oil may squirt from IVT control soleno id valve installation hole during cranking. Use a

shop cloth to prevent engine oil from splashin g on worker, engine components and vehicle.

• Do not allow engine oil to get on rubber compon ents such as drive belts or engine mount insula-

tors. Immediately wipe off any splashed engine oil.

5. Clean oil groove between oil strainer and IVT control solenoid valve if engine oil does not come out from IVT control valve cover oil hole. Refer to LU-7, "

Schematic".

6. Remove components between IVT control solenoid va lve and camshaft sprocket (INT), and then check

each oil groove for clogging.

• Clean oil groove if necessary.

7. After inspection, installation of the remaining components is in the reverse order of removal.

Valve ClearanceINFOID:0000000003531536

INSPECTION

NOTE:

Perform the following inspection after removal, installation or replacement of camshaft or valve-related parts,

or if there are unusual engine conditions due to changes in valve clearance over time (starting, idling, and/or

noise).

1. Warm up the engine. Then stop the engine.

2. Remove the engine cover and. Refer to EM-12, "

Removal and Installation".

3. Remove the battery cover. Refer to SC-8, "

Removal and Installation".

4. Remove the air cleaner and air duct assembly EM-15, "

Removal and Installation".

5. Remove the RH bank and LH bank rocker covers using power tool. Refer to EM-35, "

Removal and Instal-

lation".

