air condition INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 3481 of 4083

![INFINITI QX56 2008 Factory Service Manual DIAGNOSIS SENSOR UNITSRC-83

< ECU DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

SIDE MODULE RH [OPEN] B1129Front RH side air bag module circuit is

open. 1. Visually check the wiring harness connectio INFINITI QX56 2008 Factory Service Manual DIAGNOSIS SENSOR UNITSRC-83

< ECU DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

SIDE MODULE RH [OPEN] B1129Front RH side air bag module circuit is

open. 1. Visually check the wiring harness connectio](/img/42/57030/w960_57030-3480.png)

DIAGNOSIS SENSOR UNITSRC-83

< ECU DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

SIDE MODULE RH [OPEN] B1129Front RH side air bag module circuit is

open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front RH seat back assembly.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

SIDE MODULE RH

[VB-SHORT] B1130Front RH side air bag module circuit is

shorted to a power supply circuit.

SIDE MODULE RH [GND-SHORT] B1131

Front RH side air bag module circuit is

shorted to ground.

SIDE MODULE RH [SHORT] B1132Front RH side air bag module circuits

are shorted to each other.

FR CURTN MODULE LH [OPEN] B1198LH side curtain air bag module (front)

circuit is open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the LH side curtain air bag module.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

FR CURTN MODULE LH

[VB-SHORT] B1199LH side curtain air bag module (front)

circuit is shorted to a power supply cir-

cuit.

FR CURTN MODULE LH [GND-SHORT] B1200LH side curtain air bag module (front)

circuit is shorted to ground.

FR CURTN MODULE LH [SHORT] B1201

LH side curtain air bag module (front)

circuits are shorted to each other.

FR CURTN MODULE RH [OPEN] B1193RH side curtain air bag module (front)

circuit is open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the RH side curtain air bag module.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

FR CURTN MODULE RH

[VB-SHORT] B1194RH side curtain air bag module (front)

circuit is shorted to a power supply cir-

cuit.

FR CURTN MODULE RH [GND-SHORT] B1195RH side curtain air bag module (front)

circuit is shorted to ground.

FR CURTN MODULE RH [SHORT] B1196RH side curtain air bag module (front)

circuits are shorted to each other.

CURTAIN MODULE LH [OPEN] B1150

LH side curtain air bag module (rear) cir-

cuit is open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the LH side curtain air bag module.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

CURTAIN MODULE LH

[VB-SHORT] B1151LH side curtain air bag module (rear) cir-

cuit is shorted to a power supply circuit.

CURTAIN MODULE LH [GND-SHORT] B1152LH side curtain air bag module (rear) cir-

cuit is shorted to ground.

CURTAIN MODULE LH [SHORT] B1153

LH side curtain air bag module (rear) cir-

cuits are shorted to each other.

CURTAIN MODULE RH [OPEN] B1145

RH side curtain air bag module (rear)

circuit is open. 1.

Visua

lly check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the RH side curtain air bag module.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

CURTAIN MODULE RH

[VB-SHORT] B1146RH side curtain air bag module (rear)

circuit is shorted to a power supply cir-

cuit.

CURTAIN MODULE RH [GND-SHORT] B1147

RH side curtain air bag module (rear)

circuit is shorted to ground.

CURTAIN MODULE RH [SHORT] B1148RH side curtain air bag module (rear)

circuits are shorted to each other.

PRE-TEN FRONT LH [OPEN] B1086LH seat belt pre-tensioner circuit is

open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front LH seat belt pre-tensioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

PRE-TEN FRONT LH

[VB-SHORT] B1087

LH seat belt pre-tensioner circuit is

shorted to a power supply circuit.

PRE-TEN FRONT LH [GND-SHORT] B1088LH seat belt pre-tensioner circuit is

shorted to ground.

PRE-TEN FRONT LH [SHORT] B1089LH seat belt pre-tensioner circuits are

shorted to each other.

CONSULT-III name DTC

DTC detecting condition Repair order

Revision: March 2010 2008 QX56

Page 3482 of 4083

![INFINITI QX56 2008 Factory Service Manual SRC-84

< ECU DIAGNOSIS >

DIAGNOSIS SENSOR UNIT

PRE-TEN FRONT RH [OPEN] B1081RH seat belt pre-tensioner circuit is

open. 1. Visually check the wiring harness connection.

