relay INFINITI QX56 2007 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1112 of 3061

AIR CONDITIONING CUT CONTROL

EC-29

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR CONDITIONING CUT CONTROL

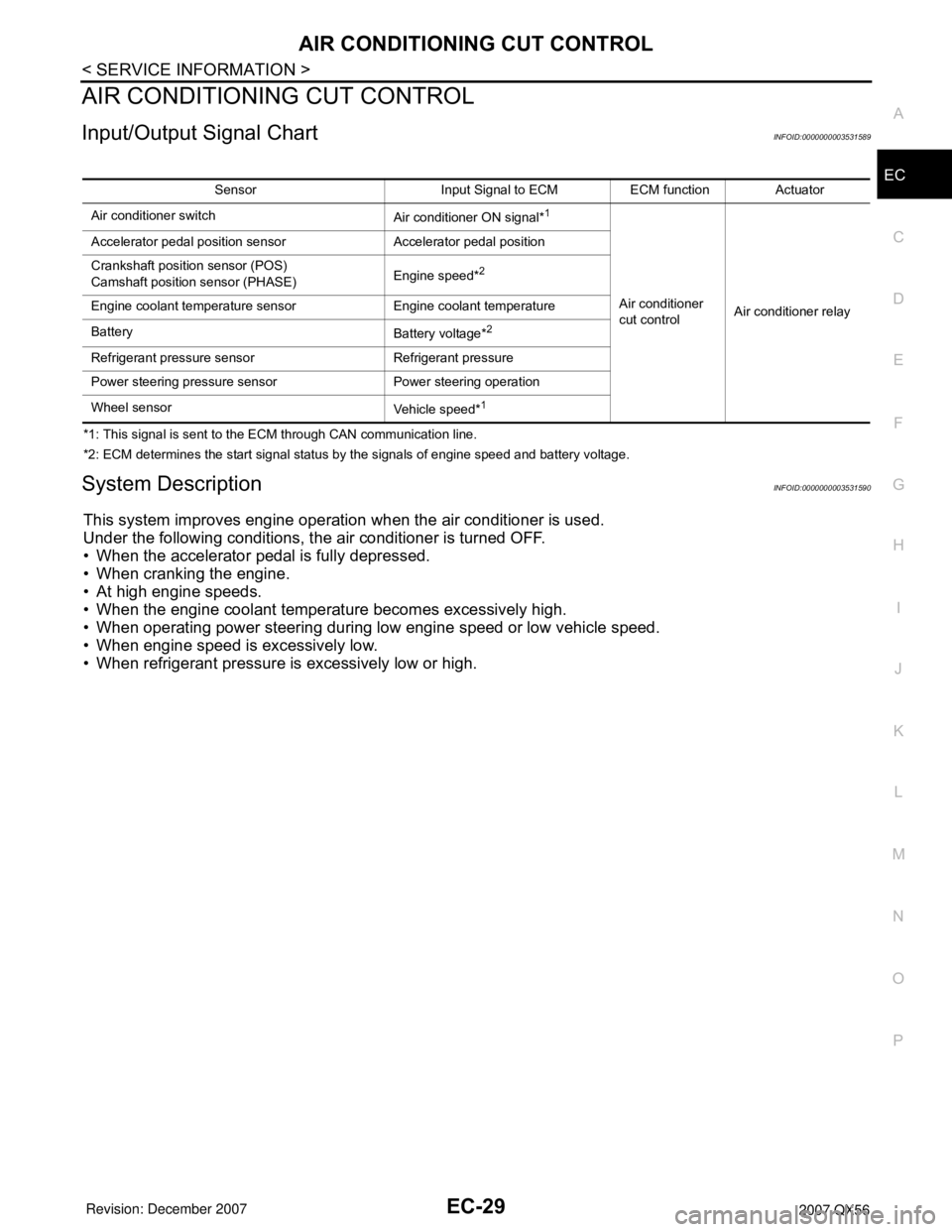

Input/Output Signal ChartINFOID:0000000003531589

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

System DescriptionINFOID:0000000003531590

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

• When the accelerator pedal is fully depressed.

