lock INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2985 of 3061

TRANSFER ASSEMBLY

TF-163

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

21. Tighten the front case bolts to the specified torque. Refer to

"COMPONENTS".

CAUTION:

Be sure to install harness bracket and air breather hose

clamp.

22. Install the drain plug with a new gasket.

CAUTION:

Do not reuse gasket.

23. Align the matching mark on the front drive shaft with the mark on

the companion flange, then install the companion flange.

24. Install the new companion flange self-lock nut. Tighten to the

specified torque using Tool. Refer to TF-128, "

Disassembly and

Assembly".

CAUTION:

Do not reuse self-lock nut.

25. Remove all the sealant from the check plug, switch mating sur-

face and front case.

CAUTION:

Remove old sealant adhering to mating surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mating surfaces.

26. Install the check ball and check spring to the front case. Apply

silicone gasket, to the check plug and wait detection switch and

install them to the front case. Tighten to the specified torque.

Refer to TF-128, "

Disassembly and Assembly".

•Use Genuine Silicone RTV or equivalent. Refer to GI-45

.

NOTE:

Wait detection switch harness connector is black.

SDIA2100E

SDIA2779E

Tool number : KV40104000 ( — )

WDIA0219E

WDIA0158E

Page 2986 of 3061

TF-164

< SERVICE INFORMATION >

TRANSFER ASSEMBLY

27. Install the new oil seal in the front case using Tool.

CAUTION:

• Do not reuse oil seal.

• Apply petroleum jelly to seal lip before installing.

28. Install the shift lever to the shift cross.

29. Install the lock pin and lock pin nut. Tighten to the specified

torque. Refer to TF-128, "

Disassembly and Assembly".

Rear Case

1. Apply petroleum jelly to the circumference of the new rear oil

seal. Install the new rear oil seal so that it is flush with the case

tip face using Tool.

CAUTION:

• Do not reuse oil seal.

• Apply petroleum jelly to seal lip before installing.

2. Apply petroleum jelly to the circumference of the new dust cover.

Position the new dust cover using the identification mark as

shown.

CAUTION:

• Do not reuse dust cover.

• Position the identification mark at the position shown.

3. Install the dust cover using Tool.

4. Install the breather tube into the rear case.

5. Remove all the sealant from the rear case to center case mating

surfaces.

CAUTION:

Remove all foreign materials such as water, oil, and grease

from center case and rear case mating surfaces.Tool number : ST22360002 (J-25679-01)

SDIA2182E

Tool number : ST30720000 (J-25405)

SDIA2204E

SDIA3436E

Tool number : KV40105310 ( — )

