brake sensor INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 105 of 3061

A/T CONTROL SYSTEM

AT-35

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

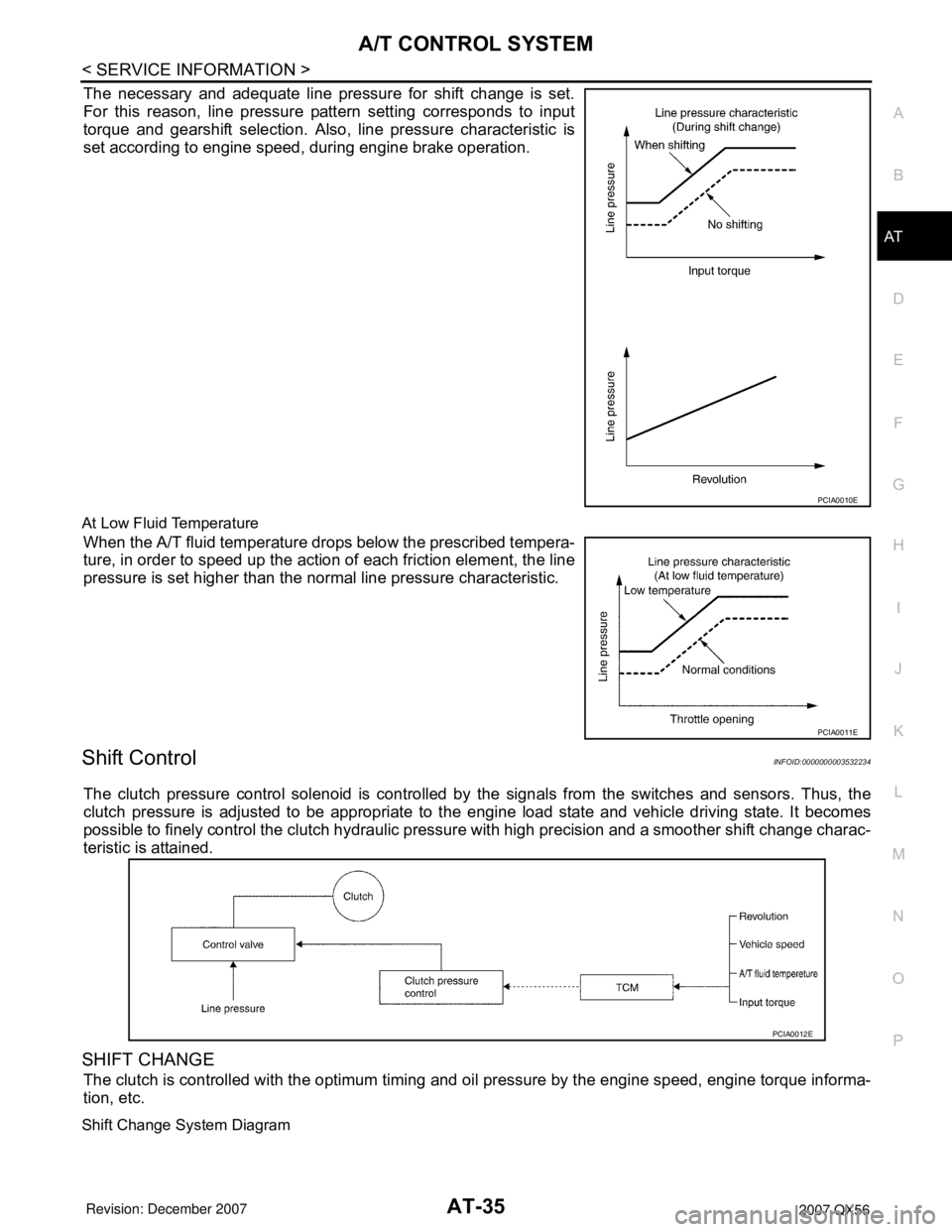

The necessary and adequate line pressure for shift change is set.

For this reason, line pressure pattern setting corresponds to input

torque and gearshift selection. Also, line pressure characteristic is

set according to engine speed, during engine brake operation.

At Low Fluid Temperature

When the A/T fluid temperature drops below the prescribed tempera-

ture, in order to speed up the action of each friction element, the line

pressure is set higher than the normal line pressure characteristic.

