lock INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1096 of 3061

INDEX FOR DTC

EC-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

•If DTC U1010 is displayed with other DTC, first perform the trouble diagnosis for DTC U1010. Refer to

EC-147

.

Items

(CONSULT-II screen terms)DTC*

1

Reference page

CONSULT-II

GST*

2ECM*3

A/F SEN1 HTR (B1) P0031 0031EC-163

A/F SEN1 HTR (B1) P0032 0032EC-163

A/F SEN1 HTR (B2) P0051 0051EC-163

A/F SEN1 HTR (B2) P0052 0052EC-163

A/F SENSOR1 (B1) P0130 0130EC-225

A/F SENSOR1 (B1) P0131 0131EC-234

A/F SENSOR1 (B1) P0132 0132EC-242

A/F SENSOR1 (B1) P0133 0133EC-250

A/F SENSOR1 (B1) P2A00 2A00EC-588

A/F SENSOR1 (B2) P0150 0150EC-225

A/F SENSOR1 (B2) P0151 0151EC-234

A/F SENSOR1 (B2) P0152 0152EC-242

A/F SENSOR1 (B2) P0153 0153EC-250

A/F SENSOR1 (B2) P2A03 2A03EC-588

A/T INTERLOCK P1730 1730AT- 1 2 6

A/T TCC S/V FNCTN P0744 0744AT- 11 3

APP SEN 1/CIRC P2122 2122EC-561

APP SEN 1/CIRC P2123 2123EC-561

APP SEN 2/CIRC P2127 2127EC-567

APP SEN 2/CIRC P2128 2128EC-567

APP SENSOR P2138 2138EC-581

ASCD BRAKE SW P1572 1572EC-520 (Models with ICC)

EC-528

(Models with ASCD)

ASCD SW P1564 1564EC-507

(Models with ICC)

EC-513

(Models with ASCD)

ASCD VHL SPD SEN*

6P1574 1574EC-535 (Models with ICC)

EC-537

(Models with ASCD)

BAT CURRENT SENSOR P1550 1550EC-483

BAT CURRENT SENSOR P1551 1551EC-489

BAT CURRENT SENSOR P1552 1552EC-489

BAT CURRENT SENSOR P1553 1553EC-495

BAT CURRENT SENSOR P1554 1554EC-501

ATF TEMP SEN/CIRC P0710 0710AT- 11 9

BRAKE SW/CIRCUIT P1805 1805EC-539

CAN COMM CIRCUIT U1000

1000*4EC-145

CAN COMM CIRCUIT U1001

1001*4EC-145

CKP SEN/CIRCUIT P0335 0335EC-336

CLOSED LOOP-B1 P1148 1148EC-466

CLOSED LOOP-B2 P1168 1168EC-466

CMP SEN/CIRC-B1 P0340 0340EC-342

COLD START CONTROL P1421 1421EC-481

Page 1100 of 3061

PRECAUTIONS

EC-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003531580

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

On Board Diagnosis (OBD) System of Engine and A/TINFOID:0000000003531581

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-66

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to light up due to the short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the EVAP system or fuel injection system,

etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionINFOID:0000000003531582

•Always use a 12 volt battery as power source.

•Do not attempt to disconnect battery cables while engine is

running.

•Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

•Before removing parts, turn ignition switch OFF and then dis-

connect negative battery cable.

SEF289H

Page 1119 of 3061

EC-36

< SERVICE INFORMATION >

EVAPORATIVE EMISSION SYSTEM

Check EVAP canister as follows:

1. Block port B.

2. Blow air into port Aand check that it flows freely out of port C.

3. Release blocked port B.

4. Apply vacuum pressure to port B and check that vacuum pres-

sure exists at the ports Aand C.