• When cranking the engine.

• At high engine speeds.

• When the engine coolant temperature becomes excessively high.

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high.

Sensor Input Signal to ECM ECM function Actuator

Air conditioner switch

Air conditioner ON signal*

1

Air conditioner

cut controlAir conditioner relay Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

Wheel sensor

Vehicle speed*

1

Page 1126 of 3061

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

EC-43

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

2. Drain fuel from the tank as follows:

a. Remove fuel feed hose located on the fuel gauge retainer.

b. Connect a spare fuel hose, one side to fuel gauge retainer where the hose was removed and the other

side to a fuel container.

c. Drain fuel using “FUEL PUMP RELAY” in “ACTIVE TEST” mode with CONSULT-II.

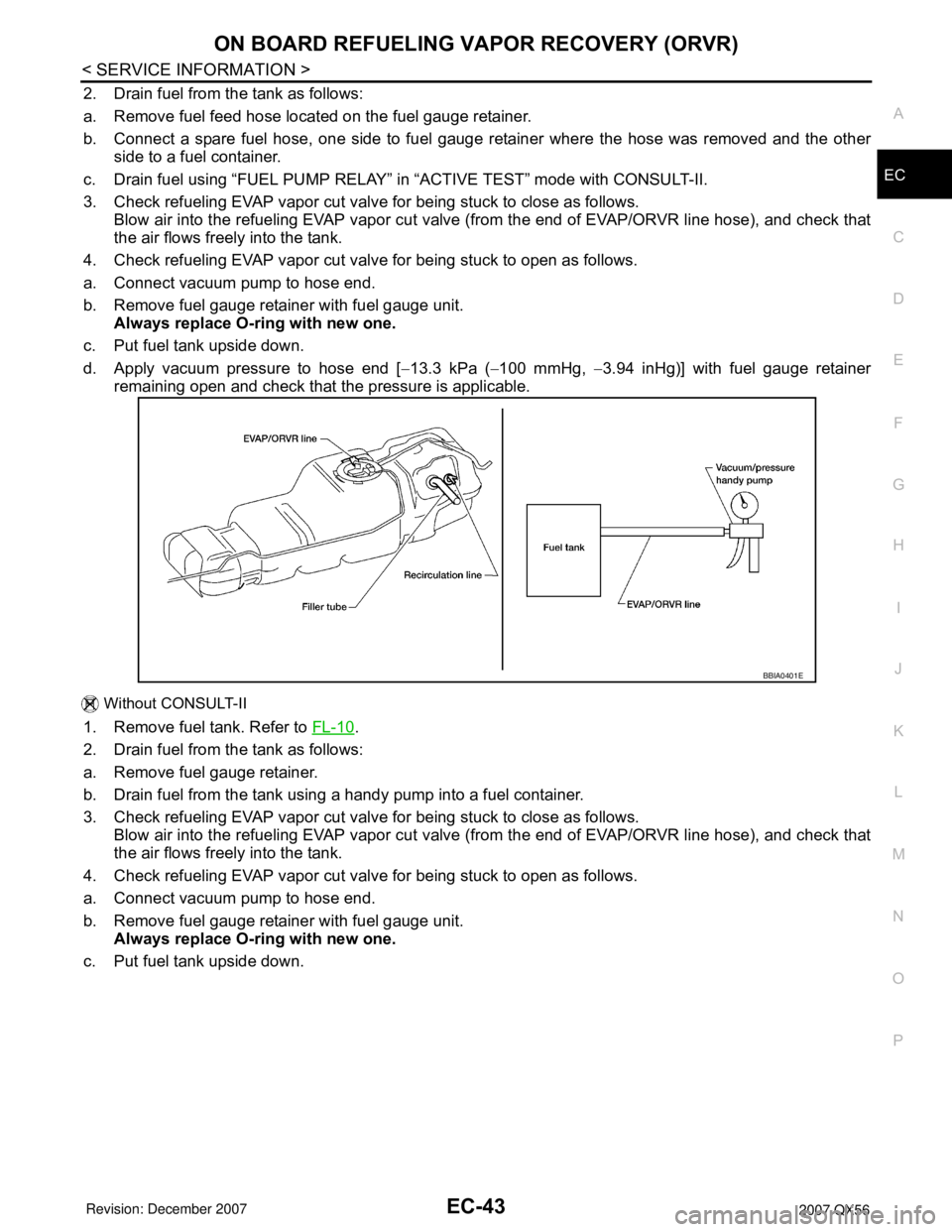

3. Check refueling EVAP vapor cut valve for being stuck to close as follows.

Blow air into the refueling EVAP vapor cut valve (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

