torque INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 72 of 3061

AT-2

DTC P0700 TCM ................................................98

Description ..............................................................98

On Board Diagnosis Logic ......................................98

Possible Cause .......................................................98

DTC Confirmation Procedure .................................98

Diagnosis Procedure ..............................................98

DTC P0705 PARK/NEUTRAL POSITION

SWITCH .............................................................

99

Description ..............................................................99

CONSULT-II Reference Value in Data Monitor

Mode .......................................................................

99

On Board Diagnosis Logic ......................................99

Possible Cause .......................................................99

DTC Confirmation Procedure .................................99

Wiring Diagram - AT - PNP/SW .............................100

Diagnosis Procedure .............................................100

DTC P0717 TURBINE REVOLUTION SEN-

SOR ..................................................................

103

Description .............................................................103

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

103

On Board Diagnosis Logic .....................................103

Possible Cause ......................................................103

DTC Confirmation Procedure ................................103

Diagnosis Procedure .............................................103

DTC P0720 VEHICLE SPEED SENSOR A/T

(REVOLUTION SENSOR) ...............................

105

Description .............................................................105

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

105

On Board Diagnosis Logic .....................................105

Possible Cause ......................................................105

DTC Confirmation Procedure ................................105

Wiring Diagram - AT - VSSA/T ..............................106

Diagnosis Procedure .............................................107

DTC P0725 ENGINE SPEED SIGNAL ............109

Description .............................................................109

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

109

On Board Diagnosis Logic .....................................109

Possible Cause ......................................................109

DTC Confirmation Procedure ................................109

Diagnosis Procedure .............................................109

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE ..........................................

111

Description .............................................................111

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

111

On Board Diagnosis Logic .....................................111

Possible Cause ......................................................111

DTC Confirmation Procedure ................................111

Diagnosis Procedure .............................................111

DTC P0744 A/T TCC S/V FUNCTION (LOCK-

UP) ...................................................................

113

Description ............................................................113

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

113

On Board Diagnosis Logic ....................................113

Possible Cause .....................................................113

DTC Confirmation Procedure ................................113

Diagnosis Procedure .............................................114

DTC P0745 LINE PRESSURE SOLENOID

VALVE ..............................................................

115

Description ............................................................115

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

115

On Board Diagnosis Logic ....................................115

Possible Cause .....................................................115

DTC Confirmation Procedure ................................115

Diagnosis Procedure .............................................115

DTC P1705 THROTTLE POSITION SENSOR ..117

Description ............................................................117

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

117

On Board Diagnosis Logic ....................................117

Possible Cause .....................................................117

DTC Confirmation Procedure ................................117

Diagnosis Procedure .............................................117

DTC P1710 A/T FLUID TEMPERATURE SEN-

SOR CIRCUIT ...................................................

119

Description ............................................................119

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

119

On Board Diagnosis Logic ....................................119

Possible Cause .....................................................119

DTC Confirmation Procedure ................................119

Wiring Diagram - AT - FTS ...................................120

Diagnosis Procedure .............................................120

Component Inspection ..........................................122

DTC P1721 VEHICLE SPEED SENSOR MTR ..124

Description ............................................................124

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

124

On Board Diagnosis Logic ....................................124

Possible Cause .....................................................124

DTC Confirmation Procedure ................................124

Diagnosis Procedure .............................................124

DTC P1730 A/T INTERLOCK ...........................126

Description ............................................................126

On Board Diagnosis Logic ....................................126

Possible Cause .....................................................126

DTC Confirmation Procedure ................................126

Judgement of A/T Interlock ...................................126

Diagnosis Procedure .............................................127

DTC P1731 A/T 1ST ENGINE BRAKING ........128

Description ............................................................128

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

128

Page 79 of 3061

PRECAUTIONS

AT-9

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

•After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) CONFIRMATION PROCEDURE”.

If the repair is completed the DTC should not be displayed in

the “DTC CONFIRMATION PROCEDURE”.

• Always use the specified brand of ATF. Refer to MA-10

.

• Use paper rags not cloth rags during work.

• After replacing the ATF, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

• Before proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to pre-

vent the internal parts from becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transmission.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

• Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

• It is very important to perform functional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to AT-

15, "A/T Fluid Cooler Cleaning".

• After overhaul, refill the transmission with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT-13, "

Changing Automatic Transmission Fluid (ATF)", AT-13, "Checking Automatic Transmission Fluid

(ATF)".

Service Notice or PrecautionINFOID:0000000003532221

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T fluid cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. For A/T fluid cooler cleaning procedure, refer to AT-15, "

A/T

Fluid Cooler Cleaning". For radiator replacement, refer to CO-13.

