air condition INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1879 of 4171

EM-56

< ON-VEHICLE REPAIR >

CAMSHAFT

c. Remove the bolts and the chain tensioner (RH) (A).NOTE:

If it is difficult to push plunger on chain tensioner (RH) (A),

remove the plunger under extended condition.

14. Loosen camshaft sprocket bolts as shown and remove camshaft sprockets.

CAUTION:

To avoid interference between valves and pistons, do not

turn crankshaft or camshaft with timing chain discon-

nected.

15. Remove the RH (A) front cover bolts and LH (B) front cover bolts.

16. Remove RH (A) camshaft bracket bolts and LH (C) camshaft bracket bolts in the reverse of order shown to remove camshaft

brackets.

• Remove No. 1 camshaft bracket.NOTE:

The bottom and front surface of bracket will be stuck because

of liquid gasket.

• : Engine front

• B: Exhaust side

• D: Intake side

WBIA0705E

KBIA2485E

WBIA0706E

WBIA0707E

Revision: December 20092009 QX56

Page 1898 of 4171

CYLINDER HEADEM-75

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

5. Press the valve guide from the camshaft side to the dimensions

as shown.

CAUTION:

Cylinder head contains heat . When working, wear protec-

tive equipment to avo id getting burned.

6. Ream the cylinder head valve guide using suitable tool.

VALVE SEAT CONTACT

• After confirming that the dimensions of the valve guides and valves are within specifications, perform this procedure.

• Apply prussian blue (or white lead) onto the contacting surface of the valve seat to check the condition of the valve contact on the

surface.

• Check if the contact area band is continuous all around the circum- ference.

• If not, grind to adjust the valve fi t and check again. If the contacting

surface still has NG conditions even after the re-check, replace the

valve seat.

VALVE SEAT REPLACEMENT

When the valve seat is removed, replace it with oversized (0.5 mm, 0.020 in) valve seat.

1. Bore out the old seat until it collapses. Boring should not continue beyond the bottom face of the seat recess in the cylinder head. Set the machine depth stop to ensure this.

2. Ream the cylinder head recess diameter for service valve seat.

• Be sure to ream in circles concentric to the valve guide center.

• This will enable valve seat to fit correctly.

KBIA2530E

Valve guide inside diameter:

Intake and exhaust : 6.000 - 6.018 mm (0.2362 - 0.2369 in)

SEM932C

SBIA0322E

Oversize [0.5 mm (0.020 in)] (Service):

Intake : 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust : 32.700 - 32.716 mm (1.2874 - 1.2880 in)

SEM795A

Revision: December 20092009 QX56

Page 1924 of 4171

HOW TO SELECT PISTON AND BEARINGEM-101

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

HOW TO SELECT PISTON AND BEARING

How to Select Piston and BearingINFOID:0000000005885904

DESCRIPTION

*For the service parts, the grade for fitting cannot be selected between a piston pin and a connecting rod.

(Only 0 grade is available.) The information at the sh

ipment from the plant is described as a reference.

• The identification grade stamped on each part is the grade for the dimension measured in new condition.

This grade cannot apply to reused parts.

• For reused or repaired parts, measure the dimens ion accurately. Determine the grade by comparing the

measurement with the values of each selection table.

• For details of the measurement method of each part , the reuse standards, and the selection method of the

selective fitting parts, follow the applicable procedures.