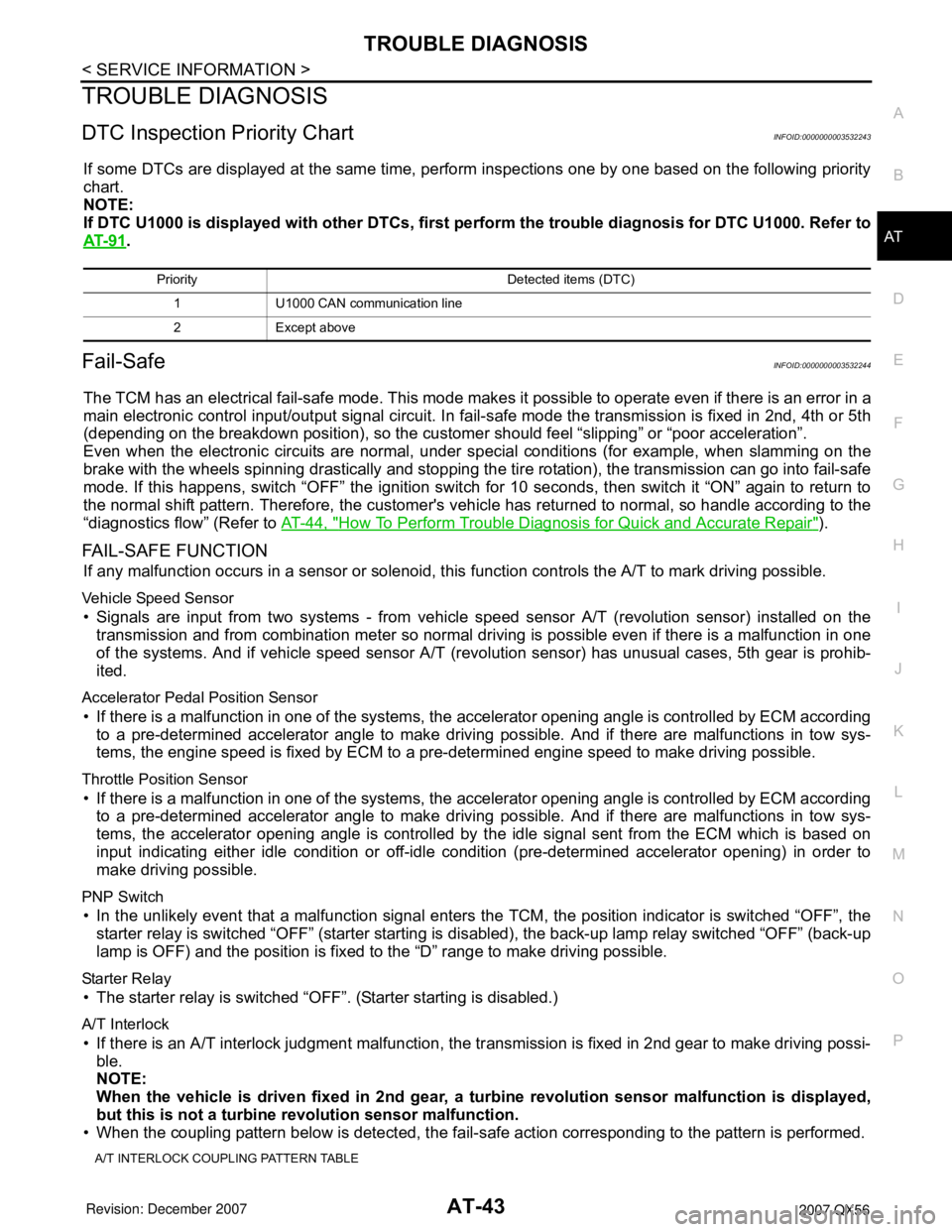

Shift ControlINFOID:0000000003532234

The clutch pressure control solenoid is controlled by the signals from the switches and sensors. Thus, the

clutch pressure is adjusted to be appropriate to the engine load state and vehicle driving state. It becomes

possible to finely control the clutch hydraulic pressure with high precision and a smoother shift change charac-

teristic is attained.

SHIFT CHANGE

The clutch is controlled with the optimum timing and oil pressure by the engine speed, engine torque informa-

tion, etc.

Shift Change System Diagram

PCIA0010E

PCIA0011E

PCIA0012E

Page 113 of 3061

TROUBLE DIAGNOSIS

AT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

TROUBLE DIAGNOSIS

DTC Inspection Priority ChartINFOID:0000000003532243

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC U1000 is displayed with other DTCs, first perform the trouble diagnosis for DTC U1000. Refer to

AT- 9 1

.

Fail-SafeINFOID:0000000003532244

The TCM has an electrical fail-safe mode. This mode makes it possible to operate even if there is an error in a

main electronic control input/output signal circuit. In fail-safe mode the transmission is fixed in 2nd, 4th or 5th

(depending on the breakdown position), so the customer should feel “slipping” or “poor acceleration”.

Even when the electronic circuits are normal, under special conditions (for example, when slamming on the

brake with the wheels spinning drastically and stopping the tire rotation), the transmission can go into fail-safe

mode. If this happens, switch “OFF” the ignition switch for 10 seconds, then switch it “ON” again to return to

the normal shift pattern. Therefore, the customer's vehicle has returned to normal, so handle according to the

“diagnostics flow” (Refer to AT-44, "

How To Perform Trouble Diagnosis for Quick and Accurate Repair").

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, this function controls the A/T to mark driving possible.

Vehicle Speed Sensor

• Signals are input from two systems - from vehicle speed sensor A/T (revolution sensor) installed on the

transmission and from combination meter so normal driving is possible even if there is a malfunction in one

of the systems. And if vehicle speed sensor A/T (revolution sensor) has unusual cases, 5th gear is prohib-

ited.

Accelerator Pedal Position Sensor

• If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM according

to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow sys-

tems, the engine speed is fixed by ECM to a pre-determined engine speed to make driving possible.

Throttle Position Sensor

• If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM according

to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow sys-

tems, the accelerator opening angle is controlled by the idle signal sent from the ECM which is based on

input indicating either idle condition or off-idle condition (pre-determined accelerator opening) in order to

make driving possible.

PNP Switch

• In the unlikely event that a malfunction signal enters the TCM, the position indicator is switched “OFF”, the

starter relay is switched “OFF” (starter starting is disabled), the back-up lamp relay switched “OFF” (back-up

lamp is OFF) and the position is fixed to the “D” range to make driving possible.

Starter Relay

• The starter relay is switched “OFF”. (Starter starting is disabled.)

A/T Interlock

• If there is an A/T interlock judgment malfunction, the transmission is fixed in 2nd gear to make driving possi-

ble.

NOTE:

When the vehicle is driven fixed in 2nd gear, a turbine revolution sensor malfunction is displayed,

but this is not a turbine revolution sensor malfunction.

• When the coupling pattern below is detected, the fail-safe action corresponding to the pattern is performed.

A/T INTERLOCK COUPLING PATTERN TABLE

Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 114 of 3061

AT-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

l: NG X: OK

A/T 1st Engine Braking

• When there is an A/T first gear engine brake judgment malfunction, the low coast brake solenoid is switched

“OFF” to avoid the engine brake operation.

Line Pressure Solenoid

• The solenoid is switched “OFF” and the line pressure is set to the maximum hydraulic pressure to make driv-

ing possible.

Torque Converter Clutch Solenoid

• The solenoid is switched “OFF” to release the lock-up.

