engine oil INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 144 of 3061

AT-74

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

36

Slips/Will

Not En-

gageWith selector lever in

“R” position, accelera-

tion is extremely poor.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. ATF pressure switch 6, high and low reverse clutch sole-

noid valveAT- 1 5 6,

AT- 1 4 2

5. CAN communication lineAT- 9 1

6. PNP switchAT- 9 9

7. Control cable adjustmentAT- 2 0 8

8. Control valve with TCMAT- 2 1 0

OFF vehicle9. Gear systemAT- 2 2 810. Output shaftAT- 2 4 0

11. Reverse brakeAT- 2 4 0

37While starting off by

accelerating in 1st, en-

gine races or slippage

occurs.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. CAN communication lineAT- 9 1

5. Control valve with TCMAT- 2 1 0

OFF vehicle6. Torque converterAT- 2 4 0

7. Oil pump assemblyAT- 2 5 8

8. 3rd one-way clutchAT- 2 6 0

9. 1st one-way clutchAT- 2 6 7

10. Gear systemAT- 2 2 8

11. Reverse brakeAT- 2 4 0

12. Forward one- way clutch (Parts behind drum support is

impossible to perform inspection by disassembly. Refer to AT-

19, AT- 2 0.)AT- 2 4 0

13. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

38While accelerating in

2nd, engine races or

slippage occurs.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. CAN communication lineAT- 9 1

5. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT- 1 3 8

6. Control valve with TCMAT- 2 1 0

OFF vehicle7. Torque converterAT- 2 4 0

8. Oil pump assemblyAT- 2 5 8

9. 3rd one-way clutchAT- 2 6 0

10. Gear systemAT- 2 2 8

11. Direct clutchAT- 2 7 4

12. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

No. Items Symptom Condition Diagnostic ItemReference

page

Page 145 of 3061

TROUBLE DIAGNOSIS

AT-75

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

39

Slips/Will

Not En-

gageWhile accelerating in

3rd, engine races or

slippage occurs.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. CAN communication lineAT- 9 1

5. ATF pressure switch 6, high and low reverse clutch sole-

noid valveAT- 1 5 6,

AT-142

6. Control valve with TCMAT-210

OFF vehicle7. Torque converterAT-240

8. Oil pump assemblyAT-258

9. 3rd one-way clutchAT-260

10. Gear systemAT-228

11. High and low reverse clutchAT-272

12. Forward one- way clutch (Parts behind drum support is

impossible to perform inspection by disassembly. Refer to AT-

19, AT- 2 0.)AT-240

13. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT-240

40While accelerating in

4th, engine races or

slippage occurs.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. CAN communication lineAT- 9 1

5. ATF pressure switch 3 and input clutch solenoid valveAT- 1 5 2,

AT-130

6. Control valve with TCMAT-210

OFF vehicle7. Torque converterAT-240

8. Oil pump assemblyAT-258

9. Input clutchAT-262

10. Gear systemAT-228

11. High and low reverse clutchAT-272

12. Direct clutchAT-274

No. Items Symptom Condition Diagnostic ItemReference

page

Page 146 of 3061

AT-76

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

41

Slips/Will

Not En-

gage While accelerating in

5th, engine races or

slippage occurs.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. CAN communication lineAT- 9 1

5. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT- 1 3 4

6. Control valve with TCMAT- 2 1 0

OFF vehicle7. Torque converterAT- 2 4 0

8. Oil pump assemblyAT- 2 5 8

9. Front brake (brake band)AT- 2 4 0

10. Input clutchAT- 2 6 2

11. Gear systemAT- 2 2 8

12. High and low reverse clutchAT- 2 7 2

42 Slips at lock-up.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Engine speed signalAT- 1 0 9

4. Turbine revolution sensorAT- 1 0 3

5. Torque converter clutch solenoid valveAT- 111

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT- 2 1 0

OFF vehicle8. Torque converterAT- 2 4 09. Oil pump assemblyAT- 2 5 8

43No creep at all.