5. Block port Aand B.

6. Apply pressure to port C and check that there is no leakage.

FUEL TANK VACUUM RELIEF VALVE (BUILT INTO FUEL FILLER CAP)

1. Wipe clean valve housing.

2. Check valve opening pressure and vacuum.

3. If out of specification, replace fuel filler cap as an assembly.

CAUTION:

Use only a genuine fuel filler cap as a replacement. If an incor-

rect fuel filler cap is used, the MIL may come on.

EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Refer to EC-366and EC-373.

FUEL TANK TEMPERATURE SENSOR

Refer to EC-310and EC-314.

EVAP CANISTER VENT CONTROL VALVE

Refer to EC-379and EC-386.

EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-392, EC-395and EC-401.

EVAP SERVICE PORT

PBIB1212E

SEF445Y

Pressure:

15.3 - 20.0 kPa (0.156 - 0.204 kg/cm2, 2.22 -

2.90 psi)

Vacuum:

−6.0 to −3.3 kPa (−0.061 to −0.034 kg/cm

2,

−0.87 to −0.48 psi)

SEF943S

Page 1120 of 3061

EVAPORATIVE EMISSION SYSTEM

EC-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

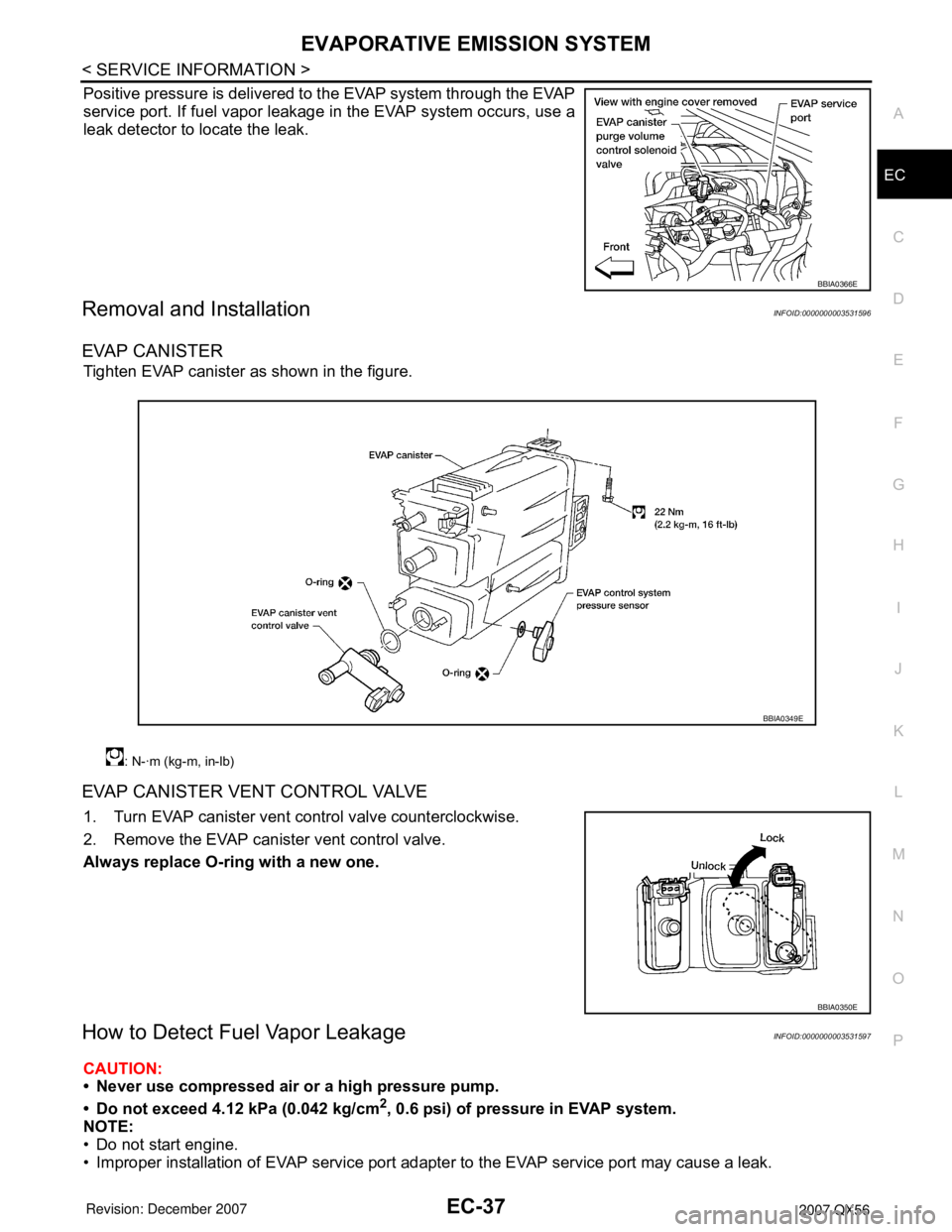

Positive pressure is delivered to the EVAP system through the EVAP

service port. If fuel vapor leakage in the EVAP system occurs, use a

