battery INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 809 of 4171

PRECAUTIONSDEF-41

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005855808

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Handling for Adhesive and PrimerINFOID:0000000003776363

• Do not use an adhesive which is past its usable date. Shelf life of this product is limited to six months afterthe date of manufacture. Carefully adhere to the ex piration or manufacture date printed on the box.

• Keep primers and adhesive in a cool, dry place. I deally, they should be stored in a refrigerator.

• Open the seal of the primer and adhesive just before application. Discard the remainder.

• Before application, be sure to shake the primer container to stir the contents. If any floating material is found,

do not use it.

• If any primer or adhesive contacts the skin, wipe it off with gasoline or equivalent and wash the skin with

soap.

• When using primer and adhesive, always observe the precautions in the instruction manual.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005855987

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

Revision: December 20092009 QX56

Page 810 of 4171

DEF-42

< PRECAUTION >

PRECAUTIONS

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Revision: December 20092009 QX56

Page 811 of 4171

REAR WINDOW DEFOGGERDEF-43

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

ON-VEHICLE REPAIR

REAR WINDOW DEFOGGER

Filament CheckINFOID:0000000003776364

1. When measuring voltage, wrap tin foil around the top of the neg- ative probe.Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of each filament.

3. If a filament is burned out, circuit tester registers 0 or battery voltage.

4. To locate burned out point, move probe to left and right along fil- ament. Test needle will swing abruptly when probe passes the

point.

Filament RepairINFOID:0000000003776365

REPAIR EQUIPMENT

• Conductive silver composition (DuPont No. 4817 or equivalent)

• Ruler 30 cm (11.8 in) long

SEL122R

SEL263

SEL265

Revision: December 20092009 QX56

Page 813 of 4171

DLK-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION DLK

A

B

DLK

N

O P

CONTENTS

DOOR & LOCK

WITH INTELLIGENT KEY SYSTEM

BASIC INSPECTION ....... .............................

6

DIAGNOSIS AND REPAIR WORKFLOW ..... .....6

Work Flow ........................................................... ......6

INSPECTION AND ADJUSTMENT .....................9

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ......

9

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Description ......

9

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement ................................................. ......

9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

9

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

9

FUNCTION DIAGNOSIS ..............................10

AUTOMATIC DOOR LOCKS ......................... ....10

System Diagram .................................................. ....10

System Description .................................................10

Component Parts Location ....................................12

Component Description ..........................................12

DOOR LOCK FUNCTION ..................................14

DOOR LOCK AND UNLOCK SWITCH ................. ....14

DOOR LOCK AND UNLOCK SWITCH : System

Diagram ...................................................................

14

DOOR LOCK AND UNLOCK SWITCH : System

Description ..............................................................

14

DOOR LOCK AND UNLOCK SWITCH :

Component Parts Location ....................................

15

DOOR LOCK AND UNLOCK SWITCH :

Component Description ..........................................

15

DOOR REQUEST SWITCH ................................... ....16

DOOR REQUEST SWITCH : System Diagram .......16

DOOR REQUEST SWITCH : System Description ....16

DOOR REQUEST SWITCH :

Component Parts Location ....................................

19

DOOR REQUEST SWITCH :

Component Description ..........................................

21

INTELLIGENT KEY ................................................ ....21

INTELLIGENT KEY : System Diagram ....................21

INTELLIGENT KEY : System Description ...............21

INTELLIGENT KEY : Component Parts Location ....24

INTELLIGENT KEY : Component Description ........25

BACK DOOR OPENER FUNCTION .................27

BACK DOOR OPENER SWITCH .......................... ....27

BACK DOOR OPENER SWITCH : System Dia-

gram ........................................................................

27

BACK DOOR OPENER SWITCH : System De-

scription ...................................................................

27

BACK DOOR OPENER SWITCH :

Component Parts Location ....................................

32

BACK DOOR OPENER SWITCH :

Component Description ..........................................