Refer to AT-172, "

Ve -

hicle Does Not Creep

Backward in "R" Posi-

tion", AT- 1 7 5 , "Vehicle

Does Not Creep For-

ward in "D" Position"

ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT- 1 3 8

5. PNP switchAT- 9 9

6. CAN communication lineAT- 9 1

7. Control cable adjustmentAT- 2 0 8

8. Control valve with TCMAT- 2 1 0

OFF vehicle9. Torque converterAT- 2 4 0

10. Oil pump assemblyAT- 2 5 8

11. 1st one-way clutchAT- 2 6 7

12. Gear systemAT- 2 2 8

13. Reverse brakeAT- 2 4 0

14. Direct clutchAT- 2 7 4

15. Forward one- way clutch (Parts behind drum support is

impossible to perform inspection by disassembly. Refer to AT-

19, AT- 2 0.)AT- 2 4 0

16. Forward brake (Parts behind drum support is impossible

to perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

No. Items Symptom Condition Diagnostic ItemReference

page

Page 148 of 3061

AT-78

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

48

OthersShift point is low in “D”

position.ON vehicle1. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5

,

AT- 1 2 4

2. Accelerator pedal position sensorAT- 11 7

3. CAN communication lineAT- 9 1

4. Control valve with TCMAT- 2 1 0

49Judder occurs during

lock-up.ON vehicle1. Fluid level and stateAT- 5 1

2. Engine speed signalAT- 1 0 9

3. Turbine revolution sensorAT- 1 0 3

4. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

5. Accelerator pedal position sensorAT- 11 7

6. CAN communication lineAT- 9 1

7. Torque converter clutch solenoid valveAT- 111

8. Control valve with TCMAT- 2 1 0

OFF vehicle 9. Torque converterAT- 2 4 0

50Strange noise in “R”

position.ON vehicle1. Fluid level and stateAT- 5 1

2. Engine speed signalAT- 1 0 9

3. CAN communication lineAT- 9 1

4. Control valve with TCMAT- 2 1 0

OFF vehicle5. Torque converterAT- 2 4 0

6. Oil pump assemblyAT- 2 5 8

7. Gear systemAT- 2 2 8

8. High and low reverse clutchAT- 2 7 2

9. Reverse brakeAT- 2 4 0

51Strange noise in “N”

position.ON vehicle1. Fluid level and stateAT- 5 1

2. Engine speed signalAT- 1 0 9

3. CAN communication lineAT- 9 1

4. Control valve with TCMAT- 2 1 0

OFF vehicle5. Torque converterAT- 2 4 06. Oil pump assemblyAT- 2 5 8

7. Gear systemAT- 2 2 8

52Strange noise in “D”

