INFINITI QX56 2008 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 3611 of 4083

TM-64

< COMPONENT DIAGNOSIS >

P0740 TORQUE CONVERTER

4. Read out the value of “TCC SOLENOID” while driving.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to TM-92, "

Diagnosis Procedure".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-201, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2".

NG >> Repair or replace damaged parts.

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-63, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

Item name Condition Display value (Approx.)

TCC SOLENOID When performing slip lock-up

0.2 - 0.4 A

When performing lock-up 0.4 - 0.6 A

Revision: March 2010 2008 QX56

Page 3612 of 4083

P0744 TORQUE CONVERTERTM-65

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

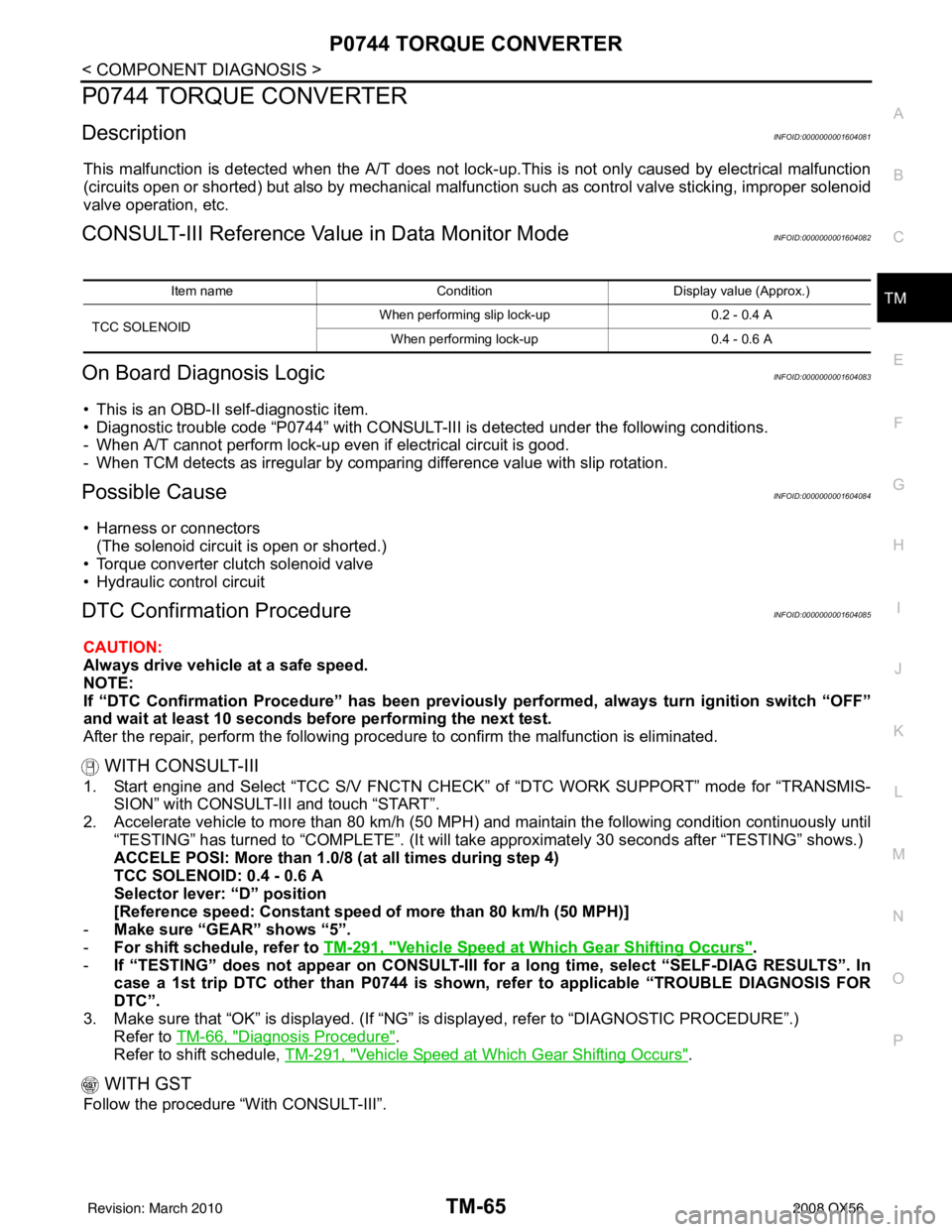

P0744 TORQUE CONVERTER

DescriptionINFOID:0000000001604081

This malfunction is detected when the A/T does not lock- up.This is not only caused by electrical malfunction

(circuits open or shorted) but also by mechanical malfunc tion such as control valve sticking, improper solenoid

valve operation, etc.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000001604082

On Board Diagnosis LogicINFOID:0000000001604083

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744” with CONSULT-III is detected under the following conditions.