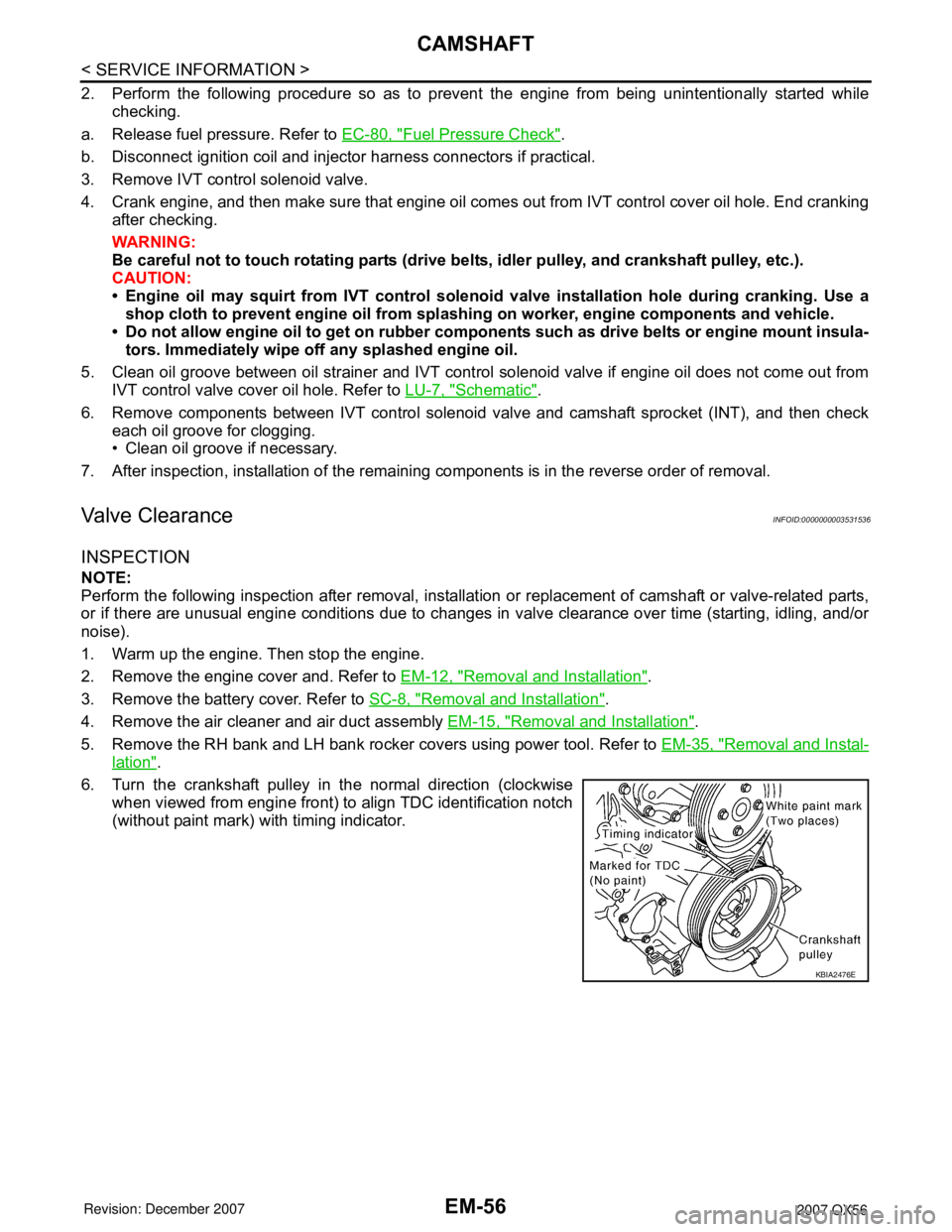

6. Turn the crankshaft pulley in the normal direction (clockwise when viewed from engine front) to align TDC identification notch

(without paint mark) with timing indicator.

