engine oil INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 992 of 3061

PRECAUTIONS

CO-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

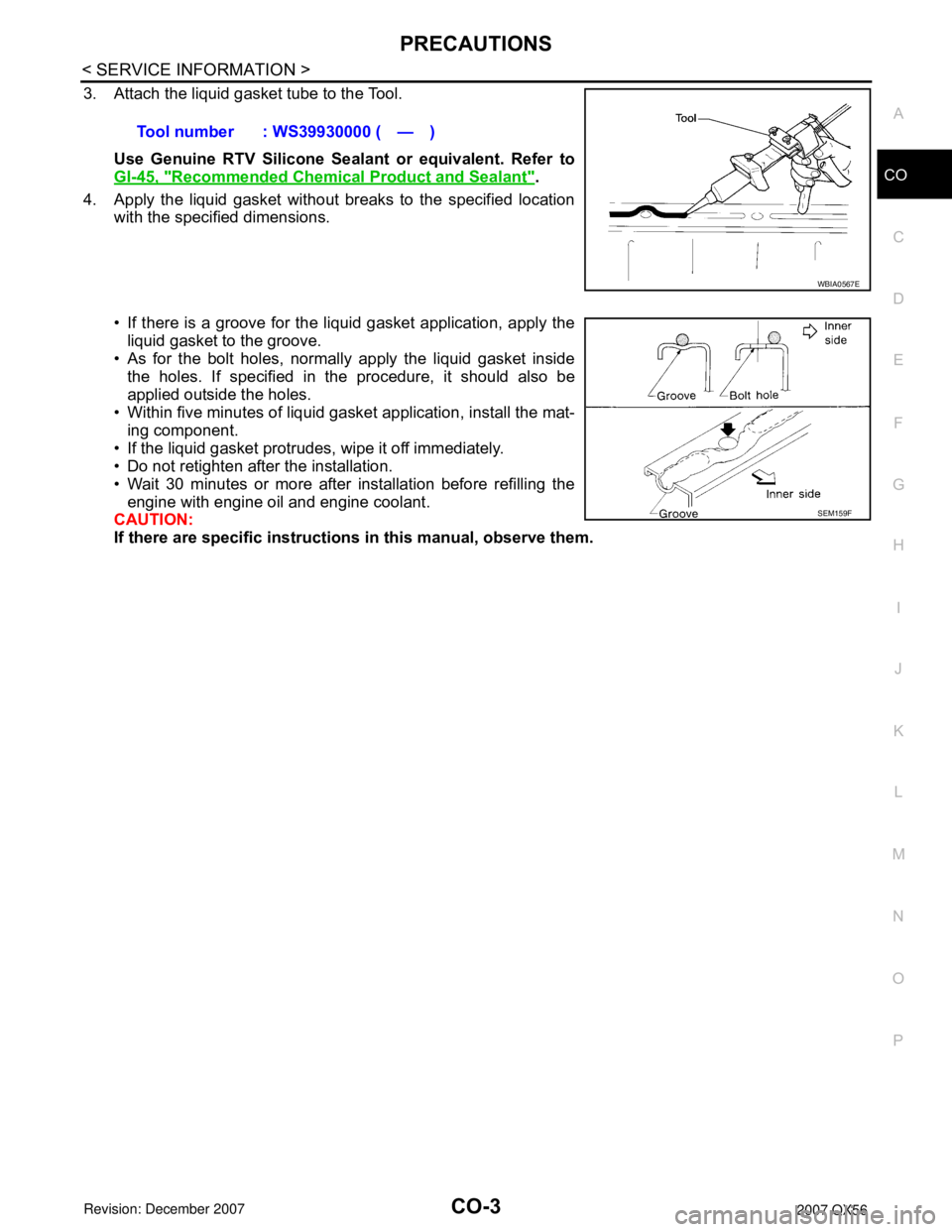

3. Attach the liquid gasket tube to the Tool.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-45, "

Recommended Chemical Product and Sealant".

