air condition INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2118 of 3061

IP-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000003533145

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Page 2119 of 3061

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

IP-7

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

IP

N

O

P

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rearseat back lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2132 of 3061

LAN-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION LAN

A

B

LAN

N

O

P

CONTENTS

LAN SYSTEM

CAN FUNDAMENTAL

SERVICE INFORMATION ............................

3

PRECAUTIONS ...................................................3

Precaution When Using CONSULT-II .......................3

Precaution for Trouble Diagnosis ..............................3

Precaution for Harness Repair ..................................3

SYSTEM DESCRIPTION .....................................4

CAN Communication System ....................................4

Diag on CAN .............................................................5

TROUBLE DIAGNOSIS ......................................7

Condition of Error Detection ......................................7

Symptom When Error Occurs in CAN Communi-

cation System ............................................................

7

Self-Diagnosis .........................................................10

CAN Diagnostic Support Monitor ............................10

TROUBLE DIAGNOSES WORK FLOW ............13

Information Needed for Trouble Diagnosis .............13

How to Use CAN Communication Signal Chart ......13

Trouble Diagnosis Flow Chart .................................14

Trouble Diagnosis Procedure ..................................14

CAN

SERVICE INFORMATION ...........................

36

INDEX FOR DTC ................................................36

DTC No. Index ........................................................36

HOW TO USE THIS SECTION ...........................37

Caution ....................................................................37

Abbreviation List ......................................................37

PRECAUTIONS ..................................................38

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

38

Precaution When Using CONSULT-II .....................38

Precaution for Trouble Diagnosis ............................38

Precaution for Harness Repair ................................38

TROUBLE DIAGNOSIS ....................................40

CAN Diagnostic Support Monitor .............................40

CAN System Specification Chart .............................44

CAN Communication Signal Chart ..........................44

Schematic ................................................................49

Wiring Diagram - CAN - ...........................................50

Interview Sheet ........................................................53

Data Sheet ...............................................................54

CAN System (Type 1) ..............................................57

CAN System (Type 2) ..............................................58

CAN System (Type 3) ..............................................59

CAN System (Type 4) ..............................................60

Component Parts Location ......................................61

Harness Layout .......................................................61

Malfunction Area Chart ............................................61

Main Line Between TCM and Driver Seat Control

Unit ..........................................................................

62

Main Line Between TCM and ICC Sensor ...............63

Main Line Between ICC Sensor and ICC Unit .........64

Main Line Between ICC Unit and Driver Seat Con-

trol Unit ....................................................................

65

Main Line Between Driver Seat Control Unit and

Data Link Connector ................................................

65

Main Line Between Data Link Connector and ABS

Actuator and Electric Unit (Control Unit) ..................

66

ECM Branch Line Circuit .........................................67

TCM Branch Line Circuit .........................................67

ICC Sensor Branch Line Circuit ...............................68

ICC Unit Branch Line Circuit ....................................69

Driver Seat Control Unit Branch Line Circuit ...........69

BCM Branch Line Circuit .........................................70

Display Control Unit Branch Line Circuit .................70

Data Link Connector Branch Line Circuit ................71

Front Air Control Branch Line Circuit .......................71

Combination Meter Branch Line Circuit ...................72

Steering Angle Sensor Branch Line Circuit .............72

Transfer Control Unit Branch Line Circuit ................73

ABS Actuator and Electric Unit (Control Unit)

Branch Line Circuit ..................................................

74

Page 2275 of 3061

LT-68

< SERVICE INFORMATION >

TURN SIGNAL AND HAZARD WARNING LAMPS

Without CONSULT-II

Check voltage between BCM harness connector M18 terminal 29

and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-24, "BCM".

NG >> GO TO 3.

3.CHECK HAZARD SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and hazard switch connector.

3. Check continuity between BCM harness connector M18 terminal

29 and hazard switch harness connector M55 terminal 2.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK GROUND

Check continuity between hazard switch harness connector M55 ter-

minal 1 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK HAZARD SWITCH

1. Disconnect hazard switch connector.

2. Check continuity of hazard switch.

OK or NG

OK >> Replace BCM if hazard warning lamps do not work after

setting the connector again. Refer to BCS-24, "

BCM".

NG >> Replace hazard switch. Refer to LT-71, "

Removal and Installation".

Turn Signal Indicator Lamp Does Not OperateINFOID:0000000003533416

1.CHECK CAN COMMUNICATION SYSTEM

Te r m i n a l s

ConditionVoltag e

(Approx.) (+)

(–)

Connector Terminal

M18 29 GroundHazard switch is ON 0V

Hazard switch is OFF 5V

WKIA1969E

29 - 2 : Continuity should exist.