32

INTELLIGENT KEY ................................................ ....33

INTELLIGENT KEY : System Diagram ....................33

INTELLIGENT KEY : System Description ...............33

INTELLIGENT KEY : Component Parts Location ....35

INTELLIGENT KEY : Component Description ........36

WARNING FUNCTION ......................................38

System Description ..................................................38

Component Parts Location ....................................42

KEY REMINDER FUNCTION ............................44

System Description ..................................................44

Component Parts Location ....................................45

HAZARD AND BUZZER REMINDER FUNC-

TION ..................................................................

47

Revision: December 20092009 QX56

Page 815 of 4171

DLK-3

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

PASSENGER SIDE : Diagnosis Procedure ........

....

87

REAR LH ............................................................... ....88

REAR LH : Description ............................................88

REAR LH : Component Function Check ...............88

REAR LH : Diagnosis Procedure ............................88

REAR RH ............................................................... ....89

REAR RH : Description ...........................................89

REAR RH : Component Function Check ...............90

REAR RH : Diagnosis Procedure ............................90

BACK DOOR ......................................................... ....91

BACK DOOR : Description ......................................91

GLASS HATCH LOCK ACTUATOR ..................92

Diagnosis Procedure ...............................................92

PASSENGER SELECT UNLOCK RELAY .........93

Description .......................................................... ....93

Component Function Check ....................................93

Diagnosis Procedure ...............................................93

INTELLIGENT KEY WARNING BUZZER ..........95

Description .......................................................... ....95

Component Function Check ..................................95

Diagnosis Procedure ...............................................95

Component Inspection ............................................96

OUTSIDE KEY ANTENNA .................................97

Description .......................................................... ....97

Component Function Check ..................................97

Diagnosis Procedure ...............................................97

STEERING LOCK UNIT .....................................99

Diagnosis Procedure ........................................... ....99

A/T SHIFT SELECTOR (PARK POSITION

SWITCH) ...........................................................

101

Diagnosis Procedure ........................................... ..101

REMOTE KEYLESS ENTRY RECEIVER ........103

Description .......................................................... ..103

Component Function Check ................................103

Diagnosis Procedure .............................................103

INTELLIGENT KEY BATTERY AND FUNC-

TION .................................................................

106

Description .......................................................... ..106

Component Function Check ................................106

Diagnosis Procedure .............................................106

HORN FUNCTION ............................................108

Description .......................................................... ..108

Component Function Check ................................108

Diagnosis Procedure ............................................108

COMBINATION METER DISPLAY FUNC-

TION .................................................................

110

Description .......................................................... ..110

Component Function Check ................................110

Diagnosis Procedure .............................................110

WARNING CHIME FUNCTION .......................111

Description ........................................................... ..111

Component Function Check ................................111

Diagnosis Procedure .............................................111

HAZARD FUNCTION ......................................112

Description .............................................................112

Component Function Check ................................112

Diagnosis Procedure .............................................112

KEY SWITCH (INTELLIGENT KEY UNIT IN-

PUT) ................................................................

113

Diagnosis Procedure .............................................113

KEY SWITCH (BCM INPUT) ...........................115

Diagnosis Procedure .............................................115

IGNITION KNOB SWITCH ..............................116

Ignition Knob Switch Check ...................................116

HEADLAMP FUNCTION .................................118

Diagnosis Procedure .............................................118

MAP LAMP AND IGNITION KEYHOLE ILLU-

MINATION FUNCTION ...................................

119

Diagnosis Procedure .............................................119

KEYFOB ID SET UP WITH CONSULT-III ......120

ID Code Entry Procedure ......................................120

KEYFOB ID SET UP WITHOUT CONSULT-III .121

ID Code Entry Procedure .................................... ..121

AUTOMATIC BACK DOOR SELF-DIAGNO-

SIS PROCEDURE ...........................................

123

Self-Diagnosis Procedure ......................................123

POWER LIFTGATE SWITCH FUNCTION ......125

Diagnosis Procedure ........................................... ..125

GLASS HATCH SWITCH ................................127

Diagnosis Procedure .............................................127

GLASS HATCH AJAR SWITCH .....................129

Diagnosis Procedure .............................................129

BACK DOOR CLOSE (CLOSE) SWITCH

SYSTEM ..........................................................

131

Diagnosis Procedure ........................................... ..131

BACK DOOR CLOSE (CANCEL) SWITCH

SYSTEM ..........................................................