4. Apply the liquid gasket without breaks to the specified location

with the specified dimensions.

• If there is a groove for the liquid gasket application, apply the

liquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the

engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them. Tool number : WS39930000 ( — )

WBIA0567E

SEM159F

Page 993 of 3061

CO-4

< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003531564

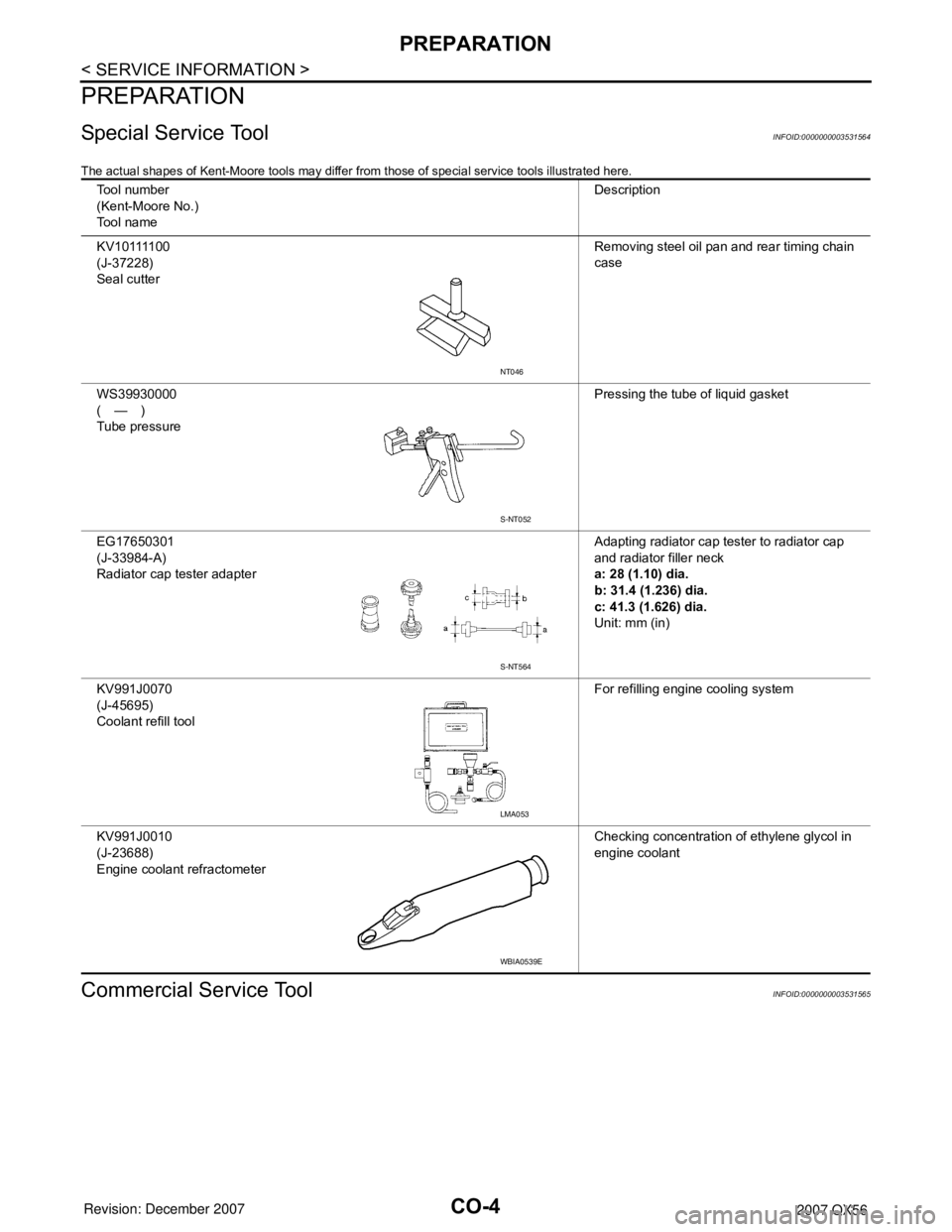

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000003531565

Tool number

(Kent-Moore No.)

