remote control INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 693 of 3061

BCS-6

< SERVICE INFORMATION >

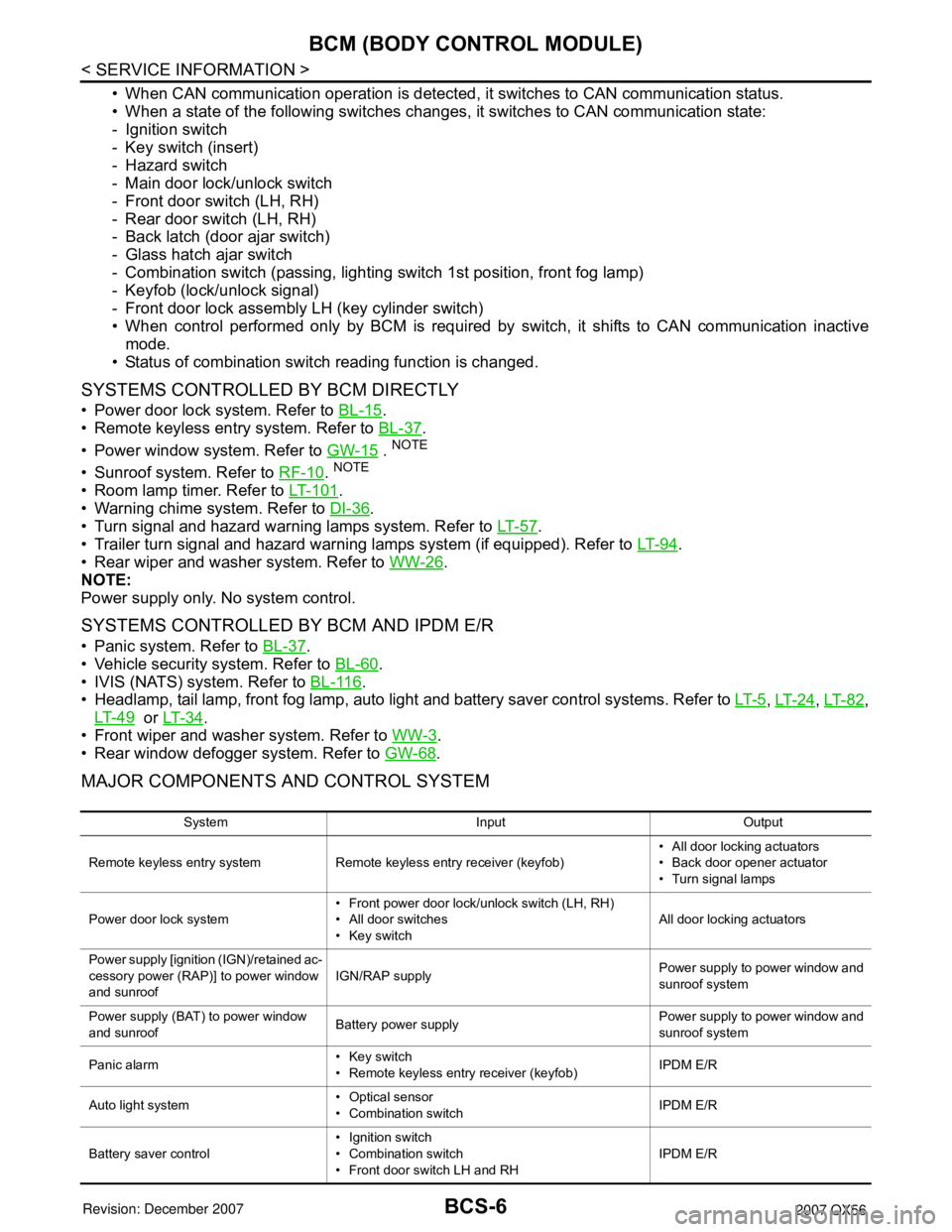

BCM (BODY CONTROL MODULE)

• When CAN communication operation is detected, it switches to CAN communication status.