4. Check refueling EVAP vapor cut valve for being stuck to open as follows.

a. Connect vacuum pump to hose end.

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new one.

c. Put fuel tank upside down.

d. Apply vacuum pressure to hose end [−13.3 kPa (−100 mmHg, −3.94 inHg)] with fuel gauge retainer

remaining open and check that the pressure is applicable.

Without CONSULT-II

1. Remove fuel tank. Refer to FL-10.

2. Drain fuel from the tank as follows:

a. Remove fuel gauge retainer.

b. Drain fuel from the tank using a handy pump into a fuel container.

3. Check refueling EVAP vapor cut valve for being stuck to close as follows.

Blow air into the refueling EVAP vapor cut valve (from the end of EVAP/ORVR line hose), and check that

the air flows freely into the tank.

4. Check refueling EVAP vapor cut valve for being stuck to open as follows.

a. Connect vacuum pump to hose end.

b. Remove fuel gauge retainer with fuel gauge unit.

Always replace O-ring with new one.

c. Put fuel tank upside down.

BBIA0401E

Page 1172 of 3061

TROUBLE DIAGNOSIS

EC-89

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

• When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there

is malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected

as NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by

means of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

DTC No. Detected items Engine operating condition in fail-safe mode

P0102

P0103Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time after turning

ignition switch ON or START.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-II display)

Just as ignition switch is turned ON

or START40°C (104°F)

More than approx. 4 minutes after

ignition ON or START80°C (176°F)

Except as shown above40 - 80°C (104 - 176°F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122

P0123

P0222

P0223

P2135Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2100

P2103Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2101 Electric throttle control

functionECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2119 Electric throttle control ac-

tuator(When electric throttle control actuator does not function properly due to the return spring

malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control actuator by regulating the throttle opening to 20

degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops, the

engine stalls.

The engine can restart in N or P position, and engine speed will not exceed 1,000 rpm or

more.

P2122

P2123

P2127

P2128

P2138Accelerator pedal position

sensorThe ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Page 1186 of 3061

TROUBLE DIAGNOSIS

EC-103

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ECM Harness Connector Terminal LayoutINFOID:0000000003531624

ECM Terminal and Reference ValueINFOID:0000000003531625

PREPARATION

ECM is located in the engine room passenger side behind battery.

ECM INSPECTION TABLE

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECMs transistor. Use a ground other than ECM terminals, such as the ground.

PBIB3368E

BBIA0386E

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

1 B ECM ground[Engine is running]

• Idle speedBody ground

2 LG/B A/F sensor 1 heater (bank 1)[Engine is running]

•Warm-up condition

• Idle speed

(More than 140 seconds after starting en-

gine)Approximately 2.9 - 8.8V

3LThrottle control motor relay

power supply[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

4 L/W Throttle control motor (Close)[Ignition switch: ON]

• Engine: Stopped

• Selector lever: D

• Accelerator pedal: Fully released0 - 14V

PBIA8148J

PBIB1104E

Page 1193 of 3061

![INFINITI QX56 2007 Factory Repair Manual EC-110

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

98 G/RAccelerator pedal position

sensor 2[Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully released0.25 - 0.50V

[Ignition switch: INFINITI QX56 2007 Factory Repair Manual EC-110

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

98 G/RAccelerator pedal position

sensor 2[Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully released0.25 - 0.50V

[Ignition switch:](/img/42/57029/w960_57029-1192.png)

EC-110

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

98 G/RAccelerator pedal position

sensor 2[Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully released0.25 - 0.50V

[Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully depressed2.0 - 2.5V

99 G/YASCD steering switch

(Models with ICC system)[Ignition switch: ON]

• ICC steering switch: OFFApproximately 4.3V

[Ignition switch: ON]

• MAIN switch: PressedApproximately 0V

[Ignition switch: ON]

• CANCEL switch: PressedApproximately 1.3V

[Ignition switch: ON]

• RESUME/ACCELERATE switch: PressedApproximately 3.7V

[Ignition switch: ON]

• SET/COAST switch: PressedApproximately 3V

[Ignition switch: ON]

• DISTANCE switch: PressedApproximately 2.2V

99 G/YASCD steering switch

(Models with ASCD system)[Ignition switch: ON]

• ASCD steering switch: OFFApproximately 4V

[Ignition switch: ON]

• MAIN switch: PressedApproximately 0V

[Ignition switch: ON]

• CANCEL switch: PressedApproximately 1V

[Ignition switch: ON]

• RESUME/ACCELERATE switch: PressedApproximately 3V

[Ignition switch: ON]

• SET/COAST switch: PressedApproximately 2V

101 R/W Stop lamp switch[Ignition switch: OFF]

• Brake pedal: Fully releasedApproximately 0V

[Ignition switch: OFF]

• Brake pedal: Slightly depressedBATTERY VOLTAGE

(11 - 14V)

102 GR/R PNP switch[Ignition switch: ON]

• Selector lever: P or NApproximately 0V

[Ignition switch: ON]

• Except the above gear positionBATTERY VOLTAGE

(11 - 14V)

104 O Throttle control motor relay[Ignition switch: OFF]BATTERY VOLTAGE

(11 - 14V)

[Ignition switch: ON]0 - 1.0V

106 BR/WAccelerator pedal position

sensor 1[Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully released0.5 - 1.0V

[Ignition switch: ON]

• Engine: Stopped

• Accelerator pedal: Fully depressed4.2 - 4.8V

107 V/R Fuel tank temperature sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with fuel

tank temperature. TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

Page 1194 of 3061

TROUBLE DIAGNOSIS

EC-111

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

*:Before measuring the terminal voltage, confirm that the battery is fully charged. Refer to SC-4

.

CONSULT-II Function (ENGINE)INFOID:0000000003531626

FUNCTION

108 BR/WICC brake switch

(Models with ICC system)

ASCD brake switch

(Models with ASCD system)[Ignition switch: ON]

• Brake pedal: Slightly depressedApproximately 0V

[Ignition switch: ON]

• Brake pedal: Fully releasedBATTERY VOLTAGE

(11 - 14V)

109 L/W Ignition switch[Ignition switch: OFF]0V

[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 3 G R F u e l p u m p r e l a y[Ignition switch: ON]

• For 1 second after turning ignition switch

ON

[Engine is running]0 - 1.5V

[Ignition switch: ON]

• More than 1 second after turning ignition

switch ONBATTERY VOLTAGE

(11 - 14V)

11 5

11 6B

B/WECM ground[Engine is running]

• Idle speedBody ground

11 7 L / YEVAP canister vent control

valve[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

11 9

120BR

BRPower supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

121 WPower supply for ECM

(Back-up)[Ignition switch: OFF]BATTERY VOLTAGE

(11 - 14V) TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

Diagnostic test mode Function

Work supportThis mode enables a technician to adjust some devices faster and more accurately by following the in-

dications on the CONSULT-II unit.

Self-diagnostic resultsSelf-diagnostic results such as 1st trip DTC, DTCs and 1st trip freeze frame data or freeze frame data

can be read and erased quickly.*

Data monitor Input/Output data in the ECM can be read.

Data monitor (SPEC)Input/Output of the specification for Basic fuel schedule, AFM, A/F feedback control value and the other

data monitor items can be read.

CAN diagnostic support mon-

itorThe results of transmit/receive diagnosis of CAN communication can be read.

Active testDiagnostic Test Mode in which CONSULT-II drives some actuators apart from the ECMs and also shifts

some parameters in a specified range.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

Function test This mode is used to inform customers when their vehicle condition requires periodic maintenance.

