relay INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 967 of 3061

![INFINITI QX56 2007 Factory Workshop Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-39

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1. Disconnect ABS actuator and electric unit (control unit) connector E125.

2. INFINITI QX56 2007 Factory Workshop Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-39

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1. Disconnect ABS actuator and electric unit (control unit) connector E125.

2.](/img/42/57029/w960_57029-966.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-39

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1. Disconnect ABS actuator and electric unit (control unit) connector E125.

2. Check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace as necessary.

3.CHECKING SOLENOID POWER AND GROUND

1. Check voltage between ABS actuator and electric unit (control

unit) harness connector E125 and body ground.

2. Check resistance between ABS actuator and electric unit (con-

trol unit) harness connector E125 and body ground.

OK or NG

OK >> Perform self-diagnosis again. If the same results

appear, replace ABS actuator and electric unit (control unit). Refer to BRC-58, "

Removal and

Installation".

NG >> Repair the circuit.

Actuator Motor, Motor Relay, and Circuit InspectionINFOID:0000000003532790

INSPECTION PROCEDURE

1.CHECKING SELF-DIAGNOSIS RESULTS

Check self-diagnosis results.

Is the above displayed in the self-diagnosis display items?

YES >> GO TO 2.

NO >> Inspection End.

2.CONNECTOR INSPECTION

1. Disconnect ABS actuator and electric unit (control unit) connector E125.

2. Check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace as necessary.

3.CHECKING ABS MOTOR AND MOTOR RELAY POWER SYSTEMABS actuator and electric unit

(control unit) connector E125Body

groundMeasured

value

(Approx.)

32 — 12V

WFIA0195E

ABS actuator and electric unit

(control unit) connector E125Body

groundMeasured

value

(Approx.)

16 —

0Ω

47 —

WFIA0196E

Self-diagnosis results

PUMP MOTOR

ACTUATOR RLY

Page 969 of 3061

![INFINITI QX56 2007 Factory Workshop Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-41

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Check the voltage between the ABS actuator and electric unit (con-

trol unit) h INFINITI QX56 2007 Factory Workshop Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-41

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Check the voltage between the ABS actuator and electric unit (con-

trol unit) h](/img/42/57029/w960_57029-968.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-41

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Check the voltage between the ABS actuator and electric unit (con-

trol unit) harness connector E125 terminal 41 and body ground.

OK or NG

OK >> Perform self-diagnosis again. If the same results

appear, replace ABS actuator and electric unit (control

unit). Refer to BRC-58, "

Removal and Installation".

NG >> GO TO 4.

4.STOP LAMP RELAY CIRCUIT INSPECTION

1. Disconnect the stop lamp relay harness connector E12.

2. Check the continuity between the ABS actuator and electric unit

(control unit) harness connector E125 (B) terminal 41 and stop

lamp relay harness connector E12 (A) terminal 4.

OK or NG

OK >> Perform self-diagnosis again. If the same results

appear, replace ABS actuator and electric unit (control

unit). Refer to BRC-58, "

Removal and Installation"BRC-

58, "Removal and Installation".

NG >> Refer to "Stop Lamp Switch System Inspection".

ABS/TCS/VDC Control Unit Power and Ground Systems InspectionINFOID:0000000003532792

INSPECTION PROCEDURE

1.SELF-DIAGNOSIS RESULT CHECK

Check self-diagnosis results.

Is the above displayed in the self-diagnosis display items?

YES >> GO TO 2.

NO >> Inspection End.

2.CONNECTOR INSPECTION

1. Disconnect the ABS actuator and electric unit (control unit) connector E125.

2. Check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace as necessary.

3.ABS/TCS/VDC CONTROL UNIT POWER AND GROUND CIRCUIT INSPECTION

Measure the voltage and continuity between the ABS actuator and electric unit (control unit) harness connec-

tor E125 and body ground.Brake pedal depressed : Battery voltage

(approx. 12V)

Brake pedal not depressed : Approx. 0V

WFIA0198E

Continuity should exist

WFIA0431E

Self-diagnosis results

BATTERY VOLTAGE

Signal nameABS actuator and electric unit

(control unit) connector E125Body

groundMeasured value

Power supply1

— Battery voltage (Approx. 12V)

32

Page 1047 of 3061

DI-36

< SERVICE INFORMATION >

WARNING CHIME

WARNING CHIME

Component Parts and Harness Connector LocationINFOID:0000000003533510

System DescriptionINFOID:0000000003533511

FUNCTION

Power is supplied at all times

• through 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 19, located in the fuse block (J/B)]

1. Fuse block (J/B) 2. Fuse and fusible link box 3. Fuse and relay box

4. Combination meter M24 5. Combination switch (lighting switch)

M286. BCM M18, M19, M20 (view with in-

strument lower panel LH removed)

7. Front door switch LH B8 8. Key switch and key lock solenoid

M279. Seat belt buckle pre-tensioner as-

sembly LH (seat belt buckle switch)

B74

WKIA4594E

Page 1048 of 3061

WARNING CHIME

DI-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

• to key switch and key lock solenoid terminal 3.

With ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67

• through body grounds M57, M61, and M79.

NOTE:

When ignition key warning chime, light warning chime, and seat belt warning chime are required at the same

time, the priorities for each chime are the following.

1. Light warning chime

2. Ignition key warning chime

3. Seat belt warning chime

IGNITION KEY WARNING CHIME

With the key inserted in the ignition switch, the ignition switch in OFF position, and the driver's door open, the

warning chime will sound.

Power is supplied

• through key switch and key lock solenoid terminal 4

• to BCM terminal 37.

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter via CAN

communication lines. When the combination meter receives key warning signal, it sounds warning chime.

LIGHT WARNING CHIME

With the key removed from the ignition switch, the driver's door open, and the lighting switch (part of the com-

bination switch) in 1st or 2nd position, the warning chime will sound. [Except when headlamp battery saver

control operates (5 minutes after ignition switch is turned to OFF or ACC position) and headlamps do not illu-

minate.]

Signal is supplied

• from combination switch (lighting switch) terminals 1, 2, 3, 4, 5, 6, 7, 8, 9 and 10

• to BCM terminals 2, 3, 4, 5, 6, 32, 33, 34, 35 and 36.

NOTE:

BCM detected lighting switch in 1st or 2nd position. Refer to LT-72, "

Combination Switch Reading Function".

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects headlamps are illuminated, and sends light warning signal to combination meter CAN communi-

cation lines. When the combination meter receives light warning signal, it sounds warning chime.

SEAT BELT WARNING CHIME

When the ignition switch is turned ON with the seat belt unfastened [seat belt buckle pre-tensioner assembly

LH (seat belt buckle switch) unfastened], warning chime will sound for approximately 6 seconds.

Ground is supplied

• to combination meter terminal 27

• through seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 4.

Seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 3 is grounded through body

grounds B7 and B19.

The combination meter sends seat belt buckle switch LH unfastened signal to BCM via CAN communication

line.

BCM receives seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) unfastened signal from

combination meter via CAN communication line, and sends seat belt warning signal to the combination meter

via CAN communication line. When the combination meter receives the seat belt warning signal, it sounds the

warning chime. The BCM controls the (6 second) duration of the seat belt warning chime.

CAN Communication System DescriptionINFOID:0000000003533512

Refer to LAN-4.

Page 1057 of 3061

DI-46

< SERVICE INFORMATION >

REAR SONAR SYSTEM

REAR SONAR SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000003533524

System DescriptionINFOID:0000000003533525

FUNCTION

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 12, located in the fuse block (J/B)]

• to sonar control unit terminal 8,

• through 10A fuse (No. 51, located in the IPDM E/R)

• to back-up lamp relay terminals 1 and 3.

1. Fuse block (J/B) 2. IPDM E/R E119 3. Sonar buzzer M117

4. Rear sonar system OFF switch M116 5. Sonar control unit B56 (view of left

rear body)6. Rear sonar sensor LH outer C102

7. Rear sonar sensor LH inner C103 8. Rear sonar sensor RH inner C104 9. Rear sonar sensor RH outer C105

10. A/T assembly F9 11. Back-up lamp relay M73

WKIA4595E

Page 1058 of 3061

REAR SONAR SYSTEM

DI-47

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Ground is supplied

• to sonar control unit terminal 6

• through body grounds B7 and B19.

With the ignition switch in the ON or START position, and the transmission gear selector lever in the R posi-

tion, power is supplied

• to sonar control unit terminal 5

• from back-up lamp relay terminal 5.

With power and ground supplied, transmission gear selector lever in R position, and the rear sonar system

OFF switch ON, the rear sonar system will detect obstacles within 1.8 m (5.9 ft.) of the rear sonar sensors. The

vehicle operator is notified of obstacles by varied rate of tone from the sonar buzzer depending on distance of

obstacle being sensed.

REAR SONAR SYSTEM OFF SWITCH

With power and ground supplied to the sonar control unit, transmission gear selector lever in R position, the

sonar system can be disabled and the sonar buzzer silenced by momentarily pressing the rear sonar system

OFF switch. The rear sonar system OFF indicator lamp will be illuminated in the rear sonar system OFF

switch.