position.ON vehicle1. Fluid level and stateAT- 5 1

2. Engine speed signalAT- 1 0 9

3. CAN communication lineAT- 9 1

4. Control valve with TCMAT- 2 1 0

OFF vehicle5. Torque converterAT- 2 4 0

6. Oil pump assemblyAT- 2 5 8

7. Gear systemAT- 2 2 8

8. Forward brake (Parts behind drum support is impossible to

perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

No. Items Symptom Condition Diagnostic ItemReference

page

Page 150 of 3061

AT-80

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

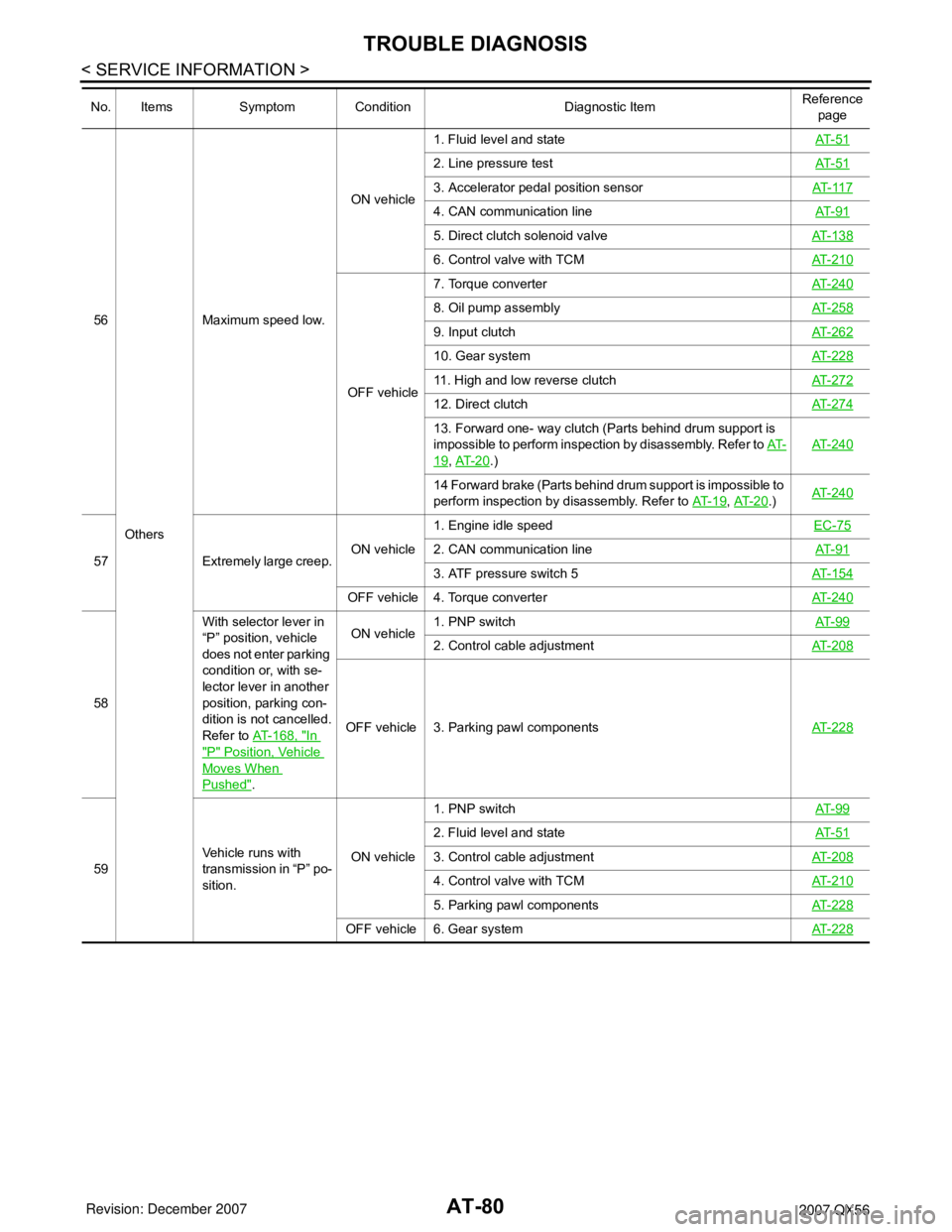

56

OthersMaximum speed low.ON vehicle1. Fluid level and stateAT- 5 1

2. Line pressure testAT- 5 1

3. Accelerator pedal position sensorAT- 11 7

4. CAN communication lineAT- 9 1

5. Direct clutch solenoid valveAT- 1 3 8

6. Control valve with TCMAT- 2 1 0

OFF vehicle7. Torque converterAT- 2 4 0

8. Oil pump assemblyAT- 2 5 8

9. Input clutchAT- 2 6 2

10. Gear systemAT- 2 2 8

11. High and low reverse clutchAT- 2 7 2

12. Direct clutchAT- 2 7 4

13. Forward one- way clutch (Parts behind drum support is

impossible to perform inspection by disassembly. Refer to AT-

19, AT- 2 0.)AT- 2 4 0

14 Forward brake (Parts behind drum support is impossible to

perform inspection by disassembly. Refer to AT- 1 9

, AT- 2 0.)AT- 2 4 0

57 Extremely large creep.ON vehicle1. Engine idle speed EC-75

2. CAN communication lineAT- 9 1

3. ATF pressure switch 5AT- 1 5 4

OFF vehicle 4. Torque converterAT- 2 4 0

58With selector lever in

“P” position, vehicle

does not enter parking

condition or, with se-

lector lever in another

position, parking con-

dition is not cancelled.

Refer to AT-168, "

In

"P" Position, Vehicle

Moves When

Pushed".ON vehicle1. PNP switchAT- 9 9

2. Control cable adjustmentAT- 2 0 8

OFF vehicle 3. Parking pawl componentsAT- 2 2 8

59Vehicle runs with

transmission in “P” po-

sition.ON vehicle1. PNP switchAT- 9 9

2. Fluid level and stateAT- 5 1

3. Control cable adjustmentAT- 2 0 8

4. Control valve with TCMAT- 2 1 0

5. Parking pawl componentsAT- 2 2 8

OFF vehicle 6. Gear systemAT- 2 2 8

No. Items Symptom Condition Diagnostic ItemReference

page

Page 185 of 3061

DTC P0745 LINE PRESSURE SOLENOID VALVE

AT-115

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC P0745 LINE PRESSURE SOLENOID VALVE

DescriptionINFOID:0000000003532316

The line pressure solenoid valve regulates the oil pump discharge pressure to suit the driving condition in

response to a signal sent from the TCM.