SDIA2205E

Page 3020 of 3061

FRONT WIPER AND WASHER SYSTEM

WW-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

WW

N

O

P

FRONT WIPER AND WASHER SYSTEM

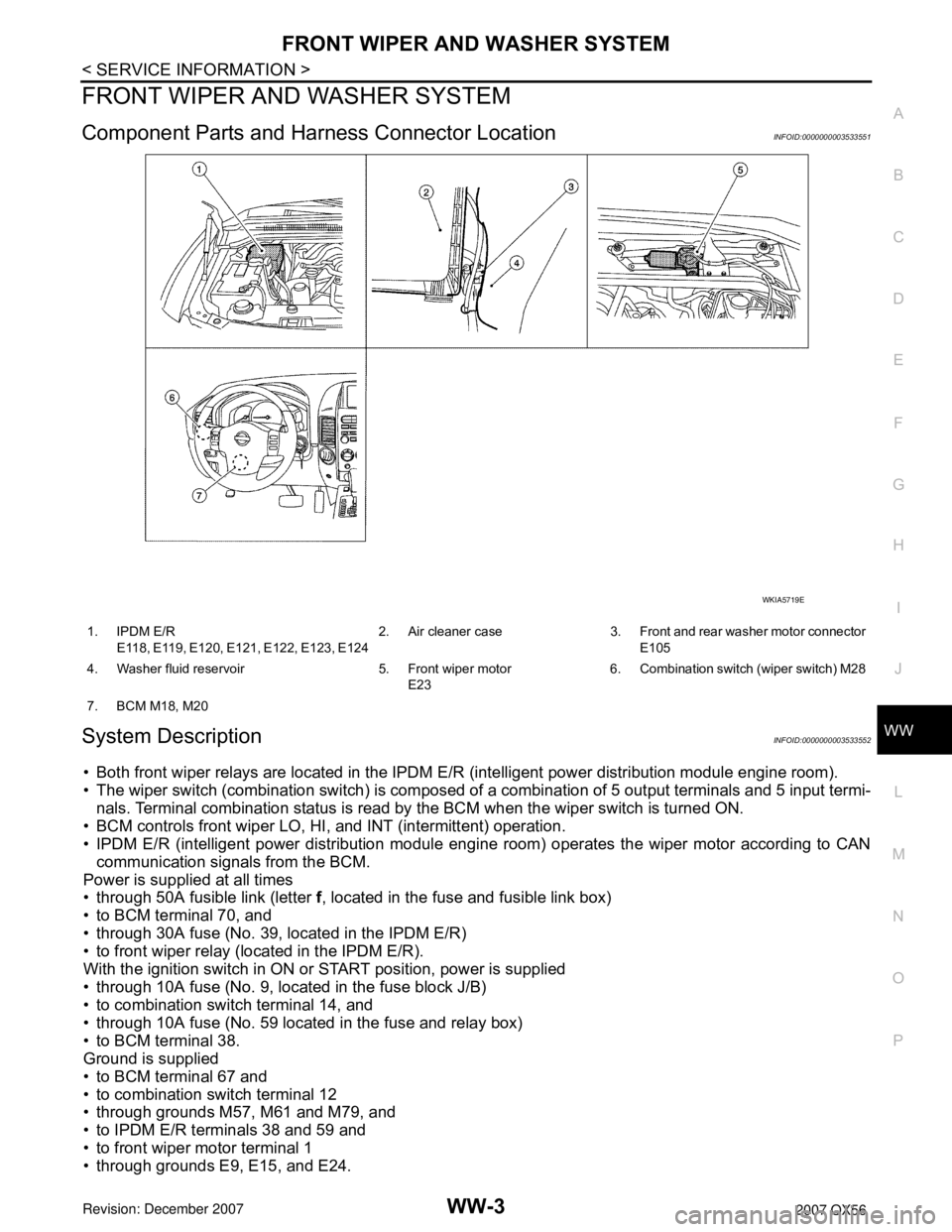

Component Parts and Harness Connector LocationINFOID:0000000003533551

System DescriptionINFOID:0000000003533552

• Both front wiper relays are located in the IPDM E/R (intelligent power distribution module engine room).

• The wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by the BCM when the wiper switch is turned ON.

• BCM controls front wiper LO, HI, and INT (intermittent) operation.

• IPDM E/R (intelligent power distribution module engine room) operates the wiper motor according to CAN

communication signals from the BCM.

Power is supplied at all times

• through 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70, and

• through 30A fuse (No. 39, located in the IPDM E/R)

• to front wiper relay (located in the IPDM E/R).

With the ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 9, located in the fuse block J/B)

• to combination switch terminal 14, and

• through 10A fuse (No. 59 located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to combination switch terminal 12

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59 and

• to front wiper motor terminal 1

• through grounds E9, E15, and E24.

WKIA5719E

1. IPDM E/R

E118, E119, E120, E121, E122, E123, E1242. Air cleaner case 3. Front and rear washer motor connector

E105

4. Washer fluid reservoir 5. Front wiper motor

E236. Combination switch (wiper switch) M28

7. BCM M18, M20

Page 3022 of 3061

FRONT WIPER AND WASHER SYSTEM

WW-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

WW

N

O

P

FRONT WASHER OPERATION

When the ignition switch is in the ON or START position, and the front and rear washer switches are OFF, the

front and rear washer motor is supplied power

• through 10A fuse (No. 9, located in the fuse block J/B)

• through combination switch (wiper switch) terminal 14

• through combination switch (wiper switch) terminal 13

• to front and rear washer motor terminal 1, and

• through combination switch (wiper switch) terminal 11

• to front and rear washer motor terminal 2.

When the front wiper switch is in the front washer position, the BCM detects a front washer signal request

through the combination switch (wiper switch) reading function.

Combination switch ground is supplied

• to front and rear washer motor terminal 2

• through combination switch (wiper switch) terminal 11

• through combination switch (wiper switch) terminal 12

• through grounds M57, M61 and M79.

With ground supplied, the front and rear washer motor is operated in the front direction.

When the BCM detects that front washer motor has operated for 0.4 seconds or longer, the BCM uses CAN

communication and sends a wiper request signal to the IPDM E/R for low speed operation of wipers.

When the BCM detects that the washer switch is OFF, low speed operation cycles approximately 3 times and

then stops.