ECM part number ECM part number can be read.

Page 1196 of 3061

TROUBLE DIAGNOSIS

EC-113

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-II screen in freeze frame data

mode only if a 1st trip DTC or DTC is detected. For details, refer to "Freeze Frame Data and 1st Trip Freeze Frame Data".

INSPECTION PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT MODE

Work Item

ENGINE CONTROL COMPONENT PARTS

OUTPUT

Fuel injector×× ×

Power transistor (Ignition timing)×× ×

Throttle control motor relay×××

Throttle control motor×

EVAP canister purge volume con-

trol solenoid valve×××××

Air conditioner relay××

Fuel pump relay××××

Cooling fan relay××××

Air fuel ratio (A/F) sensor 1 heater××××

Heated oxygen sensor 2 heater××××

EVAP canister vent control valve×× ×××

Intake valve timing control solenoid

valve××××

Alternator×× ×

Calculated load value××× ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

DATA

MONI-

TORDATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STATUSDTC

WORK

SUP-

PORT

WORK ITEM CONDITION USAGE

FUEL PRESSURE RELEASE • FUEL PUMP WILL STOP BY TOUCHING “START” DUR-

ING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure from

fuel line

IDLE AIR VOL LEARN • THE IDLE AIR VOLUME THAT KEEPS THE ENGINE

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM.When learning the idle air volume

SELF-LEARNING CONT • THE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF-

FICIENT.When clearing the coefficient of

self-learning control value

Page 1200 of 3061

![INFINITI QX56 2007 Factory Repair Manual TROUBLE DIAGNOSIS

EC-117

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PURG VOL C/V [%]• Indicates the EVAP canister purge vol-

ume control solenoid valve control value

computed by the EC INFINITI QX56 2007 Factory Repair Manual TROUBLE DIAGNOSIS

EC-117

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PURG VOL C/V [%]• Indicates the EVAP canister purge vol-

ume control solenoid valve control value

computed by the EC](/img/42/57029/w960_57029-1199.png)

TROUBLE DIAGNOSIS

EC-117

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PURG VOL C/V [%]• Indicates the EVAP canister purge vol-

ume control solenoid valve control value

computed by the ECM according to the

input signals.

• The opening becomes larger as the val-

ue increases.

INT/V TIM (B1)

[°CA]

• Indicates [°CA] of intake camshaft ad-

vanced angle.

INT/V TIM (B2)

[°CA]

INT/V SOL (B1) [%] • The control value of the intake valve tim-

ing control solenoid valve (determined by

ECM according to the input signals) is in-

dicated.

• The advance angle becomes larger as

the value increases. INT/V SOL (B2) [%]

AIR COND RLY

[ON/OFF]ו The air conditioner relay control condi-

tion (determined by ECM according to

the input signals) is indicated.

FUEL PUMP RLY

[ON/OFF]ו Indicates the fuel pump relay control con-

dition determined by ECM according to

the input signals.

VENT CONT/V

[ON/OFF]• The control condition of the EVAP canis-

ter vent control valve (determined by

ECM according to the input signals) is in-

dicated.

ON: Closed

OFF: Open

THRTL RELAY [ON/

OFF]ו Indicates the throttle control motor relay

control condition determined by the ECM

according to the input signals.

COOLING FAN

[HI/OFF]ו The control condition of the cooling fan

(determined by ECM according to the in-

put signals) is indicated.

HI: High speed operation

OFF: Stop

HO2S2 HTR (B1)

[ON/OFF]• Indicates [ON/OFF] condition of heated

oxygen sensor 2 heater determined by

ECM according to the input signals. HO2S2 HTR (B2)

[ON/OFF]

I/P PULLY SPD

[rpm]• Indicates the engine speed computed

from the turbine revolution sensor signal.

VEHICLE SPEED

[km/h] or [mph]• Indicates the vehicle speed computed

from the revolution sensor signal.

IDL A/V LEARN

[YET/CMPLT]• Display the condition of idle air volume

learning

YET: Idle Air Volume Learning has not

been performed yet.