• When a state of the following switches changes, it switches to CAN communication state:

- Ignition switch

- Key switch (insert)

- Hazard switch

- Main door lock/unlock switch

- Front door switch (LH, RH)

- Rear door switch (LH, RH)

- Back latch (door ajar switch)

- Glass hatch ajar switch

- Combination switch (passing, lighting switch 1st position, front fog lamp)

- Keyfob (lock/unlock signal)

- Front door lock assembly LH (key cylinder switch)

• When control performed only by BCM is required by switch, it shifts to CAN communication inactive

mode.

• Status of combination switch reading function is changed.

SYSTEMS CONTROLLED BY BCM DIRECTLY

• Power door lock system. Refer to BL-15.

• Remote keyless entry system. Refer to BL-37

.

• Power window system. Refer to GW-15

. NOTE

• Sunroof system. Refer to RF-10. NOTE

• Room lamp timer. Refer to LT-101.

• Warning chime system. Refer to DI-36

.

• Turn signal and hazard warning lamps system. Refer to LT- 5 7

.

• Trailer turn signal and hazard warning lamps system (if equipped). Refer to LT- 9 4

.

• Rear wiper and washer system. Refer to WW-26

.

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-37.

• Vehicle security system. Refer to BL-60

.

• IVIS (NATS) system. Refer to BL-116

.

• Headlamp, tail lamp, front fog lamp, auto light and battery saver control systems. Refer to LT- 5

, LT- 2 4, LT- 8 2,

LT- 4 9

or LT- 3 4.

• Front wiper and washer system. Refer to WW-3

.

• Rear window defogger system. Refer to GW-68

.

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system Remote keyless entry receiver (keyfob)• All door locking actuators

• Back door opener actuator

• Turn signal lamps

Power door lock system• Front power door lock/unlock switch (LH, RH)

• All door switches

• Key switchAll door locking actuators

Power supply [ignition (IGN)/retained ac-

cessory power (RAP)] to power window

and sunroofIGN/RAP supplyPower supply to power window and

sunroof system

Power supply (BAT) to power window

and sunroofBattery power supplyPower supply to power window and

sunroof system

Panic alarm• Key switch

• Remote keyless entry receiver (keyfob)IPDM E/R

Auto light system• Optical sensor

• Combination switchIPDM E/R

Battery saver control• Ignition switch

• Combination switch

• Front door switch LH and RHIPDM E/R

Page 694 of 3061

BCM (BODY CONTROL MODULE)

BCS-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

CAN Communication System DescriptionINFOID:0000000003533597

Refer to LAN-4.

Headlamp Combination switch IPDM E/R

Tail lamp Combination switch IPDM E/R

Front fog lamp Combination switch IPDM E/R

Turn signal lamp Combination switch• Turn signal lamp

• Combination meter

Hazard lamp Hazard switch• Turn signal lamp

• Combination meter

Room lamp timer• Key switch

• Remote keyless entry receiver (keyfob)

• Main power window and door lock/unlock switch

• Front door lock assembly LH (key cylinder switch)

• All door switchesInterior room lamp

Key warning chime• Key switch

• Front door switch LHCombination meter (warning buzz-

er)

Light warning chime• Combination switch

• Key switch

• Front door switch LHCombination meter (warning buzz-

er)

Vehicle-speed-sensing intermittent wip-

er• Combination switch

• Combination meterIPDM E/R

Rear window defogger Rear window defogger switch IPDM E/R

Air conditioner switch signal Front air control ECM

Blower fan switch signal Front air control ECM

Low tire pressure warning system Remote keyless entry receiver• Combination meter

• Display control unit

Trailer tow (if equipped) Combination switch Trailer turn signal relays

Vehicle security system• Remote keyless entry receiver (keyfob)

• Main power window and door lock/unlock switch

• Power window and door lock/unlock switch RH

• Front door lock assembly LH (key cylinder switch)

• All door switches

• Back door latch (door ajar switch)• IPDM E/R

• Security indicator lamp System Input Output

Page 699 of 3061

BCS-12

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

18 PRemote keyless entry

receiver and optical

sensor (ground)Output OFF — 0V

19 V/WRemote keyless entry

receiver (power sup-

ply)Output OFF Ignition switch OFF

20 G/WRemote keyless entry

receiver signal (Sig-

nal)Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. InputOFF →

ONIgnition switch (OFF → ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then

return to battery voltage.