2. Replace the harness if it h INFINITI QX56 2008 Factory Service Manual SRC-84

< ECU DIAGNOSIS >

DIAGNOSIS SENSOR UNIT

PRE-TEN FRONT RH [OPEN] B1081RH seat belt pre-tensioner circuit is

open. 1. Visually check the wiring harness connection.

2. Replace the harness if it h](/img/42/57030/w960_57030-3481.png)

SRC-84

< ECU DIAGNOSIS >

DIAGNOSIS SENSOR UNIT

PRE-TEN FRONT RH [OPEN] B1081RH seat belt pre-tensioner circuit is

open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front RH seat belt pre-tensioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

PRE-TEN FRONT RH

[VB-SHORT] B1082RH seat belt pre-tensioner circuit is

shorted to a power supply circuit.

PRE-TEN FRONT RH [GND-SHORT] B1083

RH seat belt pre-tensioner circuit is

shorted to ground.

PRE-TEN FRONT RH [SHORT] B1084RH seat belt pre-tensioner circuits are

shorted to each other.

PRE-TEN2 FRONT LH [OPEN] B1182LH seat belt buckle pre-tensioner circuit

is open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front LH seat belt buckle pre-ten-

sioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

PRE-TEN2 FRONT LH

[VB-SHORT] B1183

LH seat belt buckle pre-tensioner circuit

is shorted to a power supply circuit.

PRE-TEN2 FRONT LH [GND-SHORT] B1184LH seat belt buckle pre-tensioner circuit

is shorted to ground.

PRE-TEN2 FRONT LH [SHORT] B1185LH seat belt buckle pre-tensioner cir-

cuits are shorted to each other.

PRE-TEN2 FRONT RH [OPEN] B1177

RH seat belt buckle pre-tensioner circuit

is open. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front RH seat belt buckle pre-ten-

sioner.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

PRE-TEN2 FRONT RH

[VB-SHORT] B1178RH seat belt buckle pre-tensioner circuit

is shorted to a power supply circuit.

PRE-TEN2 FRONT RH [GND-SHORT] B1179RH seat belt buckle pre-tensioner circuit

is shorted to ground.

PRE-TEN2 FRONT RH [SHORT] B1180

RH seat belt buckle pre-tensioner cir-

cuits are shorted to each other.

CRASH ZONE SEN [UNIT FAIL] B1033 Crash zone sensor has malfunctioned. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the crash zone sensor.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

B1034

CRASH ZONE SEN [COMM FAIL] B1035Crash zone sensor communication er-

ror.

SATELLITE SENS LH [UNIT FAIL] B1118 LH side air bag satellite sensor has mal-

functioned. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the LH side air bag satellite sensor.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

B 111 9

SATELLITE SENS LH [COMM FAIL] B1120LH side air bag satellite sensor commu-

nication error.

SATELLITE SENS RH [UNIT FAIL] B1

113

RH side air bag satellite sensor has mal-

functioned. 1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the RH side air bag satellite sensor.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

B 111 4

SATELLITE SENS RH [COMM FAIL] B 111 5RH side air bag satellite sensor commu-

nication error.

CONTROL UNIT B1XXX Air bag diagnosis sensor unit is malfunc-

tioning.

1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the air bag diagnosis sensor unit.

4. Replace the related harness.

PASS A/B INDCTR CKT B1023 Front passenger air bag OFF indicator is

malfunctioning.

1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the front passenger air bag OFF in-

dicator.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

OCCUPANT SENS C/U [UNIT FAIL] B1017 The OCS control unit is malfunctioning. 1. Replace the RH front seat cushion assembly.

Do not disassemble the seat cushion assem-

bly.

B1021

B1020 The OCS control unit is malfunctioning. 1. Replace the harness if it has visible damage.

2. Replace the RH front seat cushion assembly.

Do not disassemble the seat cushion assem-

bly.