To disable the rear sonar system, ground is supplied

• to sonar control unit terminal 13

• through rear sonar system OFF switch terminal 1

• through rear sonar system OFF switch terminal 2

• from body grounds M57, M61, and M79.

To light the rear sonar system OFF indicator, power is supplied

• from sonar control unit terminal 4

• to the rear sonar system OFF switch terminal 5.

Ground is supplied

• to the rear sonar system OFF switch terminal 6

• from body grounds M57, M61, and M79.

The rear sonar system and buzzer will be disabled and the rear sonar system OFF indicator will be illuminated

until the ignition switch is turned OFF. When the ignition switch is turned ON, the rear sonar system will be

enabled. Depressing the rear sonar system OFF switch momentarily will enable the rear sonar system also.

Enabling the rear sonar system will cause the rear sonar system OFF indicator to go out.

SONAR BUZZER

With power supplied to the sonar control unit and the transmission gear selector lever in R position, a station-

ary object that is at least 7.0 cm (2.8 in.) wide and 1.0 m (39.0 in.) tall and that is closer than 1.8 meters (5.9 ft.)

will be detected by the rear sonar sensors, causing the sonar buzzer to sound a tone. As the vehicle moves

closer to the object, the rate of the tone will increase. When the object is less than 25.0 cm (10 in.) from the

rear bumper, the tone will sound continuously.

Power is supplied

• from sonar control unit terminal 7

• to sonar buzzer terminal +.

Ground is supplied

• to sonar buzzer terminal -

• from sonar control unit terminal 3.

REAR SONAR SENSOR

With power and ground supplied to the rear sonar sensors, the sonar sensors transmit a 38.4 kHz ultrasonic

signal. This signal is reflected back to the sensor by objects large enough and close enough to be detected.

The rear sonar sensors measure the time from the transmitted signal to the time the signal is reflected back

and sends this information to the sonar control unit.

Power is supplied

• from sonar control unit terminal 16

• to each rear sonar sensor terminal 1.

Ground is supplied

• to each rear sonar sensor terminal 3

• from sonar control unit terminal 15.

Signal is supplied

• from each rear sonar sensor terminal 2

• to sonar control unit terminals 9, 10, 11 and 12.

Page 1069 of 3061

DI-58

< SERVICE INFORMATION >

REAR VIEW MONITOR

REAR VIEW MONITOR

Component Parts and Harness Connector LocationINFOID:0000000003533538

System DescriptionINFOID:0000000003533539

• When the A/T selector is in the reverse position, the display shows view to the rear of the vehicle.

• Lines which indicate the vehicle clearance and distances are displayed on the monitor.

POWER SUPPLY AND GROUND

Power is supplied at all times

• through 20A fuse (No. 31, located in the fuse and fusible link box)

1. Fuse block (J/B) 2. Fuse and fusible link box 3. IPDM E/R E119

4. Rear view camera D504 5. Data link connector M22 6. A/T assembly F9

7. Rear view camera control unit B73

(view of left rear body)8. Display unit M93 9. Display control unit M94, M95

10. AV switch M98 11. Back-up lamp relay M73

WKIA4596E

Page 1070 of 3061

REAR VIEW MONITOR

DI-59

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

• to rear view camera control unit terminal 1.

When ignition switch is in ACC or ON position, power is supplied

• through 10A fuse [No. 4, located in the fuse block (J/B)]

• to rear view camera control unit terminal 2.

Ground is supplied

• to rear view camera control unit terminal 3 and

• to rear view camera terminal 2

• through grounds B7 and B19.

AV COMMUNICATION LINE

Rear view camera control unit is connected to the following units with AV communication line. Each unit trans-

mits/receives data with AV communication line.

• NAVI control unit

• Display unit

• Display control unit

• AV switch

REAR VIEW CAMERA OPERATION

When ignition switch is in ON or START position, power is supplied

• through 10A fuse (No. 51, located in the IPDM E/R)

• to back-up lamp relay terminals 1 and 3.

When A/T selector lever is in reverse position, power is supplied

• through back-up lamp relay terminal 2

• to TCM terminal 7.

Then, when back-up lamp relay is energized,

• from back-up lamp relay terminal 5

• to rear view camera control unit terminal 4.

Then, rear view camera control unit is sent camera ON signal

• through rear view camera control unit terminal 8

• to rear view camera terminal 1.

An image taken by rear view camera is sent

• through rear view camera terminals 3 and 4

• to rear view camera control unit terminals 10 and 9.

