warning INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 49 of 3061

![INFINITI QX56 2007 Factory User Guide ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK INFINITI QX56 2007 Factory User Guide ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK](/img/42/57029/w960_57029-48.png)

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK

Are any items other than “DTC 11 CONTROL UNIT” indicated on self-diagnosis display?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test" . Then perform self-diagnosis of ICC system again.

NO >> Replace ICC unit. Refer to ACS-55

. Erase DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

DTC 12 VDC CONTROL UNITINFOID:0000000003533796

1.DIAGNOSIS CHECK

With CONSULT-II

Perform self-diagnosis of ABS actuator and electric unit (control unit). Is malfunction indicated?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test". Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2.CHECK CONNECTOR ICC UNIT AND ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

1. Turn ignition switch OFF.

2. Disconnect ICC unit, and ABS actuator and electric unit (control unit) connectors, and connect them

securely again. Erase DTC, then perform self-diagnosis of ICC system again.

OK or NG

OK >> Poor connector connection. Check connector housing for disconnected, loose, bent and collapsed

terminals. If any malfunction is detected, repair as necessary. Erase DTC and perform ICC sys-

tem running test. Refer to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC

system again.

NG >> GO TO 3.

3.CHECK HARNESS BETWEEN ICC UNIT AND ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

104 LASER AIMING INCMP×× ×• Laser beam aiming of ICC sensor

is not adjustedACS-48,

"DTC 104

LASER

AIMING

INCMP"

107 LASER COMM FAIL×× ×• CAN data received by ICC sensor

is strange (from ICC unit, combi-

nation meter or ECM)ACS-48,

"DTC 107

LASER

COMM

FA IL"

109 LASER HIGH TEMP×× ×• Temperature around ICC sensor

is excessively highACS-48,

"DTC 109

LASER

HIGH

TEMP"

DTC

No.CONSULT-II screen termsICC sys-

tem

warning

lampFail-safe

Malfunctions detected where...Refer-

ence

page Vehicle-

to-vehi-

cle dis-

tance

control

modeConven-

tional

(fixed

speed)

cruise

control

modeBrake as-

sist (with

preview

function)

Page 65 of 3061

![INFINITI QX56 2007 Factory User Guide ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

• When depressing the accelerator.

• Chime does not sound when the vehicle is not driving.

• Chime does not sound when the syst INFINITI QX56 2007 Factory User Guide ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

• When depressing the accelerator.

• Chime does not sound when the vehicle is not driving.

• Chime does not sound when the syst](/img/42/57029/w960_57029-64.png)

ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

• When depressing the accelerator.

• Chime does not sound when the vehicle is not driving.

• Chime does not sound when the system does not detect any vehicle ahead. Diagnose the conditions under

which the system is detecting the vehicle ahead and when the system is malfunctioning. If there is any mal-

function in detecting the vehicle ahead. Refer to ACS-52, "

Symptom 7 the ICC System Frequently Cannot

Detect the Vehicle Ahead/The Detection Zone Is Short".

1.CHECK ICC WARNING CHIME

With CONSULT-II

1. With "ACTIVE TEST" on the CONSULT-II, check that ICC warning chime operates normally.

OK or NG

OK >> Determine preceding vehicle detection status when malfunction occurred. If chime should have

sounded replace ICC unit. Refer to ACS-55, "

ICC Unit". Perform ICC system running test. Refer

to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

NG >> GO TO 2.

2.CAN COMMUNICATION INSPECTION

With CONSULT-II

1. With CONSULT-II self-diagnosis, check “CAN COMM CIRCUIT”.

OK or NG

OK >> Refer to ACS-37, "DTC 20 CAN COMM CIRCUIT".

NG >> Replace combination meter. Refer to DI-21, "

Removal and Installation of Combination Meter".

Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

Symptom 6 Driving Force Is HuntingINFOID:0000000003533820

1.CHECK ECM

1. Perform self-diagnosis of ECM.

OK or NG

OK >> Refer to ACS-52, "Symptom 7 the ICC System Frequently Cannot Detect the Vehicle Ahead/The

Detection Zone Is Short".

NG >> Repair as necessary. Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC

System Running Test". Then perform self-diagnosis of ICC system again.

