wheel alignment INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1954 of 3061

FSU-8

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push the vehicle straight ahead about 5 m (16 ft).

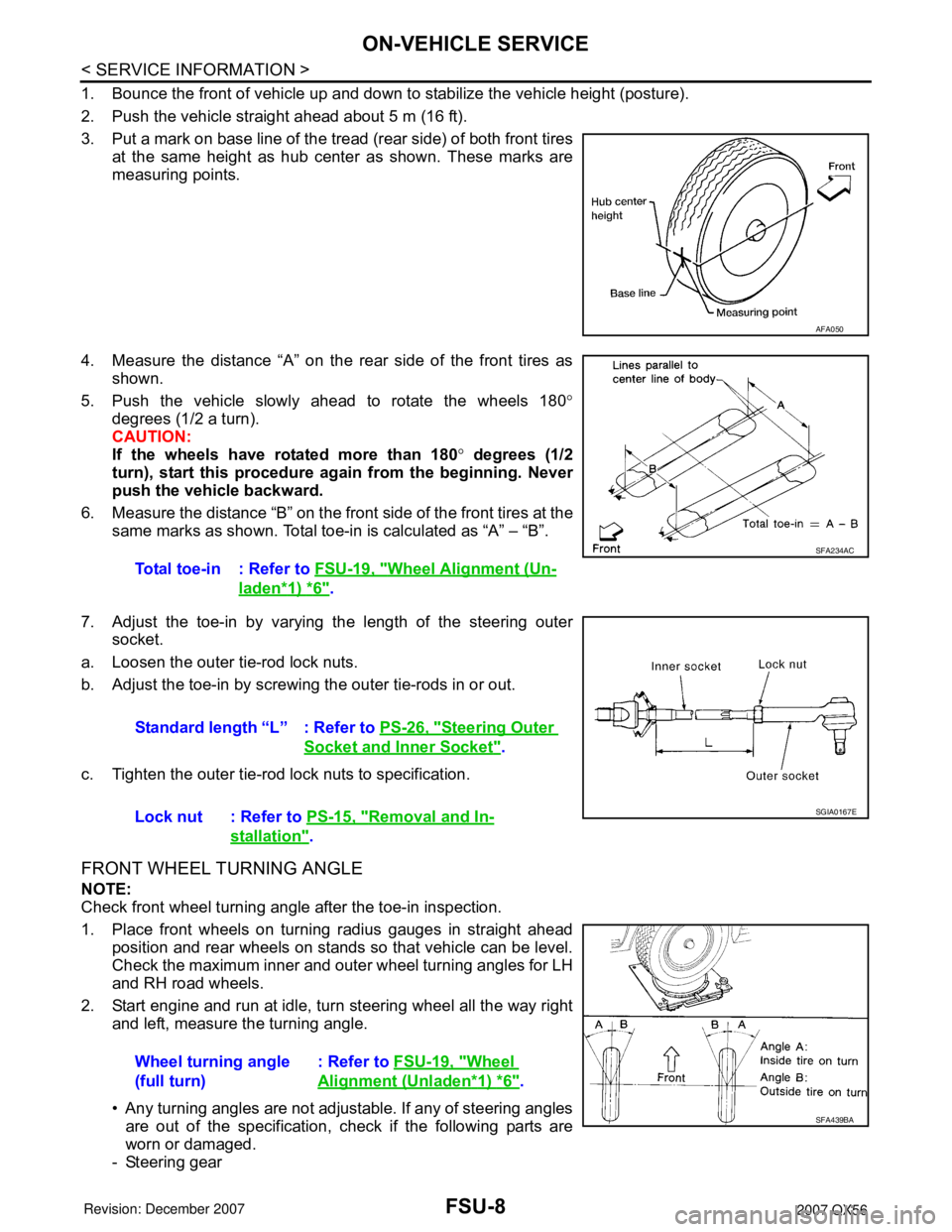

3. Put a mark on base line of the tread (rear side) of both front tires

at the same height as hub center as shown. These marks are

measuring points.