leak detector to locate the leak.

Removal and InstallationINFOID:0000000003531596

EVAP CANISTER

Tighten EVAP canister as shown in the figure.

EVAP CANISTER VENT CONTROL VALVE

1. Turn EVAP canister vent control valve counterclockwise.

2. Remove the EVAP canister vent control valve.

Always replace O-ring with a new one.

How to Detect Fuel Vapor LeakageINFOID:0000000003531597

CAUTION:

• Never use compressed air or a high pressure pump.

• Do not exceed 4.12 kPa (0.042 kg/cm

2, 0.6 psi) of pressure in EVAP system.

NOTE:

• Do not start engine.

• Improper installation of EVAP service port adapter to the EVAP service port may cause a leak.

BBIA0366E

: N-·m (kg-m, in-lb)

BBIA0349E

BBIA0350E

Page 1135 of 3061

EC-52

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ASCD SW P1564 1564 — — 1 —EC-507

(Models

with ICC)

EC-513

(Models

with AS-

CD)

ICC COMMAND VALUE*

9P1568 1568 — — 1 —EC-519

ASCD BRAKE SW P1572 1572 — — 1 —EC-520

(Models

with ICC)

EC-528

(Models

with AS-

CD)

ASCD VHL SPD SEN*

8P1574 1574 — — 1 —EC-535

(Models

with ICC)

EC-537

(Models

with AS-

CD)