132

Diagnosis Procedure ........................................... ..132

PINCH STRIP SYSTEM ..................................133

Diagnosis Procedure .............................................133

BACK DOOR WARNING CHIME SYSTEM ....134

Diagnosis Procedure .............................................134

HALF-LATCH SWITCH SYSTEM ...................135

Diagnosis Procedure .............................................135

Revision: December 20092009 QX56

Page 816 of 4171

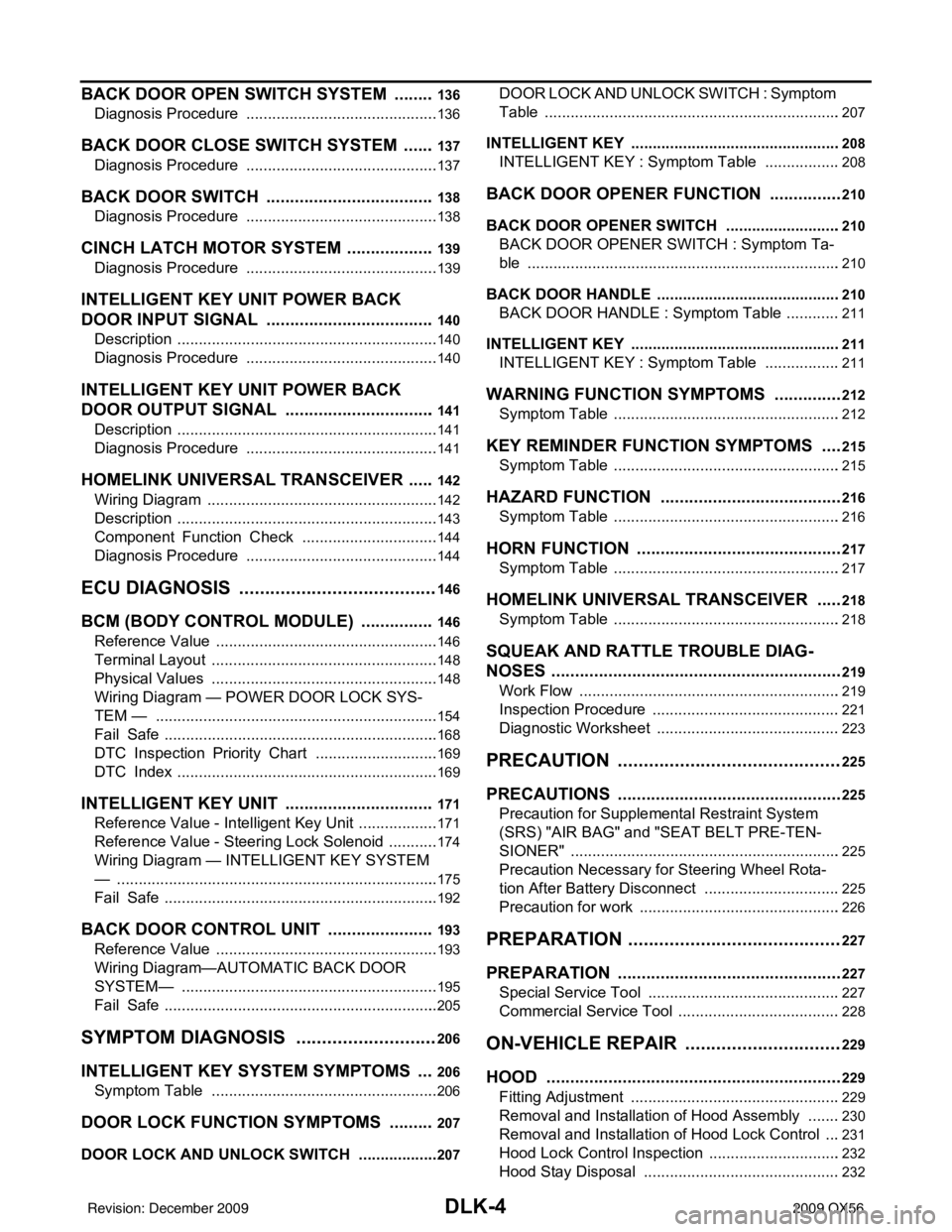

DLK-4

BACK DOOR OPEN SWITCH SYSTEM .........136

Diagnosis Procedure ........................................... ..136

BACK DOOR CLOSE SWITCH SYSTEM .......137

Diagnosis Procedure ........................................... ..137

BACK DOOR SWITCH ....................................138

Diagnosis Procedure ........................................... ..138

CINCH LATCH MOTOR SYSTEM ...................139

Diagnosis Procedure ........................................... ..139

INTELLIGENT KEY UNIT POWER BACK

DOOR INPUT SIGNAL ....................................

