engine oil INFINITI QX56 2007 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 254 of 3061

AT-184

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Do the self-diagnostic results indicate ATF pressure switch 1, ATF pressure switch 3, front brake solenoid

valve, input clutch solenoid valve, accelerator pedal position sensor, vehicle speed sensor A/T (revolution sen-

sor) and vehicle speed sensor MTR?

YES >> Check the malfunctioning system. Refer to AT-150, AT- 1 5 2' AT-130, AT-134, AT- 11 7' AT-105' AT-

124.

NO >> GO TO 3.

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT-51,

"Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high. GO TO 5.

NG - 2 >> Line pressure low. GO TO 6.

5.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

- Power train system. Refer to AT-240, "

Disassembly".

- Transmission case. Refer to AT-240, "

Disassembly".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SAT494G

Page 256 of 3061

AT-186

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Do the self-diagnostic results indicate ATF pressure switch 1, ATF pressure switch 5, front brake solenoid

valve, direct clutch solenoid valve, accelerator pedal position sensor, turbine revolution sensor, vehicle speed

sensor A/T (revolution sensor) and vehicle speed sensor MTR?

YES >> Check the malfunctioning system. Refer to AT-150' AT-154, AT-134' AT-138' AT- 11 7' AT-103, AT-

105' AT-124.

NO >> GO TO 3.

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT-51,

"Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 7.

NG - 1 >> Line pressure high. GO TO 5.

NG - 2 >> Line pressure low. GO TO 6.

5.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

- Power train system. Refer to AT-240, "

Disassembly".

- Transmission case. Refer to AT-240, "

Disassembly".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SAT494G

Page 258 of 3061

AT-188

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Check A/T fluid level. Refer to AT-13, "Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer to AT-51,

"Inspections Before Trouble Diagnosis".

OK or NG

OK >> GO TO 6.

NG - 1 >> Line pressure high. GO TO 4.

NG - 2 >> Line pressure low. GO TO 5.

4.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer to AT-240, "

Disassembly".

3. Check the following items:

- Oil pump assembly. Refer to AT-258, "

Oil Pump".

- Power train system. Refer to AT-240, "

Disassembly".

- Transmission case. Refer to AT-240, "

Disassembly".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

6.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

SAT494G

Page 261 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-191

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

The lock-up condition cannot be cancelled even after releasing the accelerator pedal.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-83, "

CONSULT-II Function (A/T)".

Do the self-diagnostic results indicate torque converter clutch solenoid valve, engine speed signal, turbine rev-

olution sensor, CAN communication?

YES >> Check the malfunctioning system. Refer to AT- 111' AT-109' AT-103' AT- 9 1.

NO >> GO TO 2.

2.CHECK SYMPTOM

Check again. Refer to AT-55, "

Check at Idle".

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.PERFORM TCM INSPECTION

1. Perform TCM input/output signals inspection. Refer to AT-82, "

TCM Input/Output Signal Reference

Va l u e".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to IdleINFOID:0000000003532463

SYMPTOM:

When a shift-down is performed, the engine speed does not smoothly return to the idling speed.

DIAGNOSTIC PROCEDURE

1.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 2.

NG >> Refill ATF.

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-83, "

CONSULT-II Function (A/T)".

Do the self-diagnostic results indicate front brake solenoid valve, direct clutch solenoid valve, ATF pressure

switch 1, ATF pressure switch 5, accelerator pedal position sensor, vehicle speed sensor A/T (revolution sen-

sor) and vehicle speed sensor MTR?

YES >> Check the malfunctioning system. Refer to AT-134' AT-138, AT-150' AT-154' AT- 11 7, AT-105' AT-

124.

NO >> GO TO 3.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

SAT638A

Page 269 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-199

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

1. Remove oil pan. Refer to AT-210, "Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 6.

NG >> GO TO 9.

6.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.17).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 2".

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

8.PERFORM TCM INSPECTION

1. Perform TCM input/output signals inspection. Refer to AT-82, "

TCM Input/Output Signal Reference

Va l u e".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.17).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Vehicle Does Not Decelerate By Engine BrakeINFOID:0000000003532468

SYMPTOM:

No engine brake is applied when the gear is shifted from the 22 to 11.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Perform self-diagnosis.