MIST OPERATION

When the wiper switch is temporarily placed in the mist position, wiper low speed operation cycles once and

then stops. For additional information about wiper operation under this condition, refer to "LOW SPEED

WIPER OPERATION".

If the switch is held in the mist position, low speed operation continues.

FAIL-SAFE FUNCTION

The BCM includes fail-safe function to prevent malfunction of electrical components controlled by CAN com-

munications if a malfunction in CAN communications occurs.

The BCM uses CAN communications to stop output of electrical components it controls.

Until the ignition switch is turned off, the front wiper system remains in same status as just before fail-safe con-

trol was initiated. (If wiper was in low speed operation just before fail-safe, it continues low speed operation

until ignition switch is turned OFF.)

When fail-safe status is initiated, the BCM remains in standby until normal signals are received.

When normal signals are received, fail-safe status is canceled.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "System Description".

CAN Communication System DescriptionINFOID:0000000003533553

Refer to LAN-4.

Page 3029 of 3061

WW-12

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

ACTIVE TEST

Display Item List

CONSULT-II Function (IPDM E/R)INFOID:0000000003533561

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

All Items, Main Items, Select Item Menu

NOTE:

Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is at ACC, the dis-

play may not be correct.

ACTIVE TEST

Display Item List

FR WASHER SW "ON/OFF"Displays "Front Washer Switch (ON)/Other (OFF)" status as judged from wiper switch

signal.

INT VOLUME (1 - 7)Displays intermittent operation dial position setting (1 - 7) as judged from wiper switch

signal.

FR WIPER STOP "ON/OFF" Displays "Stopped (ON)/Operating (OFF)" status as judged from the auto-stop signal.

VEHICLE SPEED "0.0 km/h" Displays vehicle speed as received from CAN communication. Monitor item name

"OPERATION OR UNIT"Contents

Te s t i t e mDisplay on CONSULT-II

screenDescription

Front wiper HI output FR WIPER (HI) Front wiper HI can be operated by any ON-OFF operation.

Front wiper LO output FR WIPER (LO) Front wiper LO can be operated by any ON-OFF operation.

Front wiper INT output FR WIPER (INT) Front wiper INT can be operated by any ON-OFF operation.

IPDM E/R diagnostic Mode Description

SELF-DIAG RESULTS Displays IPDM E/R self-diagnosis results.

DATA MONITOR Displays IPDM E/R input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

ALL SIGNALS Monitors all the items.

MAIN SIGNALS Monitors predetermined items.

SELECTION FROM MENU Selects and monitors the individual item selected.

Item nameCONSULT-II

screen displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Front wiper re-

questFR WIP REQ STOP/1LO/LO/HI x x x Signal status input from BCM.

Wiper auto stop WIP AUTO STOP ACT P/STOP P x x x Output status of IPDM E/R.

Wiper protection WIP PROT OFF/LS/HS/BLOCK x x x Control status of IPDM E/R.

Page 3037 of 3061

WW-20

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

1.COMBINATION SWITCH TO BCM INSPECTION

Select "BCM" on CONSULT-II. With "WIPER" data monitor, check

that "FR WASHER SW" turns ON-OFF according to operation of

front washer switch.

OK or NG

OK >> Replace BCM. Refer to BCS-24, "BCM".

NG >> Replace wiper switch. Refer to WW-23, "

Wiper and

Washer Switch".

Front Wipers Operate For 10 Seconds, Stop For 20 Seconds, And After Repeating This Operation

Five Times, They Become Inoperative

CAUTION:

• When auto stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front wip-

ers, IPDM E/R considers front wipers locked and stops wiper output, which causes this symptom.

• This status can be checked by using IPDM E/R "DATA MONITOR". Under this condition, "WIP PROT"

reads "BLOCK".

1.CHECK IPDM E/R TO FRONT WIPER MOTOR

With CONSULT-II

Select "IPDM E/R" with CONSULT-II. With data monitor, confirm that

"WIP AUTO STOP" changes from "ACT P" to "STOP P" according to

wiper operation.

Without CONSULT-II

GO TO 2.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R".

NG >> GO TO 2.

2.IPDM E/R TO FRONT WIPER MOTOR AUTO STOP CIRCUIT INSPECTION

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and front wiper motor connector.

3. Check continuity between IPDM E/R harness connector terminal

and front wiper motor harness connector terminal.

WKIA1018E

SKIA5301E

Te r m i n a l s

Continuity

Connector Terminal Connector Terminal

E122 43 E23 6 Yes

WKIA2084E

Page 3043 of 3061

WW-26

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

REAR WIPER AND WASHER SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000003533570

System DescriptionINFOID:0000000003533571

• The wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by the BCM (body control module) when switch is turned ON.