140

Description ........................................................... ..140

Diagnosis Procedure .............................................140

INTELLIGENT KEY UNIT POWER BACK

DOOR OUTPUT SIGNAL ................................

141

Description ........................................................... ..141

Diagnosis Procedure .............................................141

HOMELINK UNIVERSAL TRANSCEIVER ......142

Wiring Diagram .................................................... ..142

Description .............................................................143

Component Function Check ................................144

Diagnosis Procedure .............................................144

ECU DIAGNOSIS ..................................... ..146

BCM (BODY CONTROL MODULE) ............... .146

Reference Value .................................................. ..146

Terminal Layout .....................................................148

Physical Values .....................................................148

Wiring Diagram — POWER DOOR LOCK SYS-

TEM — ..................................................................

154

Fail Safe ................................................................168

DTC Inspection Priority Chart .............................169

DTC Index ........................................................... ..169

INTELLIGENT KEY UNIT ................................171

Reference Value - Intelligent Key Unit ................. ..171

Reference Value - Steering Lock Solenoid ............174

Wiring Diagram — INTELLIGENT KEY SYSTEM

— ......................................................................... ..

175

Fail Safe ................................................................192

BACK DOOR CONTROL UNIT .......................193

Reference Value .................................................. ..193

Wiring Diagram—AUTOMATIC BACK DOOR

SYSTEM— ............................................................

195

Fail Safe .............................................................. ..205

SYMPTOM DIAGNOSIS ............................206

INTELLIGENT KEY SYSTEM SYMPTOMS ... .206

Symptom Table ................................................... ..206

DOOR LOCK FUNCTION SYMPTOMS ..........207

DOOR LOCK AND UNLOCK SWITCH ................. ..207

DOOR LOCK AND UNLOCK SWITCH : Symptom

Table .....................................................................

207

INTELLIGENT KEY ................................................ .208

INTELLIGENT KEY : Symptom Table ..................208

BACK DOOR OPENER FUNCTION ................210

BACK DOOR OPENER SWITCH .......................... .210

BACK DOOR OPENER SWITCH : Symptom Ta-

ble ........................................................................ .

210

BACK DOOR HANDLE .......................................... .210

BACK DOOR HANDLE : Symptom Table .............211

INTELLIGENT KEY ................................................ .211

INTELLIGENT KEY : Symptom Table ..................211

WARNING FUNCTION SYMPTOMS ...............212

Symptom Table .................................................... .212

KEY REMINDER FUNCTION SYMPTOMS .....215

Symptom Table .................................................... .215

HAZARD FUNCTION ..................................... ..216

Symptom Table .................................................... .216

HORN FUNCTION ............................................217

Symptom Table .................................................... .217

HOMELINK UNIVERSAL TRANSCEIVER ......218

Symptom Table .................................................... .218

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ..............................................................

219

Work Flow ............................................................ .219

Inspection Procedure ............................................221

Diagnostic Worksheet ...........................................223

PRECAUTION ...........................................225

PRECAUTIONS .............................................. ..225

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

225

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

225

Precaution for work ...............................................226

PREPARATION .........................................227

PREPARATION .............................................. ..227

Special Service Tool ............................................ .227

Commercial Service Tool ......................................228

ON-VEHICLE REPAIR ..............................229

HOOD ............................................................. ..229

Fitting Adjustment ................................................ .229

Removal and Installation of Hood Assembly ........230

Removal and Installation of Hood Lock Control ....231

Hood Lock Control Inspection ...............................232

Hood Stay Disposal ............................................. .232

Revision: December 20092009 QX56

Page 821 of 4171

![INFINITI QX56 2009 Factory Service Manual INSPECTION AND ADJUSTMENTDLK-9

< BASIC INSPECTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVI NG BATTERY NEGATIVE TERMINA INFINITI QX56 2009 Factory Service Manual INSPECTION AND ADJUSTMENTDLK-9