22 W/V BUS — —Ignition switch ON or power

window timer operates

23 G/OSecurity indicator

lampOutput OFFGoes OFF → illuminates (Ev-

ery 2.4 seconds)Battery voltage → 0V

25 BR NATS antenna amp. InputOFF →

ONIgnition switch (OFF → ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then

return to battery voltage.

26 Y/LRear wiper auto stop

switch 2Input ONRise up position (rear wiper

arm on stopper)0V

A Position (full clockwise stop

position)0V

Forward sweep (counterclock-

wise direction)Fluctuating

B Position (full counterclock-

wise stop position)Battery voltage

Reverse sweep (clockwise di-

rection)Fluctuating Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value or waveform

(Approx.) Ignition

switchOperation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Page 704 of 3061

BCM (BODY CONTROL MODULE)

BCS-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

ITEMS OF EACH PART

NOTE:

CONSULT-II will only display systems the vehicle possesses.

WORK SUPPORT

BCM diagnostic

test itemDiagnostic mode Content

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT

MNTRThe results of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

System and itemCONSULT-II

displayDiagnostic test mode (Inspection by part)

WORK

SUPPORTSELF−

DIAG RE-

SULTSCAN DIAG

SUPPORT

MNTRDATA

MONITORECU

PA R T

NUMBERAC-

TIVE

TESTCON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock system DOOR LOCK×××

Rear defoggerREAR

DEFOGGER××

Warning chime BUZZER××

Room lamp timer INT LAMP×××

Remote keyless entry

systemMULTI REMOTE

ENT×××

Headlamp HEAD LAMP×××

Wiper (front/rear) WIPER×××

Turn signal lamp

Hazard lampFLASHER××

Blower fan switch signal

Air conditioner switch

signalAIR

CONDITIONER×

Combination switch COMB SW×

IVIS (NATS) IMMU××

Interior lamp battery

saverBATTERY SAV-

ER×××

Back door TRUNK××

Theft alarm THEFT ALM×××

Retained accessory

power controlRETAINED PWR×××

Oil pressure switch SIGNAL BUFFER××

Low tire pressure moni-

tor systemAIR PRESSURE

MONITOR×× × ×

Panic alarm PANIC ALARM×

Page 712 of 3061

BL-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

N

O

P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for work ...................................................3

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

5

Work Flow .................................................................5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

HOOD .................................................................11

Fitting Adjustment ...................................................11

Removal and Installation of Hood Assembly ...........12

Removal and Installation of Hood Lock Control ......13

Hood Lock Control Inspection .................................14

POWER DOOR LOCK SYSTEM ........................15

Component Parts and Harness Connector Loca-

tion ..........................................................................

15

System Description .................................................15

Schematic ...............................................................18

Wiring Diagram - D/LOCK - .....................................19

Terminal and Reference Value for BCM .................23

Work Flow ...............................................................23

CONSULT-II Function (BCM) ..................................24

Trouble Diagnosis Symptom Chart .........................25

BCM Power Supply and Ground Circuit Inspection

....

25

Door Switch Check ..................................................25

Key Switch (Insert) Check .......................................27

Door Lock/Unlock Switch Check .............................28

Glass Hatch Switch Circuit Inspection ....................30

Front Door Lock Assembly LH (Actuator) Check ....32

Front Door Lock Actuator RH Check .......................32

Rear Door Lock Actuator RH/LH Check ..................33

Glass Hatch Lock Actuator Check ...........................34

Front Door Lock Assembly LH (Key Cylinder

Switch) Check ..........................................................

35

REMOTE KEYLESS ENTRY SYSTEM .............37

Component Parts and Harness Connector Loca-

tion ...........................................................................

37

System Description ..................................................37

CAN Communication System Description ...............40

Schematic ................................................................41

Wiring Diagram - KEYLES - ....................................42

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ..........44

CONSULT-II Function (BCM) ..................................45

CONSULT-II Start Procedure ..................................45

CONSULT-II Application Item ..................................45

Trouble Diagnosis Procedure ..................................47

BCM Power Supply and Ground Circuit Inspection

....