WKIA1894E

1 - Ground : Continuity should exist.

WKIA1895E

Hazard switch

Condition Continuity

Te r m i n a l

12Hazard switch is ON Yes

Hazard switch is OFF No

WKIA1896E

Page 2329 of 3061

LT-122

< SERVICE INFORMATION >

ILLUMINATION

• to front heated seat switch LH and RH terminal 6

• to VDC OFF switch terminal 4

• to tow mode switch terminal 4

• to headlamp aiming switch terminal 4

• to clock terminal 4 and

• to combination meter terminal 18.

Ground is supplied

• to illumination control switch terminal 3

• to glove box lamp terminal 2

• to door mirror remote control switch terminal 15

• to display control unit terminal 3

• to rear heated seat switches terminal 6

• to electric brake (pre-wiring) terminal 1 (with trailer tow)

• to combination meter terminal 17

• through grounds M57, M61 and M79, and

• to NAVI control unit terminal 1

• to rear air control terminal 3

• to rear audio remote control unit terminal 15

• through grounds B117 and B132.

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 1ST or 2ND position (or if auto light system is acti-

vated), and the ignition switch is turned from ON or ACC to OFF, the battery saver control function is activated.

Under this condition, the illumination lamps remain illuminated for 5 minutes, then the illumination lamps are

turned off.

When the lighting switch is turned from OFF to 1ST or 2ND position (or if auto light system is activated) after

illumination lamps are turned off by the battery saver control, the illumination lamps illuminate again.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-II.

CAN Communication System DescriptionINFOID:0000000003533470

Refer to LAN-4, "CAN Communication System" .

Page 2366 of 3061

MA-4

< SERVICE INFORMATION >

GENERAL MAINTENANCE

GENERAL MAINTENANCE

General MaintenanceINFOID:0000000003533859

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owner can perform these

checks and inspections or have their INFINITI dealers perform them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

ItemReference page

TiresCheck the pressure with a gauge at least once a month and always prior to a

long distance trip. Adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Wheel lug nutsWhen checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary.WT-7, "

Rotation"

WindshieldClean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary.—

Tire rotationTires should be rotated every 12,000 km (7,500 miles).WT-7, "

Rotation"

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel bal-

ancing may be needed.WT-6, "Balancing

Wheels", FSU-6, "Front

Wheel Alignment"

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly.

—

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the back

hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently.MA-30, "

Lubricating

Locks, Hinges and Hood

Latches"

Lamps

Make sure that the head lamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head

lamp aim. Clean the head lamps on a regular basis.LT- 2 0 , "Aiming Adjust-

ment" for US, LT- 3 3 ,

"Aiming Adjustment" for

Canada

ItemReference page

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly.DI-21, "

Electrical Com-

ponent Inspection"

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.—

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner.—

Steering wheelCheck that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises.PS-7, "

On-Vehicle In-

spection and Service"

SeatsCheck seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs.—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.SB-10, "

Seat Belt Inspec-

tion", MA-30, "Checking

Seat Belts, Buckles, Re-

tractors, Anchors and

Adjusters"

Accelerator pedalCheck the pedal for smooth operation. Keep the floor mats away from the pedal. —

Page 2367 of 3061

GENERAL MAINTENANCE

MA-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

boosterCheck the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Keep the floor

mats away from the pedal.BR-5, "

Inspection and

Adjustment", BR-15,

"On-Vehicle Service"

Parking brakeCheck that the parking brake control has the proper travel and make sure that

the vehicle is held securely on a fairly steep hill when only the parking brake is

applied.PB-4

Automatic transmis-

sion “Park” mecha-

nismOn a fairly steep hill check that the vehicle is held securely with the selector lever

in the P position without applying the brakes. — ItemReference page

ItemReference page

Windshield washer

fluidCheck that there is adequate fluid in the tank.

—

Engine coolant levelCheck the coolant level when the engine is cold. —

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections.—

Brake fluid levelMake sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoirsMA-27

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level.—

Engine drive beltMake sure that no belt is frayed, worn, cracked or oily.MA-12

Engine oil levelCheck the level on the dipstick after parking the vehicle on a level spot and turn-

ing off the engine.—

Power steering fluid

level and linesCheck the level on the reservoir with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.MA-28

Automatic transmis-

sion fluid levelCheck the level on the dipstick after putting the selector lever in “P” with the en-

gine idling.MA-21

Exhaust systemMake sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it.MA-21

UnderbodyThe underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate.—

Fluid leaksCheck under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately.—

Page 2368 of 3061

MA-6

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000003533860

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage or time intervals, whichever comes first.