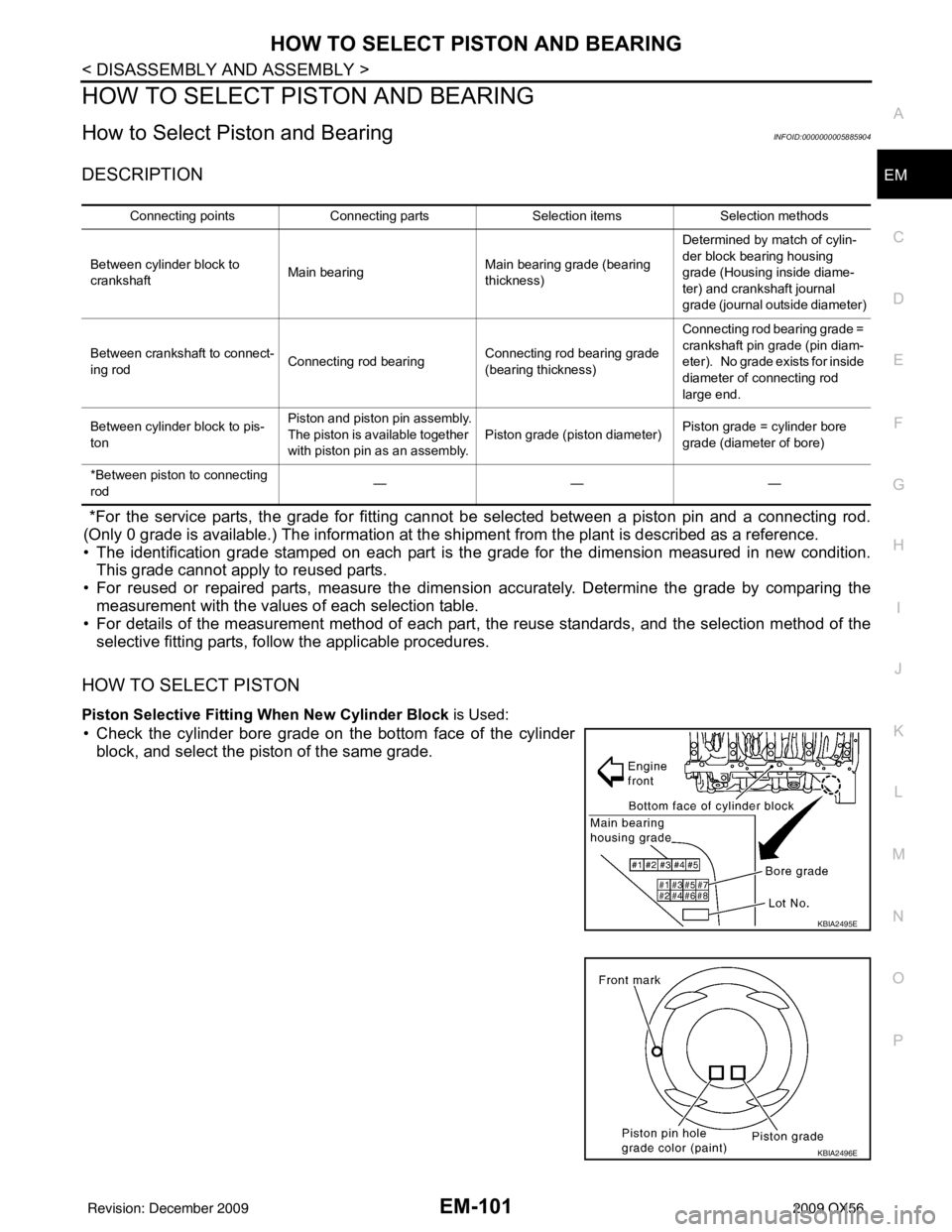

HOW TO SELECT PISTON

Piston Selective Fitting When New Cylinder Block is Used:

• Check the cylinder bore grade on the bottom face of the cylinder

block, and select the piston of the same grade.

Connecting points Connecting parts Selection itemsSelection methods

Between cylinder block to

crankshaft Main bearing Main bearing grade (bearing

thickness)Determined by match of cylin-

der block bearing housing

grade (Housing inside diame-

ter) and crankshaft journal

grade (journal outside diameter)

Between crankshaft to connect-

ing rod Connecting rod bearing Connecting rod bearing grade

(bearing thickness)Connecting rod bearing grade =

crankshaft pin grade (pin diam-

eter). No grade exists for inside

diameter of connecting rod

large end.

Between cylinder block to pis-

ton Piston and piston pin assembly.

The piston is available together

with piston pin as an assembly.