Tool nameDescription

K V 1 0 1111 0 0

(J-37228)

Seal cutterRemoving steel oil pan and rear timing chain

case

WS39930000

(—)

Tube pressurePressing the tube of liquid gasket

EG17650301

(J-33984-A)

Radiator cap tester adapterAdapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV991J0070

(J-45695)

Coolant refill toolFor refilling engine cooling system

KV991J0010

(J-23688)

Engine coolant refractometerChecking concentration of ethylene glycol in

engine coolant

NT046

S-NT052

S-NT564

LMA053

WBIA0539E

Page 999 of 3061

CO-10

< SERVICE INFORMATION >

ENGINE COOLANT

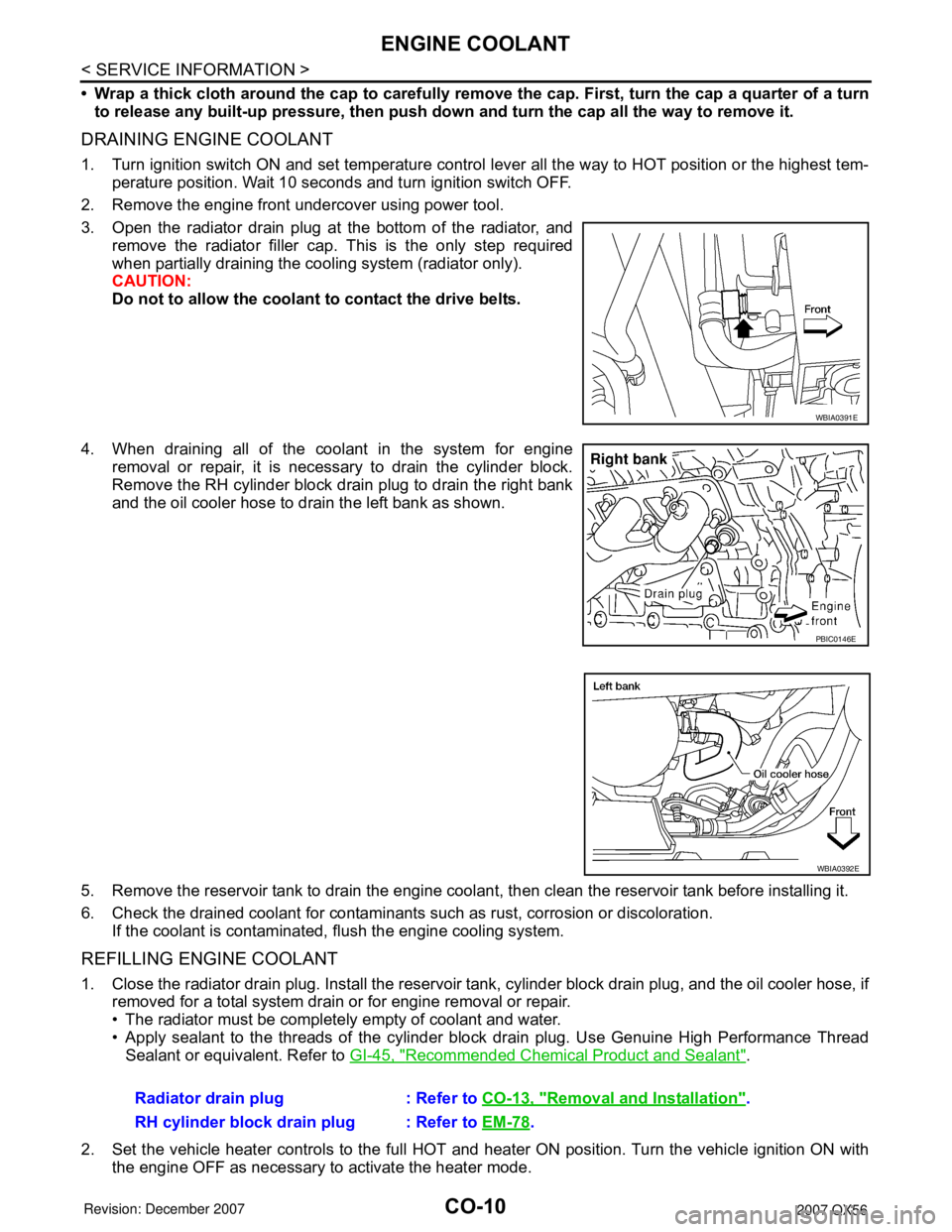

• Wrap a thick cloth around the cap to carefully remove the cap. First, turn the cap a quarter of a turn

to release any built-up pressure, then push down and turn the cap all the way to remove it.

DRAINING ENGINE COOLANT

1. Turn ignition switch ON and set temperature control lever all the way to HOT position or the highest tem-

perature position. Wait 10 seconds and turn ignition switch OFF.

2. Remove the engine front undercover using power tool.

3. Open the radiator drain plug at the bottom of the radiator, and

remove the radiator filler cap. This is the only step required

when partially draining the cooling system (radiator only).

CAUTION:

Do not to allow the coolant to contact the drive belts.

4. When draining all of the coolant in the system for engine

removal or repair, it is necessary to drain the cylinder block.

Remove the RH cylinder block drain plug to drain the right bank

and the oil cooler hose to drain the left bank as shown.

5. Remove the reservoir tank to drain the engine coolant, then clean the reservoir tank before installing it.

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Close the radiator drain plug. Install the reservoir tank, cylinder block drain plug, and the oil cooler hose, if

removed for a total system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder block drain plug. Use Genuine High Performance Thread

Sealant or equivalent. Refer to GI-45, "

Recommended Chemical Product and Sealant".

2. Set the vehicle heater controls to the full HOT and heater ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

WBIA0391E

PBIC0146E

WBIA0392E

Radiator drain plug : Refer to CO-13, "Removal and Installation".

RH cylinder block drain plug : Refer to EM-78

.