The line pressure duty cycle value is not consistent when the closed throttle position signal is “ON”.

To confirm the line pressure duty cycle at low pressure, the accelerator (throttle) should be open until

the closed throttle position signal is “OFF”.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532317

On Board Diagnosis LogicINFOID:0000000003532318

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0745 L/PRESS SOL/CIRC” with CONSULT-II is detected under the following con-

ditions.

- When TCM detects an improper voltage drop when it tries to operate the solenoid valve.

- When TCM detects as irregular by comparing target value with monitor value.

Possible CauseINFOID:0000000003532319

• Harness or connectors

(The solenoid circuit is open or shorted.)

• Line pressure solenoid valve

DTC Confirmation ProcedureINFOID:0000000003532320

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch “ON” and select “DATA MONITOR” mode for

“ENGINE” with CONSULT-II.

2. Engine start and wait at least 5 second.

3. If DTC is detected, go to AT-115, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-II”.

Diagnosis ProcedureINFOID:0000000003532321

1.CHECK INPUT SIGNAL

With CONSULT-II

Item name Condition Display value (Approx.)

LINE PRES SOL During driving 0.2 - 0.6 A

BCIA0031E

Page 244 of 3061

AT-174

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Check the line pressure with the engine idling. Refer to AT-51,

"Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 9.

NG - 1 >> Line pressure high. GO TO 7.

NG - 2 >> Line pressure low. GO TO 8.

7.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

8.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

- Power train system. Refer to AT-240, "

Disassembly".

- Transmission case. Refer to AT-240, "

Disassembly".

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

9.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 10.

NG >> GO TO 13.

10.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.43).

OK or NG

OK >> GO TO 11.

NG >> Repair or replace damaged parts.

11 .CHECK SYMPTOM

Check again. Refer to AT-55, "

Check at Idle".

OK or NG

SAT494G

SCIA5199E

Page 248 of 3061

AT-178

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

NO >> GO TO 3.

3.CHECK ACCELERATOR PEDAL POSITION (APP) SENSOR

Check accelerator pedal position (APP) sensor. Refer to AT- 11 7

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position (APP) sensor.

4.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 5.

NG >> Refill ATF.

5.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT-51,

"Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 8.

NG - 1 >> Line pressure high. GO TO 6.

NG - 2 >> Line pressure low. GO TO 7.

6.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

7.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

- Power train system. Refer to AT-240, "

Disassembly".

- Transmission case. Refer to AT-240, "

Disassembly".

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SAT494G

Page 250 of 3061

AT-180

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Do the self-diagnostic results indicate ATF pressure switch 5, direct clutch solenoid valve, accelerator pedal

position sensor, vehicle speed sensor A/T (revolution sensor) and vehicle speed sensor MTR?

YES >> Check the malfunctioning system. Refer to AT-154' AT-138' AT- 11 7' AT-105, AT-124.

NO >> GO TO 3.

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT-51,

"Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high. GO TO 5.

NG - 2 >> Line pressure low. GO TO 6.

5.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

- Power train system. Refer to AT-240, "

Disassembly".

- Transmission case. Refer to AT-240, "

Disassembly".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SAT494G

Page 252 of 3061

AT-182

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Do the self-diagnostic results indicate ATF pressure switch 6, high and low reverse clutch solenoid valve,

accelerator pedal position sensor, vehicle speed sensor A/T (revolution sensor) and vehicle speed sensor

MTR?

YES >> Check the malfunctioning system. Refer to AT-156' AT-142' AT- 11 7' AT-105' AT-124.

NO >> GO TO 3.

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT-51,

"Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high. GO TO 5.

NG - 2 >> Line pressure low. GO TO 6.

5.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

- Power train system. Refer to AT-240, "

Disassembly".

- Transmission case. Refer to AT-240, "

Disassembly".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SAT494G