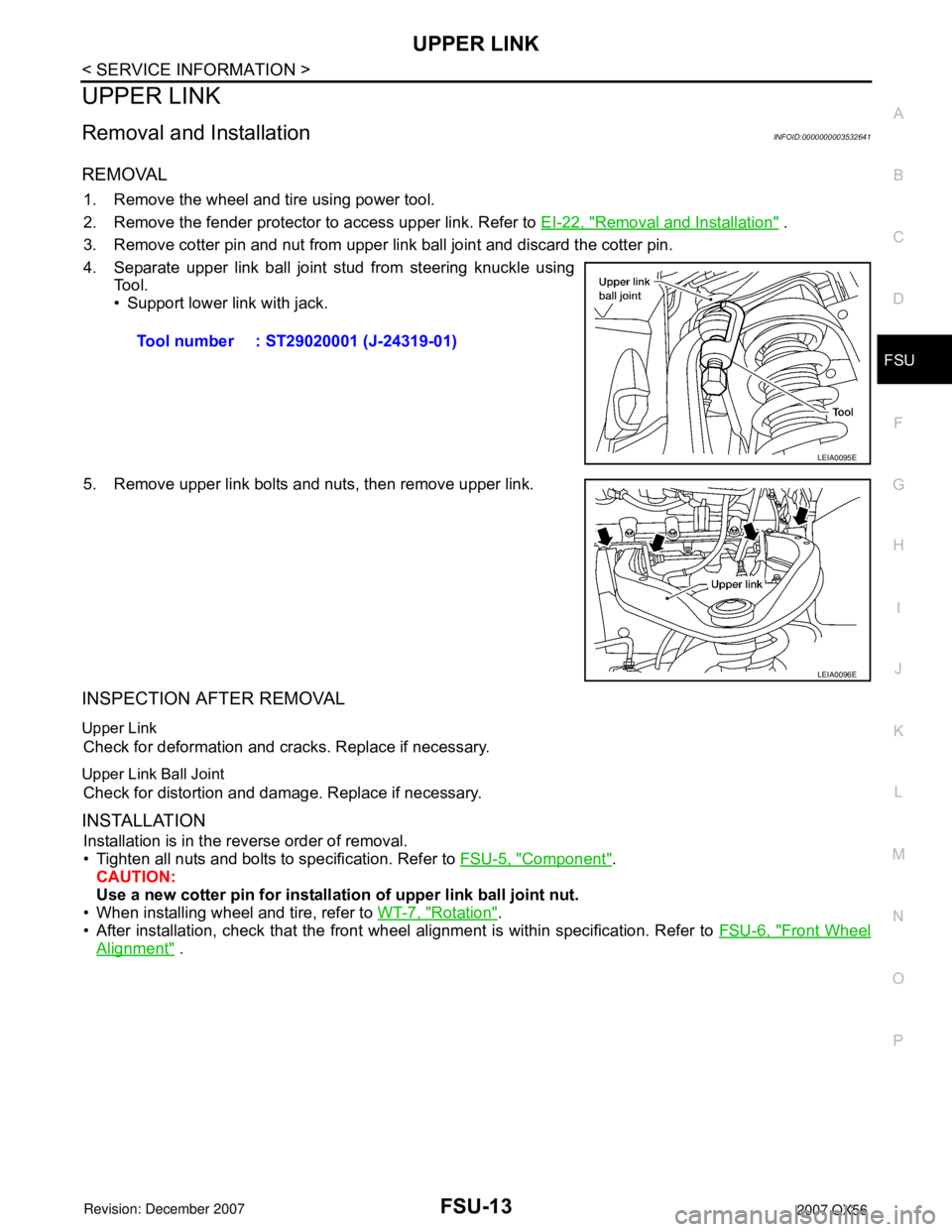

4. Measure the distance “A” on the rear side of the front tires as

shown.

5. Push the vehicle slowly ahead to rotate the wheels 180°

degrees (1/2 a turn).

CAUTION:

If the wheels have rotated more than 180° degrees (1/2

turn), start this procedure again from the beginning. Never

push the vehicle backward.

6. Measure the distance “B” on the front side of the front tires at the

same marks as shown. Total toe-in is calculated as “A” – “B”.

7. Adjust the toe-in by varying the length of the steering outer

socket.

a. Loosen the outer tie-rod lock nuts.

b. Adjust the toe-in by screwing the outer tie-rods in or out.

c. Tighten the outer tie-rod lock nuts to specification.

FRONT WHEEL TURNING ANGLE

NOTE:

Check front wheel turning angle after the toe-in inspection.

1. Place front wheels on turning radius gauges in straight ahead

position and rear wheels on stands so that vehicle can be level.

Check the maximum inner and outer wheel turning angles for LH

and RH road wheels.

2. Start engine and run at idle, turn steering wheel all the way right

and left, measure the turning angle.

• Any turning angles are not adjustable. If any of steering angles

are out of the specification, check if the following parts are

worn or damaged.

- Steering gear

AFA050

Total toe-in : Refer to FSU-19, "Wheel Alignment (Un-

laden*1) *6".

SFA234AC

Standard length “L” : Refer to PS-26, "Steering Outer

Socket and Inner Socket".

Lock nut : Refer to PS-15, "

Removal and In-

stallation".

SGIA0167E

Wheel turning angle

(full turn): Refer to FSU-19, "Wheel

Alignment (Unladen*1) *6".

SFA439BA

Page 1959 of 3061

UPPER LINK

FSU-13

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

UPPER LINK

Removal and InstallationINFOID:0000000003532641

REMOVAL

1. Remove the wheel and tire using power tool.

2. Remove the fender protector to access upper link. Refer to EI-22, "

Removal and Installation" .