Do the self-diagnosis results indicate PNP switch, ATF pressure switch 5?

YES >> Check the malfunctioning system. Refer to AT- 9 9' AT-154.

NO >> GO TO 2.

2.CHECK 1ST POSITION SWITCH CIRCUIT

With CONSULT-II

SCIA5199E

Page 295 of 3061

TRANSMISSION ASSEMBLY

AT-225

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

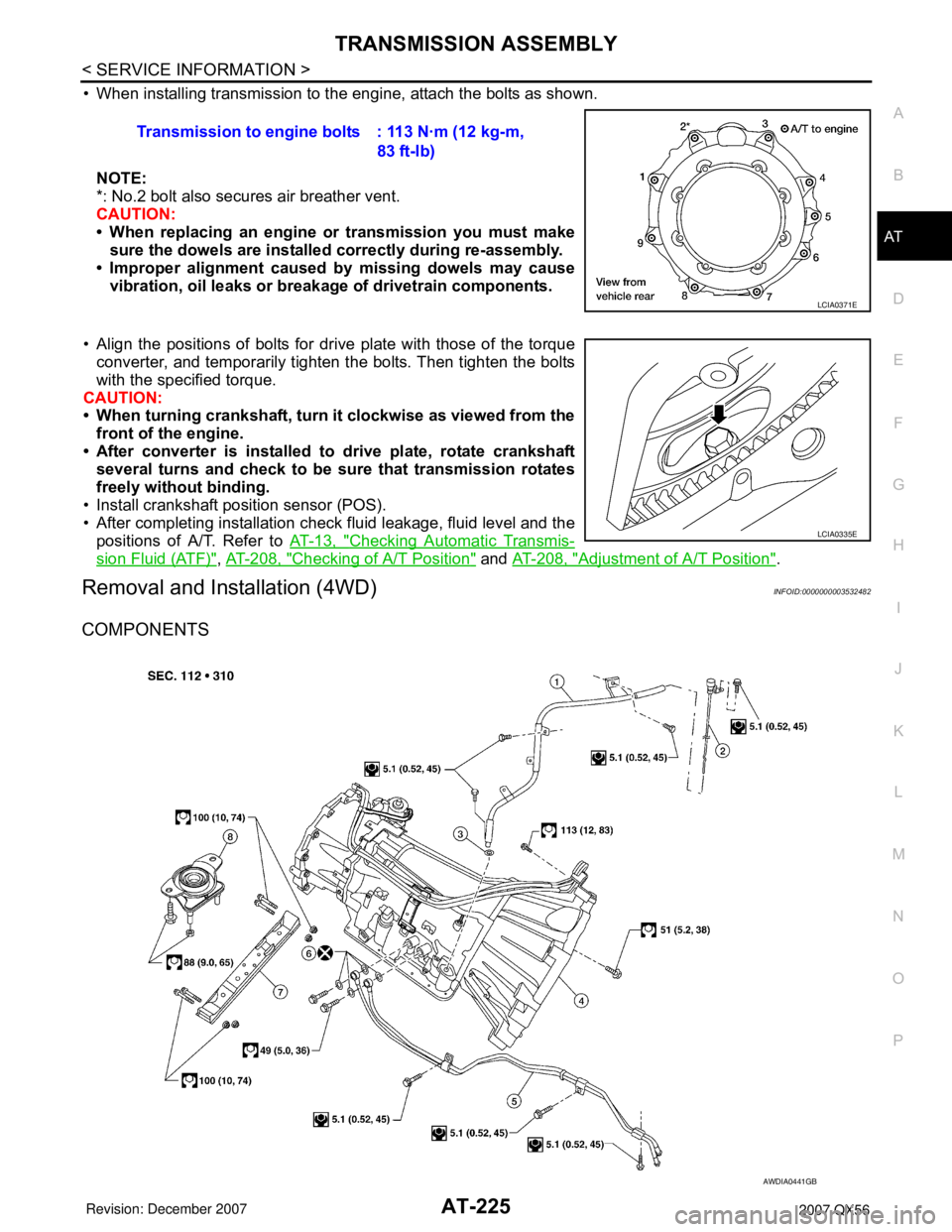

• When installing transmission to the engine, attach the bolts as shown.