KBIA2476E

Page 1827 of 3061

CAMSHAFTEM-57

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

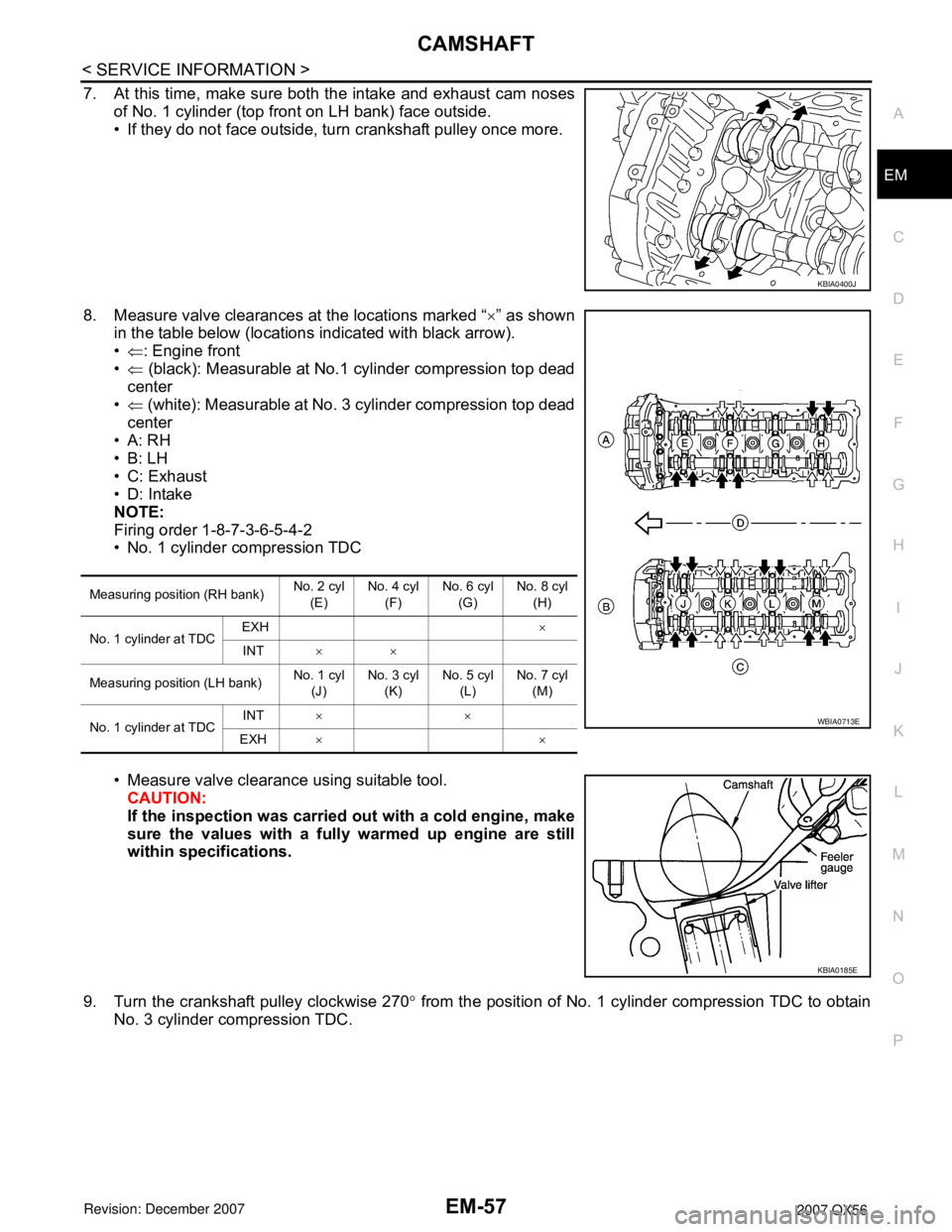

7. At this time, make sure both the intake and exhaust cam noses

of No. 1 cylinder (top front on LH bank) face outside.

• If they do not face outside, turn crankshaft pulley once more.

8. Measure valve clearances at the locations marked “ ×” as shown

in the table below (locations indicated with black arrow).

• ⇐ : Engine front

• ⇐ (black): Measurable at No.1 cylinder compression top dead

center

• ⇐ (white): Measurable at No. 3 cylinder compression top dead

center

•A: RH

•B: LH

• C: Exhaust

• D: Intake

NOTE:

Firing order 1-8-7-3-6-5-4-2

• No. 1 cylinder compression TDC

• Measure valve clearance using suitable tool. CAUTION:

If the inspection was carried out with a cold engine, make

sure the values with a fully warmed up engine are still

within specifications.

9. Turn the crankshaft pulley clockwise 270 ° from the position of No. 1 cylinder compression TDC to obtain

No. 3 cylinder compression TDC.

KBIA0400J

Measuring position (RH bank) No. 2 cyl

(E) No. 4 cyl

(F) No. 6 cyl

(G) No. 8 cyl

(H)

No. 1 cylinder at TDC EXH

×

INT ××

Measuring position (LH bank) No. 1 cyl

(J) No. 3 cyl

(K) No. 5 cyl

(L) No. 7 cyl

(M)