Symptom 7 the ICC System Frequently Cannot Detect the Vehicle Ahead/The Detec-

tion Zone Is Short

INFOID:0000000003533821

The detection function may become disrupted in the following cases:

• When the reflector of the vehicle ahead is small or not clean enough to reflect the laser.

• When driving a road with extremely sharp corners.

• When the laser cannot detect the reflector of the vehicle ahead as the vehicle ahead is passing a hill or

passing the peak.

1.VISUAL CHECK

1. Check ICC sensor body window for contamination and foreign materials.

OK or NG

OK >> If any contamination or foreign materials are found, remove them. Then perform ICC system run-

ning test. Refer to ACS-9, "

ICC System Running Test".

NG >> GO TO 2.

2.CHECK FUNCTION

1. After performing laser beam aiming adjustment, perform ICC system running test. Refer to ACS-9, "

ICC

System Running Test". Check that preceding vehicle detection performance has been improved.

OK or NG

OK >> Inspection End.

NG >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to ACS-55, "

ICC Sen-

sor".

Page 78 of 3061

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532218

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000003532219

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch “OFF” and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. Will

cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. May cause the MIL to light up due to a short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000003532220

•Before connecting or disconnecting the A/T assembly har-

ness connector, turn ignition switch “OFF” and disconnect

negative battery cable. Because battery voltage is applied to

TCM even if ignition switch is turned “OFF”.

SEF289H

Page 373 of 3061

PRECAUTIONSATC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003533217

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Workin g with HFC-134a (R-134a)INFOID:0000000003533218

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to AT C - 3 , "

Contaminated Refrigerant". To

determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use recovery/recycling

equipment and refrigerant identifier.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specifi ed is used, compressor fa ilure is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorb s moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of mois ture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the co mponents. Connect all refrigerant lo op components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usi ng certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling eq uipment], or J2209 [HFC-134a (R-134a) recovery

equipment]. If accidental system discharge occurs , ventilate work area before resuming service.

Additional health and safety information may be ob tained from refrigerant and oil manufacturers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Contaminated RefrigerantINFOID:0000000003533219

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refri gerant could damage your service equipment and refrigerant

supply.

• Suggest the customer return the vehicle to the locati on of previous service where the contamination may

have occurred.

• If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain-

ers. Do not recover contaminated refriger ant into your existing service equipment. If your facility does

Page 374 of 3061

ATC-4

< SERVICE INFORMATION >

PRECAUTIONS

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

General Refrigerant PrecautionINFOID:0000000003533220

WARNING:

• Do not release refrigerant into th e air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52 °C (125 °F).

• Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonou s gas will be produced if refrigerant burns.

• Refrigerant will displace oxygen, therefore be certa in to work in well ventilated areas to prevent suf-

focation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional heal th and safety information may be obtained from refrigerant manu-

facturers.

Precaution for Leak Detection DyeINFOID:0000000003533221

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjuncti on with an electronic refrigerant leak detector (J-

41995).

• For your safety and the customer's satisfaction, r ead and follow all manufacturer's operating instructions and

precautions prior to performing work.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

• Always remove any dye from the leak area after repairs are complete to avoid a misdiagnosis during a future

service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed .

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R -12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/ C systems or CFC-12 (R-12) leak detection dye in

HFC-134a (R-134a) A/C systems or A/C system damage may result.

• The fluorescent properties of the dye will remain for ov er three (3) years unless a compressor failure occurs.

A/C Identification LabelINFOID:0000000003533222

Vehicles with factory installed fluorescent dye have this identification label on the underside of hood.

Precaution for Refrigerant ConnectionINFOID:0000000003533223

A new type refrigerant connection has been introduced to al l refrigerant lines except the following locations.