CHECKING AND CHANGING A/T FLUID SERVICE

Increase ATF temperature by 80°C (176°F) once, and then check ATF level in 65°C (149°F) when adjusting

ATF level.

NOTE:

JA60 uses both systems of a water-cooling and of an air-cooling. Air-cooling system has a by-pass valve.

When ATF temperature is not over 50°C (122°F) with water-cooling system OFF, it does not flow to air-cooling

system. If ATF level is set without the flow of ATF, the level will be 10mm lower than the standard. Therefore,

piping should be filled with ATF when adjusting level.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. Refer to the table on AT-83,

"CONSULT-II Function (A/T)" for the indicator used to display each self-diagnostic result.

SEF217U

Page 89 of 3061

A/T CONTROL SYSTEM

AT-19

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

A/T CONTROL SYSTEM

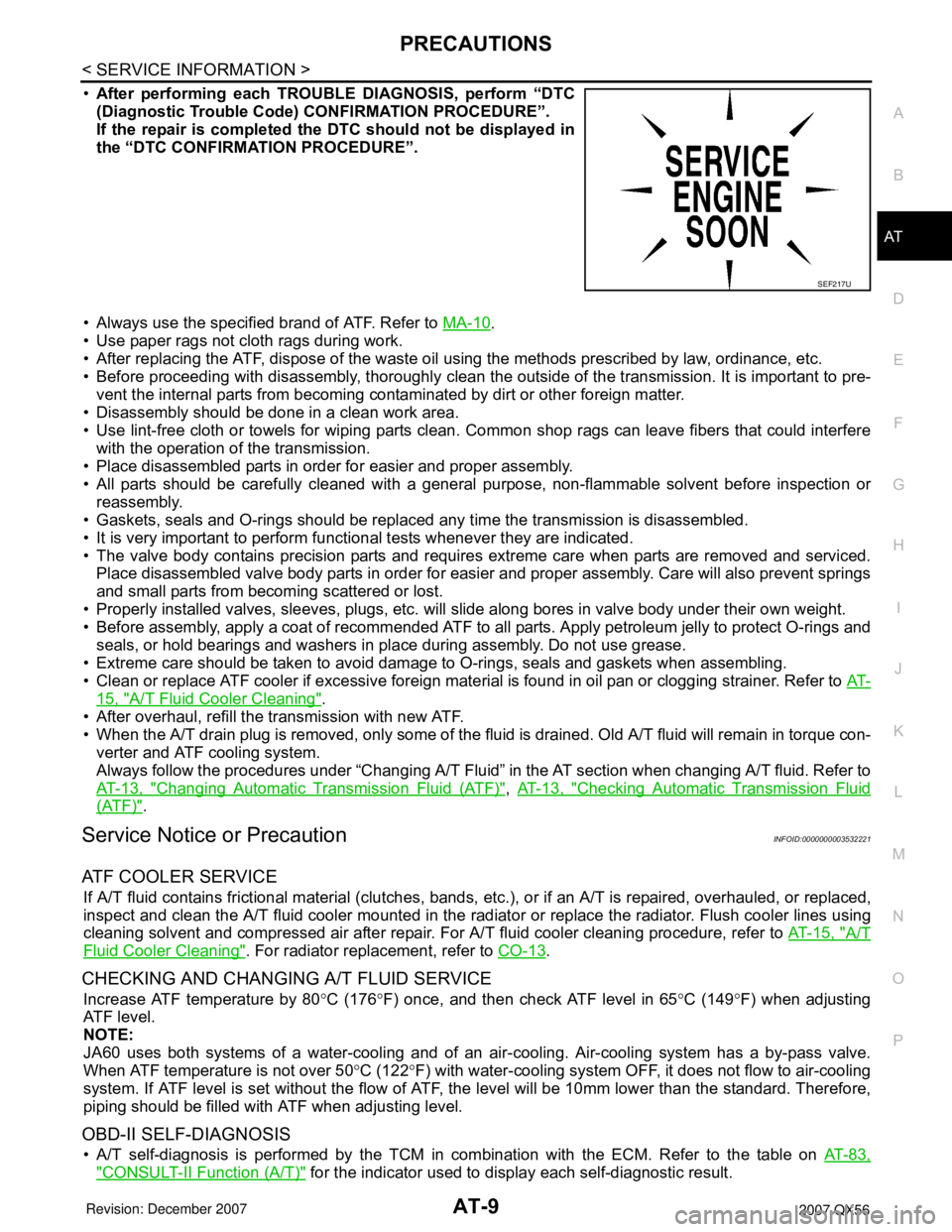

