air condition INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1 of 4083

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

O

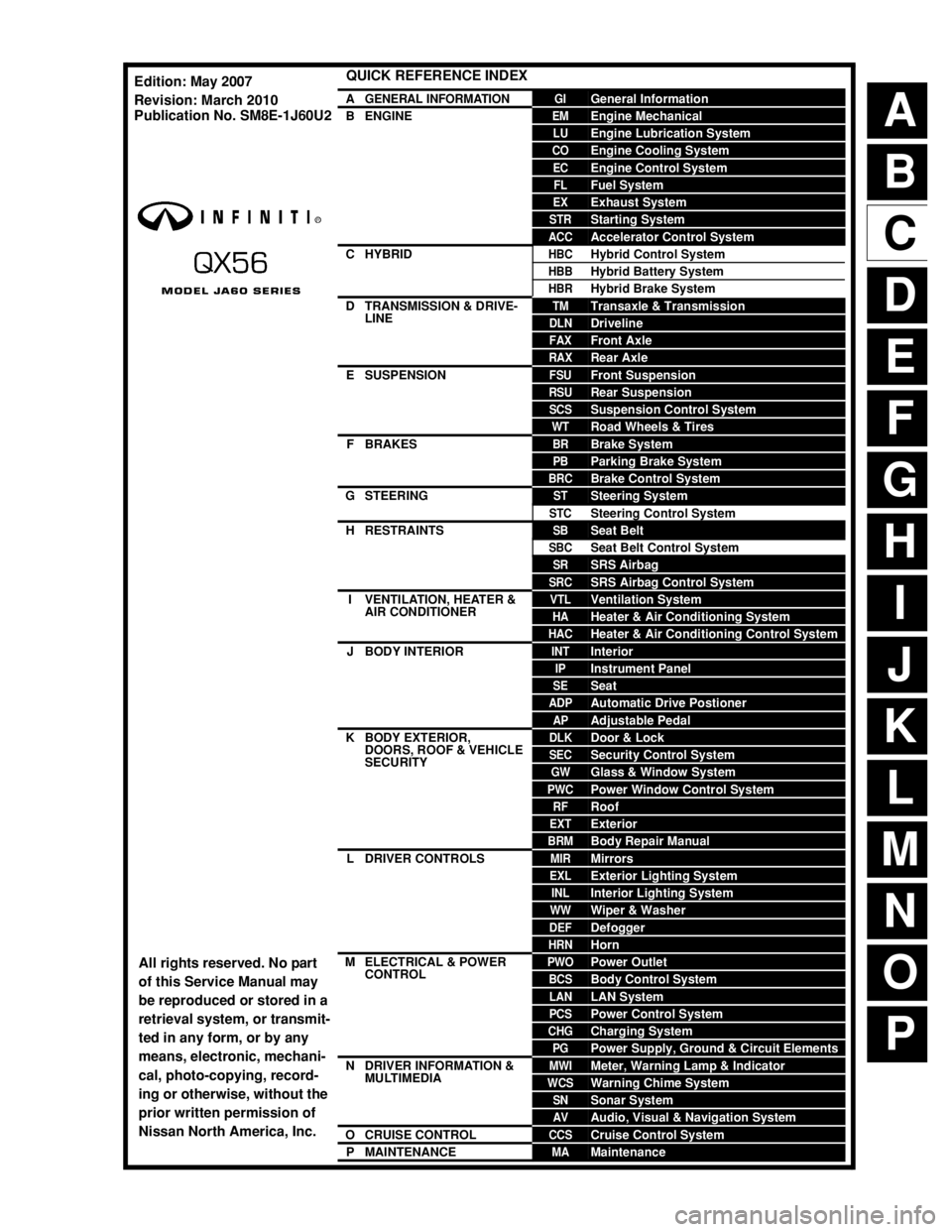

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

STRStarting System

ACCAccelerator Control System

CHYBRIDHBCHybrid Control System

HBBHybrid Battery System

HBRHybrid Brake System

DTRANSMISSION & DRIVE-

LINETMTransaxle & Transmission

DLNDriveline

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

SCSSuspension Control System

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGSTSteering System

STCSteering Control System

HRESTRAINTSSBSeat Belt

SBCSeat Belt Control System

SRSRS Airbag

SRCSRS Airbag Control System

IVENTILATION, HEATER &

AIR CONDITIONERVTLVentilation System

HAHeater & Air Conditioning System

HACHeater & Air Conditioning Control System

JBODY INTERIORINTInterior

IPInstrument Panel

SESeat

ADPAutomatic Drive Postioner

APAdjustable Pedal

KBODY EXTERIOR,

DOORS, ROOF & VEHICLE

SECURITYDLKDoor & Lock

SECSecurity Control System

GWGlass & Window System

PWCPower Window Control System

RFRoof

EXTExterior

BRMBody Repair Manual

LDRIVER CONTROLSMIRMirrors

EXLExterior Lighting System

INLInterior Lighting System

WWWiper & Washer

DEFDefogger

HRNHorn

MELECTRICAL & POWER

CONTROLPWOPower Outlet

BCSBody Control System

LANLAN System

PCSPower Control System

CHGCharging System