47

Trouble Diagnosis ....................................................47

Key Switch (Insert) Check .......................................49

Door Switch Check ..................................................49

Keyfob Battery and Function Check ........................52

Remote Keyless Entry Receiver System Inspec-

tion ...........................................................................

53

ACC Power Check ...................................................54

IPDM E/R Operation Check .....................................54

Check Hazard Function ...........................................55

Check Horn Function ...............................................55

Check Headlamp Function ......................................55

Check Map Lamp Illumination Function ..................56

ID Code Entry Procedure ........................................56

Keyfob Battery Replacement ...................................59

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ............................................................

60

Component Parts and Harness Connector Loca-

tion ...........................................................................

60

System Description ..................................................61

Page 749 of 3061

BL-38

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

• to BCM terminal 70

• through 50A fusible link (letter f , located in the fuse and fusible link box).

• to BCM terminal 57

• through 15A fuse [No. 22, located in the fuse block (J/B)].

When the key is inserted in the key switch and key lock solenoid, power is supplied

• to BCM terminal 37

• through key switch and key lock solenoid terminals 3 and 4

• through 10A fuse [No. 19, located in the fuse block (J/B)].

When the ignition switch is ACC or ON, power is supplied

• to BCM terminal 11

• through 10A fuse [No. 4, located in the fuse block (J/B)].

When the ignition switch is ON or START, power is supplied

• to BCM terminal 38

• through 10A fuse (No. 59, located in the fuse and relay box).

When the front door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

When the rear door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 2

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 2

• through rear door switch RH case ground.

When the back door latch (door ajar switch) is ON (door is OPEN), ground is supplied

• to BCM terminal 43

• through back door latch (door ajar switch) terminal 7,

• through back door latch (door ajar switch) terminal 8,

• through body grounds B7 and B19.

Keyfob signal is input into the BCM from the remote keyless entry receiver.

The remote keyless entry system controls operation of the

• power door lock

• back door opener

• interior lamp and step lamps

• panic alarm

• hazard and horn reminder

• keyless power window down (open)

• auto door lock operation

OPERATING PROCEDURE

• When the keyfob is operated, the signal from the keyfob is sent and the remote keyless entry receiver

receives the signal and sends it to the BCM. The BCM only locks/unlocks the doors if the ID number

matches. (Remote control entry functions)

• Using the keyfob, the transmitter sends radio waves to the remote keyless entry receiver, which then sends

the received waves to the BCM. Only if the ID number matches does the BCM lock/unlock the doors.

(Remote control door function)

• Unless the key is inserted into the ignition key cylinder or one of the doors is opened within 1 minute after the

UNLOCK switch on the keyfob is pressed, all the doors are automatically locked. (Auto lock function)

• When a door is locked or unlocked, the vehicle turn signal lamps flash and the horn sounds to verify opera-

tion. (Active check function)

• When the key is in the ignition key cylinder (when the key switch is ON) and one of the doors is open, the

door lock function does not work even when the door lock is operated with the keyfob.

• Keyfob ID set up is available.

• If a keyfob is lost, a new keyfob can be set up. A maximum of 5 IDs can be set up simultaneously.

Remote Control Entry Functions

Page 750 of 3061

REMOTE KEYLESS ENTRY SYSTEM

BL-39

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Operation Description

• When a button on the keyfob is operated, the signal is sent from the keyfob and received by the remote key-

less entry receiver.

• The received signal is sent to the BCM and compared with the registered ID number.

• If the ID number matches, the BCM sends the lock/unlock signal to each door lock actuator.

• When the door lock actuators receive this signal, each operates to lock/unlock its door.

• BCM locks all doors with input of LOCK signal from keyfob.

• When an UNLOCK signal is sent from keyfob once, driver's door will be unlocked.

• Then, if an UNLOCK signal is sent from keyfob again within 5 seconds, all other doors will be unlocked.

Remote control entry operation conditions

Auto Lock Function

Operation Description

• Unless the key is inserted into the ignition key cylinder, one of the doors is opened, or the keyfob is operated

within 1 minute after a door lock is unlocked by keyfob operation, all the doors are automatically locked.

