Abs INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3165 of 4171

SUSPENSION ARMRSU-17

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SUSPENSION ARM

Removal and InstallationINFOID:0000000005889874

REMOVAL

1. If equipped with rear load leveling air suspension system, use CONSULT-III “EXHAUST SOLENOID”

active test to release the air pressure from the rear load leveling air suspension system.

2. If equipped with the rear load leveling air suspension system, disconnect the electrical connectors for the

height sensor and the rear load leveling air suspension compressor assembly.

3. If equipped with the rear load leveling air suspension system, unclip the rubber cover to access the rear

load leveling air suspension compressor assembly.

4. If equipped with the rear load leveling air suspension system, disconnect the rear load leveling air suspension hoses at the

rear load leveling air suspension compressor assembly.

To disconnect the hoses, push in on the lock ring using a suit-able tool and pull the hose out.

5. Remove both of the rear wheel and tire assemblies using power tool.

6. Remove the brake caliper without disconnecting the brake hoses, using power tool. Reposition the brake caliper out of the

way using a suitable wire. Refer to BR-36, "Removal and Instal-

lation of Brake Caliper and Disc Rotor".

CAUTION:

Do not crimp or stretch the brake hose when re positioning the brake caliper out of the way.

Do not press brake pedal while the brake caliper is removed.

7. Remove the spare tire.

8. Remove both lower shock bolts.

9. Disconnect the two rear ABS sensor electrical connectors.

10. Remove the two rear drive shafts at t he rear final drive and support drive shafts.

11. Remove the rear final drive. Refer to DLN-250, "Removal and Installation"

.

12. Remove the EVAP canister bolt from the top of the rear suspension member.

13. Disconnect the parking brake cables from t he brackets on the rear suspension member.

14. Disconnect parking brake cables at equalizer. Refer to PB-7, "Removal and Installation"

.

15. Set a suitable jack to support each of the rear lower links and the coil spring tension.

16. Remove both of the rear lower link outer bolts and lower the jack to remove the rear coil springs. If equipped with the rear load leveling air suspension systemremove the height sensor bracket bolt from the LH rear lower link.