NOTE:

*: No.2 bolt also secures air breather vent.

CAUTION:

• When replacing an engine or transmission you must make

sure the dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

• Align the positions of bolts for drive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque.

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

• After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

• Install crankshaft position sensor (POS).

• After completing installation check fluid leakage, fluid level and the

positions of A/T. Refer to AT-13, "

Checking Automatic Transmis-

sion Fluid (ATF)", AT-208, "Checking of A/T Position" and AT-208, "Adjustment of A/T Position".

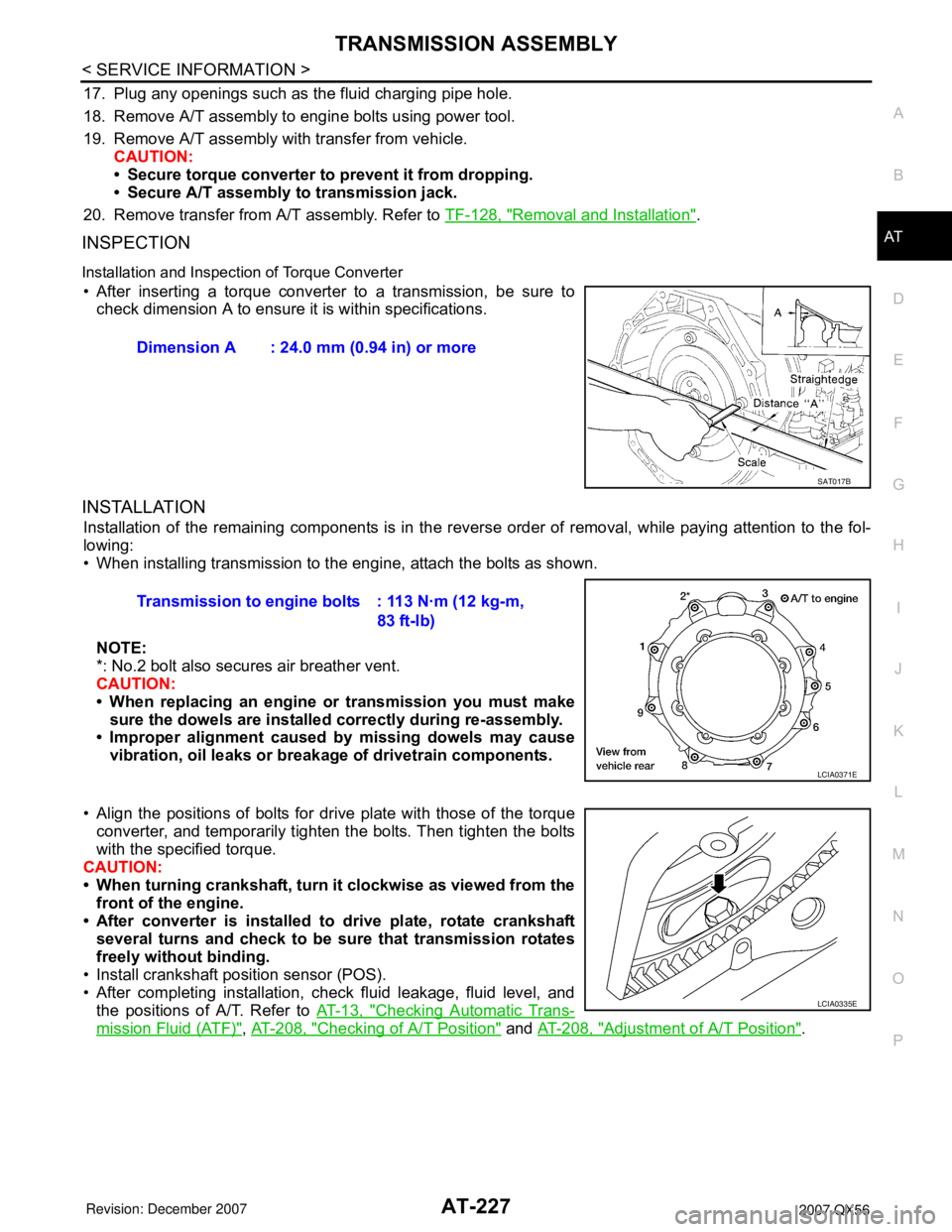

Removal and Installation (4WD)INFOID:0000000003532482

COMPONENTS

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

AWDIA0441GB

Page 297 of 3061

TRANSMISSION ASSEMBLY

AT-227

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

17. Plug any openings such as the fluid charging pipe hole.

18. Remove A/T assembly to engine bolts using power tool.

19. Remove A/T assembly with transfer from vehicle.

CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to transmission jack.