PGPower Supply, Ground & Circuit Elements

NDRIVER INFORMATION &

MULTIMEDIAMWIMeter, Warning Lamp & Indicator

WCSWarning Chime System

SNSonar System

AVAudio, Visual & Navigation System

OCRUISE CONTROLCCSCruise Control System

PMAINTENANCEMAMaintenance

All rights reserved. No part

of this Service Manual may

be reproduced or stored in a

retrieval system, or transmit-

ted in any form, or by any

means, electronic, mechani-

cal, photo-copying, record-

ing or otherwise, without the

prior written permission of

Nissan North America, Inc.

Edition: May 2007

Revision: March 2010

Publication No. SM8E-1J60U2

Page 8 of 4083

2008

QUICK REFERENCE CHART: QX56

Front Disc Brake

INFOID:0000000006237753

Unit: mm (in)

Rear Disc BrakeINFOID:0000000006237754

Unit: mm (in)

Fluids and LubricantsINFOID:0000000006237752

Brake model AD41VA

Brake pad Standard thickness (new) 12.0 (0.476)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new) 30 (1.181)

Repair limit thickness 28 (1.102)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.03 (0.001)

Brake model

AD14VE

Brake pad Standard thickness (new) 12.0 (0.472)

Repair limit thickness 1.0 (0.039)

Disc rotor Standard thickness (new) 14.0 (0.551)

Repair limit thickness 12.5 (0.492)

Maximum uneven wear (measured at 8 positions) 0.015 (0.0006)

Runout limit (with it attached to the vehicle) 0.05 (0.002)

Description

Capacity (Approximate)