LEIA0074E

LEIA0077E

Revision: December 20092009 QX56

Page 3167 of 4171

FRONT LOWER LINKRSU-19

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

FRONT LOWER LINK

Removal and InstallationINFOID:0000000005889875

REMOVAL

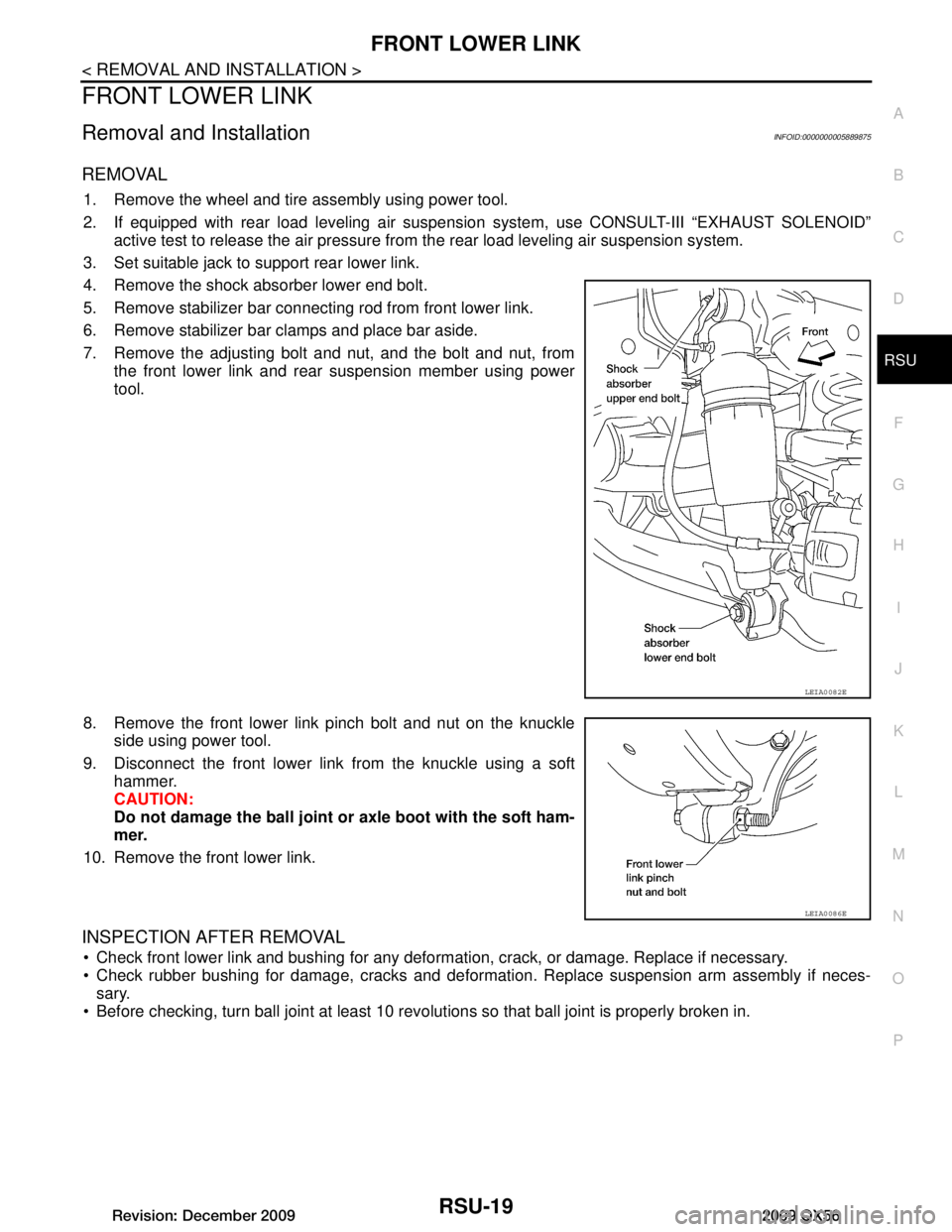

1. Remove the wheel and tire assembly using power tool.

2. If equipped with rear load leveling air suspension system, use CONSULT-III “EXHAUST SOLENOID”

active test to release the air pressure from the rear load leveling air suspension system.

3. Set suitable jack to support rear lower link.

4. Remove the shock absorber lower end bolt.

5. Remove stabilizer bar connecting rod from front lower link.

6. Remove stabilizer bar clamps and place bar aside.

7. Remove the adjusting bolt and nut, and the bolt and nut, from the front lower link and rear suspension member using power

tool.

8. Remove the front lower link pinch bolt and nut on the knuckle side using power tool.

9. Disconnect the front lower link from the knuckle using a soft hammer.

CAUTION:

Do not damage the ball joint or axle boot with the soft ham-

mer.

10. Remove the front lower link.

INSPECTION AFTER REMOVAL

Check front lower link and bushing for any deformation, crack, or damage. Replace if necessary.

Check rubber bushing for damage, cracks and deformation. Replace suspension arm assembly if neces-

sary.

Before checking, turn ball joint at least 10 revo lutions so that ball joint is properly broken in.

LEIA0082E

LEIA0086E

Revision: December 20092009 QX56

Page 3172 of 4171

RSU-24

< REMOVAL AND INSTALLATION >

REAR LOAD LEVELING AIR SUSPENSION COMPRESSOR ASSEMBLY

REAR LOAD LEVELING AIR SUSPENSION COMPRESSOR ASSEMBLY

Removal and InstallationINFOID:0000000003772299

Rear Load Leveling Air Suspension System

REMOVAL

1. Use CONSULT-III "EXHAUST SOLENOID" active test to release the air pressure from the rear load level-

ing air suspension system.

2. Disconnect the electrical connectors for the rear load leveling air suspension compressor assembly.

3. Unclip the rubber cover to access the rear load leveling air suspension compressor assembly.

4. Disconnect the rear load leveling air suspension hoses at the rear load leveling air suspension compressor assembly.

To disconnect the hoses, push in on the lock ring using a suit-

able tool and pull the hose out.

AWEIA0054GB

1. Rear load leveling air suspension

hose, RH 2. Shock absorber, RH 3. Height sensor

4. Rear load leveling air suspension hose, LH 5. Shock absorber, LH 6. Rear load leveling air suspension

compressor assembly

Front

LEIA0074E

Revision: December 20092009 QX56

Page 3175 of 4171

HEIGHT SENSORRSU-27

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

HEIGHT SENSOR

Removal and InstallationINFOID:0000000003772302

Rear Load Leveling Air Suspension System

REMOVAL

1. Use CONSULT-III “EXHAUST SOLENOID ” active test to release the air pressure from the rear load level-

ing air suspension system.