Piston grade (piston diameter)

Piston grade = cylinder bore

grade (diameter of bore)

*Between piston to connecting

rod ———

KBIA2495E

KBIA2496E

Revision: December 20092009 QX56

Page 1978 of 4171

EXL-30

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

COMPONENT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000004215535

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

ConnectorTe r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON

or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

LIIA2415E

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Revision: December 20092009 QX56

Page 1997 of 4171

OPTICAL SENSOREXL-49

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

OPTICAL SENSOR

DescriptionINFOID:0000000003776193

The optical sensor converts the outside brightness (lux) to voltage and transmits the optical sensor signal to

the BCM.

Component Function CheckINFOID:0000000003776194

1.CHECK OPTICAL SENSOR SIGNAL BY CONSULT-III

CONSULT-III

1. Turn the ignition switch ON.

2. Select "OPTICAL SENSOR" of BC M (HEAD LAMP) DATA MONITOR item.

3. Turn the lighting switch to AUTO.

4. With the optical sensor illuminat ing, check the monitor status.

*: Illuminates the optical sensor. The value may be less than the standard value if brightness is weak.

Is the item status normal?

YES >> Optical sensor is normal.

NO >> Refer to EXL-49, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776195

1.CHECK OPTICAL SENSOR GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect BCM connector M18 and optical sensor connector M302.

3. Check continuity between BCM harness connector M18 (A) ter-

minal 18 and optical sensor harness connector M302 (B) termi-

nal 3.

4. Check continuity between BCM harness connector M18 (A) ter- minal 18 and ground.

Are continuity test results as specified?

YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK OPTICAL SENSOR SIGNAL CIRCUIT

Monitor item ConditionVoltage

OPTICAL SENSOR When illuminating

3.1V or more *

When shutting off light 0.6V or less

AB

Connector Terminal Connector Terminal Continuity M181 8M3023 Y es

A —Contin u it y

Connector Terminal

M18 18Ground No

AWLIA1620ZZ

Revision: December 20092009 QX56

Page 2054 of 4171

EXL-106

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

ECU DIAGNOSIS

BCM (BODY CONTROL MODULE)