No. 1 cylinder at TDC INT

××

EXH ××

WBIA0713E

KBIA0185E

Page 1828 of 3061

EM-58

< SERVICE INFORMATION >

CAMSHAFT

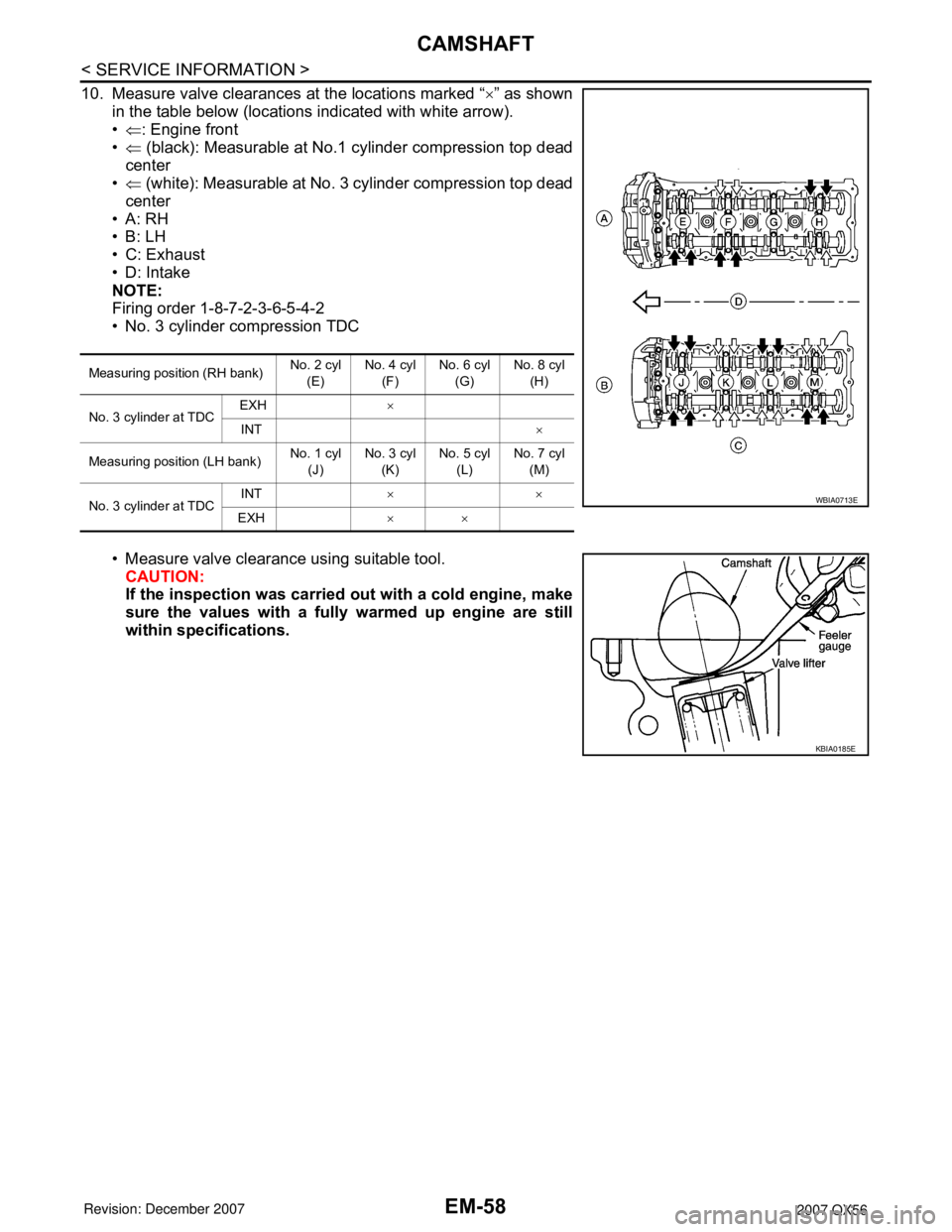

10. Measure valve clearances at the locations marked “×” as shown

in the table below (locations indicated with white arrow).

• ⇐ : Engine front

• ⇐ (black): Measurable at No.1 cylinder compression top dead

center

• ⇐ (white): Measurable at No. 3 cylinder compression top dead

center

•A: RH

•B: LH

• C: Exhaust

•D: Intake

NOTE:

Firing order 1-8-7-2-3-6-5-4-2

• No. 3 cylinder compression TDC

• Measure valve clearance using suitable tool. CAUTION:

If the inspection was carried out with a cold engine, make

sure the values with a fully warmed up engine are still

within specifications.

Measuring position (RH bank) No. 2 cyl

(E) No. 4 cyl

(F) No. 6 cyl

(G) No. 8 cyl

(H)

No. 3 cylinder at TDC EXH

×

INT ×

Measuring position (LH bank) No. 1 cyl

(J) No. 3 cyl

(K) No. 5 cyl

(L) No. 7 cyl

(M)

No. 3 cylinder at TDC INT

××

EXH ××

WBIA0713E

KBIA0185E

Page 1829 of 3061

CAMSHAFTEM-59

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

11. Turn the crankshaft pulley clockwise 90

° from the position of No.

3 cylinder compression TDC (clockwise by 360 ° from the posi-

tion of No. 1 cylinder compression TDC) to measure the intake

and exhaust valve clearances of No. 6 cylinder and the exhaust

valve clearance of No. 2 cylinder.

12. If out of specifications, adjust as necessary.

ADJUSTMENT

NOTE:

• Perform adjustment depending on the selected head thickness of the valve lifter.

• The specified valve lifter thickness is the dimension at normal temperatures. Ignore dimensional differences

caused by temperature. Us e the specifications for hot engine condition to adjust.

1. Remove the camshaft. Refer to EM-46, "

Removal and Installation".