NATS MALFUNCTIONP1610 -

P16151610 - 1615 — — 2 —BL-116

A/T INTERLOCK P1730 1730 — — 1×AT- 1 2 6

I/C SOLENOID/CIRC P1752 1752 — — 1×AT- 1 3 0

I/C SOLENOID FNCTN P1754 1754 — — 1×AT- 1 3 2

FR/B SOLENOID/CIRC P1757 1757 — — 1×AT- 1 3 4

FR/B SOLENOID FNCT P1759 1759 — — 1×AT- 1 3 6

D/C SOLENOID/CIRC P1762 1762 — — 1×AT- 1 3 8

D/C SOLENOID FNCTN P1764 1764 — — 1×AT- 1 4 0

HLR/C SOL/CIRC P1767 1767 — — 1×AT- 1 4 2

HLR/C SOL FNCTN P1769 1769 — — 1×AT- 1 4 4

LC/B SOLENOID/CIRC P1772 1772 — — 1×AT- 1 4 6

LC/B SOLENOID FNCT P1774 1774 — — 1×AT- 1 4 8

BRAKE SW/CIRCUIT P1805 1805 — — 2 —EC-539

ETC MOT PWR P2100 2100 — — 1×EC-543

ETC FUNCTION/CIRC P2101 2101 — — 1×EC-548

ETC MOT PWR P2103 2103 — — 1×EC-543

ETC MOT P2118 2118 — — 1×EC-554

ETC ACTR P2119 2119 — — 1×EC-559

APP SEN 1/CIRC P2122 2122 — — 1×EC-561

APP SEN 1/CIRC P2123 2123 — — 1×EC-561

APP SEN 2/CIRC P2127 2127 — — 1×EC-567

APP SEN 2/CIRC P2128 2128 — — 1×EC-567

TP SENSOR P2135 2135 — — 1×EC-574

APP SENSOR P2138 2138 — — 1×EC-581

Items

(CONSULT-II screen terms)DTC*

1

SRT codeTest value/

Test limit

(GST only)Trip MILRefer-

ence page CONSULT-II

GST*

2ECM*3

Page 1147 of 3061

EC-64

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When any SRT codes are not set, MIL may flash without DTC. For the details, refer to EC-49, "Emission-

related Diagnostic Information".

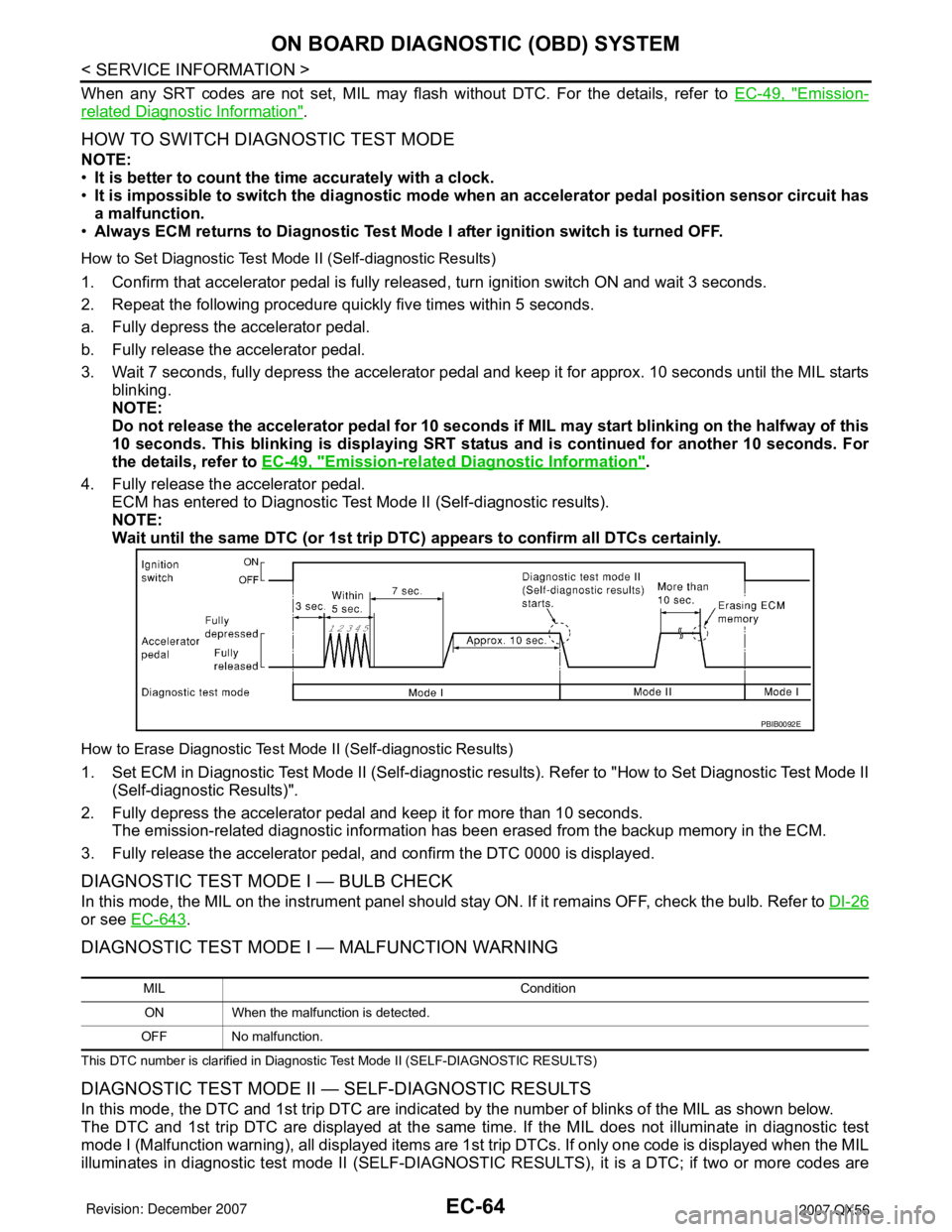

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

•It is better to count the time accurately with a clock.