Cross-Sectional View (2WD models)INFOID:0000000003532227

1. Front planetary gear 2. Mid planetary gear 3. Rear planetary gear

4. Direct clutch 5. High and low reverse clutch 6. Reverse brake

7. Drum support 8. Forward brake 9. Low coast brake

10. Input shaft 11. Torque converter 12. Oil pump

13. Front brake 14. 3rd one-way clutch 15. Input clutch

16. 1st one-way clutch 17. Control valve with TCM 18. Forward one-way clutch

19. Rear extension 20. Output shaft

SCIA5267E

Page 90 of 3061

AT-20

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

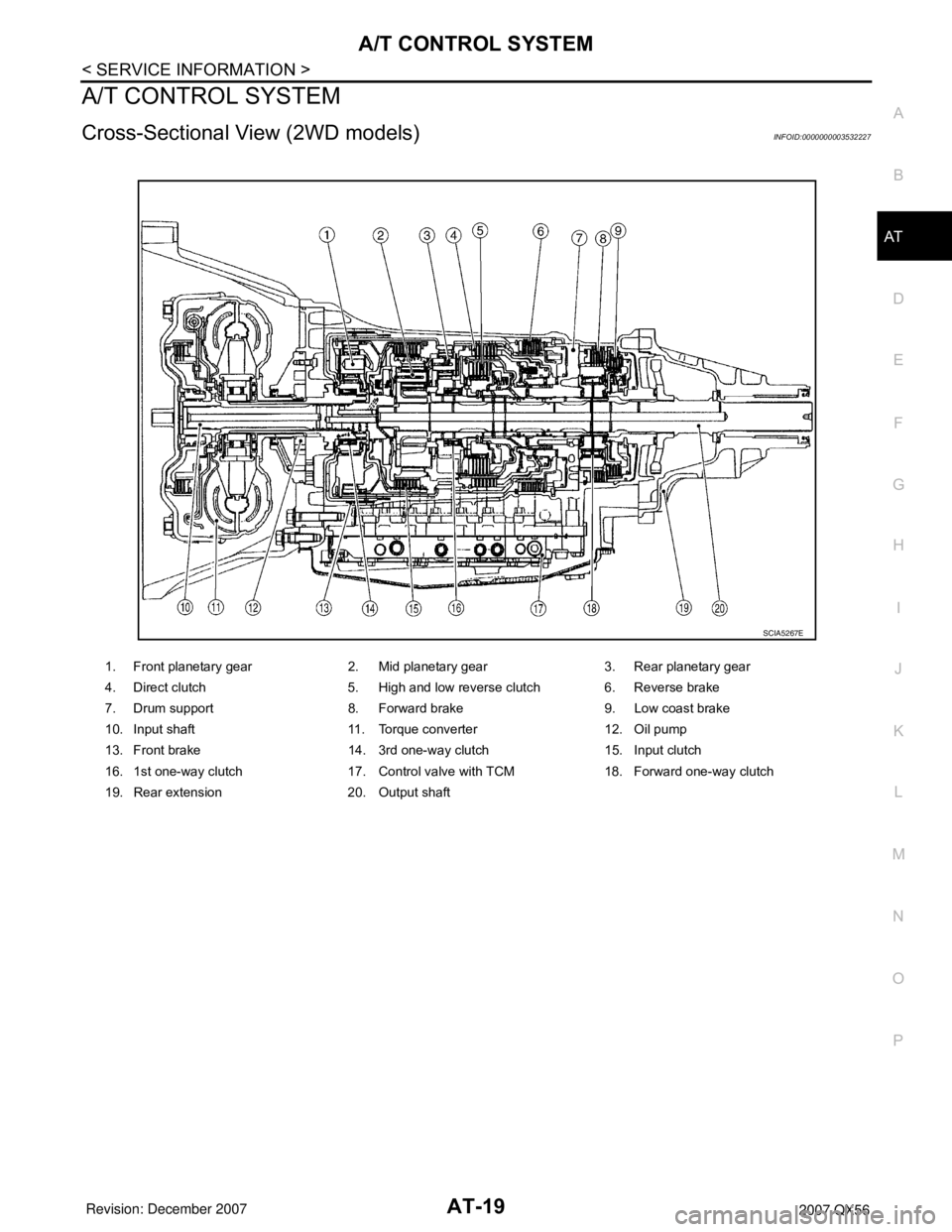

Cross-Sectional View (4WD models)

INFOID:0000000003532228

Shift MechanismINFOID:0000000003532229

The automatic transmission uses compact triple planetary gear systems to improve power-transmission effi-

ciency, simplify construction and reduce weight.