2. Disconnect the electrical connector for the height sensor.

3. Remove the two height sensor bolts and height sensor arm bracket bolt.

4. Remove the height sensor.

INSTALLATION

Installation is in the reverse order of removal.

AWEIA0054GB

1. Rear load leveling air suspension hose, RH 2. Shock absorber, RH 3. Height sensor

4. Rear load leveling air suspension hose, LH 5. Shock absorber, LH 6. Rear load leveling air suspension

compressor assembly

Front

LEIA0080E

Revision: December 20092009 QX56

Page 3300 of 4171

SE-68

< DISASSEMBLY AND ASSEMBLY >

FRONT SEAT

Disassembly and Assembly

INFOID:0000000003775483

SEATBACK TRIM AND PAD

WARNING:

Removal of front side air bag module should only be done to allow deployment of front side air bag

module prior to disposal of seatback assembly.

NOTE:

Only complete seatback assemblies can be replaced on vehicles equipped with side air bags.

Be sure to set the front/rear cushion lifter to the top position.

Driver Seat

1. Remove the headrest.

2. Unhook the j-channel.

3. From inside of the seatback, squeeze the headrest holder tabs at the base of the stay pipe and pull up to remove.

NOTE:

Before installing the headrest holder, check its orientation (front/

rear and right/left).

Passenger Seat

1. Remove the headrest.

2. Remove the seatback board from the back of the seatback.

19. Outer pedestal finisher 20. Seat cushion outer finisher21. Seat cushion assembly

22. Power seat switch escutcheon 23. Slide switch knob 24. Recliner switch knob

25. Seatback assembly 26. Headrest holder27. Seat slide/ recline switch

28. Power lumbar switch

LIIA1580E

LRS023

PIIA0163E

Revision: December 20092009 QX56

Page 3301 of 4171

FRONT SEATSE-69

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

3. Remove the retainer.

4. From inside of the seatback, squeeze the headrest holder tabs

at the base of the stay pipe and pull up to remove.

NOTE:

Before installing the headrest holder, check its orientation (front/

rear and right/left).

Removal of seatback assembly

1. After completing the steps 1 and 2 of "Seatback Trim and Pad", remove the side air bag harness connec- tor from the seat cushion.

2. Remove the mounting bolts (2 for each side) and seatback assembly.

Installation of seatback assembly

• Installation is in the reverse order of removal.

SEAT CUSHION TRIM AND PAD (DRIVER) OR SEAT CUSHION ASSEMBLY (PASSENGER)

CAUTION:

• Front passenger seat is equipped with an Occupant Classification System sensor and control mod-

ule. Do not disassemble front passenger seat cushion assembly or remove the trim as this will affect

the Occupant Classificatio n System calibration.

• Always replace passenger seat cushion as an assembly.

• When removed, the passenger seat cushion must al ways be placed pan side UP to prevent damage.

• During installation, the wire harn ess clips must be reinstalled in the holes they were originally in.

Do not add clips.

• The Occupant Classification System control module can only be replaced as part of the seat cushion

assembly.

NOTE:

If the vehicle has been involved in a collision t he seat must be inspected for damage. Refer to SR-20, "

For

Frontal Collision" .

1. Remove the power seat switch knobs, power seat switch escutcheon and lumbar switch bezel.

2. Remove the power seat and power lumbar switches.

SIIA0113E

LRS023

LIIA1581E

Revision: December 20092009 QX56

Page 3409 of 4171

![INFINITI QX56 2009 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-99

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Te r m i n a l Wire

color Signal name Signal

inpu INFINITI QX56 2009 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-99

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Te r m i n a l Wire

color Signal name Signal

inpu](/img/42/57031/w960_57031-3408.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-99