< BASIC INSPECTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVI NG BATTERY NEGATIVE TERMINA](/img/42/57031/w960_57031-820.png)

INSPECTION AND ADJUSTMENTDLK-9

< BASIC INSPECTION > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REMOVI NG BATTERY NEGATIVE TERMINAL

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : De-

scription

INFOID:0000000004190624

The automatic back door system must be initialized anytime the battery or the automatic back door control unit

has been disconnected.

ADDITIONAL SERVICE WHEN REMOVING BATTERY NEGATIVE TERMINAL : Spe-

cial Repair Requirement

INFOID:0000000004190625

1.INITIALIZATION

1. Close back door.

2. Open the back door with automatic open operation.

NOTE:

Do not stop the automatic operation until back door is fully open.

>> Work end.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPL ACING CONTROL UNIT : Description

INFOID:0000000003775673

Perform the system initialization when replacing BCM, replacing Intelligent Key or registering an additional

Intelligent Key.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000003775674

Refer to the CONSULT-III Operation Manual for the initialization procedure.

Revision: December 20092009 QX56

Page 839 of 4171

![INFINITI QX56 2009 Factory Service Manual BACK DOOR OPENER FUNCTIONDLK-27

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

BACK DOOR OPENER FUNCTION

BACK DOOR OPENER SWITCH

BACK DOOR OPENER SWITCH : Syste INFINITI QX56 2009 Factory Service Manual BACK DOOR OPENER FUNCTIONDLK-27

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

BACK DOOR OPENER FUNCTION

BACK DOOR OPENER SWITCH

BACK DOOR OPENER SWITCH : Syste](/img/42/57031/w960_57031-838.png)

BACK DOOR OPENER FUNCTIONDLK-27

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

BACK DOOR OPENER FUNCTION

BACK DOOR OPENER SWITCH

BACK DOOR OPENER SWITCH : System DiagramINFOID:0000000003775687

BACK DOOR OPENER SWITCH : System DescriptionINFOID:0000000003775688

BACK DOOR OPENER OPERATION

NOTE:

The automatic back door system must be initialized by fully closing the back door anytime the battery

power is lost to the back door control unit. Refer to DLK-9, "

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Description".

The automatic back door system consists of a one piec e unit that combines the back door control unit along

with the back door motor, back door clutch and the ba ck door encoder. The back door latch contains a lock

function that can control the two functions of autom atic back door latch closure and electrical opener with a

single motor when you close the back door to the halfway-state.

• Back door auto closure When the back door is closed to the halfway state (half- latch) position, the motor automatically drives to

rotate the latch lever and pull it in from half latched to full latched.

• Power back door With the back door closed, if you press the power liftgat e switch or press the keyfob button, or pull the back

door handle with the back door unlocked, the back door latch motor drives the open the locking plate and

releases the latch. The back door motor t hen raises the door to the full open position.

With the back door fully open, if you press the power liftgate switch, keyfob button or the back door close

switch, the back door motor closes the door to the half-latch state. The back door latch motor then drives the

latch to the full close position.

At the onset of each power open or power close applic ation, the hazard lamps will flash 3 times and the

warning chime will sound 3 dings lasting a total of 2 seconds.

OUTSIDE KEY ANTENNA DETECTION AREA

The outside key antenna detection area of back door open function

is in the range of approximately 80 cm (31.50 in) surrounding back

door opener request switch (1). However, this operating range

depends on the ambient conditions.

OPERATION DESCRIPTION

ALKIA0705GB

ALKIA0581ZZ

Revision: December 20092009 QX56

Page 840 of 4171

![INFINITI QX56 2009 Factory Service Manual DLK-28

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BACK DOOR OPENER FUNCTION

Power Liftgate Switch O

peration (Fully Closed → Fully Open Operation)

• When the power liftgate switch is pres INFINITI QX56 2009 Factory Service Manual DLK-28

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BACK DOOR OPENER FUNCTION

Power Liftgate Switch O

peration (Fully Closed → Fully Open Operation)

• When the power liftgate switch is pres](/img/42/57031/w960_57031-839.png)

DLK-28

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BACK DOOR OPENER FUNCTION

Power Liftgate Switch O

peration (Fully Closed → Fully Open Operation)

• When the power liftgate switch is pressed, back door control unit terminal 23 receives the signal.