2. Remove the valve lifters at the loca tions that are out of specification.

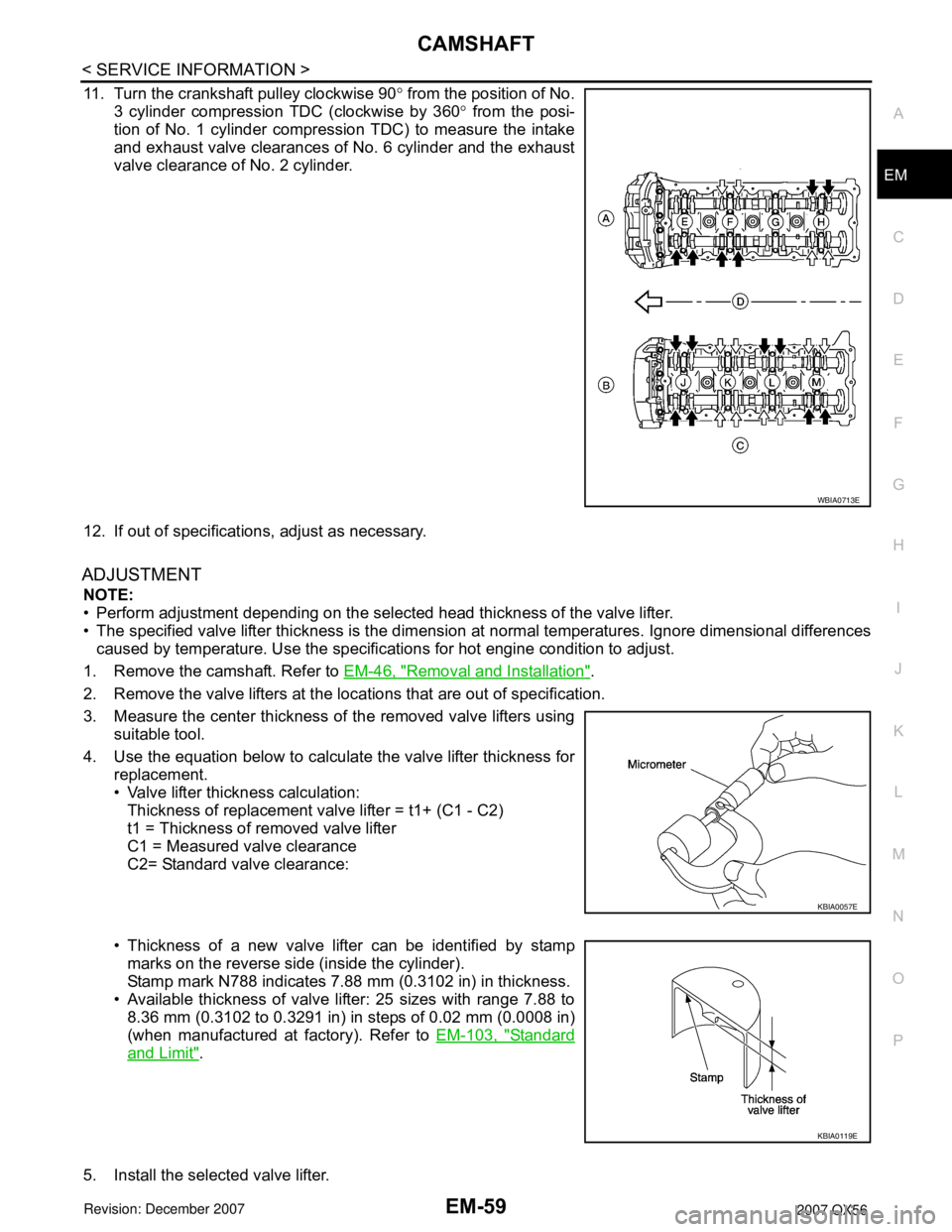

3. Measure the center thickness of the removed valve lifters using suitable tool.

4. Use the equation below to calculate the valve lifter thickness for replacement.

• Valve lifter thickness calculation:

Thickness of replacement valve lifter = t1+ (C1 - C2)

t1 = Thickness of removed valve lifter

C1 = Measured valve clearance

C2= Standard valve clearance:

• Thickness of a new valve lifter can be identified by stamp marks on the reverse side (inside the cylinder).

Stamp mark N788 indicates 7.88 mm (0.3102 in) in thickness.

• Available thickness of valve lifter: 25 sizes with range 7.88 to 8.36 mm (0.3102 to 0.3291 in) in steps of 0.02 mm (0.0008 in)

(when manufactured at factory). Refer to EM-103, "

Standard

and Limit".

5. Install the selected valve lifter.

WBIA0713E

KBIA0057E

KBIA0119E

Page 1830 of 3061

EM-60

< SERVICE INFORMATION >

CAMSHAFT

6. Install the camshaft.

7. Manually turn the crankshaft pulley a few turns.

8. Make sure the valve clearances for a cold engine are within specifications by referring to the specified val-

ues.

9. After completing the repair, check the valve clearanc es again with the specifications for a warmed engine.

Make sure the values are within specifications.