•It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

•Always ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MIL starts

blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MIL may start blinking on the halfway of this

10 seconds. This blinking is displaying SRT status and is continued for another 10 seconds. For

the details, refer to EC-49, "

Emission-related Diagnostic Information".

4. Fully release the accelerator pedal.

ECM has entered to Diagnostic Test Mode II (Self-diagnostic results).

NOTE:

Wait until the same DTC (or 1st trip DTC) appears to confirm all DTCs certainly.

How to Erase Diagnostic Test Mode II (Self-diagnostic Results)

1. Set ECM in Diagnostic Test Mode II (Self-diagnostic results). Refer to "How to Set Diagnostic Test Mode II

(Self-diagnostic Results)".

2. Fully depress the accelerator pedal and keep it for more than 10 seconds.

The emission-related diagnostic information has been erased from the backup memory in the ECM.

3. Fully release the accelerator pedal, and confirm the DTC 0000 is displayed.

DIAGNOSTIC TEST MODE I — BULB CHECK

In this mode, the MIL on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to DI-26

or see EC-643.

DIAGNOSTIC TEST MODE I — MALFUNCTION WARNING

This DTC number is clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC RESULTS)

DIAGNOSTIC TEST MODE II — SELF-DIAGNOSTIC RESULTS

In this mode, the DTC and 1st trip DTC are indicated by the number of blinks of the MIL as shown below.

The DTC and 1st trip DTC are displayed at the same time. If the MIL does not illuminate in diagnostic test

mode I (Malfunction warning), all displayed items are 1st trip DTCs. If only one code is displayed when the MIL

illuminates in diagnostic test mode II (SELF-DIAGNOSTIC RESULTS), it is a DTC; if two or more codes are

PBIB0092E

MIL Condition

ON When the malfunction is detected.

OFF No malfunction.

Page 1162 of 3061

BASIC SERVICE PROCEDURE

EC-79

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

7. Make sure that “CMPLT” is displayed on CONSULT-II screen. If

“CMPLT” is not displayed, Idle Air Volume Learning will not be

carried out successfully. In this case, find the cause of the inci-

dent by referring to the DIAGNOSTIC PROCEDURE below.

8. Rev up the engine two or three times and make sure that idle

speed and ignition timing are within the specifications.

Without CONSULT-II

NOTE:

•It is better to count the time accurately with a clock.

•It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform EC-77, "

Accelerator Pedal Released Position Learning" .

2. Perform EC-77, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREPARATION (previously mentioned) are in good order.

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Confirm that accelerator pedal is fully released, turn ignition switch ON and wait 3 seconds.

7. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

8. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops

blinking and turned ON.

9. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

10. Start engine and let it idle.

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the

specifications.

13. If idle speed and ignition timing are not within the specification, Idle Air Volume Learning will not be carried

out successfully. In this case, find the cause of the incident by referring to the DIAGNOSTIC PROCE-

DURE below.

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2.Check PCV valve operation.