It also employs an optimum shift control and super wide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

CONSTRUCTION

1. Front planetary gear 2. Mid planetary gear 3. Rear planetary gear

4. Direct clutch 5. High and low reverse clutch 6. Reverse brake

7. Drum support 8. Forward brake 9. Low coast brake

10. Input shaft 11. Torque converter 12. Oil pump

13. Front brake 14. 3rd one-way clutch 15. Input clutch

16. 1st one-way clutch 17. Control valve with TCM 18. Forward one-way clutch

19. Adapter case 20. Output shaft

SCIA5268E

Page 93 of 3061

A/T CONTROL SYSTEM

AT-23

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Since both the forward brake and the reverse brake are released, torque from the input shaft drive is not trans-

mitted to the output shaft.

“P” Position

• The same as for the “N” position, both the forward brake and the reverse brake are released, so torque from

the input shaft drive is not transmitted to the output shaft.

• The parking pawl linked with the select lever meshes with the parking gear and fastens the output shaft

mechanically.

“D”, “4”, “3”, “2” Positions 1st Gear

• The forward brake and the forward one-way clutch regulate reverse rotation of the mid sun gear.

• The 1st one-way clutch regulates reverse rotation of the rear sun gear.

• The 3rd one-way clutch regulates reverse rotation of the front sun gear.

• During deceleration, the mid sun gear turns forward, so the forward one-way clutch idles and the engine

brake is not activated.