• Expansion valve to cooling unit

• Evaporator pipes to evaporator (inside cooling unit)

• Refrigerant pressure sensor

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

Page 378 of 3061

ATC-8

< SERVICE INFORMATION >

PRECAUTIONS

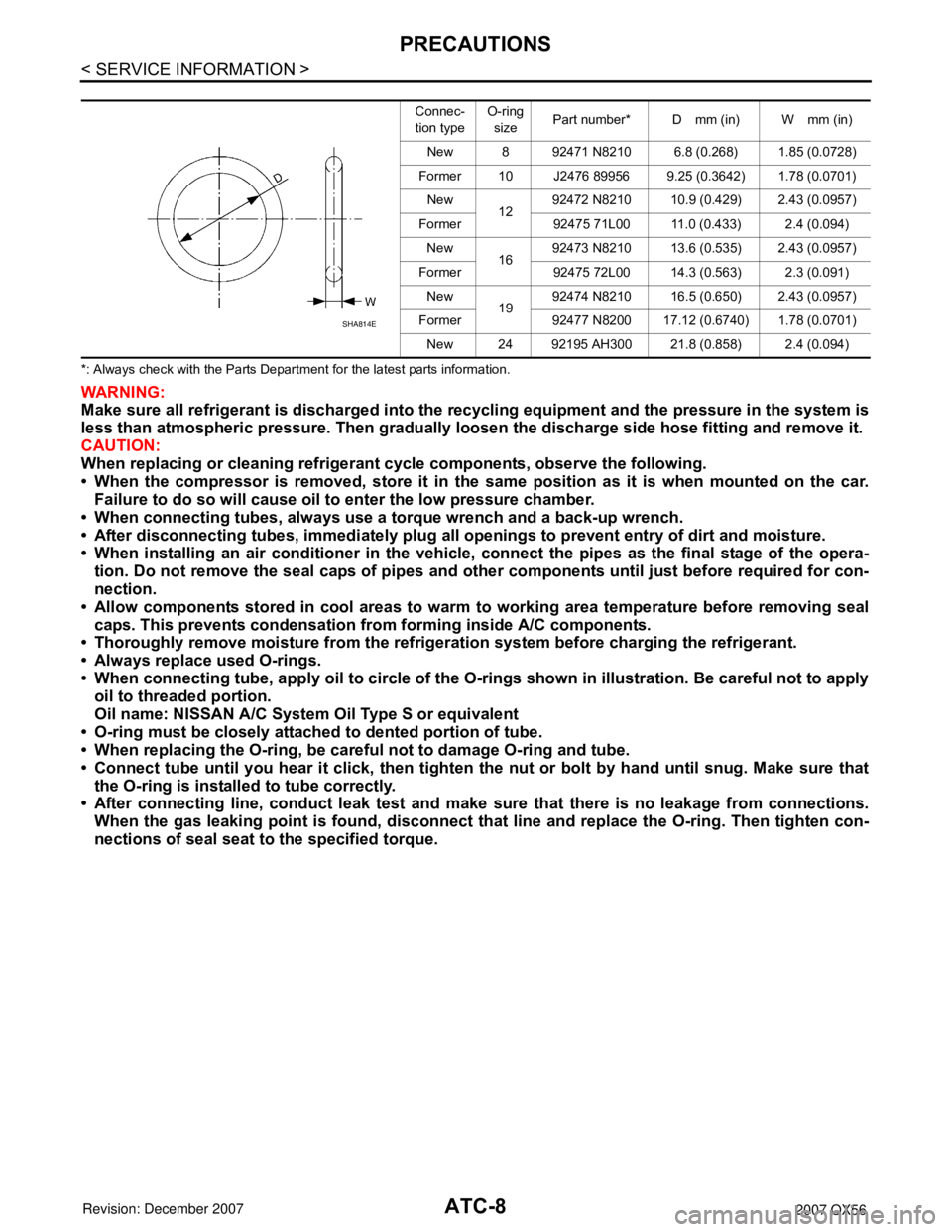

*: Always check with the Parts Department for the latest parts information.

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigeran t cycle components, observe the following.

• When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause oil to enter the low pressure chamber.

• When connecting tubes, always use a torque wrench and a back-up wrench.

• After disconnecting tubes, immedi ately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and othe r components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigerat ion system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply oil to circle of the O-rings shown in illustration. Be careful not to apply

oil to threaded portion.