Page 1005 of 3061

CO-16

< SERVICE INFORMATION >

ENGINE COOLING FAN

ENGINE COOLING FAN

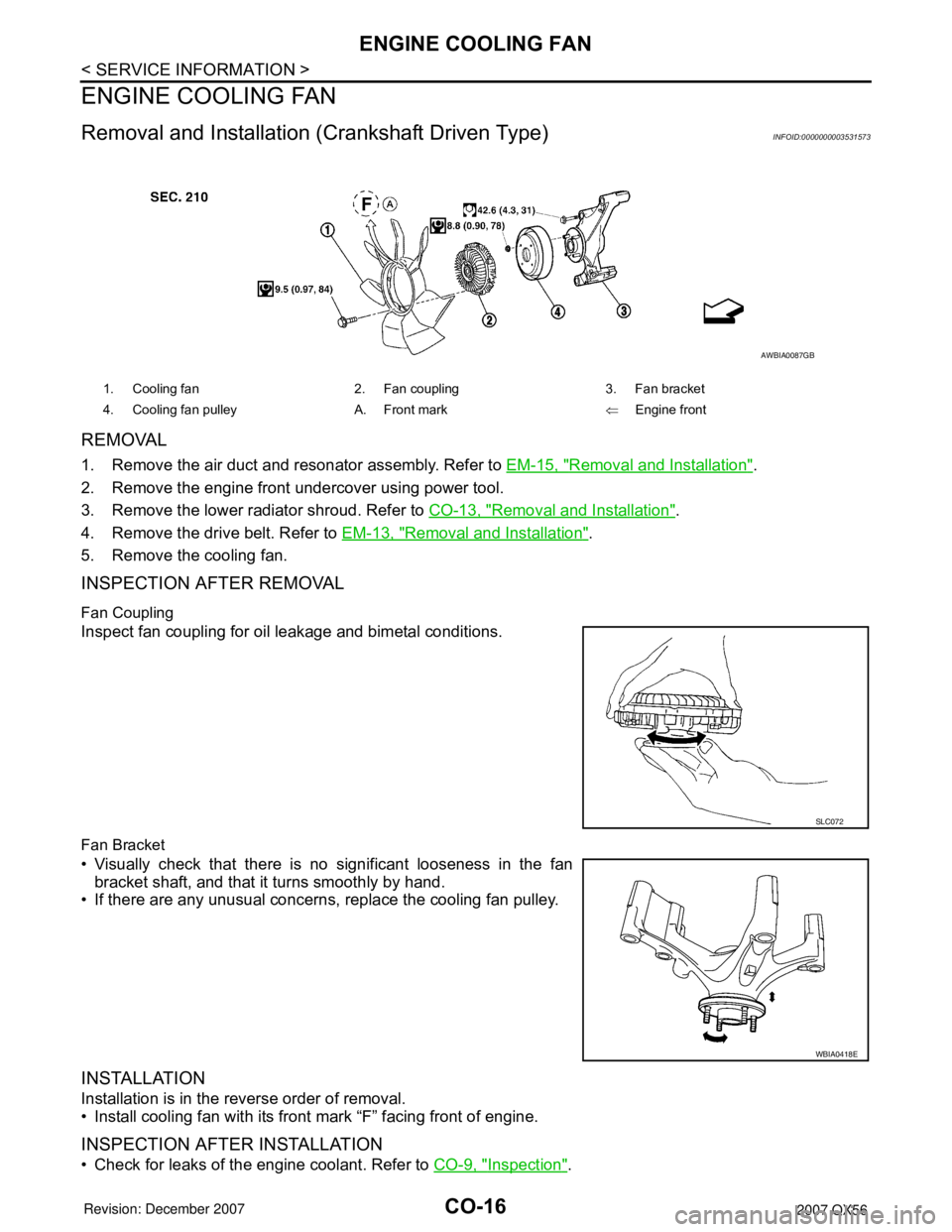

Removal and Installation (Crankshaft Driven Type)INFOID:0000000003531573

REMOVAL

1. Remove the air duct and resonator assembly. Refer to EM-15, "Removal and Installation".

2. Remove the engine front undercover using power tool.

3. Remove the lower radiator shroud. Refer to CO-13, "

Removal and Installation".

4. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

5. Remove the cooling fan.

INSPECTION AFTER REMOVAL

Fan Coupling

Inspect fan coupling for oil leakage and bimetal conditions.

Fan Bracket

• Visually check that there is no significant looseness in the fan

bracket shaft, and that it turns smoothly by hand.

• If there are any unusual concerns, replace the cooling fan pulley.

INSTALLATION

Installation is in the reverse order of removal.

• Install cooling fan with its front mark “F” facing front of engine.

INSPECTION AFTER INSTALLATION

• Check for leaks of the engine coolant. Refer to CO-9, "Inspection".

1. Cooling fan 2. Fan coupling 3. Fan bracket

4. Cooling fan pulley A. Front mark⇐Engine front

AWBIA0087GB

SLC072

WBIA0418E

Page 1012 of 3061

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................3

PRECAUTION ................................................ .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

PREPARATION ...................................................4

Commercial Service Tool .................................... ......4

COMBINATION METERS ...................................5

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

5

System Description ...................................................5

Arrangement of Combination Meter ..........................7

Internal Circuit ...........................................................8

Wiring Diagram - METER - .......................................9

Combination Meter Harness Connector Terminal

Layout .....................................................................

11

Terminal and Reference Value for Combination

Meter .......................................................................

11

Self-Diagnosis Mode of Combination Meter ........ ....12

How to Proceed with Trouble Diagnosis ............. ....15

Preliminary Check ...................................................15

Symptom Chart .......................................................16

Power Supply and Ground Circuit Inspection .........16

Vehicle Speed Signal Inspection .............................17

Engine Oil Pressure Signal Inspection ....................17

Water Temperature Signal Inspection .....................18

Engine Speed Signal Inspection ......................... ....18

Fuel Level Sensor Unit Inspection ...................... ....18

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies .................................................................. ....