- When A/T cannot perform lock-up even if electrical circuit is good.

- When TCM detects as irregular by comparing difference value with slip rotation.

Possible CauseINFOID:0000000001604084

• Harness or connectors

(The solenoid circuit is open or shorted.)

• Torque converter clutch solenoid valve

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000001604085

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and Select “TCC S/V FNCTN CHECK” of “DTC WORK SUPPORT” mode for “TRANSMIS- SION” with CONSULT-III and touch “START”.

2. Accelerate vehicle to more than 80 km/h (50 MPH) and maintain the following condition continuously until “TESTING” has turned to “COMPLETE”. (It will take approximately 30 seconds after “TESTING” shows.)

ACCELE POSI: More than 1.0/8 (at all times during step 4)

TCC SOLENOID: 0.4 - 0.6 A

Selector lever: “D” position

[Reference speed: Constant speed of more than 80 km/h (50 MPH)]

- Make sure “GEAR” shows “5”.

- For shift schedule, refer to TM-291, "

Vehicle Speed at Which Gear Shifting Occurs".

- If “TESTING” does not appear on CONSULT-III for a long time, select “SELF-DIAG RESULTS”. In

case a 1st trip DTC other than P0744 is shown, refer to applicable “TROUBLE DIAGNOSIS FOR

DTC”.

3. Make sure that “OK” is disp layed. (If “NG” is displayed, refer to “DIAGNOSTIC PROCEDURE”.)

Refer to TM-66, "

Diagnosis Procedure".

Refer to shift schedule, TM-291, "

Vehicle Speed at Which Gear Shifting Occurs".

WITH GST

Follow the procedure “With CONSULT-III”.

Item name Condition Display value (Approx.)

TCC SOLENOID When performing slip lock-up

0.2 - 0.4 A

When performing lock-up 0.4 - 0.6 A

Revision: March 2010 2008 QX56

Page 3613 of 4083

TM-66

< COMPONENT DIAGNOSIS >

P0744 TORQUE CONVERTER

Diagnosis Procedure

INFOID:0000000001604086

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch “ON”.

2. Select “MAIN SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Start the engine.

4. Read out the value of “TCC SOLENOID” while driving.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to TM-92, "

Diagnosis Procedure".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-201, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2".

NG >> Repair or replace damaged parts.

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-65, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

Item name Condition Display value (Approx.)

TCC SOLENOID When performing slip lock-up

0.2 - 0.4 A

When performing lock-up 0.4 - 0.6 A

Revision: March 2010 2008 QX56

Page 3614 of 4083

P0745 PRESSURE CONTROL SOLENOID ATM-67

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

P0745 PRESSURE CONTROL SOLENOID A

DescriptionINFOID:0000000001604087

The line pressure solenoid valve regulates the oil pum p discharge pressure to suit the driving condition in

response to a signal sent from the TCM.

The line pressure duty cycle value is not consistent when the closed throttle position signal is “ON”.

To confirm the line pressure duty cycle at low pressu re, the accelerator (throttle) should be open until

the closed throttle posi tion signal is “OFF”.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000001604088

On Board Diagnosis LogicINFOID:0000000001604089

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0745” with CONSULT-III is detected under the following conditions.

- When TCM detects an improper voltage drop when it tries to operate the solenoid valve.

- When TCM detects as irregular by comparing target value with monitor value.

Possible CauseINFOID:0000000001604090

• Harness or connectors

(The solenoid circuit is open or shorted.)

• Line pressure solenoid valve

DTC Confirmation ProcedureINFOID:0000000001604091

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON” and select “DATA MONITOR” mode for “ENGINE” with CONSULT-III.

2. Engine start and wait at least 5 second.

3. If DTC is detected, go to TM-67, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-III”.

Diagnosis ProcedureINFOID:0000000001604092

1.CHECK INPUT SIGNAL

With CONSULT-III

1. Turn ignition switch “ON”.

2. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start the engine.