CMPLT: Idle Air Volume Learning has al-

ready been performed successfully.

TRVL AFTER MIL

[km] or [mile]• Distance traveled while MIL is activated. Monitored item

[Unit]ECM IN-

PUT SIG-

NALSMAIN

SIGNALSDescription Remarks

Page 1203 of 3061

EC-120

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

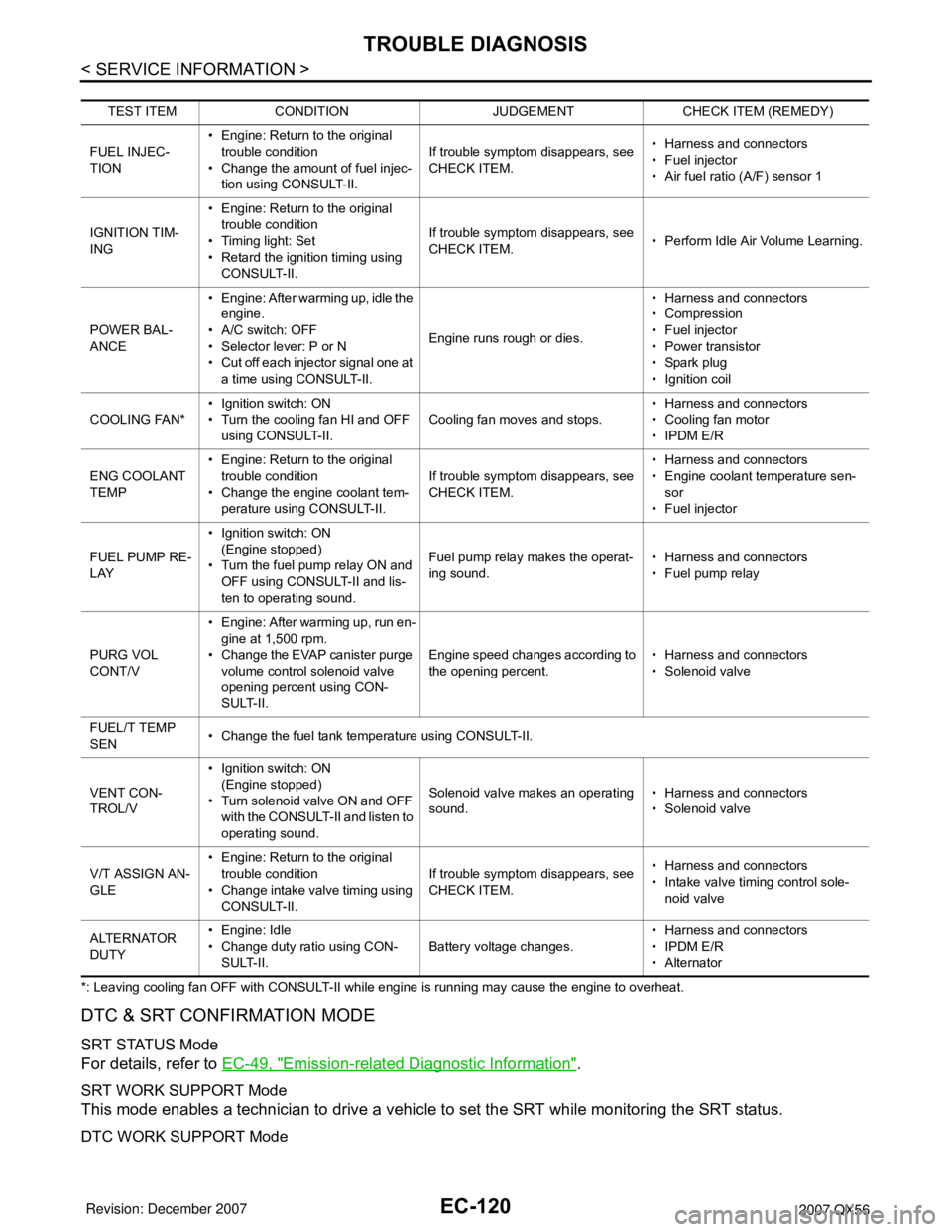

*: Leaving cooling fan OFF with CONSULT-II while engine is running may cause the engine to overheat.