20

Fuel Gauge Does Not Move to Full-position ...........20

Electrical Component Inspection ......................... ....21

Removal and Installation of Combination Meter .....21

COMPASS AND THERMOMETER ................ ....22

System Description ............................................. ....22

Wiring Diagram - COMPAS - ..................................23

Trouble Diagnosis ............................................... ....23

Calibration Procedure for Compass .................... ....24

WARNING LAMPS ............................................26

Schematic ............................................................ ....26

Wiring Diagram - WARN - .......................................27

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

32

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

33

A/T INDICATOR ................................................34

Wiring Diagram - AT/IND - .......................................34

A/T Indicator Does Not Illuminate ............................34

WARNING CHIME .............................................36

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

36

System Description ..................................................36

CAN Communication System Description ...............37

Wiring Diagram - CHIME - .......................................38

Terminal and Reference Value for BCM ..................39

Terminal and Reference Value for Combination

Meter ................................................................... ....

39

How to Proceed with Trouble Diagnosis ..................40

Preliminary Check ............................................... ....40

CONSULT-II Function (BCM) ..................................40

All Warning Chimes Do Not Operate .......................41

Key Warning Chime and Light Warning Chime Do

Not Operate (Seat Belt Warning Chime Does Op-

erate) .......................................................................

41

Key Warning Chime Does Not Operate ...................42

Light Warning Chime Does Not Operate .................44

Seat Belt Warning Chime Does Not Operate ..........44

REAR SONAR SYSTEM ...................................46

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

46

System Description ..................................................46

Wiring Diagram - SONAR - ......................................48

Sonar Control Unit Harness Connector Terminal

Layout ......................................................................

50

Page 1017 of 3061

![INFINITI QX56 2007 Factory Workshop Manual

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter t INFINITI QX56 2007 Factory Workshop Manual

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter t](/img/42/57029/w960_57029-1016.png)

DI-6

< SERVICE INFORMATION >

COMBINATION METERS

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter terminal 8.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No.14, located in the fuse block (J/B)]

• to combination meter terminal 24.

Ground is supplied

• to combination meter terminal 17

• through body grounds M57, M61 and M79.

WATER TEMPERATURE GAUGE

The water temperature gauge indicates the engine coolant temperature.

ECM provides an engine coolant temperature signal to combination meter via CAN communication lines.

ENGINE OIL PRESSURE GAUGE

The engine oil pressure gauge indicates whether the engine oil pressure is low or normal.

The oil pressure gauge is controlled by the IPDM E/R (intelligent power distribution module engine room). Low

oil pressure causes oil pressure switch terminal 1 to provide ground to IPDM E/R terminal 42. The IPDM E/R

then signals the combination meter (unified meter control unit) via CAN communication lines and a low oil

pressure indication is displayed by the oil pressure gauge.

A/T OIL TEMPERATURE GAUGE

The A/T oil temperature gauge indicates the A/T fluid temperature.

TCM (transmission control module) provides an A/T flui d temperature signal to combination meter via CAN

communication lines.

VOLTAGE GAUGE

The voltage gauge indicates the battery/charging system voltage.

The voltage gauge is regulated by the unified meter control unit.

TA C H O M E T E R

The tachometer indicates engine speed in revolutions per minute (rpm).

ECM provides an engine speed signal to combination meter via CAN communication lines.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by the unified meter control unit and a variable resistor signal supplied

• to combination meter terminal 15.

• through fuel level sensor unit and fuel pump terminal 2

• through fuel level sensor unit and fuel pump terminal 5

• from combination meter terminal 16

SPEEDOMETER

ABS actuator and electric unit (contro l unit) provides a vehicle speed signal to the combination meter via CAN

communication lines.