Low Coast Brake Solenoid

• When a (electrical or functional) malfunction occurs, in order to make driving possible, the engine brake is

not applied in 1st and 2nd gear.

Input Clutch Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid either “ON” or “OFF”, the transmission is

held in 4th gear to make driving possible.

Direct Clutch Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid either “ON” or “OFF”, the transmission is

held in 4th gear to make driving possible.

Front Brake Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid “ON”, in order to make driving possible, the

A/T is held in 5th gear; if the solenoid is OFF, 4th gear.

High and Low Reverse Clutch Solenoid

• If a (electrical or functional) malfunction occurs with the solenoid either “ON” or “OFF”, the transmission is

held in 4th gear to make driving possible.

Turbine Revolution Sensor 1 or 2

• The control is the same as if there were no turbine revolution sensors, 5th gear is prohibited.

How To Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000003532245

INTRODUCTION

The TCM receives a signal from the vehicle speed sensor, accelerator pedal position sensor (throttle position

sensor) or PNP switch and provides shift control or lock-up control via A/T solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. The A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

Gear positionATF pressure switch output

Fail-safe

functionClutch pressure output pattern after fail-safe func-

tion

SW3

(I/C)SW6

(HLR/

C)SW5

(D/C)SW1

(FR/B)SW2

(LC/B)I/C HLR/C D/C FR/B LC/B L/U

A/T interlock

coupling pat-

tern3rd – X X – lHeld in

2nd gearOFF OFF ON OFF OFF OFF

4th – X X –lHeld in

2nd gearOFF OFF ON OFF OFF OFF

5th X X – XlHeld in

2nd gearOFF OFF ON OFF OFF OFF

SAT631IB

Page 124 of 3061

AT-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

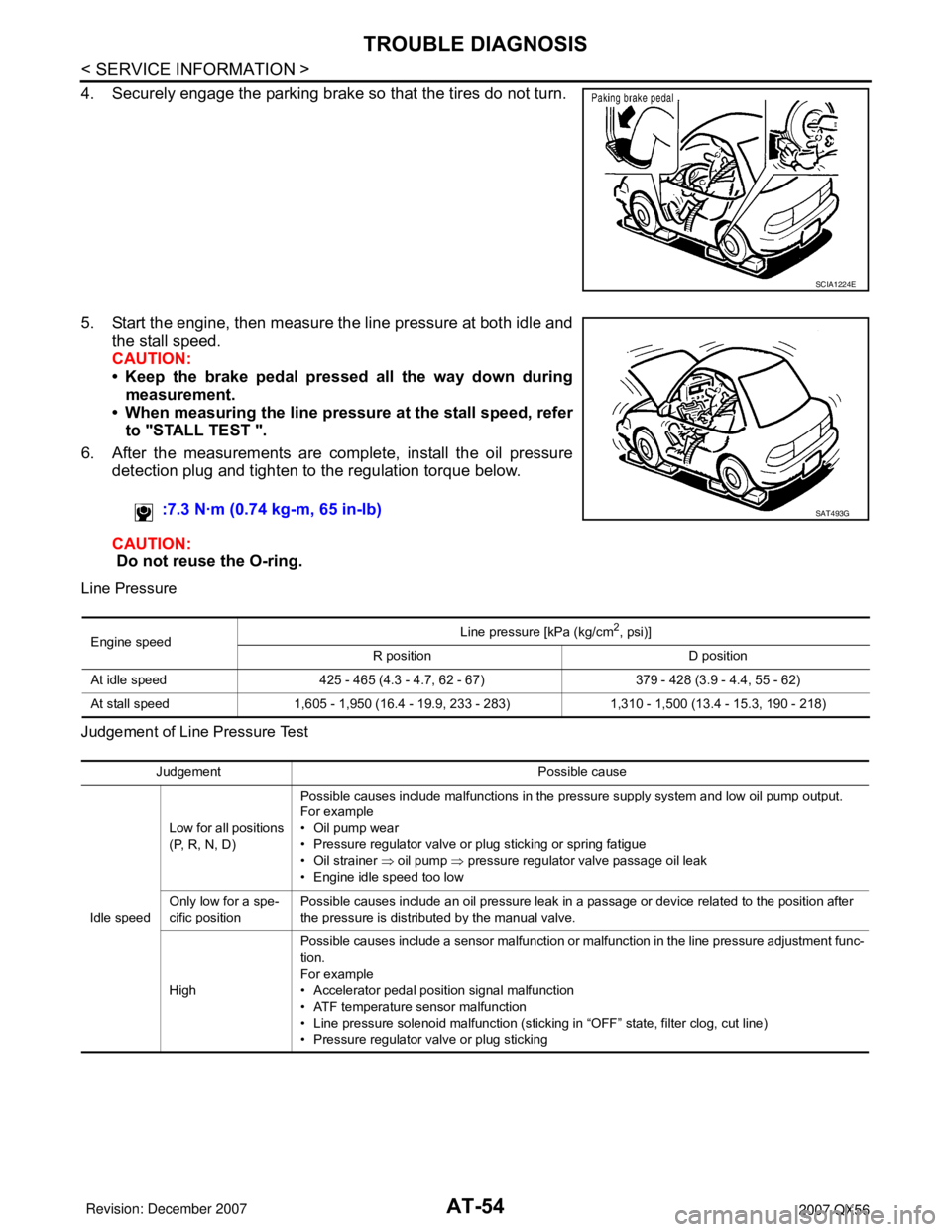

4. Securely engage the parking brake so that the tires do not turn.

5. Start the engine, then measure the line pressure at both idle and

the stall speed.

CAUTION:

• Keep the brake pedal pressed all the way down during

measurement.

• When measuring the line pressure at the stall speed, refer

to "STALL TEST ".

6. After the measurements are complete, install the oil pressure

detection plug and tighten to the regulation torque below.