Then an image is sent

• through rear view camera control unit terminals 11 and 12

• to display unit terminals 4 and 15.

An image of rear view will be projected on the display.

Side Distance Guideline

When A/T selector lever is in reverse position, rear view camera control unit is sent rear view camera guideline

image

• through rear view camera control unit terminals 11 and 12

• to display unit terminals 4 and 15.

Rear view camera guideline will be projected on the display.

Display shows image from rear view camera image and rear view camera guideline.

Page 1079 of 3061

DI-68

< SERVICE INFORMATION >

REAR VIEW MONITOR

1. Turn ignition switch ON.

2. Shift A/T selector lever to R position.

Does back-up lamp illuminate?

YES >> GO TO 2.

NO >> Check back-up lamp system. Refer to LT- 8 0

.

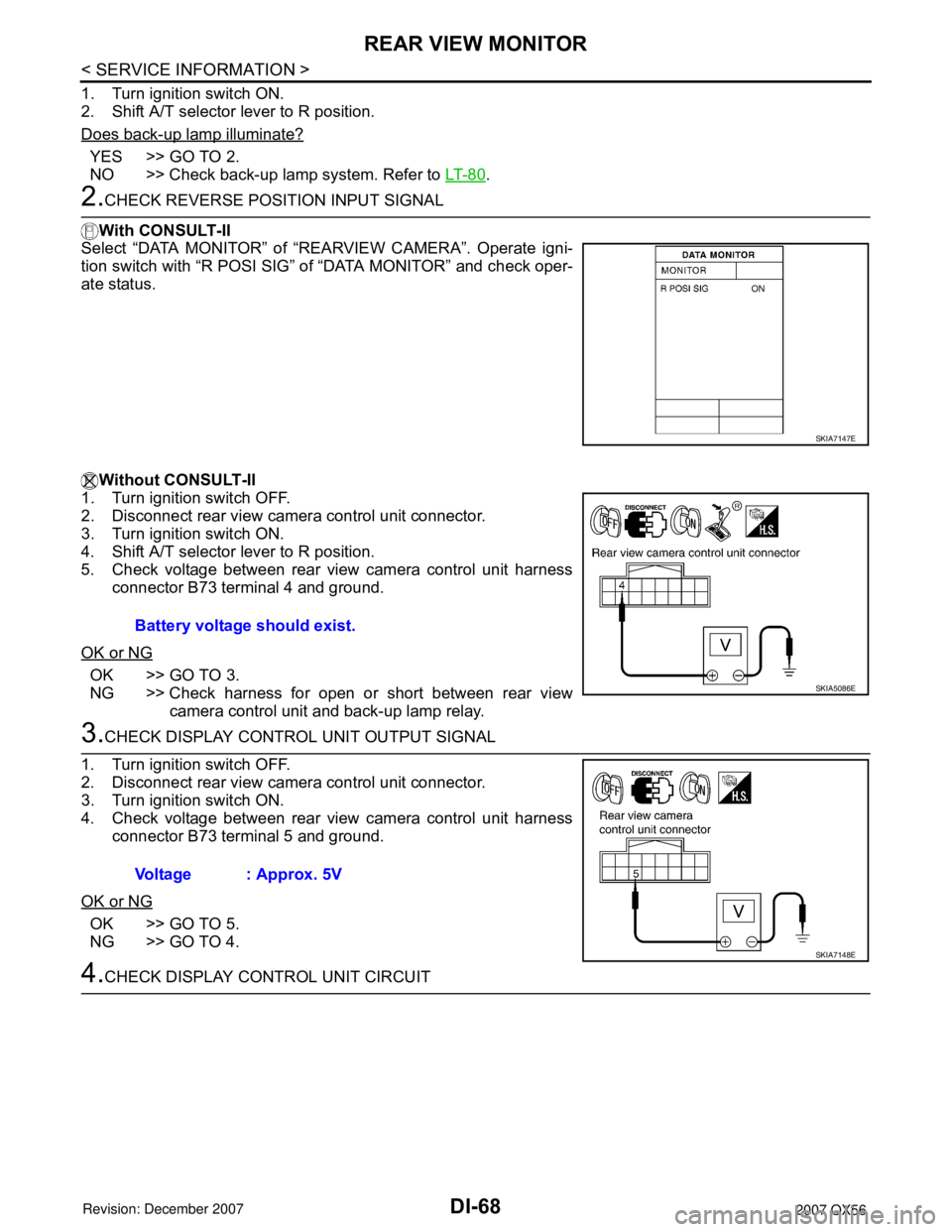

2.CHECK REVERSE POSITION INPUT SIGNAL

With CONSULT-II

Select “DATA MONITOR” of “REARVIEW CAMERA”. Operate igni-

tion switch with “R POSI SIG” of “DATA MONITOR” and check oper-

ate status.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Shift A/T selector lever to R position.