3. Remove cotter pin and nut from upper link ball joint and discard the cotter pin.

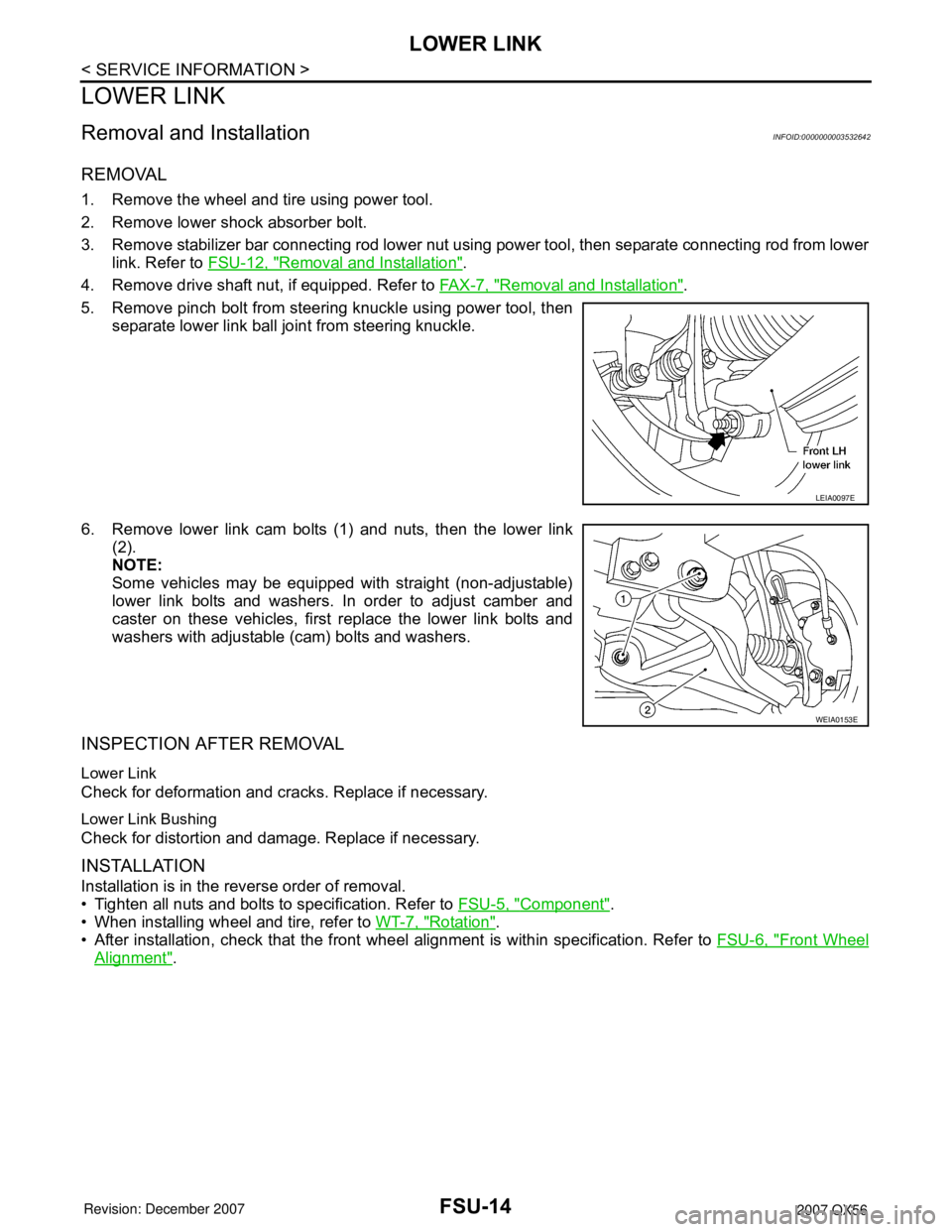

4. Separate upper link ball joint stud from steering knuckle using

Tool.

• Support lower link with jack.

5. Remove upper link bolts and nuts, then remove upper link.

INSPECTION AFTER REMOVAL

Upper Link

Check for deformation and cracks. Replace if necessary.

Upper Link Ball Joint

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten all nuts and bolts to specification. Refer to FSU-5, "

Component".

CAUTION:

Use a new cotter pin for installation of upper link ball joint nut.

• When installing wheel and tire, refer to WT-7, "

Rotation".

• After installation, check that the front wheel alignment is within specification. Refer to FSU-6, "

Front Wheel

Alignment" . Tool number : ST29020001 (J-24319-01)

LEIA0095E

LEIA0096E

Page 1960 of 3061

FSU-14

< SERVICE INFORMATION >

LOWER LINK

LOWER LINK

Removal and InstallationINFOID:0000000003532642

REMOVAL

1. Remove the wheel and tire using power tool.

2. Remove lower shock absorber bolt.

3. Remove stabilizer bar connecting rod lower nut using power tool, then separate connecting rod from lower

link. Refer to FSU-12, "

Removal and Installation".

4. Remove drive shaft nut, if equipped. Refer to FA X - 7 , "

Removal and Installation".