CAUTION:

Do not reuse the O-ring.

Line Pressure

Judgement of Line Pressure Test

SCIA1224E

:7.3 N·m (0.74 kg-m, 65 in-lb)SAT493G

Engine speedLine pressure [kPa (kg/cm

2, psi)]

R position D position

At idle speed 425 - 465 (4.3 - 4.7, 62 - 67) 379 - 428 (3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.4 - 15.3, 190 - 218)

Judgement Possible cause

Idle speedLow for all positions

(P, R, N, D)Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

•Oil pump wear

• Pressure regulator valve or plug sticking or spring fatigue

• Oil strainer ⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a spe-

cific positionPossible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

HighPossible causes include a sensor malfunction or malfunction in the line pressure adjustment func-

tion.

For example

• Accelerator pedal position signal malfunction

• ATF temperature sensor malfunction

• Line pressure solenoid malfunction (sticking in “OFF” state, filter clog, cut line)

• Pressure regulator valve or plug sticking

Page 131 of 3061

TROUBLE DIAGNOSIS

AT-61

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

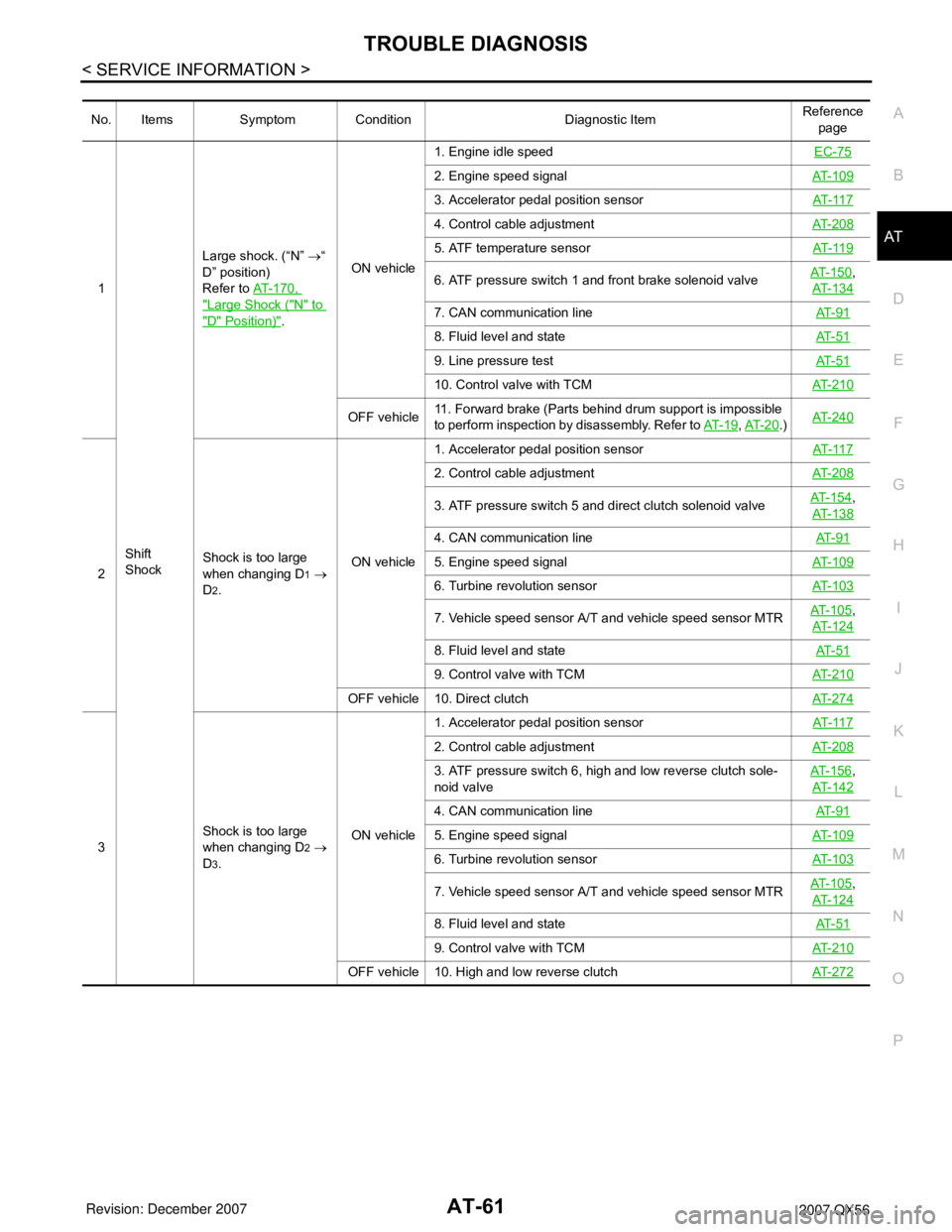

No. Items Symptom Condition Diagnostic ItemReference

page

1

Shift

ShockLarge shock. (“N” →“

D” position)

Refer to AT- 1 7 0 ,

"Large Shock ("N" to

"D" Position)".ON vehicle1. Engine idle speedEC-75

2. Engine speed signalAT-109

3. Accelerator pedal position sensorAT- 11 7

4. Control cable adjustmentAT-208

5. ATF temperature sensorAT- 11 9

6. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT-134

7. CAN communication lineAT- 9 1

8. Fluid level and stateAT- 5 1

9. Line pressure testAT- 5 1

10. Control valve with TCMAT-210

OFF vehicle11. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9, AT- 2 0.)AT-240