3. Replace the RH front seat belt assembly.

CONSULT-III name DTC

DTC detecting condition Repair order

Revision: March 2010 2008 QX56

Page 3483 of 4083

DIAGNOSIS SENSOR UNITSRC-85

< ECU DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

Trouble Diagnosis without CONSULT-IIIINFOID:0000000001735362

WARNING LAMP FLASH CODE CHART

NOTE:

Follow the procedures in numerical order when repairi ng malfunctioning parts. Confirm whether malfunction is

eliminated using air bag warning lamp each time repair is finished. If malfunction is still observed, proceed to

the next step. When malfunction is eliminated, fu rther repair work is not required.

OCCUPANT SENS

[UNIT FAIL] B1018The OCS sensor is malfunctioning. 1. Visually check the wiring harness connection

to the OCS sensor.

2. Replace the RH front seat cushion assembly. Do not disassemble the seat cushion assem-

bly.

BELT TENSION SENS [UNIT FAIL] B1019The belt tension sensor is malfunction-

ing.

1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the RH front seat belt assembly.

4. Replace the RH front seat cushion assembly.

Do not disassemble the seat cushion assem-

bly.

5. Replace the related harness.

OCCUPANT SENS C/U [COMM FAIL] B1022Communication between the OCS con-

trol unit and the air bag diagnosis sensor

unit is interrupted.

1. Visually check the wiring harness connection.

2. Replace the harness if it has visible damage.

3. Replace the RH front seat cushion assembly.

Do not disassemble the seat cushion assem-

bly.

4. Replace the air bag diagnosis sensor unit.

5. Replace the related harness.

FRONTAL COLLISION DE- TECTION B1209Driver and/or front passenger air bag

modules are deployed. Refer to SRC-71

.

SIDE COLLISION DETEC- TION B1210

Side and/or curtain air bag modules are

deployed. Refer to SRC-71

.

ROLLOVER DETECTION B1211 Curtain air bag module and seat belt

pre-tensioner are deployed.

CONSULT-III name DTC

DTC detecting condition Repair order

SHIA0026E

WHIA0260E

Revision: March 2010 2008 QX56

Page 3488 of 4083

SRC-90

< SYMPTOM DIAGNOSIS >

SRS AIR BAG SYSTEM

SYMPTOM DIAGNOSIS

SRS AIR BAG SYSTEM

"AIR BAG" Warning Lamp Does Not Turn OffINFOID:0000000001735363

DIAGNOSTIC PROCEDURE 7

1.CHECK CONDITION OF AIR BAG MODULE

Inspect for any deployed air bag modules or seat belt pre-tensioners.

Are any air bag modules or s eat belt pre-tensioners deployed?

YES >> Refer to SR-19, "For Frontal Collision" or SR-20, "For Side and Rollover Collision".

NO >> GO TO 2

2.CHECK THE AIR BAG FUSE

Check 10A fuse [No. 13, locat ed in the fuse block (J/B)].

Is the fuse blown?

Ye s > > G O T O 3

No >> GO TO 4

3.CHECK AIR BAG FUSE AGAIN

Replace 10A fuse [No. 13, located in the fu se block (J/B)] and turn ignition switch ON.

Does the fuse blow again?

YES >> Replace harness.

NO >> Inspection End.

4.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Connect CONSULT-III.

Is

“AIR BAG” displayed on CONSULT-III?

YES >> GO TO 5

NO >> Visually inspect the air bag diagnosis sensor unit harness connections. If the connections are OK,

replace the air bag diagnosis sensor unit. Refer to SR-17, "

Removal and Installation".

5.CHECK HARNESS CONNECTION

Check for loose connections between the combination meter and the air bag diagnosis sensor unit.

Are there any loose connections?

Yes >> Properly connect the combination meter and air bag diagnosis sensor unit harness connectors. If

“AIR BAG” warning lamp still does not turn off, replace the wiring harness.

No >> Replace air bag diagnosis sensor unit.

"AIR BAG" Warning La mp Does Not Turn OnINFOID:0000000001735364

DIAGNOSTIC PROCEDURE 8

1.CHECK METER FUSE

Check the 10A fuse [No. 14, located in the fuse block (J/B)] .

Is the fuse blown?

Ye s > > G O T O 2

No >> GO TO 3

2.REPLACE METER FUSE AND CHECK AGAIN

Replace 10A fuse [No. 14, located in the fu se block (J/B)] and turn ignition switch ON.