20. Remove transfer from A/T assembly. Refer to TF-128, "

Removal and Installation".

INSPECTION

Installation and Inspection of Torque Converter

• After inserting a torque converter to a transmission, be sure to

check dimension A to ensure it is within specifications.

INSTALLATION

Installation of the remaining components is in the reverse order of removal, while paying attention to the fol-

lowing:

• When installing transmission to the engine, attach the bolts as shown.

NOTE:

*: No.2 bolt also secures air breather vent.

CAUTION:

• When replacing an engine or transmission you must make

sure the dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

• Align the positions of bolts for drive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque.

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

• After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

• Install crankshaft position sensor (POS).

• After completing installation, check fluid leakage, fluid level, and

the positions of A/T. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)", AT-208, "Checking of A/T Position" and AT-208, "Adjustment of A/T Position". Dimension A : 24.0 mm (0.94 in) or more

SAT017B

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

Page 379 of 3061

PRECAUTIONSATC-9

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Precaution for Service of CompressorINFOID:0000000003533224

• Plug all openings to prevent moisture and foreign matter from entering.

• When the compressor is removed, store it in the same position as it is when mounted on the car.

• When replacing or repairing co mpressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to ATC-20, "

Maintenance of Oil Quantity in Compressor".

• Keep friction surfaces between clutch and pulley clean . If the surface is contaminated with oil, wipe

it off by using a clean wast e cloth moistened with thinner.

• After compressor service operation, turn the compressor shaft by hand more than 5 turns in both

directions. This will equa lly distribute oil inside the compresso r. After the compressor is installed,

let the engine idle and oper ate the compressor for 1 hour.

• After replacing the compressor magnet clutch, ap ply voltage to the new one and check for normal

operation. Refer to ATC-155, "

Removal and Installation for Compressor Clutch".

Precaution for Service EquipmentINFOID:0000000003533225

RECOVERY/RECYCLING EQUIPMENT

Follow the manufacturer's instructions for machine operation and machine maintenance. Never introduce any

refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions fo r tester operation and tester maintenance.