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal

Engine oil

Drain and refill With oil filter change

6.5 6 7/8 qt 5 3/4 qt

Without oil filter change 6.2 6 1/2 qt 5 1/2 qt

Dry engine (engine overhaul) 7.6 8 qt 6 3/4 qt

Cooling system With reservoir

at MAX level

14.4

15 1/4 qt 12 5/8 qt

Automatic transmission fluid (ATF) 10.6 11 1/4 qt 9 3/8 qt

Rear final drive oil 1.75 3 3/4 pt 3 1/8 pt

Transfer fluid 3.0 3 1/8 qt 2 5/8 qt

Front final drive oil 1.6 3 3/8 pt 2 7/8 pt

Power steering fluid (PSF) 1.0 1 1/8 qt 7/8 qt

Brake fluid — — —

Brake grease — — —

Multi-purpose grease — — —

Windshield washer fluid 4.9 5 1/8 qt 4 3/8 qt

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb

Air conditioning system oil 290 m9.8 fl oz 10.2 fl oz

Page 17 of 4083

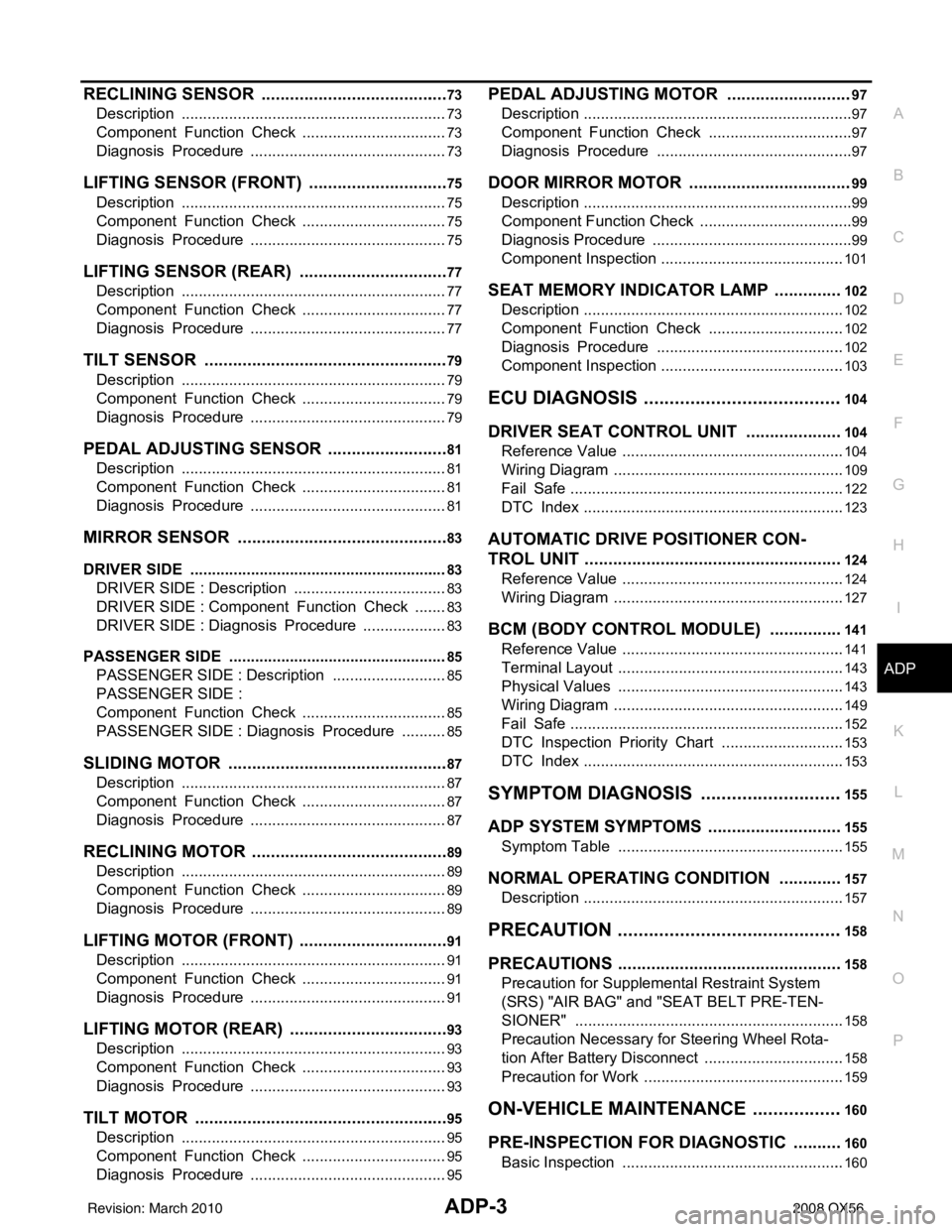

ADP-3

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

RECLINING SENSOR .................................... ....73

Description .......................................................... ....73

Component Function Check ..................................73

Diagnosis Procedure ..............................................73

LIFTING SENSOR (FRONT) ..............................75

Description .......................................................... ....75

Component Function Check ..................................75

Diagnosis Procedure ..............................................75

LIFTING SENSOR (REAR) ................................77

Description .......................................................... ....77

Component Function Check ..................................77

Diagnosis Procedure ..............................................77

TILT SENSOR ....................................................79

Description ..............................................................79

Component Function Check ..................................79

Diagnosis Procedure ..............................................79

PEDAL ADJUSTING SENSOR ..........................81

Description .......................................................... ....81

Component Function Check ..................................81

Diagnosis Procedure ..............................................81

MIRROR SENSOR .............................................83

DRIVER SIDE ........................................................ ....83

DRIVER SIDE : Description ....................................83

DRIVER SIDE : Component Function Check ........83

DRIVER SIDE : Diagnosis Procedure ....................83

PASSENGER SIDE ...................................................85

PASSENGER SIDE : Description ....................... ....85

PASSENGER SIDE :

Component Function Check ..................................