4. Read out the value of “LINE PRES SOL” while driving.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Item name Condition Display value (Approx.)

LINE PRES SOL During driving0.2 - 0.6 A

Item nameCondition Display value (Approx.)

LINE PRES SOL During driving 0.2 - 0.6 A

Revision: March 2010 2008 QX56

Page 3615 of 4083

TM-68

< COMPONENT DIAGNOSIS >

P0745 PRESSURE CONTROL SOLENOID A

Check TCM power supply and ground circuit. Refer to TM-92, "Diagnosis Procedure".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-201, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2".

NG >> Repair or replace damaged parts.

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-67, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

Revision: March 2010 2008 QX56

Page 3616 of 4083

P1705 TP SENSORTM-69

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

P1705 TP SENSOR

DescriptionINFOID:0000000001604093

Electric throttle control actuator consists of throttle control motor, accelerator pedal position sensor, throttle

position sensor, etc. The actuator sends a signal to the ECM, and ECM sends signals to TCM with CAN com-

munication.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000001604094

On Board Diagnosis LogicINFOID:0000000001604095

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1705” with CONSULT-III is detected when TCM does not receive the proper

accelerator pedal position signals (input by CAN communication) from ECM.

Possible CauseINFOID:0000000001604096

Harness or connectors

(The sensor circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000001604097

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine and let it idle for 1 second.

4. If DTC is detected, go to TM-69, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001604098

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer to TM-32, "

CONSULT-III Function (TRANSMISSION)".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer to TM-38.

NO >> GO TO 2.

2.CHECK DTC WITH TCM

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Depress accelerator pedal and read out the value of “ACCELE POSI”.

4. Select “SELF-DIAG RESULTS” mode for “T RANSMISSION” with CONSULT-III. Refer to TM-32, "

CON-

SULT-III Function (TRANSMISSION)".

Item name Condition Display value (Approx.)

ACCELE POSI Released accelerator pedal.

0.0/8

Fully depressed accelerator pedal. 8/8

Item nameCondition Display value

(Approx.)

ACCELE POSI Released accelerator pedal.

0.0/8

Fully depressed accelerator pedal. 8/8

Revision: March 2010 2008 QX56

Page 3617 of 4083

TM-70

< COMPONENT DIAGNOSIS >

P1705 TP SENSOR

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.CHECK DTC WITH ECM

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “ENGINE” with CONSULT-III. Refer to TM-32, "

CONSULT-III

Function (TRANSMISSION)".

OK or NG

OK >> GO TO 4.

NG >> Check the DTC detected item. Refer to TM-116, "

DTC No. Index".

• If CAN communication line is detected, go to TM-38, "

Description".

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-69, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

5.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to TM-92, "

Diagnosis Procedure".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-201, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2".

NG >> Repair or replace damaged parts.

Revision: March 2010 2008 QX56

Page 3618 of 4083

P1710 TRANSMISSION FLUID TEMPERATURE SENSOR

TM-71

< COMPONENT DIAGNOSIS >

C EF

G H

I

J

K L

M A

B

TM

N

O P

P1710 TRANSMISSION FLUI D TEMPERATURE SENSOR

DescriptionINFOID:0000000001604099

The A/T fluid temperature sensor detects the A/ T fluid temperature and sends a signal to the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001604100

On Board Diagnosis LogicINFOID:0000000001604101

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1710 (A/T), P0710 (ENGINE)” with CONSULT-III is detected when TCM receives

an excessively low or high voltage from the sensor.

Possible CauseINFOID:0000000001604102

• Harness or connectors (The sensor circuit is open or shorted.)

• A/T fluid temperature sensors 1, 2

DTC Confirmation ProcedureINFOID:0000000001604103

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-III.

3. Start engine and maintain the following conditions for at least 10 minutes (Total). (It is not necessary to maintain continuously.)

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.0/8

Selector lever: “D” position

4. If DTC is detected, go to TM-71, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-III”.

Diagnosis ProcedureINFOID:0000000001604104

1.CHECK A/T FLUID TEMPERATURE SENSOR 1 SIGNAL

With CONSULT-III

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITO R” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “ATF TEMP SE 1”.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

Item name Condition °C ( °F) Display value (Approx.)

ATF TEMP SE 1 0 (32) - 20 (68) - 80 (176) 3.3 - 2.7 - 0.9 V

ATF TEMP SE 2 3.3 - 2.5 - 0.7 V

Item nameCondition °C ( °F) Display value (Approx.)