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

1 B/Y Battery power supply Input OFF —Battery voltage

2 R Battery power supply Input OFF —Battery voltage

3BRECM relay Output— Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

4W/LECM relay Output— Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

6L Throttle control motor

relay Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

7 W/B ECM relay control Input — Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

8 R/B Fuse 54 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

10 G Fuse 45 Output ONDaytime light system active

0V

Daytime light system inactive Battery voltage

11 Y/B A/C compressor Output ON or

START A/C switch ON or defrost A/C

switch

Battery voltage

A/C switch OFF or defrost A/C

switch 0V

12 L/W Ignition switch sup-

plied power Input —OFF or ACC

0V

ON or START Battery voltage

13 B/Y Fuel pump relay Output — Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

14 Y/R Fuse 49 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

15 LG/B Fuse 50 (VDC) Output — Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

15 GR Fuse 50 (ABS) Output — Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

16 G Fuse 51 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

17 W Fuse 55 Output —Ignition switch ON or START

Battery voltage

Ignition switch OFF or ACC 0V

19 W/R Starter motor Output START—Battery voltage

21 BR Ignition switch sup-

plied power

Input —OFF or ACC

0V

START Battery voltage

22 G Battery power supply Output OFF —Battery voltage

23 GR/W Door mirror defogger

output signal Output —When rear defogger switch is

ON

Battery voltage

When raker defogger switch is

OFF 0V

Revision: December 20092009 QX56

Page 3480 of 4171

SPIRAL CABLESR-7

< ON-VEHICLE REPAIR >

C

DE

F

G

I

J

K L

M A

B

SR

N

O P

SPIRAL CABLE

Removal and InstallationINFOID:0000000003775158

REMOVAL

CAUTION:

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery terminals and wait at

least three minutes.

• When servicing the SRS, do not work from directly in front of air bag module.

1. Remove the instrument lower panel LH. Refer to IP-15, "

Removal and Installation".

2. Remove the steering wheel. Refer to ST-18, "

Removal and Installation".

3. Remove the column cover upper and lower.

4. Remove wiper washer switch connector, then pinch the tabs at wiper and washer switch base and slide switch away from steer-

ing column to remove.

1. Steering wheel 2. Lighting and turn signal switch 3. Wiper and washer switch

4. Spiral cable 5. Driver air bag module connector 6. Column cover upper

7. Column assembly 8. Column cover lower9. Screw (Do not remove)

10. Screw A. Refer to ST-18, "

Removal and Instal-

lation"

AWHIA0141GB

LHIA0034E

Revision: December 20092009 QX56

Page 3481 of 4171

SR-8

< ON-VEHICLE REPAIR >

SPIRAL CABLE

5. While pressing tabs, pull lighting and turn signal switch towarddriver door and disconnect from base.

6. Remove the screws, release the clip, and remove the spiral cable.

CAUTION:

• Do not disassemble spiral cable.

• Do not apply lubricant to the spiral cable.

7. Remove the spiral cable connectors. CAUTION:

With the steering linkage di sconnected, the spiral cable

may snap by turning the steer ing wheel beyond the limited

number of turns. The spiral cable can be turned counter-

clockwise about 2.5 turns fr om the neutral position.

8. Remove the steering angle sensor. Refer to BRC-118, "

Removal

and Installation".

INSTALLATION

Installation is in the reverse order of removal.

• Align spiral cable correctly when installing steering wheel. Make

sure that the spiral cable is in the neutral position. The neutral

position is detected by turning left 2.5 revolutions from the right

end position and ending with the knob at the top.

• If equipped with VDC, refer to BRC-8, "

ADJUSTMENT OF STEER-

ING ANGLE SENSOR NEUTRAL POSITION : Special Repair

Requirement" for steering angle sensor adjustment.

• After the work is completed, perform self-diagnosis to make sure no malfunction is detected. Refer to SRC-13, "

SRS Operation

Check".

CAUTION:

LHIA0035E

LHIA0036E

SHIA0193E

WGIA0038E

Revision: December 20092009 QX56

Page 3674 of 4171

TM-26

< FUNCTION DIAGNOSIS >

A/T CONTROL SYSTEM

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In th is way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converte r clutch solenoid is varied to gradually increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put into

half-clutched status, the torque converter clutch pi ston operating pressure is increased and the coupling is

completed smoothly.

Slip Lock-up Control

In the slip region, the torque converter clutch solenoid current is controlled with the TCM to put it into the

half-clutched state. This absorbs the engine tor que fluctuation and lock-up operates from low speed.

This raises the fuel efficiency for 4GR and 5GR at both low speed and when the accelerator has a low

degree of opening.