85

PASSENGER SIDE : Diagnosis Procedure ...........85

SLIDING MOTOR ...............................................87

Description ..............................................................87

Component Function Check ..................................87

Diagnosis Procedure ..............................................87

RECLINING MOTOR ..........................................89

Description .......................................................... ....89

Component Function Check ..................................89

Diagnosis Procedure ..............................................89

LIFTING MOTOR (FRONT) ................................91

Description .......................................................... ....91

Component Function Check ..................................91

Diagnosis Procedure ..............................................91

LIFTING MOTOR (REAR) ..................................93

Description .......................................................... ....93

Component Function Check ..................................93

Diagnosis Procedure ..............................................93

TILT MOTOR ......................................................95

Description .......................................................... ....95

Component Function Check ..................................95

Diagnosis Procedure ..............................................95

PEDAL ADJUSTING MOTOR ..........................97

Description ........................................................... ....97

Component Function Check ..................................97

Diagnosis Procedure ..............................................97

DOOR MIRROR MOTOR ..................................99

Description ...............................................................99

Component Function Check ....................................99

Diagnosis Procedure ...............................................99

Component Inspection ...........................................101

SEAT MEMORY INDICATOR LAMP ..............102

Description .............................................................102

Component Function Check ................................102

Diagnosis Procedure ............................................102

Component Inspection ...........................................103

ECU DIAGNOSIS .......................................104

DRIVER SEAT CONTROL UNIT ....................104

Reference Value .................................................. ..104

Wiring Diagram ......................................................109

Fail Safe ................................................................122

DTC Index .............................................................123

AUTOMATIC DRIVE POSITIONER CON-

TROL UNIT ......................................................

124

Reference Value ....................................................124

Wiring Diagram ......................................................127

BCM (BODY CONTROL MODULE) ...............141

Reference Value ....................................................141

Terminal Layout .....................................................143

Physical Values ................................................... ..143

Wiring Diagram ......................................................149

Fail Safe ................................................................152

DTC Inspection Priority Chart .............................153

DTC Index .............................................................153

SYMPTOM DIAGNOSIS ............................155

ADP SYSTEM SYMPTOMS ............................155

Symptom Table ................................................... ..155

NORMAL OPERATING CONDITION .............157

Description .............................................................157

PRECAUTION ............................................158

PRECAUTIONS ...............................................158

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

158

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

158

Precaution for Work ...............................................159

ON-VEHICLE MAINTENANCE ..................160

PRE-INSPECTION FOR DIAGNOSTIC ..........160

Basic Inspection .................................................. ..160

Revision: March 2010 2008 QX56

Page 20 of 4083

ADP-6

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred).

>> GO TO 2

2. CHECK DTC WITH AUTOMATIC DRIVE POSITIONER SYSTEM

Check “Self Diagnostic Result” with CONSULT-III.

Refer to ADP-123, "

DTCIndex".

Is any symptom described and any DTC is displayed?

Symptom is described, DTC is displayed.>>GO TO 3

Symptom is not described, DTC is displayed.>>GO TO 7

Symptom is described, DTC is not displayed.>>GO TO 4

3. CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 7

4. CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 5

5. CHECK NORMAL OPERATING CONDITION

Check normal operating condition. Refer to ADP-157, "

Description".

Is the incident normal operation?

YES >> INSPECTION END

NO >> GO TO 6

6. PERFORM BASIC INSPECTION

Isolate the malfunctioning point with the basic inspection. Refer to ADP-8, "

Preliminary Check".

>> GO TO 8

7. PERFORM DTC CONFIRMATION PROCEDURE

Perform the confirmation procedure for the detected DTC.

Is the DTC displayed?

YES >> GO TO 9

NO >> Check intermittent incident. Refer to GI-38, "

Intermittent Incident".

8. PERFORM COMPONENT FUNCTION CHECK

Perform the component function check for the isolated malfunctioning point.

>> GO TO 9

9. DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Isolate the malfunctioning point by performing the di agnosis procedure relevant to the symptom during the

component diagnosis.