2Shock is too large

when changing D1 →

D

2.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT-138

4. CAN communication lineAT- 9 1

5. Engine speed signalAT-109

6. Turbine revolution sensorAT-103

7. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

8. Fluid level and stateAT- 5 1

9. Control valve with TCMAT-210

OFF vehicle 10. Direct clutchAT-274

3Shock is too large

when changing D2 →

D

3.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. ATF pressure switch 6, high and low reverse clutch sole-

noid valveAT- 1 5 6,

AT-142

4. CAN communication lineAT- 9 1

5. Engine speed signalAT-109

6. Turbine revolution sensorAT-103

7. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

8. Fluid level and stateAT- 5 1

9. Control valve with TCMAT-210

OFF vehicle 10. High and low reverse clutchAT-272

Page 132 of 3061

AT-62

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

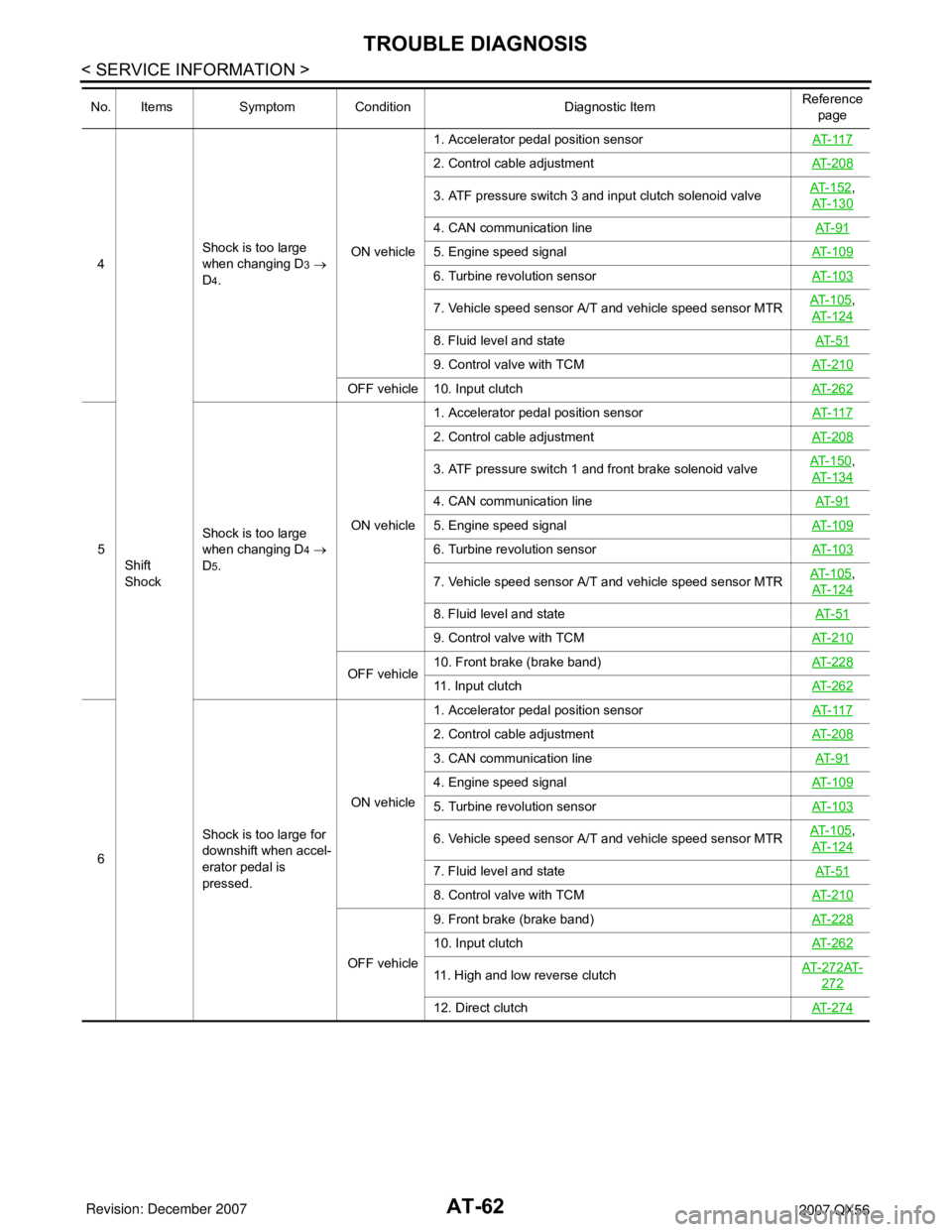

4

Shift

ShockShock is too large

when changing D3 →

D

4.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT- 2 0 8

3. ATF pressure switch 3 and input clutch solenoid valveAT- 1 5 2,

AT- 1 3 0

4. CAN communication lineAT- 9 1

5. Engine speed signalAT- 1 0 9

6. Turbine revolution sensorAT- 1 0 3

7. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

8. Fluid level and stateAT- 5 1

9. Control valve with TCMAT- 2 1 0

OFF vehicle 10. Input clutchAT- 2 6 2

5Shock is too large

when changing D4 →

D

5.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT- 2 0 8

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT- 1 3 4

4. CAN communication lineAT- 9 1

5. Engine speed signalAT- 1 0 9

6. Turbine revolution sensorAT- 1 0 3

7. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

8. Fluid level and stateAT- 5 1

9. Control valve with TCMAT- 2 1 0

OFF vehicle10. Front brake (brake band)AT- 2 2 811. Input clutchAT- 2 6 2

6Shock is too large for

downshift when accel-

erator pedal is

pressed.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT- 2 0 8

3. CAN communication lineAT- 9 1

4. Engine speed signalAT- 1 0 9

5. Turbine revolution sensorAT- 1 0 3

6. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

7. Fluid level and stateAT- 5 1

8. Control valve with TCMAT- 2 1 0

OFF vehicle9. Front brake (brake band)AT- 2 2 8

10. Input clutchAT- 2 6 2

11. High and low reverse clutchAT- 2 7 2AT-

272

12. Direct clutchAT- 2 7 4

No. Items Symptom Condition Diagnostic ItemReference

page

Page 133 of 3061

TROUBLE DIAGNOSIS

AT-63

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

7

Shift

ShockShock is too large for

upshift when accelera-

tor pedal is released.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. Engine speed signalAT-109