The 1 minute timer count is executed by the BCM and after 1 minute, the BCM sends the lock signal to all

doors.

Lock operations are the same as for the remote control entry function.

Remote Control Automatic Back Door Function

Switching from all closed to all open

• When a button on the keyfob is operated, the signal is sent from the keyfob and received by the remote key-

less entry receiver.

• The received signal is sent to the BCM and compared with the registered ID number.

• If the ID number matches, the BCM uses power window serial link communication to send the back door

open signal to the back door control unit

• When the back door control unit receives the back door open signal for 0.5 seconds, if the remote control

automatic back door operation enable conditions are met, the warning chime is sounded and the back door

unlock signal is sent to the back door latch using communication.

• When the back door latch receives the back door unlock signal, it operates the release actuator and

releases to back door latch.

• The back door control unit operates the back door motor to open the back door. (At this time, speed control,

input reverse, and overload reverse control are executed.)

• When the back door is opened to the fully open position, the full-open position is detected with the rotation

sensor, the back door motor is stopped.

• The door held by the back door stays at the full open position.

Full open → full closed operation

• When a button of the keyfob is operated, the signal is sent from the keyfob and received by the remote key-

less entry receiver.

• The received signal is sent to the BCM and compared with the registered ID number.

• If the ID number matches, the BCM uses power window serial link communication to send the back door

close request signal to the back door control unit.

• When the back door control unit receives the back door close request signal for 0.5 seconds, if the remote

control automatic back door operation enable conditions are met, the warning chime is sounded and the

back door motor begins closing the back door.

• The back door control unit operates the magnetic clutch and the back door motor to close the back door. (At

this time, the back door control unit executes speed control, input reverse, and overload reverse control.)

• When the back door comes to the half-latch state, the back door latch detects the half-latch state through

half-latch switch operation. The back door latch latches the back door.

For the automatic back door system operation enable conditions, refer to BL-80

.

Active Check Function

Operation Description

When a door is locked or unlocked by keyfob operation, the vehicle turn signals flash and the horn sounds to

verify operation.

• When a button on the keyfob is operated, the signal is sent from the remote controller and received by the

keyless remote entry receiver.

Keyfob operation Operation condition

Door lock operation (locking)• With key removed (key switch: OFF)

• Closing all doors (door switch: OFF)

Door lock operation (unlocking) With key removed (key switch: OFF)

Page 767 of 3061

BL-56

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

Check Map Lamp Illumination Function

INFOID:0000000003532935

1.CHECK MAP LAMP ILLUMINATION FUNCTION

When map lamp switch is in DOOR position, open the front door LH or RH.

OK or NG

OK >> System is OK.

NG >> Check map lamp illumination circuit. Refer to LT-120

.

ID Code Entry ProcedureINFOID:0000000003532936

KEYFOB ID SET UP WITH CONSULT-II

NOTE:

•If a keyfob is lost, the ID code of the lost keyfob must be erased to prevent unauthorized use. A spe-

cific ID code can be erased with CONSULT-II. However, when the ID code of a lost keyfob is not

known, all controller ID codes should be erased. After all ID codes are erased, the ID codes of all

remaining and/or new keyfobs must be re-registered.

•When registering an additional keyfob, the existing ID codes in memory may or may not be erased. If

five ID codes are stored in memory when an additional code is registered, only the oldest code is

erased. If less than five codes are stored in memory when an additional code is registered, the new

ID code is added and no ID codes are erased.

•Entry of a maximum of five ID codes is allowed. When more than five codes are entered, the oldest ID

code will be erased.

•Even if the same ID code that is already in memory is input, the same ID code can be entered. The

code is counted as an additional code.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to the

data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)”.Map lamp and ignition keyhole illumination should illuminate.

BBIA0336E

BCIA0029E

Page 769 of 3061

BL-58

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

KEYFOB ID SET UP WITHOUT CONSULT-II

NOTE:

• If a keyfob is lost, the ID code of the lost keyfob must be erased to prevent unauthorized use. A specific ID

code can be erased with CONSULT-II. However, when the ID code of a lost keyfob is not known, all control-

ler ID codes should be erased. After all ID codes are erased, the ID codes of all remaining and/or new key-

fobs must be re-registered.