ITEM SPECIFICATION

Idle speed 650 ± 50 rpm (in P or N position)

Ignition timing 15 ± 5° BTDC (in P or N position)

MBIB0238E

ITEM SPECIFICATION

Idle speed 650 ± 50 rpm (in P or N position)

Ignition timing 15 ± 5° BTDC (in P or N position)

SEC897C

Page 1175 of 3061

EC-92

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FL-10

Fuel piping 5 5 5 5 5 5FL-4

Va p o r l o c k—

Valve deposit

5 555 55 5—

Poor fuel (Heavy weight gasoline,

Low octane)—

Air Air duct

55555 5EM-15

Air cleanerEM-15

Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator)

5555EM-15

Electric throttle control actuatorEM-17

Air leakage from intake manifold/

Collector/GasketEM-17

Cranking Battery

111111

11SC-4

Generator circuitSC-15

Starter circuit 3SC-9

Signal plate 6EM-38

Park/Neutral position (PNP)

switch4AT- 9 9

Engine Cylinder head

55555 55 5EM-64

Cylinder head gasket 4 3

Cylinder block

66666 66 64

EM-78

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nismTiming chain

55555 55 5EM-38

CamshaftEM-46

Intake valve timing controlEM-46

Intake valve

3EM-64

Exhaust valve

Page 1415 of 3061

EC-332

< SERVICE INFORMATION >

DTC P0327, P0328, P0332, P0333 KS

DTC P0327, P0328, P0332, P0333 KS

Component DescriptionINFOID:0000000003531825

The knock sensor is attached to the cylinder block. It senses engine

knocking using a piezoelectric element. A knocking vibration from

the cylinder block is sensed as vibrational pressure. This pressure is

converted into a voltage signal and sent to the ECM.

On Board Diagnosis LogicINFOID:0000000003531826

The MIL will not light up for these self-diagnoses.

DTC Confirmation ProcedureINFOID:0000000003531827

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

WITH CONSULT-II

1. Turn ignition switch ON and select “DATA MONITOR” mode with

CONSULT-II.

2. Start engine and run it for at least 5 seconds at idle speed.

3. If 1st trip DTC is detected, go to EC-334, "

Diagnosis Procedure"

With GST

Follow the procedure “WITH CONSULT-II” above.

PBIB0021E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0327

0327

(bank 1)Knock sensor circuit low in-

putAn excessively low voltage from the sensor

is sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Knock sensor P0332

0332

(bank 2)

P0328

0328

(bank 1)Knock sensor circuit high in-

putAn excessively high voltage from the sensor

is sent to ECM.

P0333

0333

(bank 2)

SEF058Y

Page 1437 of 3061

EC-354

< SERVICE INFORMATION >

DTC P0441 EVAP CONTROL SYSTEM

DTC P0441 EVAP CONTROL SYSTEM

System DescriptionINFOID:0000000003531851

NOTE:

If DTC P0441 is displayed with other DTC such as P2122, P2123, P2127, P2128 or P2138, first perform

trouble diagnosis for other DTC.

In this evaporative emission (EVAP) control system, purge flow occurs during non-closed throttle conditions.

Purge volume is related to air intake volume. Under normal purge conditions (non-closed throttle), the EVAP

canister purge volume control solenoid valve is open to admit purge flow. Purge flow exposes the EVAP con-

trol system pressure sensor to intake manifold vacuum.

On Board Diagnosis LogicINFOID:0000000003531852

Under normal conditions (non-closed throttle), sensor output voltage indicates if pressure drop and purge flow

are adequate. If not, a malfunction is determined.

DTC Confirmation ProcedureINFOID:0000000003531853

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Always perform test at a temperature of 5°C (41°F) or more.

WITH CONSULT-II

1. Start engine and warm it up to normal operating temperature.

PBIB1026E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0441

0441EVAP control system in-

correct purge flowEVAP control system does not operate proper-

ly, EVAP control system has a leak between in-

take manifold and EVAP control system

pressure sensor.• EVAP canister purge volume control so-

lenoid valve stuck closed

• EVAP control system pressure sensor

and the circuit

• Loose, disconnected or improper con-

nection of rubber tube

• Blocked rubber tube

• Cracked EVAP canister

• EVAP canister purge volume control so-

lenoid valve circuit

• Accelerator pedal position sensor

• Blocked purge port

• EVAP canister vent control valve