Oil name: NISSAN A/C System Oil Type S or equivalent

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it cl ick, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is foun d, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

Connec-

tion typeO-ring

size Part number* D mm (in) W mm (in)

New 8 92471 N8210 6.8 (0.268) 1.85 (0.0728)

Former 10 J2476 89956 9.25 (0.3642) 1.78 (0.0701) New 1292472 N8210 10.9 (0.429) 2.43 (0.0957)

Former 92475 71L00 11.0 (0.433) 2.4 (0.094) New 1692473 N8210 13.6 (0.535) 2.43 (0.0957)

Former 92475 72L00 14.3 (0.563) 2.3 (0.091) New 1992474 N8210 16.5 (0.650) 2.43 (0.0957)

Former 92477 N8200 17.12 (0.6740) 1.78 (0.0701) New 24 92195 AH300 21.8 (0.858) 2.4 (0.094)

SHA814E

Page 520 of 3061

ATC-150

< SERVICE INFORMATION >

REFRIGERANT LINES

REFRIGERANT LINES

HFC-134a (R-134a) Service ProcedureINFOID:0000000003533291

SETTING OF SERVICE TOOLS AND EQUIPMENT

Discharging Refrigerant

WARNING:

Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) refrigerant from the A/C system using certified service equipment meeting

requirements of SAE J2210 HFC-134a (R-134a) r ecycling equipment or SAE J2201 HFC-134a (R-134a)

recovery equipment. If an accident al system discharge occurs, ventila te the work area before resum-

ing service. Additional h ealth and safety information may be obtain ed from the refrigerant and oil man-

ufacturers.

Evacuating System and Charging Refrigerant

1. Shut-off valve 2. A/C service valve 3. Recovery/recycling equipment

WJIA0579E

1. Shut-off valve 2. A/C service valve 3. Recovery/recycling equipment

4. Refrigerant container (HFC-134a) 5. Weight scale (J-39650) 6. Evacuating vacuum pump (J-39699)

7. Manifold gauge set (J-39183)

WJIA0580E

Page 542 of 3061

AV-2

Wiring Diagram - COMM - ......................................86

Terminal and Reference Value for NAVI Control

Unit .........................................................................

89

Terminal and Reference Value for Display Control

unit ..........................................................................

91

Terminal and Reference Value for Display unit ......95

Terminal and Reference Value for AV Switch ........96

Terminal and Reference Value for BCM .................97

On Board Self-Diagnosis Function .........................97

Self-Diagnosis Mode (DCU) ...................................98

Self-Diagnosis Mode (NAVI) ..................................101

Confirmation/Adjustment Mode .............................103

CAN Diagnostic Support Monitor ...........................109

AV Switch Self-Diagnosis Function .......................110

Power Supply and Ground Circuit Inspection for

NAVI Control Unit ..................................................

110

Power Supply and Ground Circuit Inspection for

Display Control Unit ...............................................

111

Power Supply and Ground Circuit Inspection for

Display Unit ...........................................................

112

Power Supply and Ground Circuit Inspection for

AV Switch ..............................................................

113

Vehicle Speed Signal Inspection for NAVI Control

Unit ........................................................................

114

Vehicle Speed Signal Inspection for Display Con-

trol Unit ..................................................................

115

Illumination Signal Inspection for NAVI Control

Unit ........................................................................

116

Illumination Signal Inspection for Display Control

Unit ........................................................................

116

Ignition Signal Inspection for NAVI Control Unit ....117

Ignition Signal Inspection for Display Control Unit ..117

Reverse Signal Inspection for NAVI Control Unit ..117

Reverse Signal Inspection for Display Control Unit

..

118

AV Communication Line Check (Between Display

Control Unit and NAVI Control Unit) ......................

118

Audio Communication Line Check (Between Dis-

play Control Unit and Audio Unit) ..........................

119

Display Communication Line Check (Between

Display Control Unit and Display Unit) ...................

121

AV Communication Line Check (Between Display

Control Unit and AV Switch) ..................................

122

CAN Communication Line Check ..........................123

If NAVI Control Unit Detects That DVD-ROM Map

Is Not Inserted .......................................................

123

If NAVI Control Unit Detects That Inserted DVD-

ROM Map Is Malfunctioning or If It Is Impossible to

Load Data from DVD-ROM Map ...........................

123

If Connection Between NAVI Control Unit and

GPS Antenna Is Malfunctioning ............................

124

Operating Screen for Audio and A/C Is Not Dis-

played When Showing NAVI Screen ....................

124

Color of RGB Image Is Not Proper (Only NAVI

Screen Looks Bluish) ............................................

125

Color of RGB Image Is Not Proper (Only NAVI

Screen Looks Reddish) .........................................

126

Color of RGB Image Is Not Proper (Only NAVI

Screen Looks Yellowish) .......................................