• The back door control unit checks the A/T shift sele ctor (P) position through terminal 18, vehicle speed

through terminal 21, ignition status through terminal 7, glass hatch is closed through terminal 17 and battery

voltage is present through terminal 3.

• When the back door control unit receives the signal, if the auto back door operating enable conditions are

met, it sends a 5 volt signal through terminal 6 and grounds terminal 9 to sound the warning chime, sends a

signal to the BCM through terminal 4 to flash the hazard lamps and unlocks the back door latch through ter-

minal 12.

• The back door control unit supplies power to the magnetic clutch and the back door motor and moves the back door in the open direction. (At this time, it also executes speed control, input reverse, and anti-pinch

detection control.)

• When the back door is opened to the full-open position, the full-open position is detected by the encoder, and the back door control unit switches the back door motor OFF and the magnetic clutch is pulsed and then

turned OFF.

• The back door is held in the fully open position by the gas stays.

Remote Keyless Entry Operation (Fully Closed → Fully Open Operation)

• When the keyfob button is pressed for at least 0.5 seconds, back door control unit terminal 21 receives the

signal.

• The back door control unit checks the A/T shift sele ctor (P) position through terminal 18, vehicle speed

through terminal 21, ignition status through terminal 7, glass hatch is closed through terminal 17 and battery

voltage is present through terminal 3.

• When the back door control unit receives the signal, if the auto back door operating enable conditions are

met, it sends a 5 volt signal through terminal 6 and grounds terminal 9 to sound the warning chime, sends a

signal to the BCM through terminal 4 to flash the hazard lamps and unlocks the back door latch through ter-

minal 12.

• The back door control unit supplies power to the magnetic clutch and the back door motor and moves the

back door in the open direction. (At this time, it also executes speed control, input reverse, and anti-pinch

detection control.)

• When the back door is opened to the full-open position, the full-open position is detected by the encoder,

and the back door control unit switches the back door motor OFF and the magnetic clutch is pulsed and then

turned OFF.

• The back door is held in the fully open position by the gas stays.

Back Door Handle Switch Operation (Fully Closed → Fully Open Operation)

• When the back door handle is pulled, back door control unit terminal 26 receives the signal.

• The back door control unit checks that the back door is unlocked and checks the A/T shift selector (P) posi-

tion through terminal 18, vehicle speed through terminal 21, ignition status through terminal 7, glass hatch is

closed, battery voltage and back door close switch position through terminal 13.

• When the back door control unit receives the signal, if all auto back door operating enable conditions are

met, it sends a 5 volt signal through terminal 6 and grounds terminal 9 to sound the warning chime, sends a

signal to the BCM through terminal 4 to flash the hazard lamps and unlocks the back door latch through ter-

minal 12.

• The back door control unit supplies power to the magnetic clutch and the back door motor and moves the

back door in the open direction. (At this time, it also executes speed control, input reverse, and anti-pinch

detection control.)

• When the back door is opened to the full-open position, the full-open position is detected by the encoder,

and the back door control unit switches the back door motor OFF and the magnetic clutch is pulsed and then

turned OFF.

• The back door is held in the fully open position by the gas stays.

Power Liftgate Switch Operation (Fully Open → Fully Closed Operation)

• When the power liftgate switch is pressed, the ba ck door control unit terminal 23 receives the signal.

• The back door control units checks door position through the rotary encoder.

• When the back door control unit receives the signal, if the auto back door operating enable conditions are

met, it sends a signal through terminal 6 and grounds terminal 9 to sound the warning chime and sends a

signal to the BCM through terminal 4 to flash the hazard lamps.

• The back door control unit supplies power to the magnetic clutch and the back door motor and move the back door in the close direction. (At this time, it al so executes speed control, input reverse, and anti-pinch

detection control.)