VACUUM PUMP

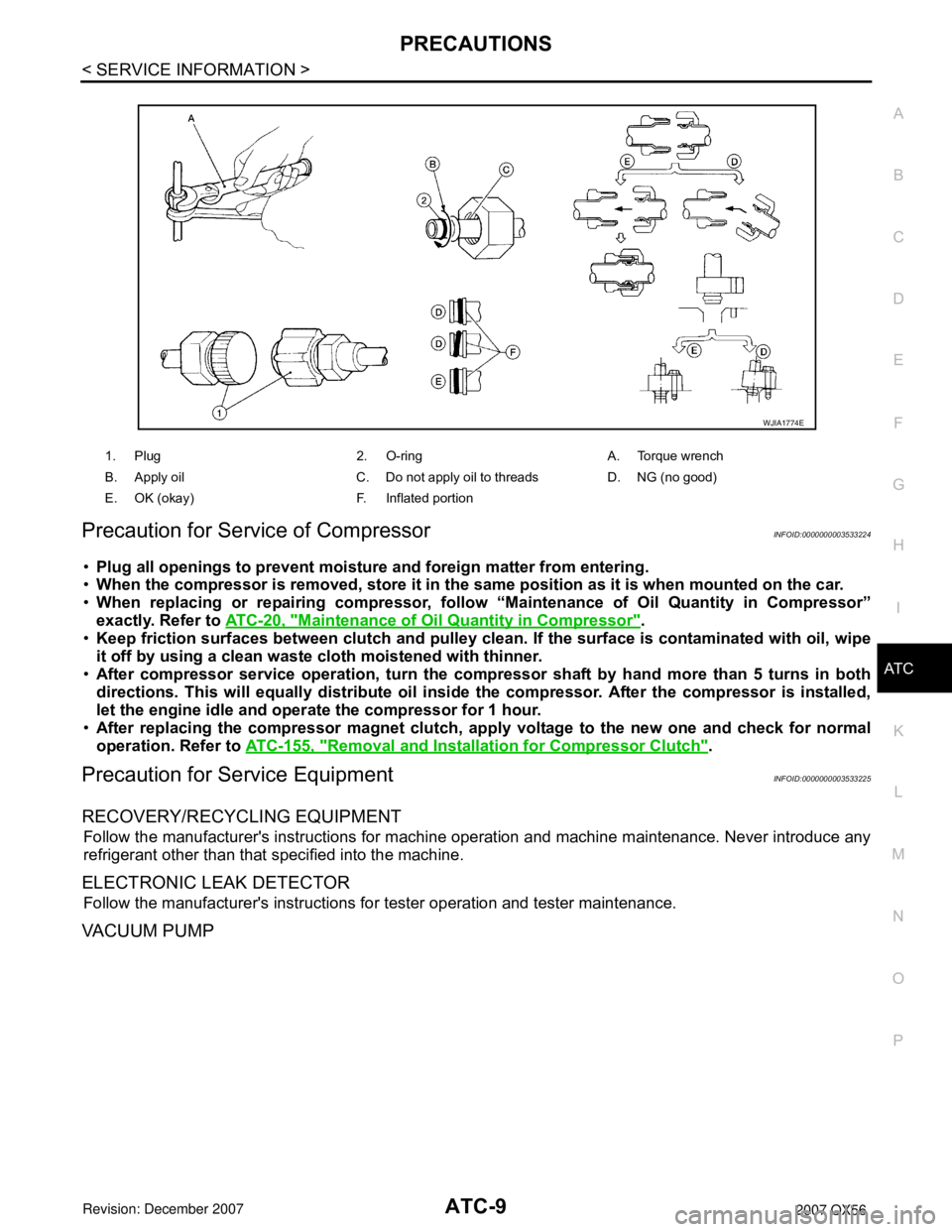

1. Plug 2. O-ring A. Torque wrench

B. Apply oil C. Do not apply oil to threads D. NG (no good)

E. OK (okay) F. Inflated portion

WJIA1774E

Page 390 of 3061

ATC-20

< SERVICE INFORMATION >

OIL

OIL

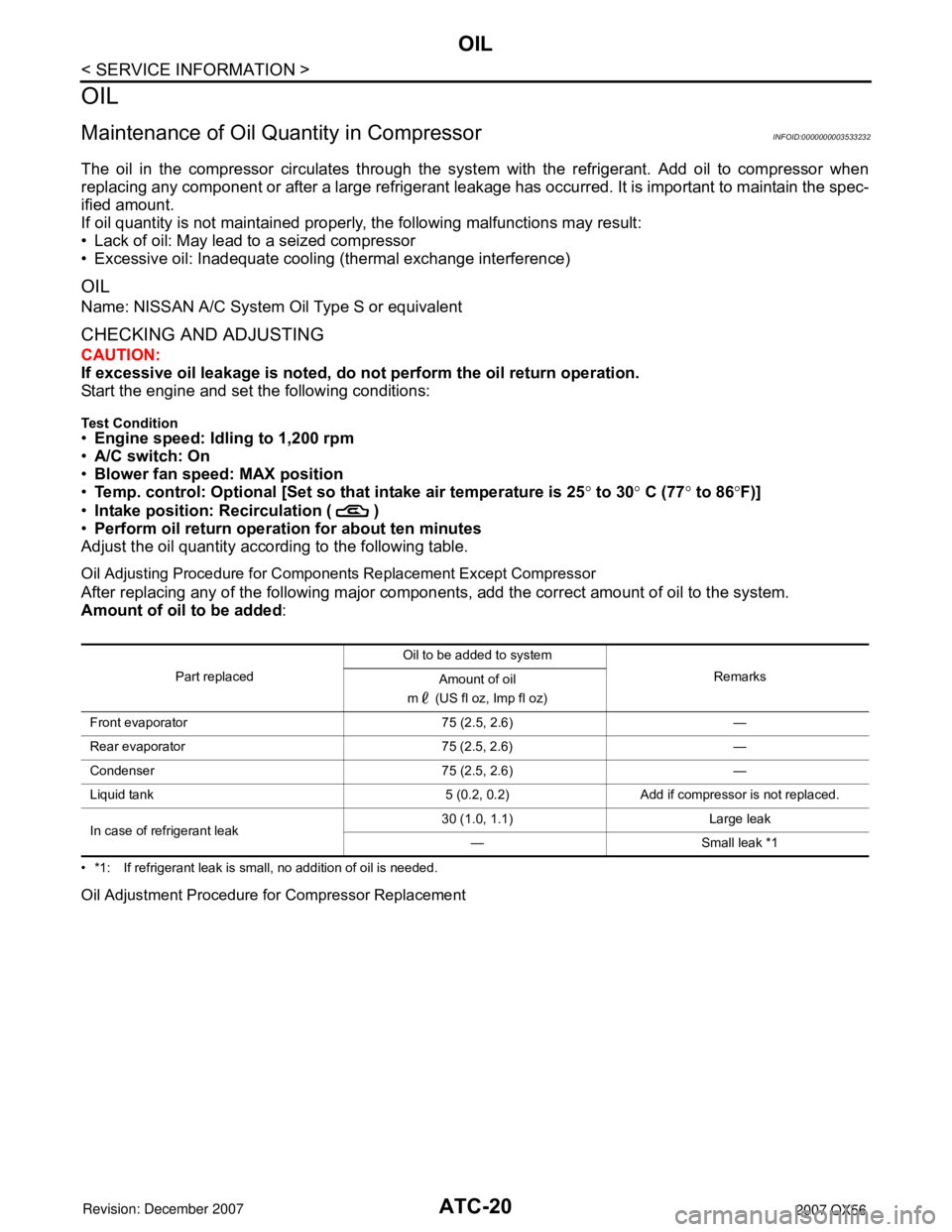

Maintenance of Oil Quantity in CompressorINFOID:0000000003533232

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage has occurred. It is important to maintain the spec-

ified amount.

If oil quantity is not maintained properly, the following malfunctions may result:

• Lack of oil: May lead to a seized compressor

• Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

Name: NISSAN A/C System Oil Type S or equivalent

CHECKING AND ADJUSTING

CAUTION:

If excessive oil leakage is noted, do no t perform the oil return operation.

Start the engine and set the following conditions:

Test Condition

• Engine speed: Idling to 1,200 rpm

• A/C switch: On

• Blower fan speed: MAX position

• Temp. control: Optional [Set so that intake air temperature is 25 ° to 30 ° C (77 ° to 86 °F)]

• Intake position: Recirculation ( )

• Perform oil return operation for about ten minutes

Adjust the oil quantity according to the following table.

Oil Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major component s, add the correct amount of oil to the system.

Amount of oil to be added :

• *1: If refrigerant leak is small, no addition of oil is needed.

Oil Adjustment Procedure for Compressor Replacement

Part replaced Oil to be added to system

Remarks

Amount of oil

m (US fl oz, Imp fl oz)

Front evaporator 75 (2.5, 2.6) —

Rear evaporator 75 (2.5, 2.6) —

Condenser 75 (2.5, 2.6) —

Liquid tank 5 (0.2, 0.2) Add if compressor is not replaced.