127

Color of RGB Image Is Not Proper (All Screens

Look Bluish) ..........................................................

128

Color of RGB Image Is Not Proper (All Screens

Look Reddish) .......................................................

129

Color of RGB Image Is Not Proper (All Screens

Look Yellowish) .....................................................

129

NAVI Screen Is Rolling .........................................130

Guide Sound Is Not Heard ....................................132

Screen Is Not Shown ............................................132

A/C Screen Is Not Shown (NAVI Screen Is

Shown) ..................................................................

133

FUEL ECONOMY Screen Is Not Shown ..............133

Average Fuel Economy Display Is Not Shown ("

*** " Is Shown) .......................................................

133

Distance to Empty Display Is Not Shown (" *** " Is

Shown) ..................................................................

133

Driving Distance or Average Speed Display Is Not

Shown (" *** " Is Shown) .......................................

134

WARNING DOOR OPEN Screen Is Not Shown ...134

Unable to Operate All of AV Switches (Unable to

Start Self-Diagnosis) .............................................

134

Audio Does Not Work ...........................................135

Navigation System Does Not Activate ..................135

Previous NAVI Conditions Are Not Stored ............135

Previous Vehicle Conditions Are Not Stored ........135

Position of Current Location Mark Is Not Correct .135

Radio Wave from GPS Satellite Is Not Received .136

Driving Test ...........................................................136

Example of Symptom Judged Not Malfunction .....137

Program Loading of NAVI Control Unit .................145

Removal and Installation .......................................145

Page 543 of 3061

PRECAUTIONS

AV-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003533661

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 674 of 3061

AV-134

< SERVICE INFORMATION >

NAVIGATION SYSTEM

3.CHECK CAN COMMUNICATION LINE

Check CAN communication line. Refer to AV-123, "

CAN Communication Line Check".

OK or NG

OK >> Replace display control unit. Refer to AV-145, "Removal and Installation".

NG >> After filling out CAN DIAG SUPPORT MONITOR check sheet, GO TO LAN-40

.

Driving Distance or Average Speed Display Is Not Shown (" *** " Is Shown)

INFOID:0000000003533758

1. CHECK IGNITION SIGNAL

Check ignition signal. Refer to AV-117, "

Ignition Signal Inspection for Display Control Unit".

OK or NG

OK >> GO TO 2.

NG >> After filling out CAN DIAG SUPPORT MONITOR check sheet, GO TO LAN-40

.

2.CHECK VEHICLE SPEED SIGNAL

Check vehicle speed signal. Refer to AV-115, "

Vehicle Speed Signal Inspection for Display Control Unit".

OK or NG

OK >> Replace display control unit. Refer to AV-145, "Removal and Installation".

NG >> Check the malfunctioning parts.

WARNING DOOR OPEN Screen Is Not ShownINFOID:0000000003533759

1. CHECK IGNITION SIGNAL

Check ignition signal. Refer to AV-117, "

Ignition Signal Inspection for Display Control Unit".

OK or NG

OK >> GO TO 2.

NG >> Check the malfunctioning parts.

2.CHECK VEHICLE SPEED SIGNAL

Check vehicle speed signal. Refer to AV-115, "

Vehicle Speed Signal Inspection for Display Control Unit".

OK or NG

OK >> GO TO 3.

NG >> Check the malfunctioning parts.

3.CHECK CAN COMMUNICATION LINE

Check CAN communication line. Refer to AV-123, "

CAN Communication Line Check".

OK or NG

OK >> Replace display control unit. Refer to AV-145, "Removal and Installation".

NG >> After filling out CAN DIAG SUPPORT MONITOR check sheet, GO TO LAN-40

.

Unable to Operate All of AV Switches (Unable to Start Self-Diagnosis)INFOID:0000000003533760

1.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check power supply and ground circuit for AV switch. Refer to AV-113, "

Power Supply and Ground Circuit

Inspection for AV Switch".

OK or NG

OK >> GO TO 2.

NG >> Check the malfunctioning parts.

2.AV SWITCH SELF-DIAGNOSIS

AV switch self-diagnosis. Refer to AV-110, "

AV Switch Self-Diagnosis Function".

OK or NG

OK >> GO TO 3.

NG >> Check the malfunctioning parts.