4. CAN communication lineAT- 9 1

5. Turbine revolution sensorAT-103

6. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

7. Fluid level and stateAT- 5 1

8. Control valve with TCMAT-210

OFF vehicle9. Front brake (brake band)AT-22810. Input clutchAT-262

11. High and low reverse clutchAT-272

12. Direct clutchAT-274

8Shock is too large for

lock-up.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. Engine speed signalAT-109

4. CAN communication lineAT- 9 1

5. Turbine revolution sensorAT-103

6. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

7. Torque converter clutch solenoid valveAT- 111

8. Fluid level and stateAT- 5 1

9. Control valve with TCMAT-210

OFF vehicle 10. Torque converterAT-240

9Shock is too large dur-

ing engine brake.ON vehicle1. Accelerator pedal position sensorAT- 11 7

2. Control cable adjustmentAT-208

3. CAN communication lineAT- 9 1

4. Fluid level and stateAT- 5 1

5. Control valve with TCMAT-210

OFF vehicle6. Front brake (brake band)AT-2287. Input clutchAT-262

8. High and low reverse clutchAT-272

9. Direct clutchAT-274

No. Items Symptom Condition Diagnostic ItemReference

page

Page 134 of 3061

AT-64

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

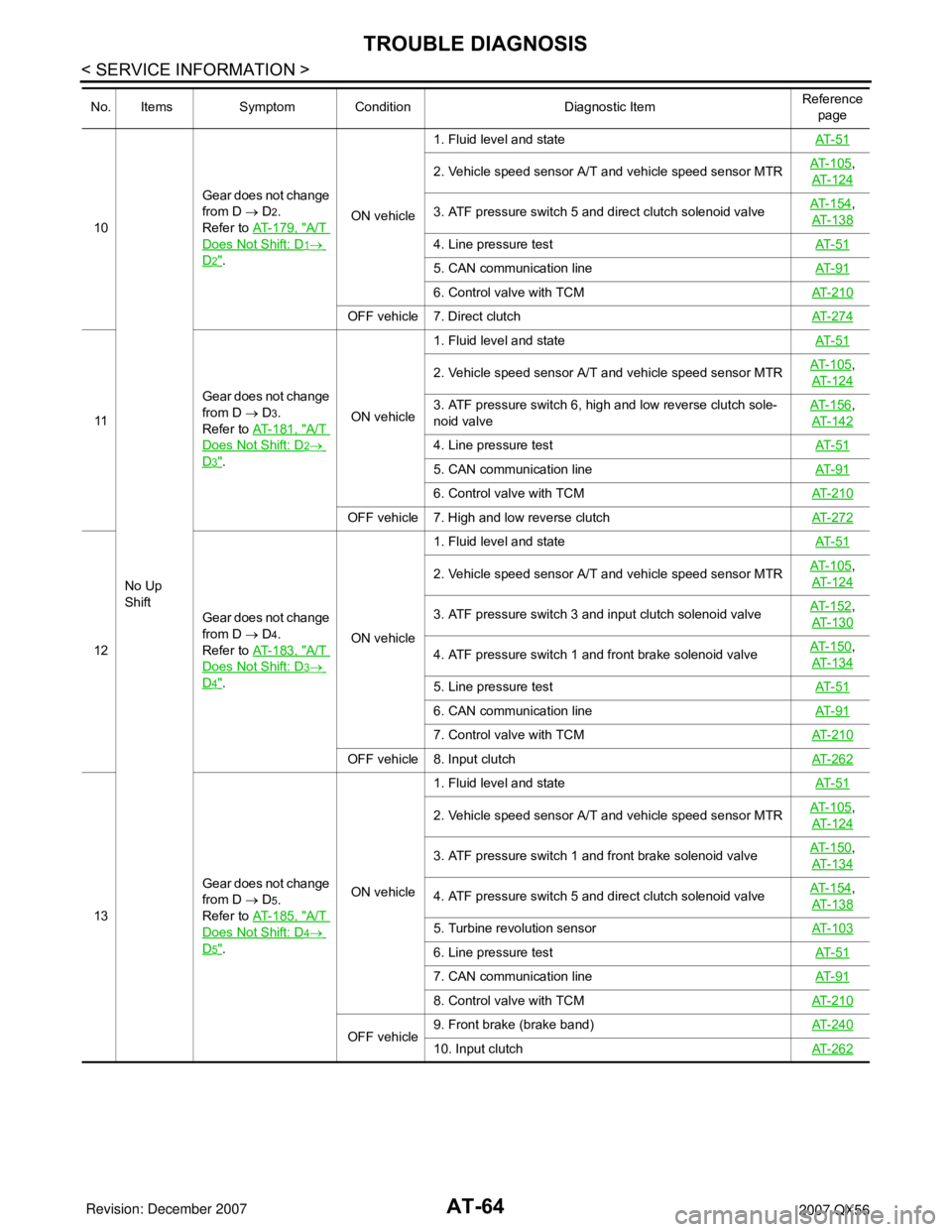

10

No Up

ShiftGear does not change

from D → D

2.

Refer to AT-179, "

A/T

Does Not Shift: D1→

D2".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT- 1 3 8

4. Line pressure testAT- 5 1

5. CAN communication lineAT- 9 1

6. Control valve with TCMAT- 2 1 0

OFF vehicle 7. Direct clutchAT- 2 7 4

11Gear does not change

from D → D3.

Refer to AT-181, "

A/T

Does Not Shift: D2→

D3".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. ATF pressure switch 6, high and low reverse clutch sole-

noid valveAT- 1 5 6,

AT- 1 4 2

4. Line pressure testAT- 5 1

5. CAN communication lineAT- 9 1

6. Control valve with TCMAT- 2 1 0

OFF vehicle 7. High and low reverse clutchAT- 2 7 2

12Gear does not change

from D → D

4.