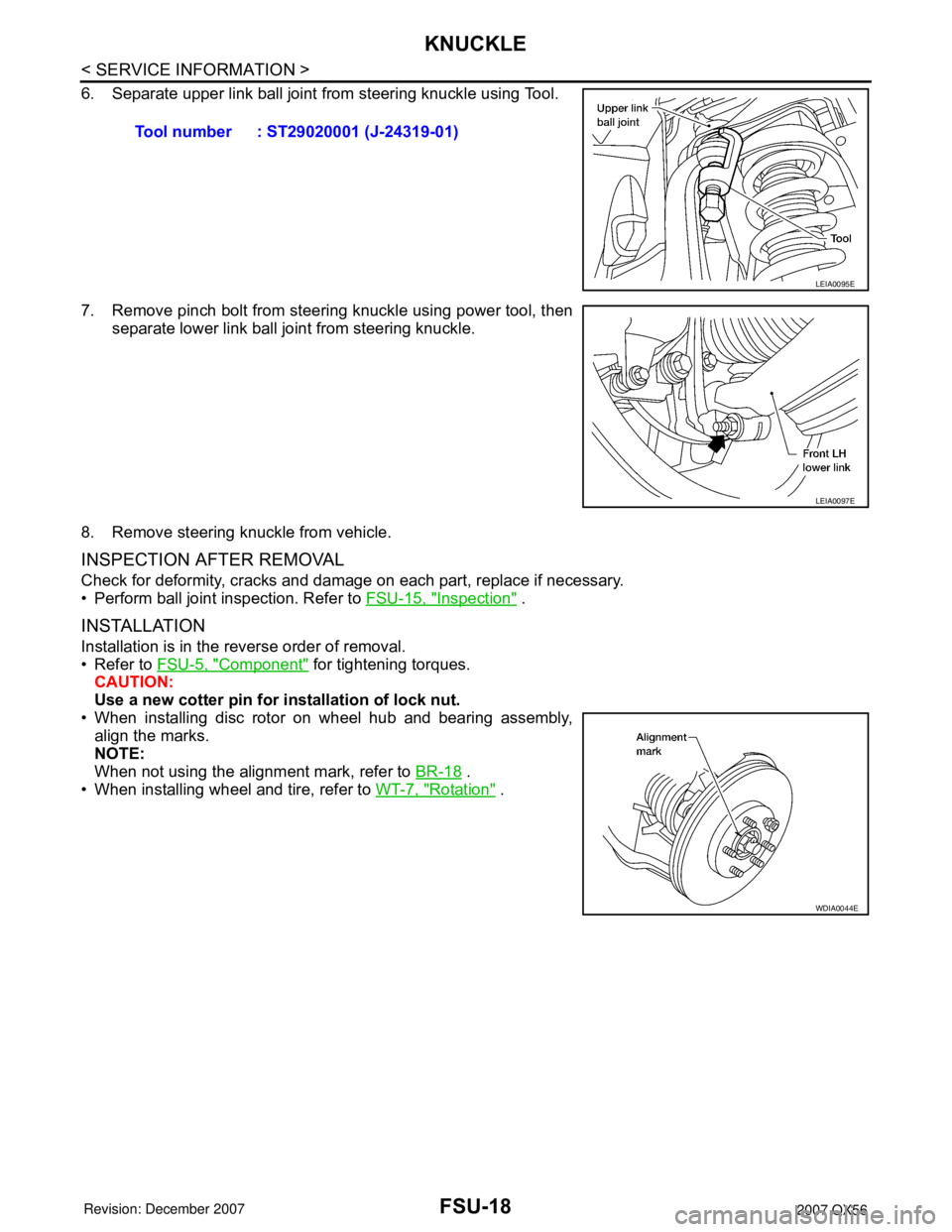

5. Remove pinch bolt from steering knuckle using power tool, then

separate lower link ball joint from steering knuckle.

6. Remove lower link cam bolts (1) and nuts, then the lower link

(2).

NOTE:

Some vehicles may be equipped with straight (non-adjustable)

lower link bolts and washers. In order to adjust camber and

caster on these vehicles, first replace the lower link bolts and

washers with adjustable (cam) bolts and washers.

INSPECTION AFTER REMOVAL

Lower Link

Check for deformation and cracks. Replace if necessary.

Lower Link Bushing

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten all nuts and bolts to specification. Refer to FSU-5, "

Component".

• When installing wheel and tire, refer to WT-7, "

Rotation".

• After installation, check that the front wheel alignment is within specification. Refer to FSU-6, "

Front Wheel

Alignment".

LEIA0097E

WEIA0153E

Page 1964 of 3061

FSU-18

< SERVICE INFORMATION >

KNUCKLE

6. Separate upper link ball joint from steering knuckle using Tool.

7. Remove pinch bolt from steering knuckle using power tool, then

separate lower link ball joint from steering knuckle.

8. Remove steering knuckle from vehicle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

• Perform ball joint inspection. Refer to FSU-15, "

Inspection" .

INSTALLATION

Installation is in the reverse order of removal.

• Refer to FSU-5, "

Component" for tightening torques.

CAUTION:

Use a new cotter pin for installation of lock nut.

• When installing disc rotor on wheel hub and bearing assembly,

align the marks.

NOTE:

When not using the alignment mark, refer to BR-18

.

• When installing wheel and tire, refer to WT-7, "

Rotation" . Tool number : ST29020001 (J-24319-01)