1. Front brake 2. Input clutch 3. Direct clutch

4. High and low reverse clutch 5. Reverse brake 6. Forward brake

7. Low coast brake 8. 1st one-way clutch 9. Forward one-way clutch

10. 3rd one-way clutch 11. Front sun gear 12. Input shaft

13. Mid internal gear 14. Front internal gear 15. Rear carrier

16. Rear sun gear 17. Mid sun gear 18. Front carrier

19. Mid carrier 20. Rear internal gear 21. Output shaft

22. Parking gear 23. Parking pawl

PCIA0003J

Page 102 of 3061

AT-32

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

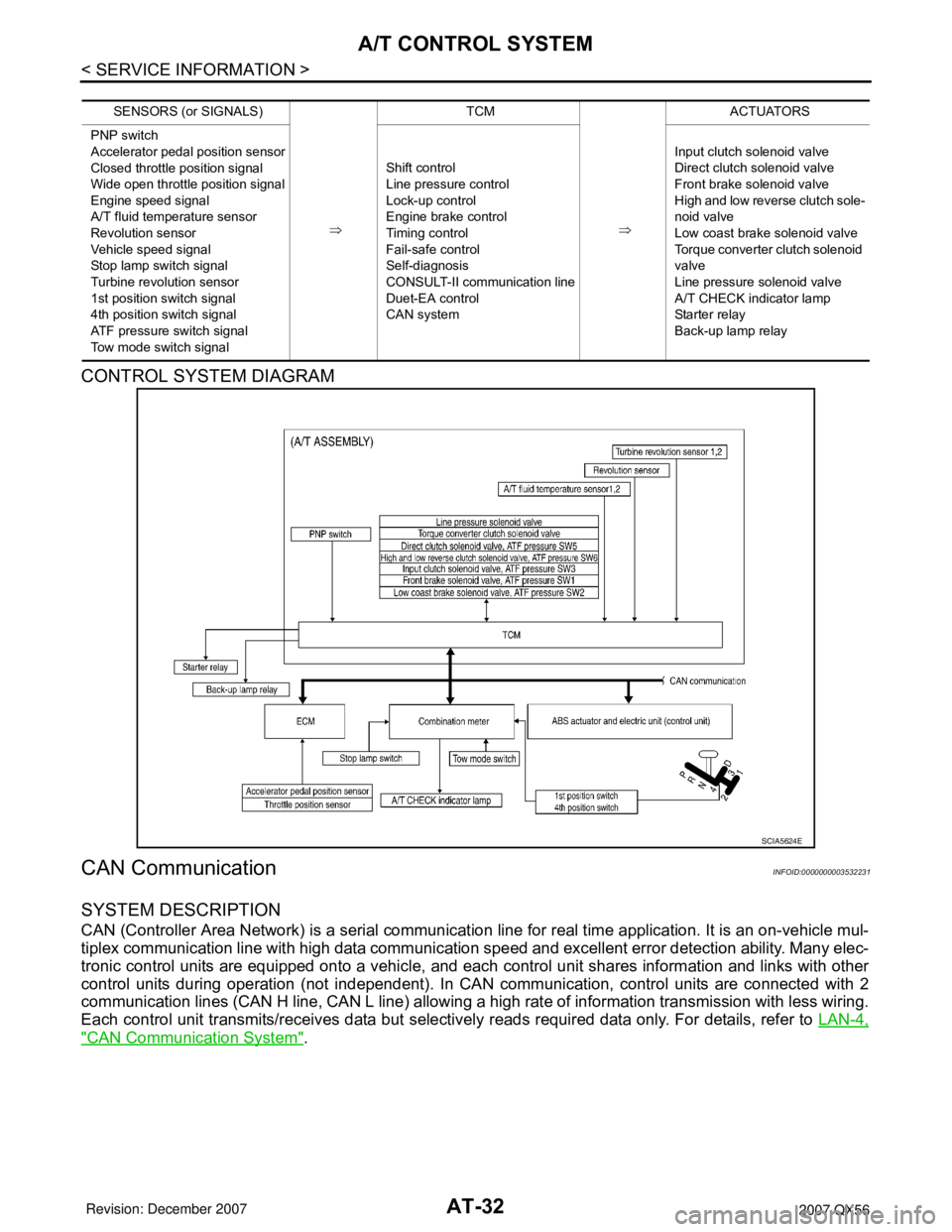

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000003532231

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-4,

"CAN Communication System".

SENSORS (or SIGNALS)

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position sensor

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Stop lamp switch signal

Turbine revolution sensor

1st position switch signal

4th position switch signal

ATF pressure switch signal

Tow mode switch signalShift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

Duet-EA control

CAN systemInput clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

SCIA5624E

Page 103 of 3061

A/T CONTROL SYSTEM

AT-33

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Input/Output Signal of TCMINFOID:0000000003532232

*1: Spare for vehicle speed sensor·A/T (revolution sensor)

*2: Spare for accelerator pedal position signal

*3: If these input and output signals are different, the TCM triggers the fail-safe function.

*4: CAN communications

Line Pressure ControlINFOID:0000000003532233

• When an input torque signal equivalent to the engine drive force is sent from the ECM to the TCM, the TCM

controls the line pressure solenoid.