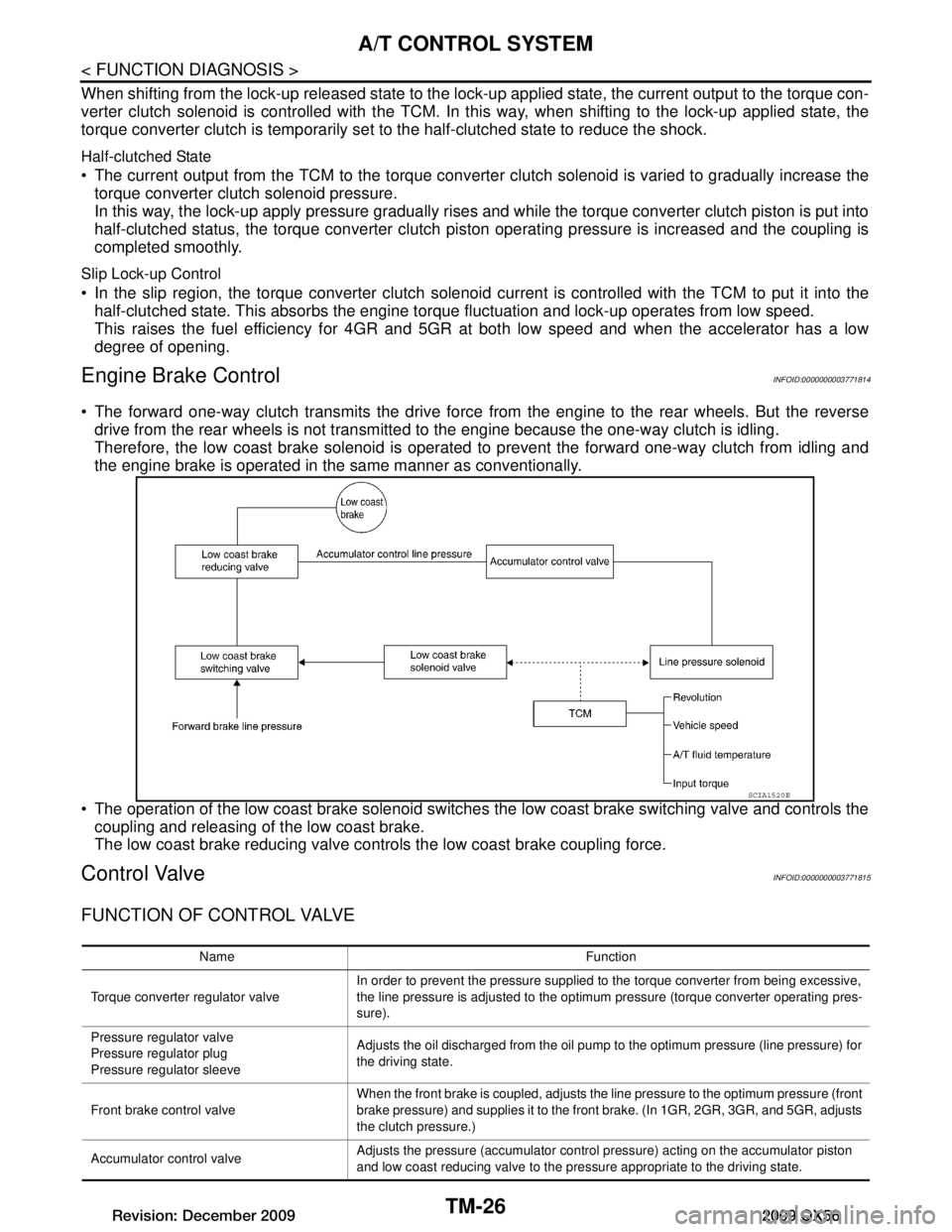

Engine Brake ControlINFOID:0000000003771814

The forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

The operation of the low coast brake solenoid switches the low coast brake switching valve and controls the

coupling and releasing of the low coast brake.

The low coast brake reducing valve contro ls the low coast brake coupling force.

Control ValveINFOID:0000000003771815

FUNCTION OF CONTROL VALVE

SCIA1520E

Name Function

Torque converter regulator valve In order to prevent the pressure supplied to the torque converter from being excessive,

the line pressure is adjusted to the optimum pressure (torque converter operating pres-

sure).

Pressure regu lator valve

Pressure regulator plug

Pressure regu lator sleeve Adjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valve When the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1GR, 2GR, 3GR, and 5GR, adjusts

the clutch pressure.)

Accumulator control valve Adjusts the pressure (accumulator control pressure) acting on the accumulator piston

and low coast reducing valve to the pressure appropriate to the driving state.

Revision: December 20092009 QX56