ATF TEMP SE 1 0 (32) - 20 (68) - 80 (176) 3.3 - 2.7 - 0.9 V

Revision: March 2010 2008 QX56

Page 3619 of 4083

TM-72

< COMPONENT DIAGNOSIS >

P1710 TRANSMISSION FLUID TEMPERATURE SENSOR

2.CHECK A/T FLUID TEMPERATURE SENSOR 2 SIGNAL

With CONSULT-III

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out the value of “ATF TEMP SE 2”.

OK or NG

OK >> GO TO 8.

NG >> GO TO 5.

3.CHECK A/T FLUID TEMPERATURE SENSOR 1

Check A/T fluid temperature sensor 1. Refer to TM-73, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Replace the control valve with TCM. Refer to TM-201, "

Control Valve with TCM and A/T Fluid

Temperature Sensor 2".

4.CHECK SUB-HARNESS

1. Disconnect transmission range switch connector and TCM connector.

2. Check continuity between transmission range switch connector (A) terminals and TCM connector (B) terminals.

3. If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

5.CHECK A/T FLUID TEMPERATURE SENSOR 2

Check A/T fluid temperature sensor 2. Refer to TM-73, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace the A/T fluid temperature sensor 2. Refer to TM-201, "

Control Valve with TCM and A/T

Fluid Temperature Sensor 2".

6.CHECK TERMINAL CORD ASSEMBLY

1. Disconnect A/T fluid temperature sensor 2 connector and TCM connector.

2. Check continuity between A/T fluid temperature sensor 2 con- nector terminals and TCM connector terminals.

Item name Condition °C (°F) Display value (Approx.)

ATF TEMP SE 2 0 (32) - 20 (68) - 80 (176) 3.3 - 2.5 - 0.7 V

Item Connector Terminal Continuity

Transmission range switch con-

nector F505 (A)

6

Ye s

TCM connector F503 (B)19

Transmission range switch con-

nector F505 (A)

7

Ye s

TCM connector F503 (B)18

JSDIA1330ZZ

Item Connector Terminal Continuity

A/T fluid temperature sensor 2

connector F507

1

Ye s

TCM connector F5023

A/T fluid temperature sensor 2

connector F507

2

Ye s

TCM connector F5025

SCIA5462E

Revision: March 2010 2008 QX56

Page 3620 of 4083

P1710 TRANSMISSION FLUID TEMPERATURE SENSOR

TM-73

< COMPONENT DIAGNOSIS >

C EF

G H

I

J

K L

M A

B

TM

N

O P

3. If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

7.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

1. Check TCM power supply and ground circuit. Refer to TM-92, "

Diagnosis Procedure".

2. Reinstall any part removed.

OK or NG

OK >> Replace the control valve with TCM. Refer to TM-201, "Control Valve with TCM and A/T Fluid

Temperature Sensor 2".

NG >> Repair or replace damaged parts.

8.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to TM-71, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 1.

Component InspectionINFOID:0000000001604105

A/T FLUID TEMPERATURE SENSOR 1

1. Remove control valve with TCM. Refer to TM-201, "Control Valve with TCM and A/T Fluid Temperature

Sensor 2".

2. Check resistance between the transmission range switch con- nector (A) terminals.

3. If NG, replace the control valve with TCM. Refer to TM-201,

"Control Valve with TCM and A/T Fluid Temperature Sensor 2"

A/T FLUID TEMPERATURE SENSOR 2

1. Remove A/T fluid temperature sensor 2. Refer to TM-201, "Control Valve with TCM and A/T Fluid Temper-

ature Sensor 2".

2. Check resistance between terminals.

3. If NG, replace the A/T fluid te mperature sensor 2. Refer to TM-

201, "Control Valve with TCM and A/T Fluid Temperature Sen-

sor 2".

NameTerminalTemperature

°C

(° F) Resistance (Ap-

prox.) (k Ω)

0 (32) 15

A/T fluid temperature sensor 1 6-7 20 (68)6.5

80 (176) 0.9

JSDIA1331ZZ

NameTerminalTemperature

°C

(° F) Resistance (Ap-

prox.) (k Ω)

0 (32) 10

A/T fluid temperature sensor 2 1-2 20 (68) 4

80 (176) 0.5

SCIA5271E

Revision: March 2010 2008 QX56