Revision: December 20092009 QX56

Page 841 of 4171

![INFINITI QX56 2009 Factory Service Manual BACK DOOR OPENER FUNCTIONDLK-29

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

• When the back door reaches the half-latch state, the half- latch switch detec INFINITI QX56 2009 Factory Service Manual BACK DOOR OPENER FUNCTIONDLK-29

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

• When the back door reaches the half-latch state, the half- latch switch detec](/img/42/57031/w960_57031-840.png)

BACK DOOR OPENER FUNCTIONDLK-29

< FUNCTION DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

• When the back door reaches the half-latch state, the half- latch switch detects this and the signal is sent to

the back door control unit terminal 22.

• When the back door control unit receives the half latch switch signal, it switches OFF the back door motor

and the magnetic clutch and operates the cinch latch motor.

• When the back door latch operates and full close is det ected through terminal 14 of the back door control

unit, the cinch latch motor reverses to the neutral position and the back door aut\

o closure operation ends

and the door is fully closed.

Remote Keyless Entry Operation (Fully Open → Fully Closed Operation)

• When the remote keyless entry switch is pressed for at least 0.5 seconds, the back door control unit terminal

21 receives the signal.

• The back door control units checks door position through the rotary encoder.

• When the back door control unit receives the signal, if the auto back door operating enable conditions are

met, it sends a signal through terminal 6 and grounds terminal 9 to sound the warning chime and sends a

signal to the BCM through terminal 4 to flash the hazard lamps.

• The back door control unit supplies power to the m agnetic clutch and the back door motor and move the

back door in the close direction. (At this time, it al so executes speed control, input reverse, and anti-pinch

detection control.)

• When the back door reaches the half-latch state, the half- latch switch detects this and the signal is sent to

the back door control unit terminal 22.

• When the back door control unit receives the half latch switch signal, it switches OFF the back door motor

and the magnetic clutch and operates the cinch latch motor.

• When the back door latch operates and full close is det ected through terminal 14 of the back door control

unit, the cinch latch motor reverses to the neutral position and the back door aut\

o closure operation ends

and the door is fully closed.

Back Door Close Switch Operation (Fully Open → Fully Closed Operation)

• When the back door close switch is pressed, the ba ck door control unit terminal 8 receives the signal.

• The back door control units checks back door close switch (terminal 13) status and door position (must be

fully opened), through rotary encoder and battery voltage.

• When the back door control unit receives the signal, if the auto back door operating enable conditions are met, it sends a signal through terminal 6 and grounds terminal 9 to sound the warning chime and sends a

signal to the BCM through terminal 4 to flash the hazard lamps.

• The back door control unit supplies power to the m agnetic clutch and the back door motor and move the

back door in the close direction. (At this time, it al so executes speed control, input reverse, and anti-pinch

detection control.)

• When the back door reaches the half-latch state, the half- latch switch detects this and the signal is sent to

the back door control unit terminal 22.

• When the back door control unit receives the half latch switch signal, it switches OFF the back door motor and the magnetic clutch and operates the cinch latch motor.

• When the back door latch operates and full close is det ected through terminal 14 of the back door control

unit, the cinch latch motor reverses to the neutral position and the back door aut\

o closure operation ends

and the door is fully closed.

Reversal

The door will reverse direction during power open or close operation if the automatic door main switch, keyfob

or back door close switch is operated. A chime will sound to announce the reversal.

Anti-Pinch Function

• During auto operation, if an object is detected in the door's path, a warning chime sounds and the back door

operates in the reverse direction to prevent pinching.

• During auto close operation, if an object is detected by the pinch strips in the door's path, a warning chime sounds and the back door operates in the open direction until it is fully open.

Gas Stay Check

• During each power open operation, the back door control unit monitors motor current draw to determine ifthe gas stays are functioning properly.

• If a malfunction of the gas stays is detected, the back door control unit will close the back door while sound-

ing the warning chime. The back door cannot be opened usi ng the switches until the gas stay malfunction is

repaired.

Warning Functions

• The hazard warning lamps flash and a warning chime is sounded according to the back door operating state,

operations, and conditions.

Revision: December 20092009 QX56