Control itemLine

pressure

controlVehicle

speed

controlShift

controlLock-up

controlEngine

brake

controlFail-safe

function

(*3)Self-diag-

nostics

function

InputAccelerator pedal position signal

(*4)XXXXXXX

Vehicle speed sensor A/T

(revolution sensor)XXXX XX

Vehicle speed sensor MTR

(*1) (*4)XXXX X

Closed throttle position signal

(*4)(*2) X (*2) X X (*2) X X

Wide open throttle position signal

(*4)(*2) X (*2) X (*2) X X

Turbine revolution sensor 1 X X X X X

Turbine revolution sensor 2

(for 4th speed only)XXXXX

Engine speed signals

(*4)XX

PNP switch XXXXXXX

A/T fluid temperature sensors 1, 2 X X X X X X X

ASCDOperation signal

(*4)XXXX

Overdrive cancel sig-

nal

(*4)XXX

TCM power supply voltage signal X X X X X X

Out-

putDirect clutch solenoid (ATF pressure

switch 5)XX XX

Input clutch solenoid (ATF pressure

switch 3)XX XX

High and low reverse clutch sole-

noid (ATF pressure switch 6)XX XX

Front brake solenoid (ATF pressure

switch 1)XX XX

Low coast brake solenoid (ATF

pressure switch 2)XX XXX

Line pressure solenoid X X X X X X X

TCC solenoid X X X

Starter relayXX

Page 105 of 3061

A/T CONTROL SYSTEM

AT-35

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

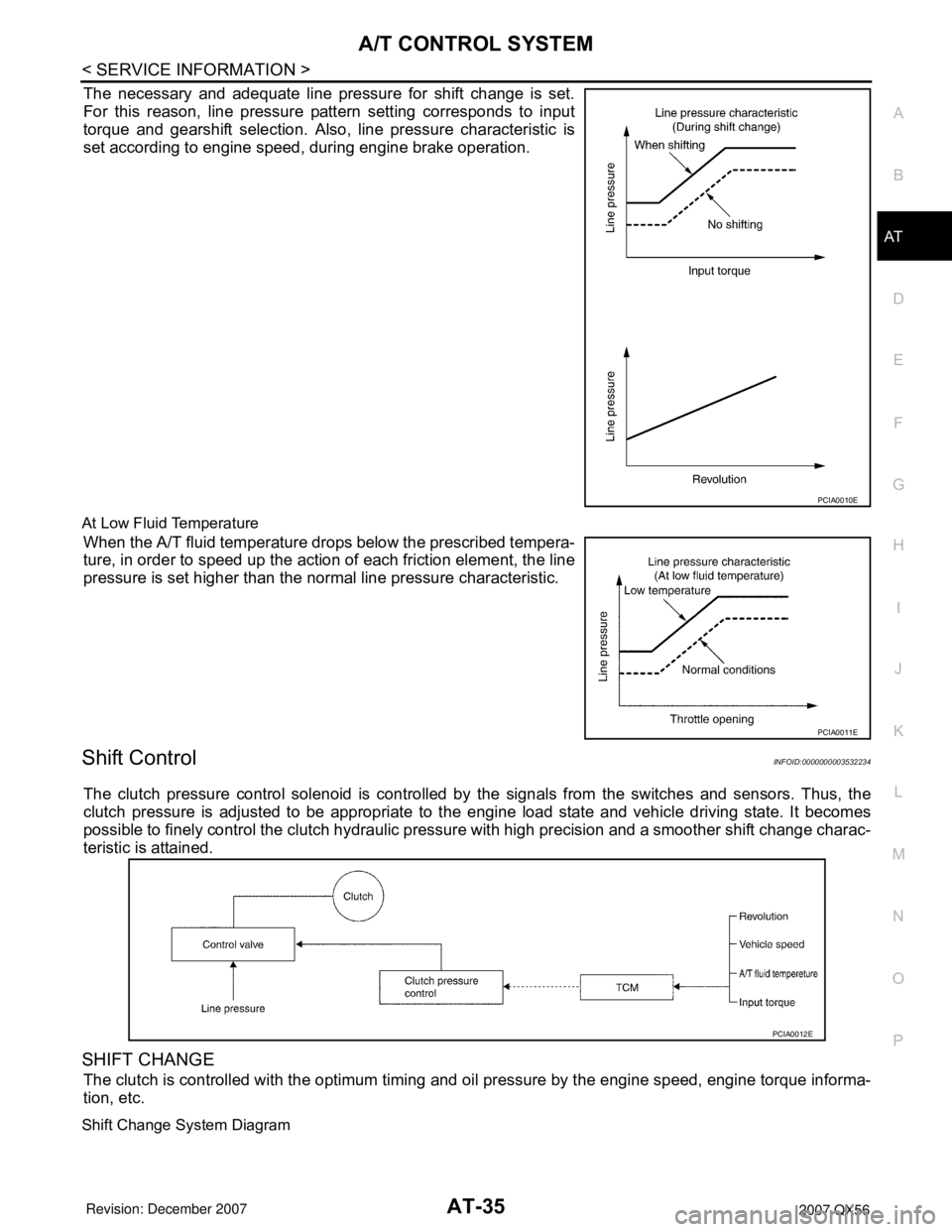

The necessary and adequate line pressure for shift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

set according to engine speed, during engine brake operation.

At Low Fluid Temperature

When the A/T fluid temperature drops below the prescribed tempera-

ture, in order to speed up the action of each friction element, the line

pressure is set higher than the normal line pressure characteristic.

Shift ControlINFOID:0000000003532234

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to the engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressure with high precision and a smoother shift change charac-

teristic is attained.