Does the fuse blow again?

Yes >> Replace harness.

No >> Inspection End.

3.CHECK HARNESS CONNECTIONS BET WEEN AIR BAG DIAGNOSIS SENSOR UNIT AND COMBINA-

Revision: March 2010 2008 QX56

Page 3506 of 4083

STEERING WHEELST-15

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

ON-VEHICLE REPAIR

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000004920096

CHECKING CONDITION OF INSTALLATION

• Check installation condition of steering gear assembly, front suspension, axle and steering column.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Check if the nuts for steering gear assembly are loose. Refer to ST-23, "

Removal and Installation".

CHECKING STEERING WHEEL PLAY

1. Turn tires straight ahead, start engine, then turn steer ing wheel to the left and right lightly, and measure

steering wheel movement on the outer circumference when steering wheel is turned up to the point where

tires start moving.

CHECKING NEUTRAL POSITION ON STEERING WHEEL

• Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to FSU-

7, "Front Wheel Alignment".

1. Turn tires straight ahead, check if steering wheel is in the neutral position.

2. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

3. If the neutral position cannot be attained by repositi oning the steering wheel two teeth or less on steering

stem, loosen tie-rod lock nuts of steering outer socket s, then adjust tie-rods by the same amount in the

opposite direction.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to operating temperature of 60 ° – 80 °C (140 ° – 176 °F).

4. Tires need to be inflated to specified pressure. Refer to WT-51, "

Tire".

5. Check steering wheel turning force using Tool when steering wheel has been turned 360 ° from the neutral position.

End play of the axial direction

for steering wheel : 0 mm (0 in)

LGIA0024E

Steering wheel play on the outer circumference : 0 − 35 mm (0 − 1.38 in)

Tool number — (J-44372)

Steering wheel turning force : 39 N (4 kg-f, 9 lb-f) or less

WGIA0035E

Revision: March 2010 2008 QX56

Page 3532 of 4083

PRECAUTIONSSTR-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Power Generation Variable Voltage Control SystemINFOID:0000000001538874

CAUTION:

For this model, the battery current sensor that is installed to the negative battery cable measures the

charging/discharging current of the battery and performs various engine controls. If an electrical com-

ponent is connected directly to the negative battery terminal, the current flowing through that compo-

nent will not be measured by the battery current sensor. This condition may cause a malfunction of

the engine control system and battery discharge m ay occur. Do not connect an electrical component

or ground wire directly to the battery terminal.