5. Check voltage between rear view camera control unit harness

connector B73 terminal 4 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open or short between rear view

camera control unit and back-up lamp relay.

3.CHECK DISPLAY CONTROL UNIT OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Check voltage between rear view camera control unit harness

connector B73 terminal 5 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK DISPLAY CONTROL UNIT CIRCUIT

SKIA7147E

Battery voltage should exist.

SKIA5086E

Voltage : Approx. 5V

SKIA7148E

Page 1090 of 3061

EC-7

C

D

E

F

G

H

I

J

K

L

M

ECA

N

O

P

DTC P1564 ICC STEERING SWITCH .............507

Component Description .........................................507

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

507

On Board Diagnosis Logic ....................................507

DTC Confirmation Procedure ................................507

Wiring Diagram .....................................................509

Diagnosis Procedure .............................................510

Component Inspection ..........................................512

DTC P1564 ASCD STEERING SWITCH .........513

Component Description .........................................513

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

513

On Board Diagnosis Logic ....................................513

DTC Confirmation Procedure ................................513

Wiring Diagram .....................................................515

Diagnosis Procedure .............................................516

Component Inspection ..........................................518

DTC P1568 ICC FUNCTION ............................519

On Board Diagnosis Logic ....................................519

DTC Confirmation Procedure ................................519

Diagnosis Procedure .............................................519

DTC P1572 ICC BRAKE SWITCH ...................520

Component Description .........................................520

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

520

On Board Diagnosis Logic ....................................520

DTC Confirmation Procedure ................................520

Wiring Diagram .....................................................522

Diagnosis Procedure .............................................523

Component Inspection ..........................................526

DTC P1572 ASCD BRAKE SWITCH ...............528

Component Description .........................................528

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

528

On Board Diagnosis Logic ....................................528

DTC Confirmation Procedure ................................528

Wiring Diagram .....................................................530

Diagnosis Procedure .............................................531

Component Inspection ..........................................534

DTC P1574 ICC VEHICLE SPEED SENSOR ..535

Component Description .........................................535

On Board Diagnosis Logic ....................................535

DTC Confirmation Procedure ................................535

Diagnosis Procedure .............................................536

DTC P1574 ASCD VEHICLE SPEED SEN-

SOR ..................................................................

537

Component Description .........................................537

On Board Diagnosis Logic ....................................537

DTC Confirmation Procedure ................................537

Diagnosis Procedure .............................................538

DTC P1805 BRAKE SWITCH ..........................539

Description ............................................................539

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

539

On Board Diagnosis Logic .....................................539

DTC Confirmation Procedure ................................539

Wiring Diagram ......................................................540

Diagnosis Procedure .............................................541

Component Inspection ...........................................542

DTC P2100, P2103 THROTTLE CONTROL

MOTOR RELAY ..............................................

543

Component Description .........................................543

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

543

On Board Diagnosis Logic .....................................543

DTC Confirmation Procedure ................................543

Wiring Diagram ......................................................545

Diagnosis Procedure .............................................546

DTC P2101 ELECTRIC THROTTLE CON-

TROL FUNCTION ...........................................

548

Description .............................................................548

On Board Diagnosis Logic .....................................548

DTC Confirmation Procedure ................................548

Wiring Diagram ......................................................549

Diagnosis Procedure .............................................550

Component Inspection ...........................................553

Removal and Installation .......................................553

DTC P2118 THROTTLE CONTROL MOTOR .554

Component Description .........................................554

On Board Diagnosis Logic .....................................554

DTC Confirmation Procedure ................................554

Wiring Diagram ......................................................555

Diagnosis Procedure .............................................556

Component Inspection ...........................................557

Removal and Installation .......................................557

DTC P2119 ELECTRIC THROTTLE CON-

TROL ACTUATOR ..........................................

559

Component Description .........................................559

On Board Diagnosis Logic .....................................559

DTC Confirmation Procedure ................................559

Diagnosis Procedure .............................................560

DTC P2122, P2123 APP SENSOR .................561

Component Description .........................................561

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

561

On Board Diagnosis Logic .....................................561

DTC Confirmation Procedure ................................561

Wiring Diagram ......................................................563

Diagnosis Procedure .............................................564

Component Inspection ...........................................566

Removal and Installation .......................................566

DTC P2127, P2128 APP SENSOR .................567

Component Description .........................................567

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

567

On Board Diagnosis Logic .....................................567