Maintenance for Off-road Driving (4WD only)INFOID:0000000003533861

After driving the vehicle off-road through sand, mud, or water; more frequent maintenance may be required for

the following items:

Brake pads and rotors

Brake lines and hoses

Rear final drive oil, transmission fluid, and transfer fluid

Steering linkage

Drive shafts

Engine air cleaner filter

In-cabin microfilters

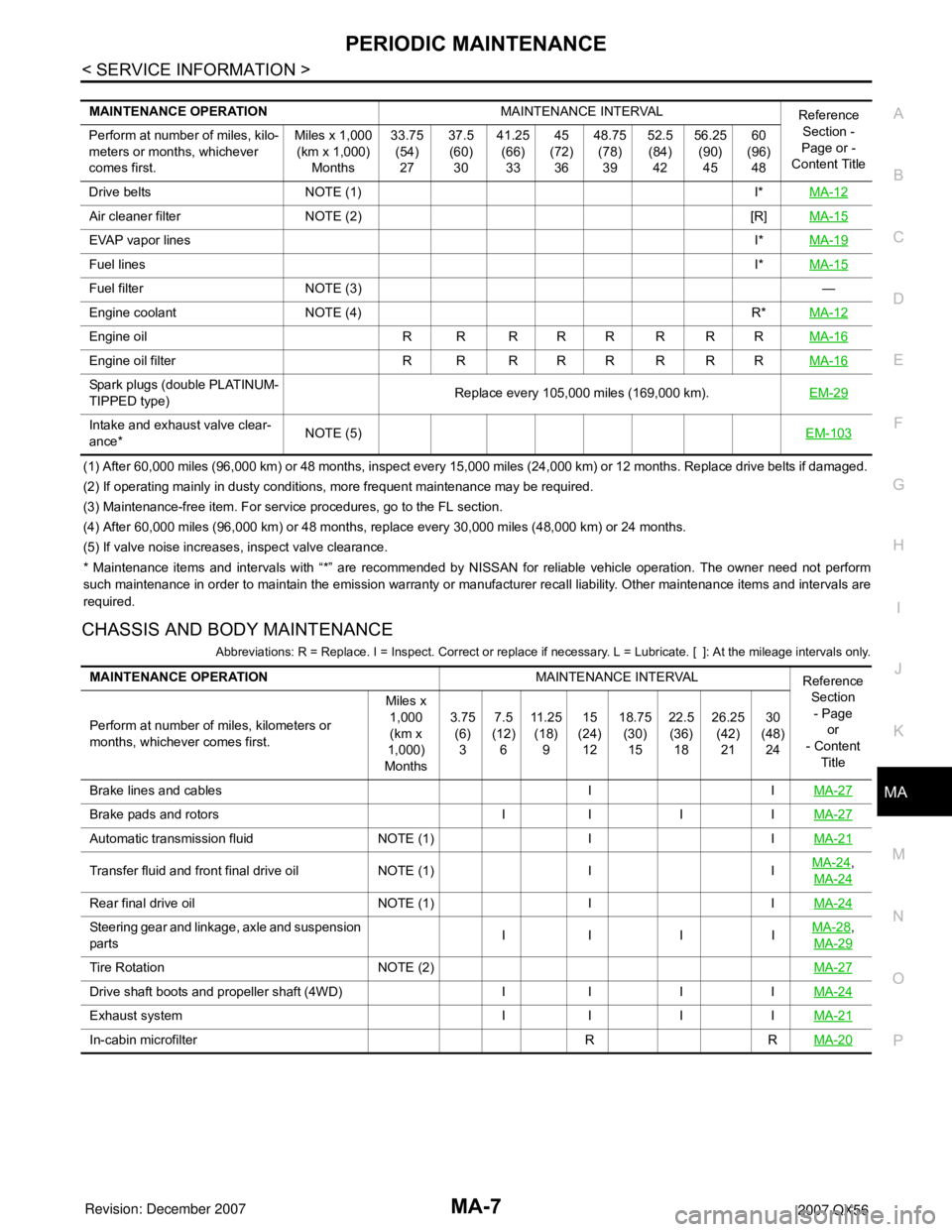

Schedule 1INFOID:0000000003533862

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer or using a car-top carrier.Emission Control Sys-

tem MaintenanceMA-6

Chassis and Body

MaintenanceMA-6

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to the driving habits.Emission Control Sys-

tem MaintenanceMA-8Chassis and Body

MaintenanceMA-8

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months3.75

(6)

37.50

(12)

611 . 2 5

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

24

Drive belts NOTE (1)MA-12

Air cleaner filter NOTE (2) [R]MA-15

EVAP vapor linesI*MA-19

Fuel linesI*MA-15

Fuel filter NOTE (3)—

Engine coolant NOTE (4)MA-12

Engine oil R R R R R R R RMA-16

Engine oil filter R R R R R R R RMA-16

Spark plugs (double PLATINUM-

TIPPED type)Replace every 105,000 miles (169,000 km).EM-29

Intake and exhaust valve clear-

ance*NOTE (5)EM-103

Page 2369 of 3061

PERIODIC MAINTENANCE

MA-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace drive belts if damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, go to the FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate. [ ]: At the mileage intervals only.