Revision: March 2010 2008 QX56

Page 3540 of 4083

S CONNECTOR CIRCUITSTR-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

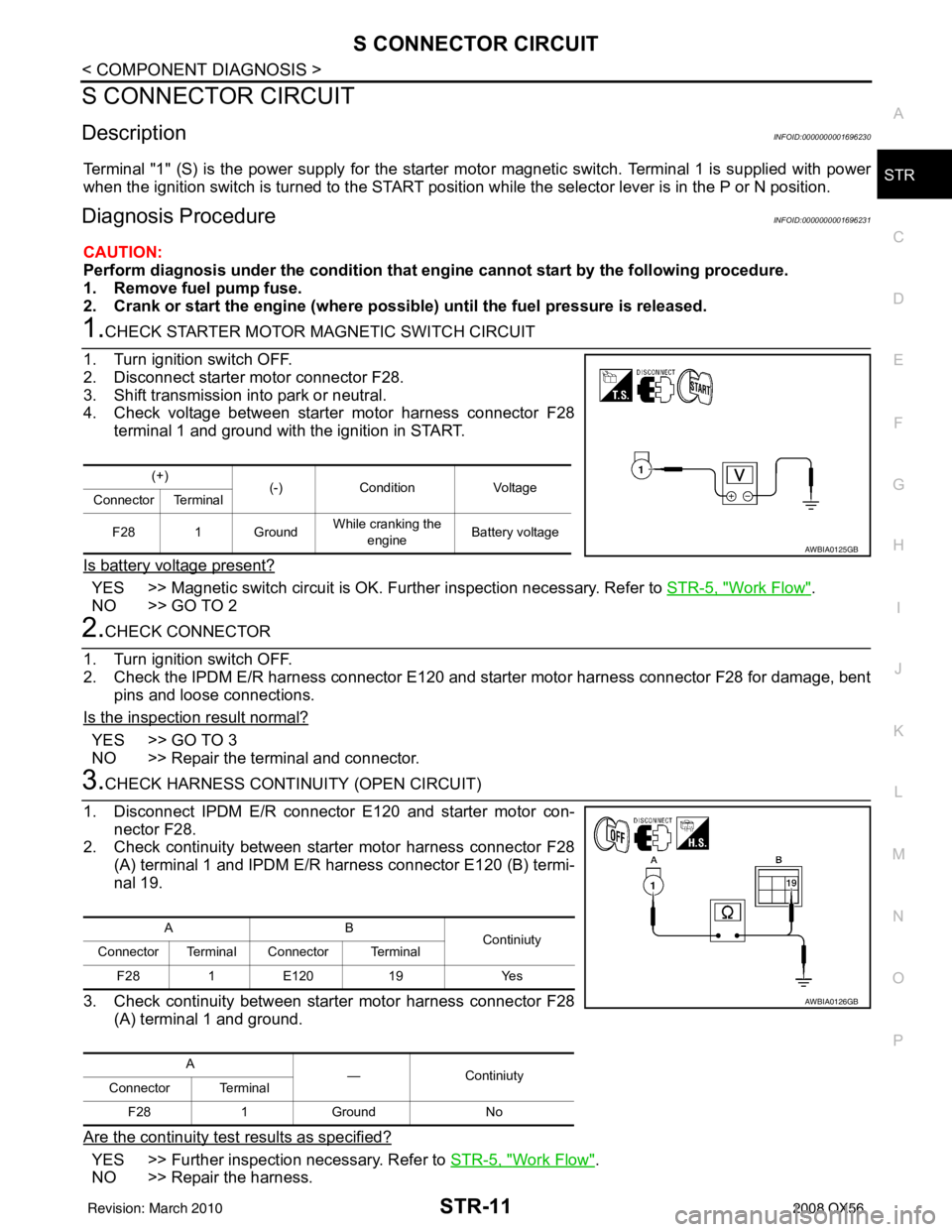

S CONNECTOR CIRCUIT

DescriptionINFOID:0000000001696230

Terminal "1" (S) is the power supply for the starter mo

tor magnetic switch. Terminal 1 is supplied with power

when the ignition switch is turned to the START position while the selector lever is in the P or N position.

Diagnosis ProcedureINFOID:0000000001696231

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK STARTER MOTOR MAGNETIC SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector F28.

3. Shift transmission into park or neutral.

4. Check voltage between starter motor harness connector F28 terminal 1 and ground with the ignition in START.

Is battery voltage present?

YES >> Magnetic switch circuit is OK. Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> GO TO 2

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check the IPDM E/R harness connector E120 and starter motor harness connector F28 for damage, bent pins and loose connections.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the terminal and connector.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector E120 and starter motor con- nector F28.

2. Check continuity between starter motor harness connector F28 (A) terminal 1 and IPDM E/R harness connector E120 (B) termi-

nal 19.

3. Check continuity between starter motor harness connector F28 (A) terminal 1 and ground.

Are the continuity test results as specified?

YES >> Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> Repair the harness.

(+) (-)Condition Voltage

Connector Terminal

F28 1 Ground While cranking the

engine Battery voltage

AWBIA0125GB

AB

Continiuty

Connector Terminal Connector Terminal

F28 1E120 19 Yes

A —Continiuty

Connector Terminal

F28 1Ground No

AWBIA0126GB

Revision: March 2010 2008 QX56

Page 3552 of 4083

DIAGNOSIS AND REPAIR WORKFLOWTM-5

< BASIC INSPECTION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000001603985

INTRODUCTION

The TCM receives a signal from the output speed sensor, accelera-

tor pedal position sensor (throttle position sensor) or transmission

range switch. Then provides shift c ontrol or lock-up control via A/T

solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used wit h the OBD-related parts of the

A/T system for malfunction-diagnostic purposes. The TCM is capa-

ble of diagnosing malfunctioning parts while the ECM can store mal-

functions in its memory.