Reference ValueINFOID:0000000004215521

VALUES ON THE DIAGNOSIS TOOL

Monitor ItemCondition Value/Status

AIR COND SW A/C switch OFF

OFF

A/C switch ON ON

AUT LIGHT SYS Outside of the room is dark

OFF

Outside of the room is bright ON

AUTO LIGHT SW Lighting switch OFF

OFF

Lighting switch AUTO ON

BACK DOOR SW Back door closed

OFF

Back door opened ON

CDL LOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the LOCK side ON

CDL UNLOCK SW Door lock/unlock switch does not operate

OFF

Press door lock/unlock switch to the UNLOCK side ON

DOOR SW-AS Front door RH closed

OFF

Front door RH opened ON

DOOR SW-DR Front door LH closed

OFF

Front door LH opened ON

DOOR SW-RL Rear door LH closed

OFF

Rear door LH opened ON

DOOR SW-RR Rear door RH closed

OFF

Rear door RH opened ON

ENGINE RUN Engine stopped

OFF

Engine running ON

FR FOG SW Front fog lamp switch OFF

OFF

Front fog lamp switch ON ON

FR WASHER SW Front washer switch OFF

OFF

Front washer switch ON ON

FR WIPER LOW Front wiper switch OFF

OFF

Front wiper switch LO ON

FR WIPER HI Front wiper switch OFF

OFF

Front wiper switch HI ON

FR WIPER INT Front wiper switch OFF

OFF

Front wiper switch INT ON

FR WIPER STOP Any position other than front wiper stop position

OFF

Front wiper stop position ON

HAZARD SW When hazard switch is not pressed

OFF

When hazard switch is pressed ON

LIGHT SW 1ST Lighting switch OFF

OFF

Lighting switch 1st ON

Revision: December 20092009 QX56

Page 2069 of 4171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-121

< ECU DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

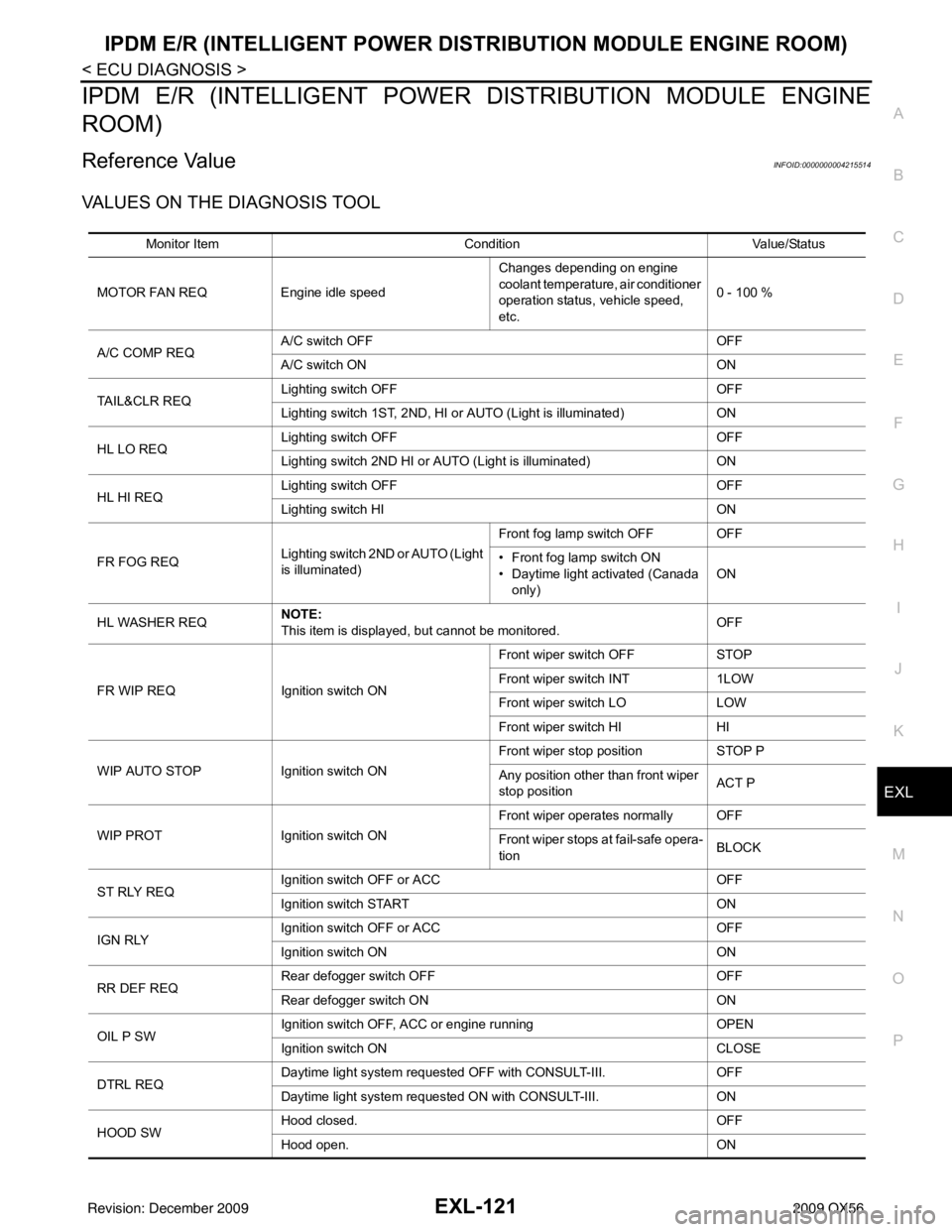

Reference ValueINFOID:0000000004215514

VALUES ON THE DIAGNOSIS TOOL

Monitor Item ConditionValue/Status

MOTOR FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQ A/C switch OFF

OFF

A/C switch ON ON

TA I L & C L R R E Q Lighting switch OFF

OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQ Lighting switch OFF

OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQ Lighting switch OFF

OFF

Lighting switch HI ON

FR FOG REQ Lighting switch 2ND or AUTO (Light

is illuminated) Front fog lamp switch OFF OFF

• Front fog lamp switch ON

• Daytime light activated (Canada

only) ON

HL WASHER REQ NOTE:

This item is displayed, but cannot be monitored.