In case of refrigerant leak 30 (1.0, 1.1) Large leak

— Small leak *1

Page 455 of 3061

TROUBLE DIAGNOSISATC-85

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

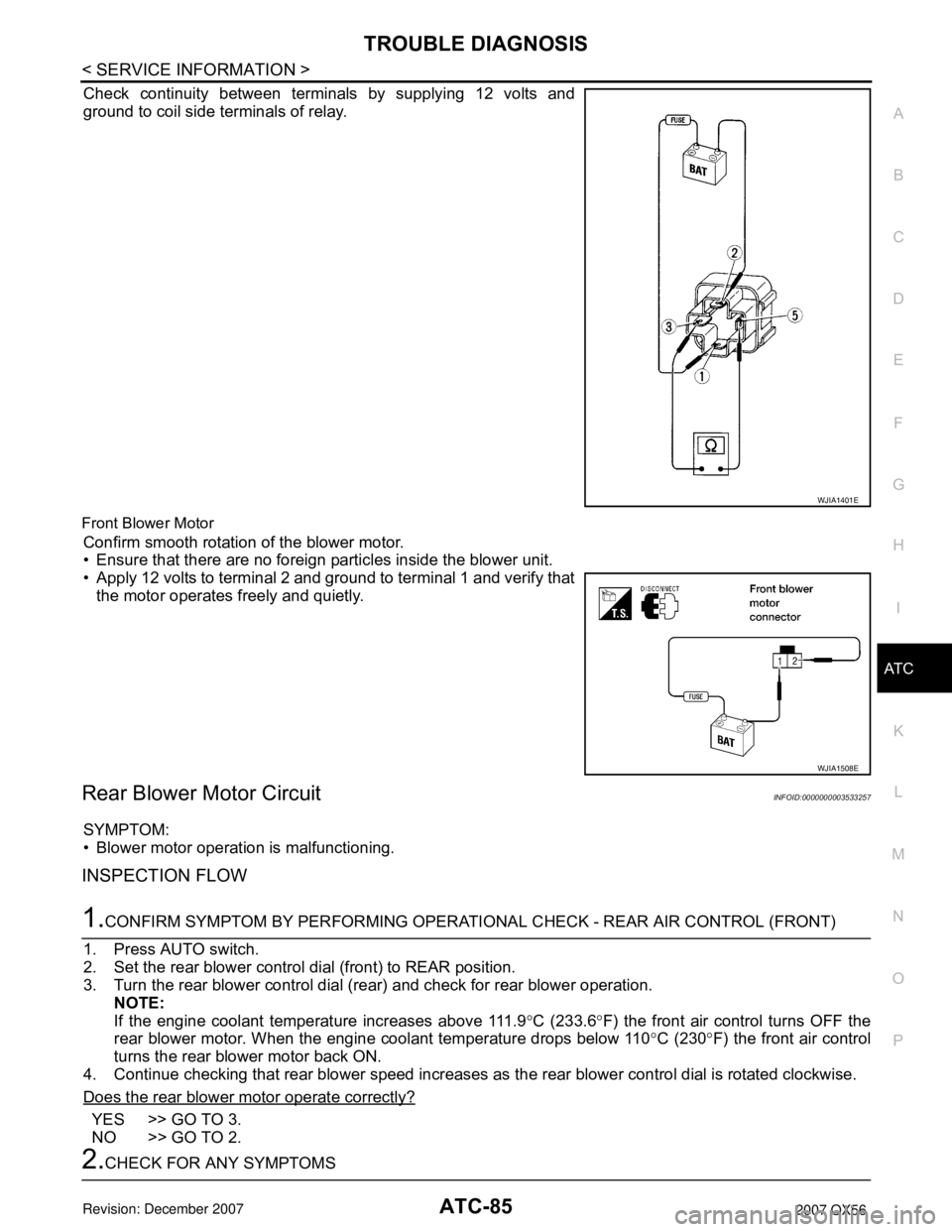

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Front Blower Motor

Confirm smooth rotation of the blower motor.

• Ensure that there are no foreign particles inside the blower unit.

• Apply 12 volts to terminal 2 and ground to terminal 1 and verify that the motor operates freely and quietly.

Rear Blower Motor CircuitINFOID:0000000003533257

SYMPTOM:

• Blower motor operation is malfunctioning.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIO NAL CHECK - REAR AIR CONTROL (FRONT)

1. Press AUTO switch.

2. Set the rear blower control dial (front) to REAR position.

3. Turn the rear blower control dial (rear) and check for rear blower operation. NOTE:

If the engine coolant temperature increases above 111.9 °C (233.6 °F) the front air control turns OFF the

rear blower motor. When the engine coolant temperature drops below 110 °C (230 °F) the front air control

turns the rear blower motor back ON.

4. Continue checking that rear blower speed increases as the rear blower control dial is rotated clockwise.

Does the rear blower motor operate correctly?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

WJIA1401E

WJIA1508E