Refer to AT-183, "

A/T

Does Not Shift: D3→

D4".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. ATF pressure switch 3 and input clutch solenoid valveAT- 1 5 2,

AT- 1 3 0

4. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT- 1 3 4

5. Line pressure testAT- 5 1

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT- 2 1 0

OFF vehicle 8. Input clutchAT- 2 6 2

13Gear does not change

from D → D

5.

Refer to AT-185, "

A/T

Does Not Shift: D4→

D5".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT- 1 3 4

4. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT- 1 3 8

5. Turbine revolution sensorAT- 1 0 3

6. Line pressure testAT- 5 1

7. CAN communication lineAT- 9 1

8. Control valve with TCMAT- 2 1 0

OFF vehicle9. Front brake (brake band)AT- 2 4 010. Input clutchAT- 2 6 2

No. Items Symptom Condition Diagnostic ItemReference

page

Page 135 of 3061

TROUBLE DIAGNOSIS

AT-65

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

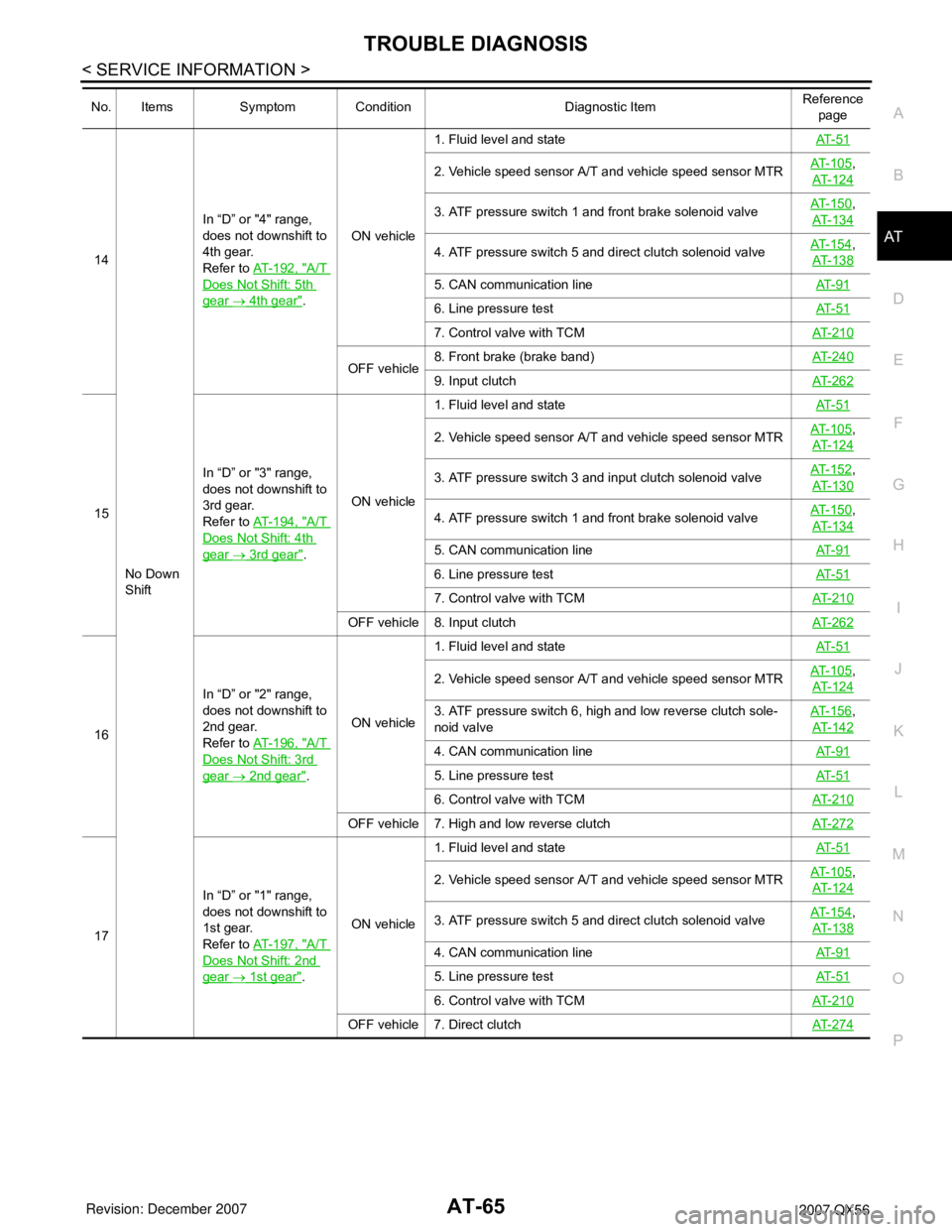

14

No Down

ShiftIn “D” or "4" range,

does not downshift to

4th gear.

Refer to AT- 1 9 2 , "A/T

Does Not Shift: 5th

gear → 4th gear".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0

,

AT-134

4. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT-138

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 5 1

7. Control valve with TCMAT-210

OFF vehicle8. Front brake (brake band)AT-2409. Input clutchAT-262

15In “D” or "3" range,

does not downshift to

3rd gear.

Refer to AT- 1 9 4 , "A/T

Does Not Shift: 4th

gear → 3rd gear".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

3. ATF pressure switch 3 and input clutch solenoid valveAT- 1 5 2,

AT-130

4. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT-134

5. CAN communication lineAT- 9 1

6. Line pressure testAT- 5 1

7. Control valve with TCMAT-210

OFF vehicle 8. Input clutchAT-262

16In “D” or "2" range,

does not downshift to

2nd gear.