>> GO TO 10

10. REPAIR OR REPLACE

Repair or replace the malfunctioning part.

Revision: March 2010 2008 QX56

Page 43 of 4083

U1000 CAN COMM CIRCUITADP-29

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

COMPONENT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000001735433

Refer to LAN-4, "System Description".

DTC LogicINFOID:0000000001735434

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON and wait at least 3 seconds.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-29, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000001735435

Refer to LAN-10, "Self-Diagnosis".

Special Repair RequirementINFOID:0000000001735436

Refer to Owner’s Manual.

DTC Trouble diagnosis

name DTC detecting condition

Possible cause

U1000 CAN COMM CIR-

CUIT • Driver seat control unit cannot communicate to other

control units.

• Driver seat control unit c annot communicate for more

than the specified time. • Harness or connectors

(CAN communication line is

open or shorted)

Revision: March 2010 2008 QX56

Page 48 of 4083

ADP-34

< COMPONENT DIAGNOSIS >

B2117 ADJ PEDAL MOTOR

B2117 ADJ PEDAL MOTOR

DescriptionINFOID:0000000001735449

• The pedal adjusting motor is installed to the pedal assembly.

• The pedal adjusting motor is activated with the automatic drive positioner control unit.

• The pedal assembly is adjusted forward/backward by changing the rotation direction of pedal adjustingmotor.

DTC LogicINFOID:0000000001735450

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1. STEP 1

Turn ignition switch ON.

>> GO TO 2

2. STEP 2

Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Perform diagnosis procedure. Refer to ADP-34, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000001735451

1. CHECK PEDAL ADJUSTING MECHANISM

Check the following.

• Operation malfunction caused by pedal adjusting mechanism deformation or pinched harness or other for- eign materials

• Operation malfunction and interference wit h other parts by poor installation

Is the inspection result normal

YES >> GO TO 2

NO >> Repair or replace the malfunctioning part and check again.

2. CHECK FUNCTION

1. Turn ignition switch ON.

2. Check “ADJ PEDAL MOTOR” in "Active test" mode with CONSULT-III.

Is the inspection result normal?

YES >> Pedal adjusting motor circuit is OK.

NO >> GO TO 3

3. CHECK PEDAL ADJUSTING MOTOR CIRCUIT HARNESS CONTINUITY

DTC No. Trouble diagnosis

name DTC detecting condition

Possible cause

B2117 ADJ PEDAL MOTOR When any manual or automatic operations are not

performed, if motor operation is detected for 0.1

second or more, status is judged "Output error". • Harness and connectors

(pedal adjusting motor circuit is

opened/shorted, pedal adjusting

motor power supp ly circuit is

opened/shorted.)

• Pedal adjusting motor

Test item Description

ADJ PEDAL MOTOR The pedal adjusting motor is activated by receiving the drive signal.

Revision: March 2010 2008 QX56

Page 49 of 4083

B2117 ADJ PEDAL MOTORADP-35

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and pedal adjusting motor.

3. Check continuity between automatic drive positioner control unit connector M34 (A) terminals 37, 45 and pedal adjusting motor

connector E109 (B) terminals 1, 2.

4. Check continuity between automat ic drive positioner control unit

connector M34 (A) terminals 37, 45 and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK AUTOMATIC DRIVE POSITION ER CONTROL UNIT OUTPUT SIGNAL

1. Connect the automatic drive positioner control unit and pedal adjusting motor.

2. Check voltage between automatic drive positioner control unit

connector and ground.

Is the inspection result normal?

YES >> Replace pedal adjusting motor.

NO >> GO TO 5

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "

Intermittent Incident".

Is the inspection result normal?

YES >> Replace automatic driv e positioner control unit.

NO >> Repair or replace the malfunctioning part. 37 - 1

: Continuity should exist.

45 - 2 : Continuity should exist.

37 - Ground : Continuity should not exist.

45 - Ground : Continuity should not exist.

ALJIA0195ZZ

Connec-

tor Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M34 37

Ground Pedal adjusting switch ON

(FORWARD operation)

Battery voltage

Other than above 0

45 Pedal adjusting switch ON

(BACKWARD operation)

Battery voltage

Other than above 0

PIIA4806E

Revision: March 2010 2008 QX56

Page 51 of 4083

B2118 TILT SENSORADP-37

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner connector

and ground.