OFF

FR WIP REQ Ignition switch ON Front wiper switch OFF

STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ON Front wiper stop position

STOP P

Any position other than front wiper

stop position ACT P

WIP PROT Ignition switch ON Front wiper operates normally OFF

Front wiper stops at fail-safe opera-

tion

BLOCK

ST RLY REQ Ignition switch OFF or ACC

OFF

Ignition switch START ON

IGN RLY Ignition switch OFF or ACC

OFF

Ignition switch ON ON

RR DEF REQ Rear defogger switch OFF

OFF

Rear defogger switch ON ON

OIL P SW Ignition switch OFF, ACC or engine running

OPEN

Ignition switch ON CLOSE

DTRL REQ Daytime light system requested OFF with CONSULT-III.

OFF

Daytime light system reques ted ON with CONSULT-III. ON

HOOD SW Hood closed.

OFF

Hood open. ON

Revision: December 20092009 QX56

Page 2085 of 4171

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

EXL-137

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

BOTH SIDE HEADLAMPS DO NOT SWITCH TO HIGH BEAM

DescriptionINFOID:0000000003776212

The headlamps (both sides) do not switch to high beam when the lighting switch is in the HI or PASS setting.

Diagnosis ProcedureINFOID:0000000003776213

1.COMBINATION SWITCH INSPECTION

Check the combination switch. Refer to BCS-36, "

Diagnosis Procedure".

Is the combination switch normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (HI) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL HI REQ" of IPDM E/R DATA MONITOR item.

2. With operating the lighting switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installation" .

3.HEADLAMP (HI) CIRCUIT INSPECTION

Check the headlamp (HI) circuit. Refer to EXL-32, "

Description".

Is the headlamp (HI) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL HI REQ Lighting switch

(2ND)HI or PASS

ON

Except for HI or

PA S S OFF

Revision: December 20092009 QX56

Page 2086 of 4171

EXL-138

< SYMPTOM DIAGNOSIS >

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON

DescriptionINFOID:0000000003776214

The headlamps (both sides) do not turn ON in any lighting switch setting.

Diagnosis ProcedureINFOID:0000000003776215

1.CHECK COMBINATION SWITCH

Check the combination switch. Refer to BCS-36, "

Diagnosis Procedure".

Is the combination switch normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK HEADLAMP (LO) REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "HL LO REQ" of IPDM E/R DATA MONITOR item.

2. With operating the lighting switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installation" .

3.HEADLAMP (LO) CIRCUIT INSPECTION

Check the headlamp (LO) circuit. Refer to EXL-35, "

Description".

Is the headlamp (LO) circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R" .

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

HL LO REQ Lighting switch 2ND

ON

OFF OFF

Revision: December 20092009 QX56

Page 2087 of 4171

PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED ON

EXL-139

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

EXL

N

O P

PARKING, LICENSE PLATE AND TA IL LAMPS ARE NOT TURNED ON

DescriptionINFOID:0000000003776216

The parking, license plate and tail lamps do not turn ON in with any lighting switch setting.

Diagnosis ProcedureINFOID:0000000003776217

1.COMBINATION SWITCH INSPECTION

Check the combination switch. Refer to BCS-36, "

Diagnosis Procedure".

Is the combination switch normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning part.

2.CHECK TAIL LAMP RELAY REQUEST SIGNAL INPUT

CONSULT-III DATA MONITOR

1. Select "TAIL & CLR REQ" of IPDM E/R DATA MONITOR item.

2. With operating the lighting switch, check the monitor status.

Is the item status normal?

YES >> GO TO 3.

NO >> Replace BCM. Refer to BCS-56, "

Removal and Installation".

3.PARK LAMP CIRCUIT INSPECTION

Check the parking lamp circuit. Refer to EXL-40, "

Description".

Is the tail lamp circuit normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R".

NO >> Repair or replace the malfunctioning part.

Monitor item ConditionMonitor status

TAIL & CLR

REQ Lighting switch 1ST

ON

OFF OFF

Revision: December 20092009 QX56