Input and output signals must always be correct and stable in the

operation of the A/T system. T he A/T system must be in good oper-

ating condition and be free of valve seizure, solenoid valve malfunc-

tion, etc.

It is much more difficult to diagnose an error that occurs intermit-

tently rather than continuously. Most intermittent errors are caused

by poor electric connections or impr oper wiring. In this case, careful

checking of suspected circuits may help prevent the replacement of

good parts.

A visual check only may not find t he cause of the errors. A road test

with CONSULT-III (or GST) or a circuit tester connected should be

performed. Follow the “DETAILED FLOW”.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such errors, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic work sheet” as shown on

the example (Refer to TM-6

) should be used.

Start your diagnosis by looking for “conventional” errors first. This will

help troubleshoot driveability errors on an electronically controlled

engine vehicle.

Also check related Service bulletins.

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) us ing diagnosis worksheet. Refer to TM-6, "

Diagnostic Work Sheet".

>> GO TO 2.

2.CHECK SYMPTOM 1

Check the following items based on the in formation obtained from the customer.

• Fail-safe. Refer to TM-114, "

Fail-Safe".

• A/T fluid inspection. Refer to TM-178, "

Checking the A/T Fluid (ATF)".

• Stall test. Refer to TM-185, "

Inspection and Judgment".

• Line pressure test. Refer to TM-187, "

Inspection and Judgment".

SAT631IB

SAT632I

SEF234G

Revision: March 2010 2008 QX56

Page 3553 of 4083

TM-6

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

>> GO TO 3.

3.CHECK DTC

1. Check DTC.

2. Perform the following procedure if DTC is detected.

• Record DTC.

• Erase DTC. Refer to TM-30, "

OBD-II Diagnostic Trouble Code (DTC)".

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 6.

4.PERFORM DIAGNOSTIC PROCEDURE

Perform “Diagnosis Procedure” for the displayed DTC.

>> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE

Perform “DTC CONFIRMATION PROCEDURE”.

Is DTC detected?

YES >> GO TO 4.

NO >> GO TO 6.

6.CHECK SYMPTOM 2

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 7.

NO >> INSPECTION END

7.ROAD TEST

Perform “ROAD TEST”. Refer to TM-189, "

Description".

>> GO TO 8.

8.CHECK SYMPTOM 3

Try to confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 2.

NO >> INSPECTION END

Diagnostic Work SheetINFOID:0000000001603986

INFORMATION FROM CUSTOMER

KEY POINTS• WHAT ..... Vehicle and A/T model

• WHEN ..... Date, Frequencies

• WHERE ..... Road conditions

• HOW ..... Operating conditions, Symptoms

Customer name MR/MS Model and Year VIN

Trans. Model EngineMileage

Malfunction Date Manuf. DateIn Service Date

Frequency �† Continuous �† Intermittent ( times a day)

Revision: March 2010 2008 QX56

Page 3586 of 4083

P0615 STARTER RELAYTM-39

< COMPONENT DIAGNOSIS >

CEF

G H

I

J

K L

M A

B

TM

N

O P

P0615 STARTER RELAY

DescriptionINFOID:0000000001604014

• TCM prohibits cranking other than at “P” or “N” position.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000001604015

On Board Diagnosis LogicINFOID:0000000001604016

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0615” with CONSULT-III is det ected when starter relay is switched “ON” other

than at “P” or “N” position. (Or when s witched “OFF” at “P” or “N” position).

Possible CauseINFOID:0000000001604017

• Harness or connectors

The starter relay and TCM circuit is open or shorted.

•Starter relay

DTC Confirmation ProcedureINFOID:0000000001604018

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Drive vehicle for at least 2 consecutive seconds.

5. If DTC is detected, go to TM-39, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001604020

1.CHECK STARTER RELAY

With CONSULT-III

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III

and check monitor “STARTER RELAY” ON/OFF.

Without CONSULT-III

Item name Condition Display value

STARTER RELAY Selector lever in

“N”,“P” position. ON

Selector lever in other position. OFF

Item nameCondition Display value

STARTER RELAY Selector lever in "N

'', "P'' positions. ON

Selector lever in other positions. OFF

Revision: March 2010 2008 QX56