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer to EC-49, "Emission-related Diagnostic Information".

SRT WORK SUPPORT Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

DTC WORK SUPPORT Mode

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION• Engine: Return to the original

trouble condition

• Change the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Fuel injector

• Air fuel ratio (A/F) sensor 1

IGNITION TIM-

ING• Engine: Return to the original

trouble condition

• Timing light: Set

• Retard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Perform Idle Air Volume Learning.

POWER BAL-

ANCE• Engine: After warming up, idle the

engine.

• A/C switch: OFF

• Selector lever: P or N

• Cut off each injector signal one at

a time using CONSULT-II.Engine runs rough or dies.• Harness and connectors

• Compression

• Fuel injector

• Power transistor

•Spark plug

• Ignition coil

COOLING FAN*• Ignition switch: ON

• Turn the cooling fan HI and OFF

using CONSULT-II.Cooling fan moves and stops.• Harness and connectors

• Cooling fan motor

• IPDM E/R

ENG COOLANT

TEMP• Engine: Return to the original

trouble condition

• Change the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Engine coolant temperature sen-

sor

• Fuel injector

FUEL PUMP RE-

LAY• Ignition switch: ON

(Engine stopped)

• Turn the fuel pump relay ON and

OFF using CONSULT-II and lis-

ten to operating sound.Fuel pump relay makes the operat-

ing sound.• Harness and connectors

•Fuel pump relay

PURG VOL

CONT/V• Engine: After warming up, run en-

gine at 1,500 rpm.

• Change the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according to

the opening percent.• Harness and connectors

• Solenoid valve

FUEL/T TEMP

SEN• Change the fuel tank temperature using CONSULT-II.

VENT CON-

TROL/V• Ignition switch: ON

(Engine stopped)

• Turn solenoid valve ON and OFF

with the CONSULT-II and listen to

operating sound.Solenoid valve makes an operating

sound.• Harness and connectors

• Solenoid valve

V/T ASSIGN AN-

GLE• Engine: Return to the original

trouble condition

• Change intake valve timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.• Harness and connectors

• Intake valve timing control sole-

noid valve

ALTERNATOR

DUTY•Engine: Idle

• Change duty ratio using CON-

SULT-II.Battery voltage changes.• Harness and connectors

• IPDM E/R

•Alternator

Page 1208 of 3061

TROUBLE DIAGNOSIS

EC-125

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N POSI SW • Ignition switch: ONSelector lever: P or N ON

Selector lever: Except above OFF

PW/ST SIGNAL• Engine: After warming up, idle the

engineSteering wheel: Not being turned

(Forward direction)OFF

Steering wheel: Being turned ON

LOAD SIGNAL • Ignition switch: ONRear window defogger switch is ON

and/or lighting switch is in 2nd.ON

Rear window defogger switch is OFF

and lighting switch is OFF.OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW• Engine: After warming up, idle the

engineHeater fan control switch: ON ON

Heater fan control switch: OFF OFF

BRAKE SW • Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1

INJ PULSE-B2• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 2.0 - 2.8 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 10° - 20° BTDC

2,000 rpm 25° - 45° BTDC

CAL/LD VALUE• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 14% - 33%

2,500 rpm 12% - 25%

MASS AIRFLOW• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 3.0 - 9.0 g·m/s

2,500 rpm 9.0 - 28.0 g·m/s

PURG VOL C/V• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle

(Accelerator pedal: Not depressed

even slightly, after engine starting.)0%

2,000 rpm —

INT/V TIM (B1)

INT/V TIM (B2)• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 20°CA

INT/V SOL (B1)

INT/V SOL (B2)• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 0% - 2%

2,000 rpm Approx. 25% - 50%

AIR COND RLY• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor: Operates)ON

FUEL PUMP RLY• For 1 second after turning ignition switch ON

• Engine running or crankingON

• Except above conditions OFF

VENT CONT/V • Ignition switch: ON OFF

THRTL RELAY • Ignition switch: ON ONMONITOR ITEM CONDITION SPECIFICATION