• The BCM controls rear wiper ON and INT (intermittent) operation.

Power is supplied at all times

• through 50A fusible link (letter f, located in fusible link box)

• to BCM terminal 70.

With the ignition switch in ON or START position, power is supplied

• through 10A fuse [No. 9, located in fuse block (J/B)]

• to combination switch terminal 14, and

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to combination switch terminal 12

• through grounds M57, M61 and M79.

REAR WIPER OPERATION

When the ignition switch is in the ON or START position, and the rear wiper switch is in the ON position, the

BCM detects a rear wiper ON request through the combination switch (wiper switch) reading function.

The BCM will first check the status of the glass hatch ajar switch before supplying power to the rear wiper

motor. If the glass hatch ajar switch is closed (ground) the BCM will not turn on the rear wiper motor. If the

glass hatch ajar switch is open (not grounded) the BCM will control the rear wiper motor as follows.

The BCM controls rear wiper motor operation by switching direction of current flow between the two rear wiper

motor output circuits.

Power is supplied to output circuit 1 for forward operation (counterclockwise sweep),

• through BCM terminal 55

• to rear wiper motor terminal 4.

Ground is supplied

• to rear wiper motor terminal 6

WKIA3462E

Page 3044 of 3061

REAR WIPER AND WASHER SYSTEM

WW-27

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

WW

N

O

P

• through BCM terminal 54

• through BCM terminal 67

• through grounds M57, M61 and M79.

With output circuit 1 power and ground supplied, the rear wiper motor operates in a counterclockwise sweep

direction until auto stop switch 1 closes (full sweep position). Auto stop switch 1 supplies ground

• to BCM terminal 44

• through rear wiper motor terminal 2

• through rear wiper motor terminal 5

• through grounds B117 and B132.

When the BCM receives this ground signal it turns off output circuit 1 and turns on output circuit 2.

Power is supplied to output circuit 2 for reverse operation (clockwise sweep),

• through BCM terminal 54

• to rear wiper motor terminal 6.

Ground is supplied

• to rear wiper motor terminal 4

• through BCM terminal 55

• through BCM terminal 67

• through grounds M57, M61 and M79.

With output circuit 2 power and ground supplied the rear wiper motor operates in a clockwise sweep direction

until auto stop switch 2 closes (full sweep position). Auto stop switch 2 supplies ground

• to BCM terminal 26

• through rear wiper motor terminal 1

• through rear wiper motor terminal 3

• through grounds B117 and B132.

When the BCM receives this ground signal it turns off output circuit 2 and turns on output circuit 1. This pro-

cess repeats until the rear wiper switch or ignition switch is turned off.

If the ignition switch is turned to OFF during operation, the rear wiper motor will immediately stop. If the igni-

tion switch is turned ON after this condition, and the BCM does not receive a rear wiper switch ON or INT sig-

nal, the BCM will operate the rear wiper to the auto stop position.

If the BCM does not receive a change in status in either auto stop switch 1 or auto stop switch 2 within a 5 sec-

ond period of output circuit 1 or output circuit 2 operation, the BCM will turn off output circuit 1 and output cir-

cuit 2.

If the BCM detects the rear door glass ajar signal during rear wiper motor operation, the BCM will operate the

rear wiper motor to the auto stop position. Once the rear door glass ajar signal returns to open (not grounded)

for 5 or more seconds, the BCM will resume rear wiper motor operation.

INTERMITTENT OPERATION

The rear wiper motor operates the wiper arm at low speed approximately every 7 seconds.

When the wiper switch is in the rear wiper INT position, the BCM detects a rear wiper INT request through the

combination switch (wiper switch) reading function.

The BCM controls rear wiper motor operation by switching direction of current flow between the two rear wiper

motor output circuits.

Power is supplied to output circuit 1 for forward operation (counterclockwise sweep),

• through BCM terminal 55

• to rear wiper motor terminal 4.

Ground is supplied

• to rear wiper motor terminal 6

• through BCM terminal 54

• through BCM terminal 67

• through grounds M57, M61 and M79.

With output circuit 1 power and ground supplied, the rear wiper motor operates in a counterclockwise sweep

direction until auto stop switch 1 closes (full sweep position). Auto stop switch 1 supplies ground

• to BCM terminal 44

• through rear wiper motor terminal 2

• through rear wiper motor terminal 5

• through grounds B117 and B132.