LEIA0095E

LEIA0097E

WDIA0044E

Page 1965 of 3061

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-19

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

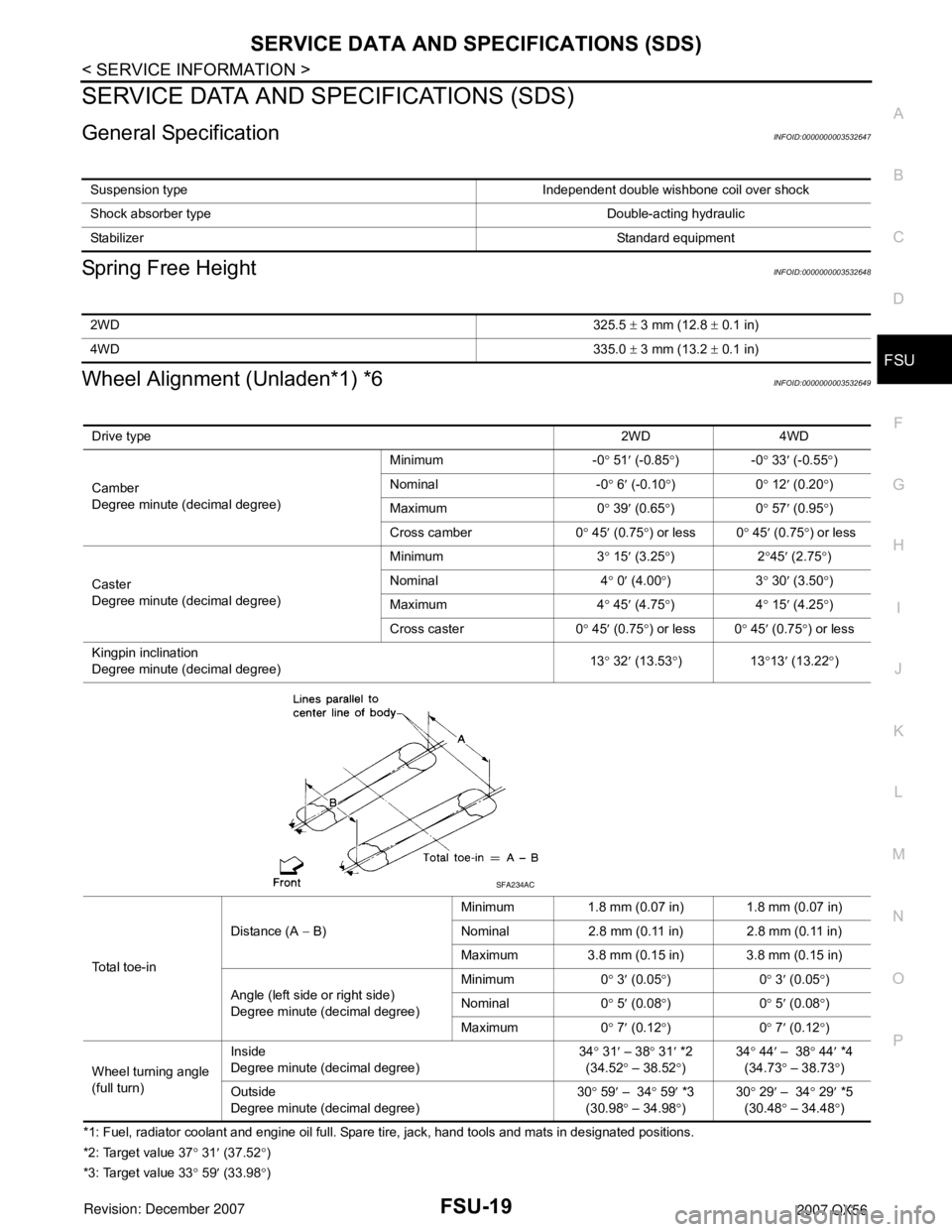

General SpecificationINFOID:0000000003532647

Spring Free HeightINFOID:0000000003532648

Wheel Alignment (Unladen*1) *6INFOID:0000000003532649

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Target value 37° 31′ (37.52°)

*3: Target value 33° 59′ (33.98°) Suspension type Independent double wishbone coil over shock

Shock absorber type Double-acting hydraulic

StabilizerStandard equipment

2WD325.5 ± 3 mm (12.8 ± 0.1 in)

4WD335.0 ± 3 mm (13.2 ± 0.1 in)

Drive type2WD 4WD

Camber

Degree minute (decimal degree)Minimum -0° 51′ (-0.85°)-0° 33′ (-0.55°)

Nominal -0° 6′ (-0.10°)0° 12′ (0.20°)

Maximum 0° 39′ (0.65°)0° 57′ (0.95°)

Cross camber 0° 45′ (0.75°) or less 0° 45′ (0.75°) or less

Caster

Degree minute (decimal degree)Minimum 3° 15′ (3.25°)2°45′ (2.75°)

Nominal 4° 0′ (4.00°)3° 30′ (3.50°)

Maximum 4° 45′ (4.75°)4° 15′ (4.25°)

Cross caster 0° 45′

(0.75°) or less 0° 45′ (0.75°) or less

Kingpin inclination

Degree minute (decimal degree)13° 32′ (13.53°)13°13′ (13.22°)

Total toe-inDistance (A − B)Minimum 1.8 mm (0.07 in) 1.8 mm (0.07 in)

Nominal 2.8 mm (0.11 in) 2.8 mm (0.11 in)

Maximum 3.8 mm (0.15 in) 3.8 mm (0.15 in)

Angle (left side or right side)

Degree minute (decimal degree)Minimum 0° 3′ (0.05°)0° 3′ (0.05°)

Nominal 0° 5′ (0.08°)0° 5′ (0.08°)

Maximum 0° 7′ (0.12°)0° 7′ (0.12°)

Wheel turning angle

(full turn)Inside

Degree minute (decimal degree)34° 31′ – 38° 31′ *2

(34.52° – 38.52°)34° 44′ – 38° 44′ *4

(34.73° – 38.73

°)

Outside

Degree minute (decimal degree)30° 59′ – 34° 59′ *3

(30.98° – 34.98°)30° 29′ – 34° 29′ *5

(30.48° – 34.48°)