Refer to AT- 1 9 6 , "A/T

Does Not Shift: 3rd

gear → 2nd gear".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

3. ATF pressure switch 6, high and low reverse clutch sole-

noid valveAT- 1 5 6

,

AT-142

4. CAN communication lineAT- 9 1

5. Line pressure testAT- 5 1

6. Control valve with TCMAT-210

OFF vehicle 7. High and low reverse clutchAT-272

17In “D” or "1" range,

does not downshift to

1st gear.

Refer to AT- 1 9 7 , "A/T

Does Not Shift: 2nd

gear → 1st gear".ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT-124

3. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT-138

4. CAN communication lineAT- 9 1

5. Line pressure testAT- 5 1

6. Control valve with TCMAT-210

OFF vehicle 7. Direct clutchAT-274

No. Items Symptom Condition Diagnostic ItemReference

page

Page 136 of 3061

AT-66

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

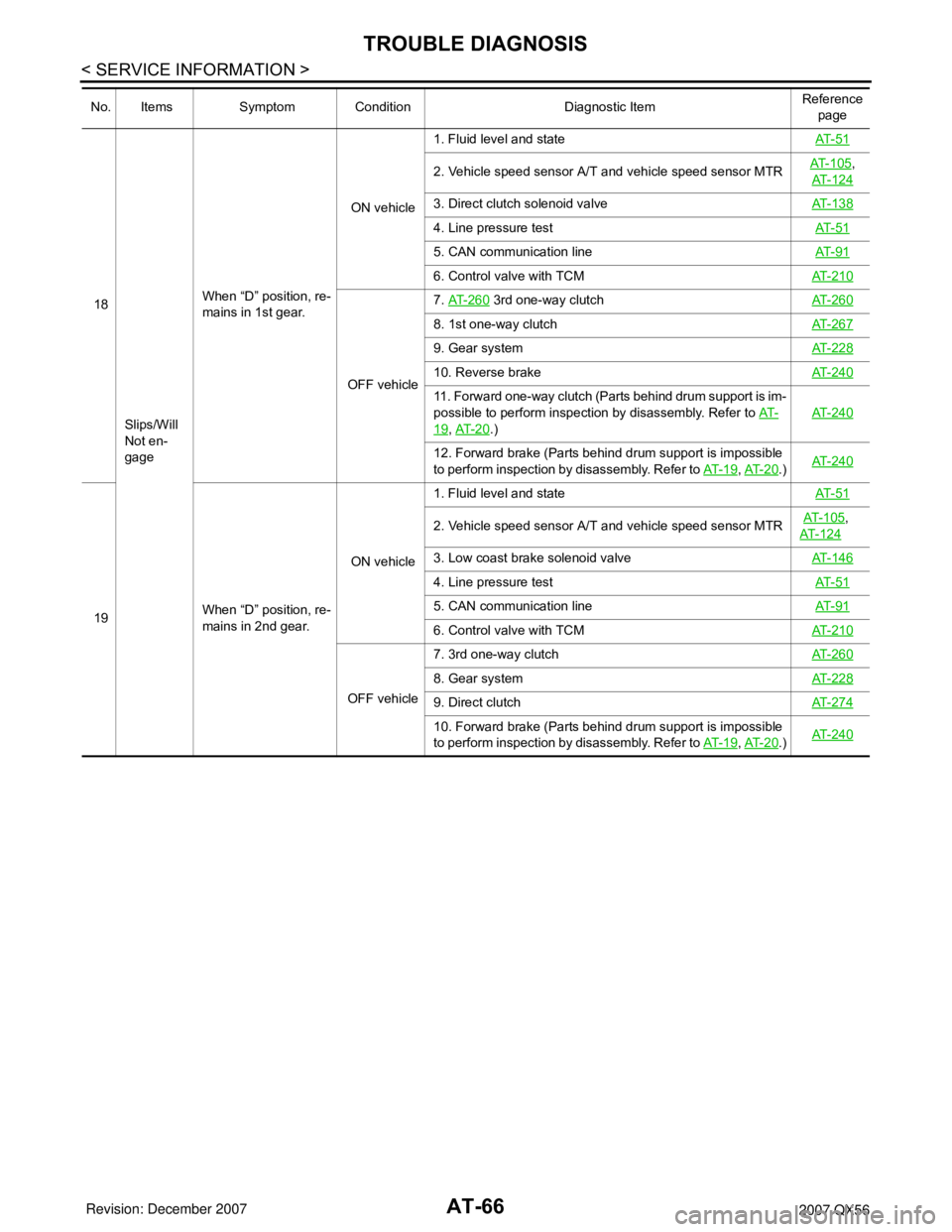

18

Slips/Will

Not en-

gageWhen “D” position, re-

mains in 1st gear.ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

3. Direct clutch solenoid valveAT- 1 3 8

4. Line pressure testAT- 5 1

5. CAN communication lineAT- 9 1

6. Control valve with TCMAT- 2 1 0

OFF vehicle7. AT- 2 6 0

3rd one-way clutchAT- 2 6 0

8. 1st one-way clutchAT- 2 6 7

9. Gear systemAT- 2 2 8

10. Reverse brakeAT- 2 4 0

11. Forward one-way clutch (Parts behind drum support is im-

possible to perform inspection by disassembly. Refer to AT-

19, AT- 2 0.)AT- 2 4 0

12. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

19When “D” position, re-

mains in 2nd gear.ON vehicle1. Fluid level and stateAT- 5 1

2. Vehicle speed sensor A/T and vehicle speed sensor MTR AT- 1 0 5,

AT- 1 2 4

3. Low coast brake solenoid valveAT- 1 4 6

4. Line pressure testAT- 5 1

5. CAN communication lineAT- 9 1

6. Control valve with TCMAT- 2 1 0

OFF vehicle7. 3rd one-way clutchAT- 2 6 0

8. Gear systemAT- 2 2 8

9. Direct clutchAT- 2 7 4

10. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

No. Items Symptom Condition Diagnostic ItemReference

page