When the BCM receives this ground signal it turns off output circuit 1 and turns on output circuit 2.

Power is supplied to output circuit 2 for reverse operation (clockwise sweep),

• through BCM terminal 54

• to rear wiper motor terminal 6.

Ground is supplied

• to rear wiper motor terminal 4

Page 3045 of 3061

WW-28

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

• through BCM terminal 55

• through BCM terminal 67

• through grounds M57, M61 and M79.

With output circuit 2 power and ground supplied the rear wiper motor operates in a clockwise sweep direction

until auto stop switch 2 closes (full sweep position). Auto stop switch 2 supplies ground

• to BCM terminal 26

• through rear wiper motor terminal 1

• through rear wiper motor terminal 3

• through grounds B117 and B132.

When the BCM receives this ground signal it turns off output circuit 2 and starts the timing function of 7 sec-

onds. After approximately 7 seconds the BCM turns on output circuit 1. This process repeats until the rear

wiper switch or ignition switch is turned off.

AUTO STOP OPERATION

When the rear wiper switch is turned off, the BCM will continue the cycle of output circuit 1 or output circuit 2

until auto stop switch 1 and auto stop switch 2 are both in the closed position. When the BCM receives ground

signals from auto stop switch 1 and auto stop switch 2 simultaneously, output circuit 1 and output circuit 2 are

both turned off.

REAR WASHER OPERATION

When the ignition switch is in the ON or START position, and the front and rear washer switches are OFF, the

front and rear washer motor is supplied power

• through 10A fuse (No. 9, located in the fuse block J/B)

• through combination switch (wiper switch) terminal 14

• through combination switch (wiper switch) terminal 11

• to front and rear washer motor terminal 2, and

• through combination switch (wiper switch) terminal 13

• to front and rear washer motor terminal 1.

When the rear wiper switch is in rear washer position, the BCM detects a rear washer signal by BCM wiper

switch reading function. Combination switch ground is supplied

• to front and rear washer motor terminal 1

• through combination switch (wiper switch) terminal 13

• through combination switch (wiper switch) terminal 12

• through grounds M57, M61 and M79.

With ground supplied, the front and rear washer motor is operated in the rear direction.

When the BCM detects that the rear washer motor has operated for 0.4 seconds or longer, BCM operates the

rear wiper motor.

When the BCM detects that the rear washer switch is in OFF, the rear wiper motor cycles approximately 3

times and then stops.

If the rear washer is operated with the rear wiper switch in the INT position, normal rear wiper operation will

take over. Once the rear washer switch is released the rear wiper will return to INT operation.

BCM Wiper Switch Reading Function

Refer to BCS-3, "System Description".

Page 3052 of 3061

REAR WIPER AND WASHER SYSTEM

WW-35

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

WW

N

O

P

Select "BCM" on CONSULT-II. With "WIPER" data monitor, make

sure "RR WIPER STOP" and "RR AUTO STOP 2" turn ON-OFF

according to wiper operation.

OK or NG

OK >> Replace BCM. Refer to BCS-24, "BCM".

NG >> GO TO 2.

2.CHECK AUTO STOP CIRCUITS FOR SHORT TO GROUND

1. Turn ignition switch to OFF.

2. Disconnect BCM and rear wiper motor connectors.

3. Check continuity between BCM harness connector terminals

and ground.

OK or NO

OK >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK REAR WIPER MOTOR AUTO STOP SWITCH GROUNDS

Check continuity between rear wiper motor harness connector D704

terminals and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4. CHECK REAR WIPER OPERATINGWhen wiper switch is OFF

and arm on stop: RR WIPER STOP ON

: RR AUTO STOP 2 ON

When wiper switch is ON

and arm in position A: RR WIPER STOP OFF

: RR AUTO STOP 2 ON

When wiper switch is ON

counterclockwise sweep: RR WIPER STOP OFF

: RR AUTO STOP 2 OFF

When wiper switch is ON

and arm in position B: RR WIPER STOP ON

: RR AUTO STOP 2 OFF

When wiper switch is ON

clockwise sweep: RR WIPER STOP OFF

: RR AUTO STOP 2 OFF

When wiper switch is ON

and arm in position A: RR WIPER STOP ON

: RR AUTO STOP 2 OFF

WKIA1418E

Te r m i n a l s

Continuity

Connector Terminal

M18 26

Ground No

M19 44

WKIA2096E

Te r m i n a l s

Continuity

Connector Terminal

D7041

GroundNo

2

3

Ye s

5

WKIA2097E