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

PCIA0010E

PCIA0011E

PCIA0012E

Page 106 of 3061

AT-36

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

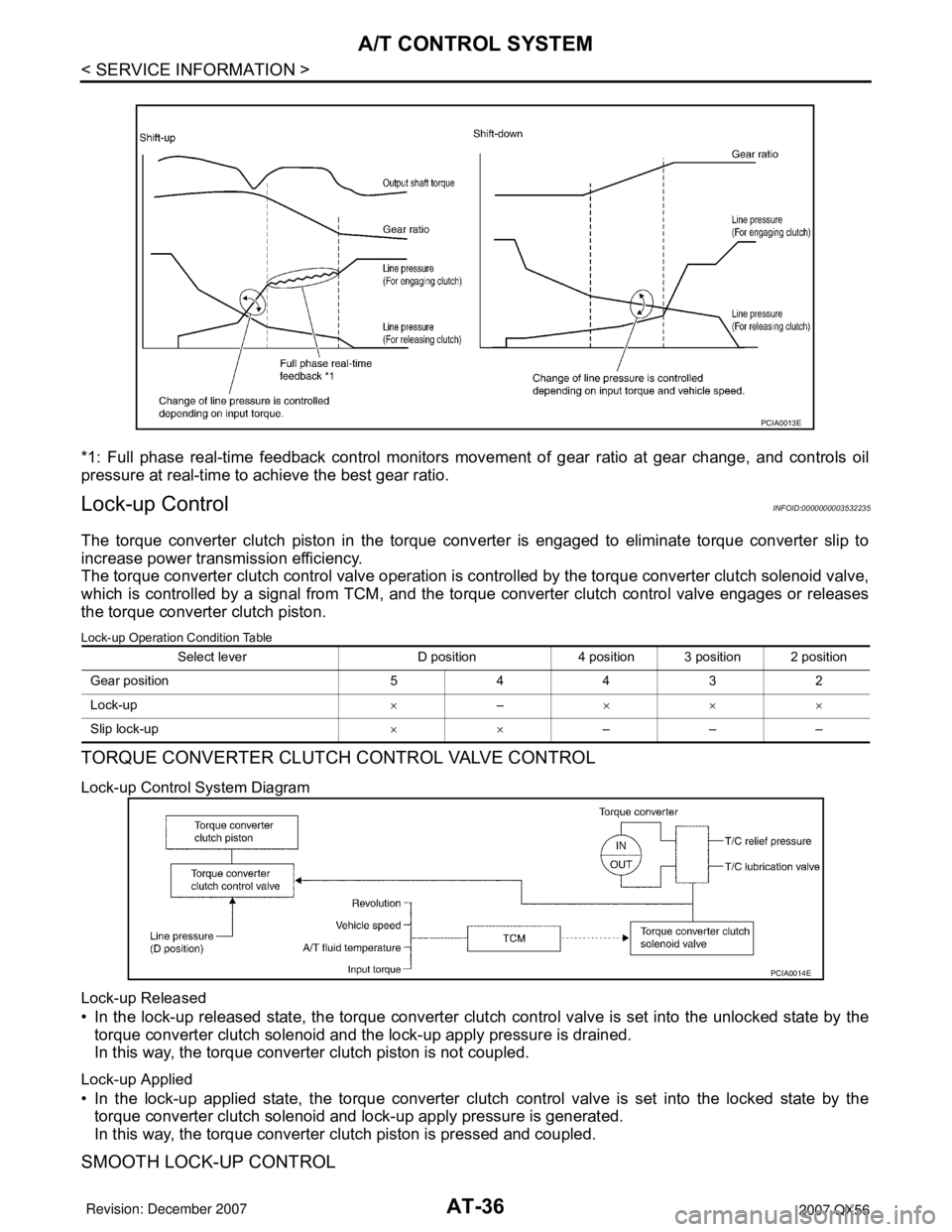

*1: Full phase real-time feedback control monitors movement of gear ratio at gear change, and controls oil

pressure at real-time to achieve the best gear ratio.

Lock-up ControlINFOID:0000000003532235

The torque converter clutch piston in the torque converter is engaged to eliminate torque converter slip to

increase power transmission efficiency.

The torque converter clutch control valve operation is controlled by the torque converter clutch solenoid valve,

which is controlled by a signal from TCM, and the torque converter clutch control valve engages or releases

the torque converter clutch piston.

Lock-up Operation Condition Table

TORQUE CONVERTER CLUTCH CONTROL VALVE CONTROL

Lock-up Control System Diagram

Lock-up Released

• In the lock-up released state, the torque converter clutch control valve is set into the unlocked state by the

torque converter clutch solenoid and the lock-up apply pressure is drained.

In this way, the torque converter clutch piston is not coupled.

Lock-up Applied

• In the lock-up applied state, the torque converter clutch control valve is set into the locked state by the

torque converter clutch solenoid and lock-up apply pressure is generated.

In this way, the torque converter clutch piston is pressed and coupled.

SMOOTH LOCK-UP CONTROL

PCIA0013E

Select lever D position 4 position 3 position 2 position

Gear position 5 4 4 3 2

Lock-up×–×××

Slip lock-up××–––

PCIA0014E

Page 107 of 3061

A/T CONTROL SYSTEM

AT-37

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

• The current output from the TCM to the torque converter clutch solenoid is varied to gradually increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put into

half-clutched status, the torque converter clutch piston operating pressure is increased and the coupling is

completed smoothly.

Slip Lock-up Control

• In the slip region, the torque converter clutch solenoid current is controlled with the TCM to put it into the

half-clutched state. This absorbs the engine torque fluctuation and lock-up operates from low speed.

This raises the fuel efficiency for 4th and 5th gears at both low speed and when the accelerator has a low

degree of opening.