SFA234AC

Page 2112 of 3061

IDX-8

ALPHABETICAL INDEX

Three way catalyst ............................................ EM-21

Three way catalyst function (Bank 1) ............... EC-376

Three way catalyst function (Bank 2) ............... EC-376

Three way catalyst precautions ............................ GI-5

Throttle control motor ....................................... EC-601

Throttle control motor relay .............................. EC-589

Throttle position sensor (TPS) .. EC-224, EC-343, EC-

514, EC-516, EC-621

Throttle valve closed position learning ............... EC-80

Tie-rod ............................................................... PS-15

Timing chain ..................................................... EM-37

Tire rotation ....................................................... MA-28

Tire size .............................................................. GI-51

Torque converter installation AT-239, AT-240, AT-243,

AT-244

Torque convertor clutch solenoid valve ... AT-114, AT-

116

Tow truck towing ................................................. GI-44

Towing point ....................................................... GI-45

TPS1 - Wiring diagram .................................... EC-345

TPS2 - Wiring diagram .................................... EC-226

TPS3 - Wiring diagram .................................... EC-623

Traction control system - Wiring diagram ....... BRC-16

Transfer control device ............. TF-75, TF-79, TF-138

Transfer control unit inspection table ................. TF-35

Transfer dropping resistor .................................. TF-89

Transfer fluid temperature sensor TF-103, TF-154, TF-

167

Transfer motor .................................... TF-101, TF-142

Transfer motor relay ........................................ TF-101

Transfer oil replacement ................................... MA-24

Transfer serial number ........................................ GI-50

Transmission serial number ................................ GI-50

Tread-FR&RR (Dimensions) ............................... GI-51

Trim ..................................................................... EI-35

TRNSCV - Wiring diagram .................. BL-130, BL-146

Trouble diagnoses .............................................. GI-11

Turbine revolution sensor ................................ AT-105

TURN - Wiring diagram ...................................... LT-67

Turn signal lamp ................................................. LT-63

Two trip detection logic ...................................... EC-49

Two-pole lift ........................................................ GI-43

V

Vacuum hose (brake system) ............................ BR-20

Vacuum hose drawing (Engine control) ........... EC-106

Valve clearance ................................................ EM-55

Valve guide ....................................................... EM-69

Vanity mirror lamp ............................................. LT-110

VDC (vehicle dynamics control) ........................ BRC-7

VDC -Wiring diagram ...................................... BRC-16

Vehicle identification number .............................. GI-49

Vehicle recovery (freeing a stuck vehicle) .......... GI-45

Vehicle security (theft warning) system ............. BL-67

Vehicle speed sensor (VSS) ............................ EC-464

VEHSEC - Wiring diagram ................................. BL-71

VENT/V - Wiring diagram .................. EC-412, EC-419

VIN registration .................................................. EC-79

Viscosity number (SAE) .................................... MA-12

VSS A/T - Wiring diagram .................. AT-107, AT-109

W

W/ANT - Wiring diagram .................................... AV-59

Wait detection switch ......................................... TF-68

WARN - Wiring diagram ...................................... DI-29

Warning chime .................................................... DI-38

Warning lamps .................................................... DI-28

Washer, front ..................................................... WW-4

Washer, rear .................................................... WW-29

Water pump ...................................................... CO-19

Water temperature gauge ..................................... DI-5

Wheel alignment (front) ..................................... FSU-6

Wheel alignment (rear) ................................... RSU-25

Wheel bearing (front) ........................................ FAX-5

Wheel bearing (rear) ......................................... RAX-5

Wheel hub (rear) ............................................... RAX-5

Wheel size .......................................................... GI-51

Wheelbase (Dimensions) .................................... GI-51

Width (Dimensions) ............................................. GI-51

WINDOW - Wiring diagram .............................. GW-22

Window, door ...................................... GW-62, GW-65

Windshield ....................................................... GW-11

WIP/R - Wiring diagram ................................... WW-33

WIPER - Wiring diagram .................................... WW-8

Wiper, front ........................................................ WW-4

Wiper, rear ....................................................... WW-29

Wiring Diagram (Cell code) list ......................... PG-62

Wiring diagrams .................................................. GI-15

WT-T/WARN - Wiring diagram .......................... WT-11

Page 2366 of 3061

MA-4

< SERVICE INFORMATION >

GENERAL MAINTENANCE

GENERAL MAINTENANCE

General MaintenanceINFOID:0000000003533859

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owner can perform these

checks and inspections or have their INFINITI dealers perform them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

ItemReference page

TiresCheck the pressure with a gauge at least once a month and always prior to a

long distance trip. Adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Wheel lug nutsWhen checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary.WT-7, "

Rotation"

WindshieldClean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary.—

Tire rotationTires should be rotated every 12,000 km (7,500 miles).WT-7, "

Rotation"

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel bal-

ancing may be needed.WT-6, "Balancing

Wheels", FSU-6, "Front

Wheel Alignment"

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly.

—

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the back

hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently.MA-30, "

Lubricating

Locks, Hinges and Hood

Latches"

Lamps

Make sure that the head lamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head

lamp aim. Clean the head lamps on a regular basis.LT- 2 0 , "Aiming Adjust-

ment" for US, LT- 3 3 ,

"Aiming Adjustment" for

Canada

ItemReference page

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly.DI-21, "

Electrical Com-

ponent Inspection"

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.—

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner.—

Steering wheelCheck that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises.PS-7, "

On-Vehicle In-

spection and Service"

SeatsCheck seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs.—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.SB-10, "

Seat Belt Inspec-

tion", MA-30, "Checking

Seat Belts, Buckles, Re-

tractors, Anchors and

Adjusters"

Accelerator pedalCheck the pedal for smooth operation. Keep the floor mats away from the pedal. —