To erase all ID codes in memory, register one ID code (keyfob) five times. After all ID codes are erased, the

ID codes of all remaining and/or new keyfobs must be re-registered.

LIIA1670E

Page 792 of 3061

AUTOMATIC BACK DOOR SYSTEM

BL-81

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

The automatic back door system must be initialized by fully closing the back door anytime the battery

power is lost to the back door control unit.

The automatic back door system consists of a one piece unit that combines the back door control unit along

with the back door motor, back door clutch and the back door encoder. The back door latch contains a lock

function that can control the two functions of automatic back door latch closure and electrical opener with a

single motor when you close the back door to the halfway-state.

• Back door auto closure

When the back door is closed to the halfway state (half-latch) position, the motor automatically drives to

rotate the latch lever and pull it in from half latched to full latched.

• Power back door

With the back door closed, press the power liftgate switch or press the keyfob button, or pull the back door

handle with the back door unlocked, the back door latch motor opens the locking plate and releases the

latch. The back door motor then raises the door to the full open position.

With the back door fully open, press the power liftgate switch, keyfob button or the back door close switch,

the back door motor closes the door to the half-latch state. The back door latch motor then drives the latch to

the full close position.

At the onset of each power open or power close application, the hazard lamps will flash 3 times and the

warning chime will sound 3 times lasting a total of 2 seconds.

OPERATION DESCRIPTION

Power Liftgate Switch Operation (Fully Closed → Fully Open Operation)

• When the power liftgate switch is pressed, back door control unit terminal 23 receives the signal.

• The back door control unit checks the A/T selector lever (P position) through terminal 18, vehicle speed

through terminal 21, ignition status through terminal 7, glass hatch is closed through terminal 17 and battery

voltage is present through terminal 3.

• When the back door control unit receives the signal, if the auto back door operating enable conditions are

met, it sends a 5 volt signal through terminal 6 and grounds terminal 9 to sound the warning chime, sends a

signal to the BCM through terminal 4 to flash the hazard lamps and unlocks the back door latch through ter-

minal 12.

• The back door control unit supplies power to the magnetic clutch and the back door motor and moves the

back door in the open direction. (At this time, it also executes speed control, input reverse, and anti-pinch

detection control.)

• When the back door is opened to the full-open position, the full-open position is detected by the encoder,

and the back door control unit switches the back door motor OFF and the magnetic clutch is pulsed and then

turned OFF.

• The back door is held in the fully open position by the gas stays.

Remote Keyless Entry Operation (Fully Closed → Fully Open Operation)

• When the keyfob button is pressed for at least 0.5 seconds, back door control unit terminal 21 receives the

signal.

• The back door control unit checks the A/T selector lever (P position) through terminal 18, vehicle speed

through terminal 21, ignition status through terminal 7, glass hatch is closed through terminal 17 and battery

voltage is present through terminal 3.

• When the back door control unit receives the signal, if the auto back door operating enable conditions are

met, it sends a 5 volt signal through terminal 6 and grounds terminal 9 to sound the warning chime, sends a

signal to the BCM through terminal 4 to flash the hazard lamps and unlocks the back door latch through ter-

minal 12.

• The back door control unit supplies power to the magnetic clutch and the back door motor and moves the

back door in the open direction. (At this time, it also executes speed control, input reverse, and anti-pinch

detection control.)

• When the back door is opened to the full-open position, the full-open position is detected by the encoder,

and the back door control unit switches the back door motor OFF and the magnetic clutch is pulsed and then

turned OFF.

• The back door is held in the fully open position by the gas stays.

Back Door Handle Switch Operation (Fully Closed → Fully Open Operation)

• When the back door handle is pulled, back door control unit terminal 26 receives the signal.

• The back door control unit checks that the back door is unlocked and checks the A/T selector lever (P posi-

tion) through terminal 18, vehicle speed through terminal 21, ignition status through terminal 7, glass hatch is

closed, battery voltage and back door close switch position through terminal 13.

• When the back door control unit receives the signal, if all auto back door operating enable conditions are

met, it sends a 5 volt signal through terminal 6 and grounds terminal 9 to sound the warning chime, sends a