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months33.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

Drive belts NOTE (1) I*MA-12

Air cleaner filter NOTE (2) [R]MA-15

EVAP vapor linesI*MA-19

Fuel linesI*MA-15

Fuel filter NOTE (3)—

Engine coolant NOTE (4) R*MA-12

Engine oil R R R R R R R RMA-16

Engine oil filter R R R R R R R RMA-16

Spark plugs (double PLATINUM-

TIPPED type)Replace every 105,000 miles (169,000 km).EM-29

Intake and exhaust valve clear-

ance*NOTE (5)EM-103

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section

- Page

or

- Content

Title Perform at number of miles, kilometers or

months, whichever comes first.Miles x

1,000

(km x

1,000)

Months3.75

(6)

37.5

(12)

611 . 2 5

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

24

Brake lines and cables I IMA-27

Brake pads and rotors I I I IMA-27

Automatic transmission fluid NOTE (1) I IMA-21

Transfer fluid and front final drive oil NOTE (1) I IMA-24,

MA-24

Rear final drive oil NOTE (1) I IMA-24

Steering gear and linkage, axle and suspension

partsII I IMA-28,

MA-29

Tire Rotation NOTE (2)MA-27

Drive shaft boots and propeller shaft (4WD) I I I IMA-24

Exhaust system I I I IMA-21

In-cabin microfilter R RMA-20

Page 2372 of 3061

MA-10

< SERVICE INFORMATION >

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

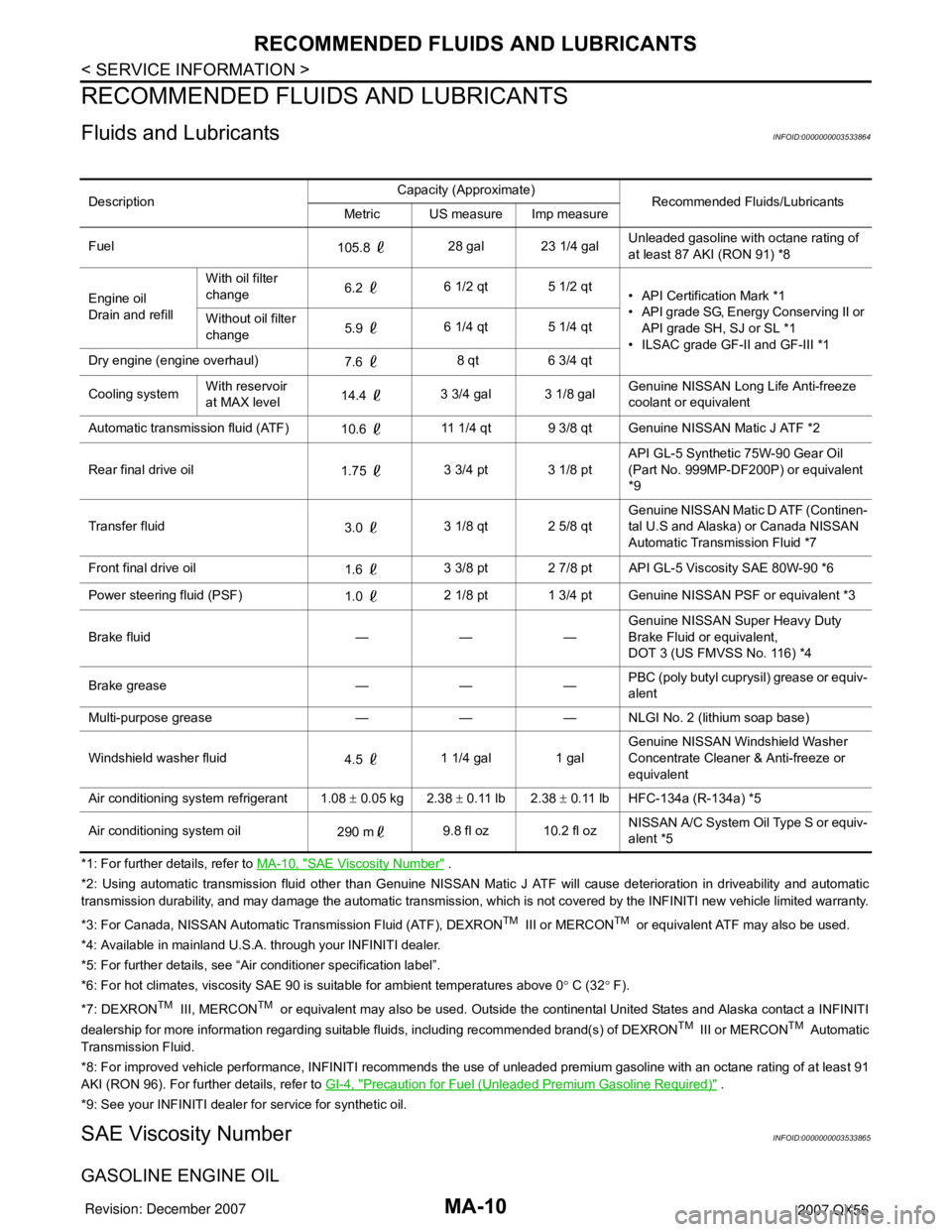

Fluids and LubricantsINFOID:0000000003533864

*1: For further details, refer to MA-10, "SAE Viscosity Number" .

*2: Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and automatic

transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new vehicle limited warranty.

*3: For Canada, NISSAN Automatic Transmission Fluid (ATF), DEXRON

TM III or MERCONTM or equivalent ATF may also be used.

*4: Available in mainland U.S.A. through your INFINITI dealer.

*5: For further details, see “Air conditioner specification label”.

*6: For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 0° C (32° F).

*7: DEXRON

TM III, MERCONTM or equivalent may also be used. Outside the continental United States and Alaska contact a INFINITI

dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTM III or MERCONTM Automatic

Transmission Fluid.

*8: For improved vehicle performance, INFINITI recommends the use of unleaded premium gasoline with an octane rating of at least 91

AKI (RON 96). For further details, refer to GI-4, "

Precaution for Fuel (Unleaded Premium Gasoline Required)" .

*9: See your INFINITI dealer for service for synthetic oil.

SAE Viscosity NumberINFOID:0000000003533865

GASOLINE ENGINE OIL

DescriptionCapacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel

105.8 28 gal 23 1/4 galUnleaded gasoline with octane rating of

at least 87 AKI (RON 91) *8

Engine oil

Drain and refillWith oil filter

change6.2 6 1/2 qt 5 1/2 qt

• API Certification Mark *1

• API grade SG, Energy Conserving II or

API grade SH, SJ or SL *1

• ILSAC grade GF-II and GF-III *1 Without oil filter

change5.9 6 1/4 qt 5 1/4 qt

Dry engine (engine overhaul)

7.6 8 qt 6 3/4 qt

Cooling systemWith reservoir

at MAX level14.4 3 3/4 gal 3 1/8 galGenuine NISSAN Long Life Anti-freeze

coolant or equivalent

Automatic transmission fluid (ATF)

10.6 11 1/4 qt 9 3/8 qt Genuine NISSAN Matic J ATF *2

Rear final drive oil

1.75 3 3/4 pt 3 1/8 ptAPI GL-5 Synthetic 75W-90 Gear Oil

(Part No. 999MP-DF200P) or equivalent

*9

Transfer fluid

3.0 3 1/8 qt 2 5/8 qtGenuine NISSAN Matic D ATF (Continen-

tal U.S and Alaska) or Canada NISSAN

Automatic Transmission Fluid *7

Front final drive oil

1.6 3 3/8 pt 2 7/8 pt API GL-5 Viscosity SAE 80W-90 *6

Power steering fluid (PSF)

1.0 2 1/8 pt 1 3/4 pt Genuine NISSAN PSF or equivalent *3

Brake fluid — — —Genuine NISSAN Super Heavy Duty

Brake Fluid or equivalent,

DOT 3 (US FMVSS No. 116) *4

Brake grease — — —PBC (poly butyl cuprysil) grease or equiv-

alent

Multi-purpose grease — — — NLGI No. 2 (lithium soap base)

Windshield washer fluid

4.5 1 1/4 gal 1 galGenuine NISSAN Windshield Washer

Concentrate Cleaner & Anti-freeze or

equivalent

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb HFC-134a (R-134a) *5

Air conditioning system oil

290 m9.8 fl oz 10.2 fl ozNISSAN A/C System Oil Type S or equiv-

alent *5