Page 2498 of 3061

STEERING WHEEL

PS-7

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000003532824

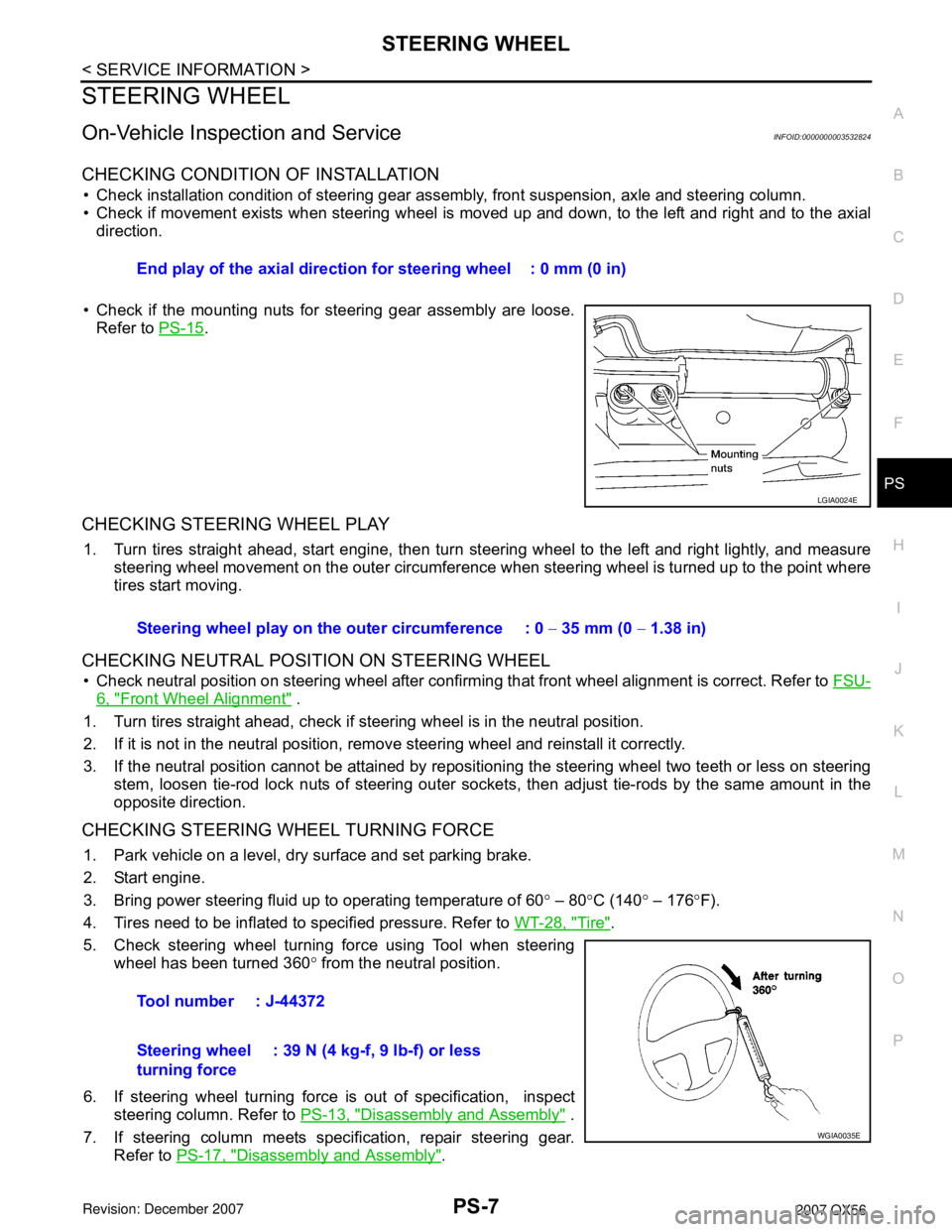

CHECKING CONDITION OF INSTALLATION

• Check installation condition of steering gear assembly, front suspension, axle and steering column.

• Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

• Check if the mounting nuts for steering gear assembly are loose.

Refer to PS-15

.

CHECKING STEERING WHEEL PLAY

1. Turn tires straight ahead, start engine, then turn steering wheel to the left and right lightly, and measure

steering wheel movement on the outer circumference when steering wheel is turned up to the point where

tires start moving.

CHECKING NEUTRAL POSITION ON STEERING WHEEL

• Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to FSU-

6, "Front Wheel Alignment" .

1. Turn tires straight ahead, check if steering wheel is in the neutral position.

2. If it is not in the neutral position, remove steering wheel and reinstall it correctly.

3. If the neutral position cannot be attained by repositioning the steering wheel two teeth or less on steering

stem, loosen tie-rod lock nuts of steering outer sockets, then adjust tie-rods by the same amount in the

opposite direction.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to operating temperature of 60° – 80°C (140° – 176°F).

4. Tires need to be inflated to specified pressure. Refer to WT-28, "

Tire".

5. Check steering wheel turning force using Tool when steering

wheel has been turned 360° from the neutral position.

6. If steering wheel turning force is out of specification, inspect

steering column. Refer to PS-13, "

Disassembly and Assembly" .

7. If steering column meets specification, repair steering gear.

Refer to PS-17, "

Disassembly and Assembly". End play of the axial direction for steering wheel : 0 mm (0 in)

LGIA0024E

Steering wheel play on the outer circumference : 0 − 35 mm (0 − 1.38 in)

Tool number : J-44372

Steering wheel

turning force: 39 N (4 kg-f, 9 lb-f) or less

WGIA0035E

Page 2499 of 3061

PS-8

< SERVICE INFORMATION >

STEERING WHEEL

CHECKING FRONT WHEEL TURNING ANGLE

When checking front wheel turning angle, refer to FSU-6, "Front Wheel Alignment" .

Removal and InstallationINFOID:0000000003532825

REMOVAL

1. Set the front wheels in the straight-ahead position.

2. Remove the driver air bag module. Refer to SRS-35, "

Removal and Installation".

3. Disconnect steering wheel switches.

4. Remove the steering wheel center nut.

5. Remove the steering wheel using Tools.

CAUTION:

Place a piece of tape across the spiral cable so it will not be

rotated out of position.

6. Inspect the steering wheel near the puller holes for damage. If

damaged, replace the steering wheel.

• Remove steering wheel rear cover and steering wheel

switches, if required.

INSTALLATION

Installation is in the reverse order of removal.

• Align spiral cable correctly when installing steering wheel. Make

sure that the spiral cable is in the neutral position. The neutral

position is detected by turning left 2.5 revolutions from the right

end position and ending with the knob at the top.

• If equipped with VDC, refer to BRC-54, "

Adjustment of Steering

Angle Sensor Neutral Position" for steering angle sensor adjust-

ment.