ODO/TRIP METER

The vehicle speed signal and the memory signals from the meter memory circuit are processed by the combi-

nation meter and the mileage is displayed.

How to Change the Display

Refer to Owner's Manual for odo/tr ip meter operating instructions.

CAN COMMUNICATION SYSTEM DESCRIPTION

Refer to LAN-4.

Page 1024 of 3061

COMBINATION METERSDI-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Next test requested EprXX Displays 8-bit software

configuration value in Hex

format.Bit Coding

7-2 = reserved for future use

1 = A/T Oil Temp (gauge)

0 = not present

1 = present

1 = Odo Units 0 = kilometers

1 = miles

Next test requested 1nFXX Displays 8-bit market info

value in Hex format.$31 = USA

$2A = Canada

Next test requested cYLXX Displays 8-bit engine con-

figuration value in Hex for-

mat.$08 = 8 cylinder

$06 = 6 cylinder

Next test requested bulb Illuminates all micro-con-

trolled lamps/LEDs re-

gardless of SW

configuration.

Next test requested D-HI Meter/LCD Illumination.

Next test requested (All segments illuminated) Lights all odometer/trip

meter, fuel, and engine

temperature display seg-

ments.Full daytime brightness all LCD

segments active

Next test requested N-HI Meter/LCD Illumination.

Next test requested (All segments illuminated) Lights all odometer/trip

meter, fuel, and engine

temperature display seg-

ments.Full nighttime brightness all

LCD segments active

Next test requested N-LO Meter/LCD Illumination.

Next test requested (All segments illuminated) Lights all odometer/trip

meter, fuel, and engine

temperature display seg-

ments.Min. nighttime brightness all

LCD segments active

Next test requested dS XX Current dimming step. 1-21

Next test requested EE XX, FAIL Hex EE level. If EE check-

sum fault exists, display

alternates between "EE

XX" and "FAIL".

Next test requested dtXXXX Hex coding of final manu-

facturing test date.

Next test requested GAGE Performs sweep of all

gauges, then displays

present gauge values.

Performs checksum tests

on ROM and EE.Gauges sweep within 10 sec-

onds

Next test requested FFXXXX Displays 16-bit fuel flow

constant "Q" in tenths of

cc/min in Hex format.$0000 - $FFFF

Next test requested tF Displays 16-bit tire factor

"A" in hundredths in Hex

format.$0000 - $FFFF

Next test requested oP Current oil pressure value

in A/D counts in hex for-

mat.

$00 - $FF

Next test requested ot1XX Displays oil pressure tell-

tale "on" threshold in A/D

counts in Hex format.$00 - $FF

Event Odometer Display Description of Test/Data Notes:

Page 1027 of 3061

DI-16

< SERVICE INFORMATION >

COMBINATION METERS

Perform self-diagnosis mode of combination meter. Refer to DI-12, "Self-Diagnosis Mode of Combination

Meter".

Does self-diagnosis mode operate normally?

YES >> GO TO 3.

NO >> Check combination meter power supply and ground circuit. Refer to DI-16, "

Power Supply and

Ground Circuit Inspection".

3.CHECK ODOMETER OPERATION

Check segment display status of odometer.

Is the display normal?

YES >> GO TO 4.

NO >> Replace the combination meter. Refer to IP-10,

"Removal and Installation".

4.CHECK COMBINATION METER CIRCUIT

Check indication of each meter/gauge in self-diagnosis mode.

OK or NG

OK >> Go to DI-16, "Symptom Chart".

NG >> Replace the combination meter. Refer to IP-10,

"Removal and Installation".

Symptom ChartINFOID:0000000003533489

Power Supply and Ground Circuit InspectionINFOID:0000000003533490

1.CHECK FUSES

Check for blown combination meter fuses.

WKIA1531E

WKIA1814E

Trouble phenomenon Possible cause

Improper tachometer indication. Refer to DI-18, "

Engine Speed Signal Inspection".

Improper water temperature gauge indication. Refer to DI-18, "

Water Temperature Signal Inspection".