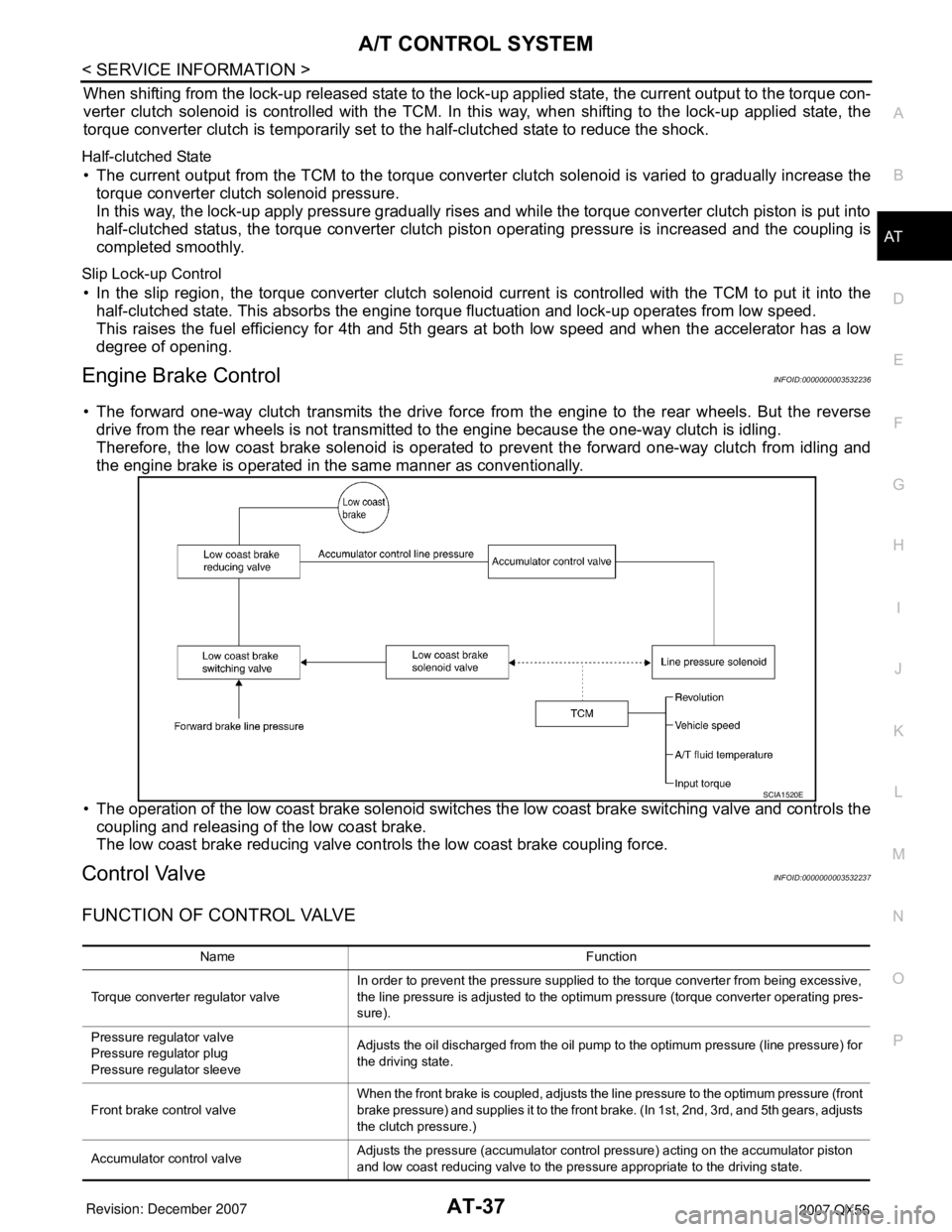

Engine Brake ControlINFOID:0000000003532236

• The forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

• The operation of the low coast brake solenoid switches the low coast brake switching valve and controls the

coupling and releasing of the low coast brake.

The low coast brake reducing valve controls the low coast brake coupling force.

Control ValveINFOID:0000000003532237

FUNCTION OF CONTROL VALVE

SCIA1520E

Name Function

Torque converter regulator valveIn order to prevent the pressure supplied to the torque converter from being excessive,

the line pressure is adjusted to the optimum pressure (torque converter operating pres-

sure).

Pressure regulator valve

Pressure regulator plug

Pressure regulator sleeveAdjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valveWhen the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1st, 2nd, 3rd, and 5th gears, adjusts

the clutch pressure.)

Accumulator control valveAdjusts the pressure (accumulator control pressure) acting on the accumulator piston

and low coast reducing valve to the pressure appropriate to the driving state.