• After the work is completed, perform self-diagnosis to make sure

no malfunction is detected. Refer to SRS-20, "

SRS Operation

Check".

• Tighten steering wheel center nut to specification. Refer to PS-10,

"Removal and Installation".

CAUTION:

• The spiral cable may snap due to steering operation if the

cable is not installed in the correct position.

• With the steering linkage disconnected, the cable may snap

by turning the steering wheel beyond the limited number of

turns. The spiral cable can be turned counterclockwise about

2.5 turns from the neutral position.Tool number A: J-1859-A

B: J-42578

WHIA0124E

WGIA0038E

PHIA0275E

Page 2507 of 3061

PS-16

< SERVICE INFORMATION >

POWER STEERING GEAR AND LINKAGE

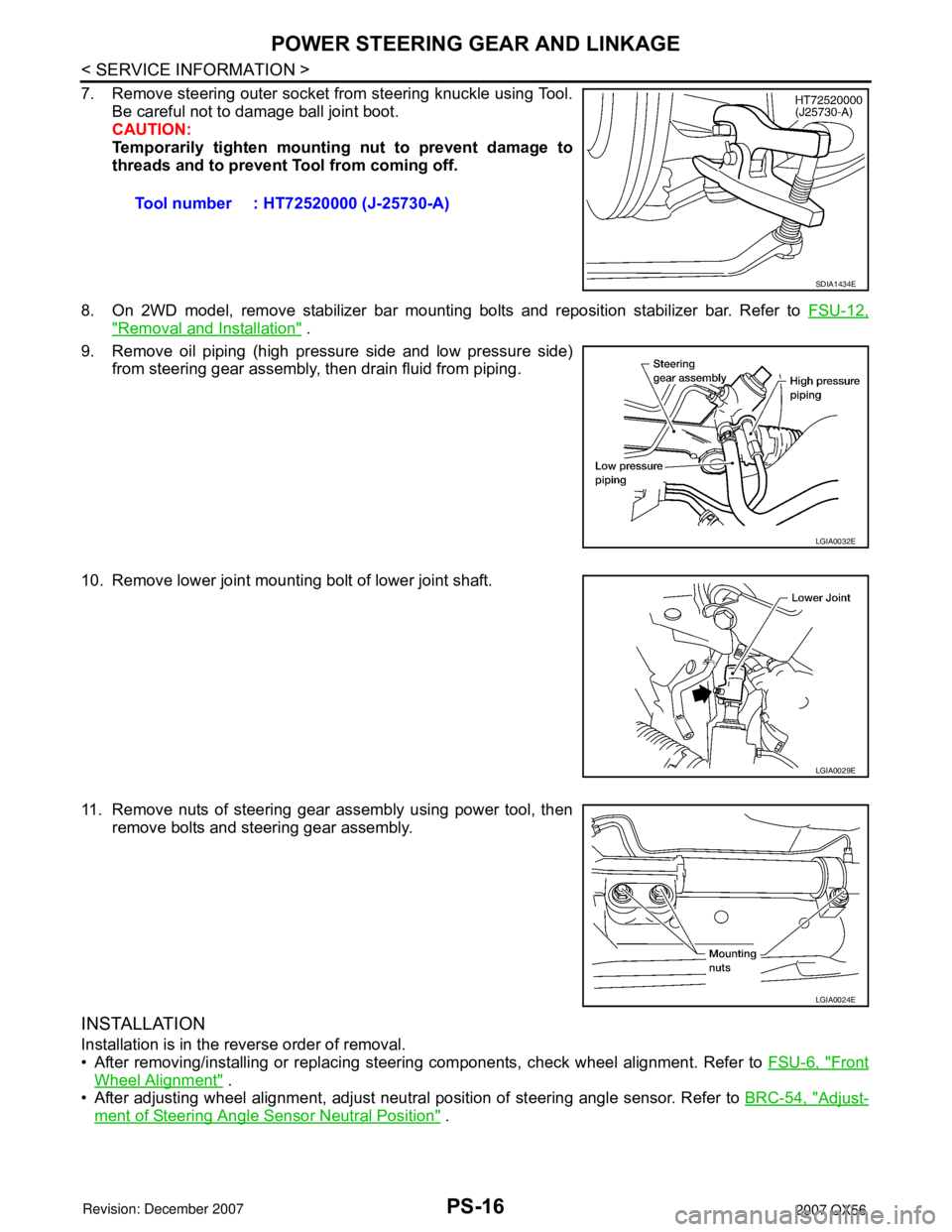

7. Remove steering outer socket from steering knuckle using Tool.

Be careful not to damage ball joint boot.

CAUTION:

Temporarily tighten mounting nut to prevent damage to

threads and to prevent Tool from coming off.

8. On 2WD model, remove stabilizer bar mounting bolts and reposition stabilizer bar. Refer to FSU-12,

"Removal and Installation" .

9. Remove oil piping (high pressure side and low pressure side)

from steering gear assembly, then drain fluid from piping.

10. Remove lower joint mounting bolt of lower joint shaft.

11. Remove nuts of steering gear assembly using power tool, then

remove bolts and steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• After removing/installing or replacing steering components, check wheel alignment. Refer to FSU-6, "

Front

Wheel Alignment" .

• After adjusting wheel alignment, adjust neutral position of steering angle sensor. Refer to BRC-54, "

Adjust-

ment of Steering Angle Sensor Neutral Position" . Tool number : HT72520000 (J-25730-A)

SDIA1434E

LGIA0032E

LGIA0029E

LGIA0024E