Improper speedometer or odometer. Refer to DI-17, "

Vehicle Speed Signal Inspection".

Improper fuel gauge indication. Refer to DI-18, "

Fuel Level Sensor Unit Inspection".

Fuel warning lamp indication is irregular.

Improper A/T oil temperature gauge indication Refer to AT- 11 9

.

Improper voltage gauge indication Replace combination meter. Refer to IP-10, "

Removal and Instal-

lation".

More than one gauge does not give proper indication.

Improper A/T position indication. Refer to DI-34

.

Illumination control does not operate properly. Refer to LT- 1 2 0

.

Page 1028 of 3061

COMBINATION METERSDI-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Refer to DI-9, "Wiring Diagram - METER -".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-

3.

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect combination meter connector.

2. Check voltage between combination meter harness connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the harness for open between combination meter and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between combination meter harness connector terminal and ground.

OK or NG

OK >> Inspection End.

NG >> Repair harness or connector.

Vehicle Speed Signal InspectionINFOID:0000000003533491

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

Refer to BRC-26, "

CONSULT-II Function (ABS)".

OK or NG

OK >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NG >> Perform "Diagnostic Procedure" for displayed DTC. Refer to BRC-26, "

CONSULT-II Function

(ABS)".

Engine Oil Pressure Signal InspectionINFOID:0000000003533492

1.CHECK SELF-DIAGNOSTIC RESULTS OF IPDM E/R

Select "IPDM E/R" on CONSULT-II, and perform self-diagnosis of IPDM E/R. Refer to PG-18, "

CONSULT-II

Function (IPDM E/R)".

Unit Power source Fuse No.

Combination meter Battery 19

Ignition switch ON or START 14

Terminals Ignition switch position

(+) (–) OFF ACC ON

Connector Terminal

M24 8

Ground Battery

voltage Battery

voltage Battery

voltage

24 0V 0V Battery

voltage

WKIA5606E

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

M24 17 Ground Yes

WKIA1526E

Page 1029 of 3061

DI-18

< SERVICE INFORMATION >

COMBINATION METERS

Self-diagnostic results content

No malfunction detected>>GO TO 2.

Malfunction detected>>GO TO PG-18, "

CONSULT-II Function (IPDM E/R)".

2.CHECK IPDM E/R INPUT SIGNAL

Select "IPDM E/R" on CONSULT-II. Operate ignition switch with "OIL

P SW" of "DATA MONITOR" and check operation status.

OK or NG

OK >> Replace combination meter. Refer to IP-10, "Removal

and Installation".

NG >> GO TO 3.

3.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E122 and oil pressure switch

connector F4.

3. Check continuity between IPDM E/R harness connector E122 (A) terminal 42 and oil pressure switch harness connector F4 (B)

terminal 1.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK OIL PRESSURE SWITCH

Check oil pressure switch. Refer to DI-21, "

Electrical Component Inspection".

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R".

NG >> Replace oil pressure switch.

Water Temperature Signal InspectionINFOID:0000000003533493

1.CHECK ECM SELF-DIAGNOSIS

Perform ECM self-diagnosis. Refer to E C - 111 , "

CONSULT-II Function (ENGINE)".

OK or NG

OK >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NG >> Perform "Diagnostic procedure" for displayed DTC. Refer to EC-82

.

Engine Speed Signal InspectionINFOID:0000000003533494

1.CHECK ECM SELF-DIAGNOSIS

Perform ECM self-diagnosis. Refer to E C - 111 , "

CONSULT-II Function (ENGINE)".

OK or NG

OK >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NG >> Perform "Diagnostic procedure" for displayed DTC. Refer to EC-82

.

Fuel Level Sensor Unit InspectionINFOID:0000000003533495

FUEL LEVEL SENSOR UNIT

The following symptoms do not indicate a malfunction.When ignition switch is in ON

position (Engine stopped)

: OIL P SW CLOSE

When engine running : OIL P SW OPEN

LKIA0403E

Continuity should exist.

WKIA5607E