OK or NG

OK >> Tilt sensor circuit is OK.

NG >> GO TO 3

3. CHECK HARNESS CONTINUITY

1. Disconnect automatic drive positioner control unit and tilt sensor.

2. Check continuity between automatic drive positioner connector M33, M34 terminals 7, 33, 41 and tilt sensor connector M85 ter-

minals 2, 3, 4.

3. Check continuity between automatic drive positioner control unit connectors M33, M34 te rminals 7, 33, 41 and ground.

OK or NG

OK >> Replace tilt motor. Refer to ST-19, "Removal and Instal-

lation".

NG >> Repair or replace harness.

4. CHECK DOOR MIRROR OPERATION

1. Connect automatic drive positioner control unit connector and tilt sensor.

2. Turn ignition switch ON.

3. Check door mirror operation with memory function.

Is the operation normal?

YES >> Replace tilt sensor. Refer to ST-19, "Removal and Installation".

NO >> GO TO 5

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "

Intermittent Incident".

Is the inspection result normal?

YES >> Replace automatic driv e positioner control unit.

NO >> Repair or replace the malfunctioning part.

Connector Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M33 7 Ground Tilt top position 2

Tilt bottom position

4

LIIA0485E

7 - 3: Continuity should exist.

33 - 2 : Continuity should exist.

41 - 4 : Continuity should exist.

7 - Ground : Continuity should not exist.

33 - Ground : Continuity should not exist.

41 - Ground : Continuity should not exist.

LIIA1432E

Revision: March 2010 2008 QX56

Page 55 of 4083

B2126 DETENT SWADP-41

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and A/T shift selector.

3. Check continuity between driver seat control unit harness con- nector (A) and A/T shift selector harness connector (B).

4. Check continuity between driver seat control unit harness con- nector (A) and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK PARK POSITION SWITCH

Check continuity between A/T shift selector (park position switch)

terminals as follows.

Is the inspection result normal?

YES >> GO TO 5

NO >> Replace A/T shift selector. Refer to TM-195, "

A/T Shift

Selector Removal and Installation".

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "

Intermittent Incident".

Is the inspection result normal?

YES >> Replace driver seat control unit.

NO >> Repair or replace the malfunctioning part.

AB Continuity

Connector Terminal Connector Terminal

B202 21 M203 6Yes

A —Contin u it y

Connector Terminal

B202 21 Ground No

ALJIA0194ZZ

TerminalsConditionContinuity

56 P position

Yes

Other than P position No

ALJIA0551ZZ

Revision: March 2010 2008 QX56

Page 58 of 4083

ADP-44

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000001735461

Refer to BCS-32, "Diagnosis Procedure".

BCM : Special Repair RequirementINFOID:0000000001735462

1. REQUIRED WORK WHEN REPLACING BCM

Initialize control unit. Refer to CONSULT-III Operation Manual.

>> Work end.

DRIVER SEAT CONTROL UNIT

DRIVER SEAT CONTROL UN IT : Diagnosis ProcedureINFOID:0000000001735463

NOTE:

Do not disconnect the battery negative terminal and the driver seat control unit connector until DTC is con-

firmed with CONSULT-III.

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Check voltage between driver seat control unit harness connec- tor and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check the following. • Repair or replace harness between driver seat control unit and fuse block (J/B).

• Circuit breaker.

2. CHECK GROUND CIRCUIT

Check continuity between the driver seat control unit harness con-

nector and ground.

Is the inspection result normal?

YES >> Driver seat control unit power supply and ground circuit are OK.

NO >> Repair or replace harness.

Te r m i n a l s

Power

source ConditionVoltage (V)

(Approx.)

(+)

(–)

Driver seat

control unit connector Te r m i n a l

B202 6

Ground START

power sup-

ply Ignition

switch

START Battery

voltage

B203 33

Battery

power sup- ply Ignition

switch OFF

40

LIIA1897E

Driver seat control unit

connector Te r m i n a l

Ground Continuity

B202 32

Ye s

B203 48

PIIA4542E

Revision: March 2010 2008 QX56