center console INFINITI QX56 2009 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1033 of 4171

![INFINITI QX56 2009 Factory Owners Manual SQUEAK AND RATTLE TROUBLE DIAGNOSESDLK-221

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Insulates where slight movement is present. Ideal for instrument panel INFINITI QX56 2009 Factory Owners Manual SQUEAK AND RATTLE TROUBLE DIAGNOSESDLK-221

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Insulates where slight movement is present. Ideal for instrument panel](/img/42/57031/w960_57031-1032.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSESDLK-221

< SYMPTOM DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000003775845

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dampers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: December 20092009 QX56

Page 2113 of 4171

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000003776101

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: December 20092009 QX56

Page 2160 of 4171

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-7

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

REMOVAL AND INSTALLATION

FUEL LEVEL SENSOR UNIT, FUEL FI

LTER AND FUEL PUMP ASSEMBLY

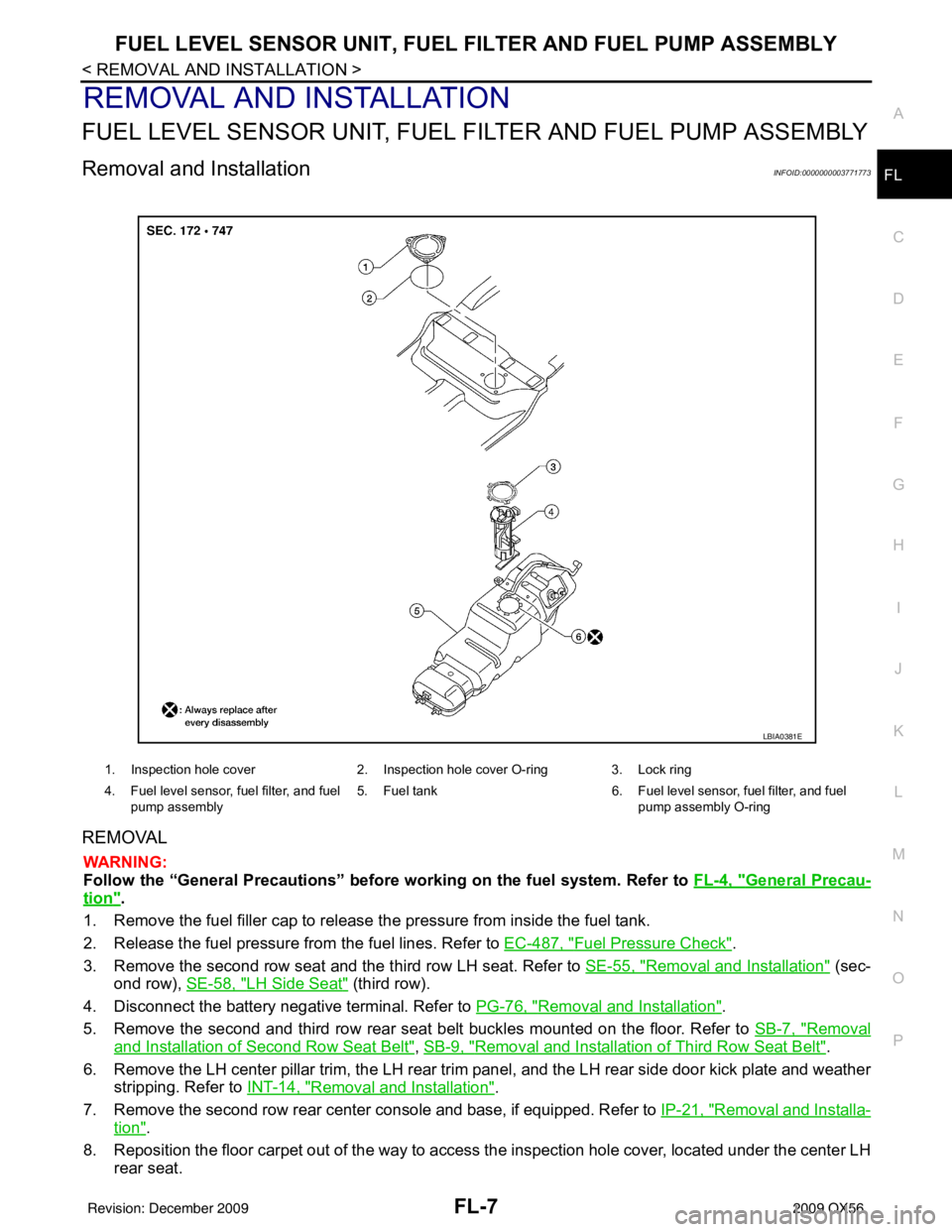

Removal and InstallationINFOID:0000000003771773

REMOVAL

WARNING:

Follow the “General Precautions” before working on the fuel system. Refer to FL-4, "

General Precau-

tion".

1. Remove the fuel filler cap to release the pressure from inside the fuel tank.

2. Release the fuel pressure from the fuel lines. Refer to EC-487, "

Fuel Pressure Check".

3. Remove the second row seat and the third row LH seat. Refer to SE-55, "

Removal and Installation" (sec-

ond row), SE-58, "

LH Side Seat" (third row).

4. Disconnect the battery negative terminal. Refer to PG-76, "

Removal and Installation".

5. Remove the second and third row rear seat belt buckles mounted on the floor. Refer to SB-7, "

Removal

and Installation of Second Row Seat Belt", SB-9, "Removal and Installation of Third Row Seat Belt".

6. Remove the LH center pillar trim, the LH rear trim panel, and the LH rear side door kick plate and weather stripping. Refer to INT-14, "

Removal and Installation".

7. Remove the second row rear center console and base, if equipped. Refer to IP-21, "

Removal and Installa-

tion".

8. Reposition the floor carpet out of the way to access the inspection hole cover, located under the center LH rear seat.

1. Inspection hole cover 2. Inspection hole cover O-ring 3. Lock ring

4. Fuel level sensor, fuel filter, and fuel pump assembly 5. Fuel tank

6. Fuel level sensor, fuel filter, and fuel

pump assembly O-ring

LBIA0381E

Revision: December 20092009 QX56

Page 2165 of 4171

FL-12

< REMOVAL AND INSTALLATION >

FUEL TANK

REMOVAL

WARNING:

Follow the “General Precautions” before working on the fuel system. Refer to FL-4, "

General Precau-

tion".

1. Remove the fuel filler cap to release the pressure from inside the fuel tank.

2. Release the fuel pressure from the fuel lines. Refer to EC-487, "

Fuel Pressure Check".

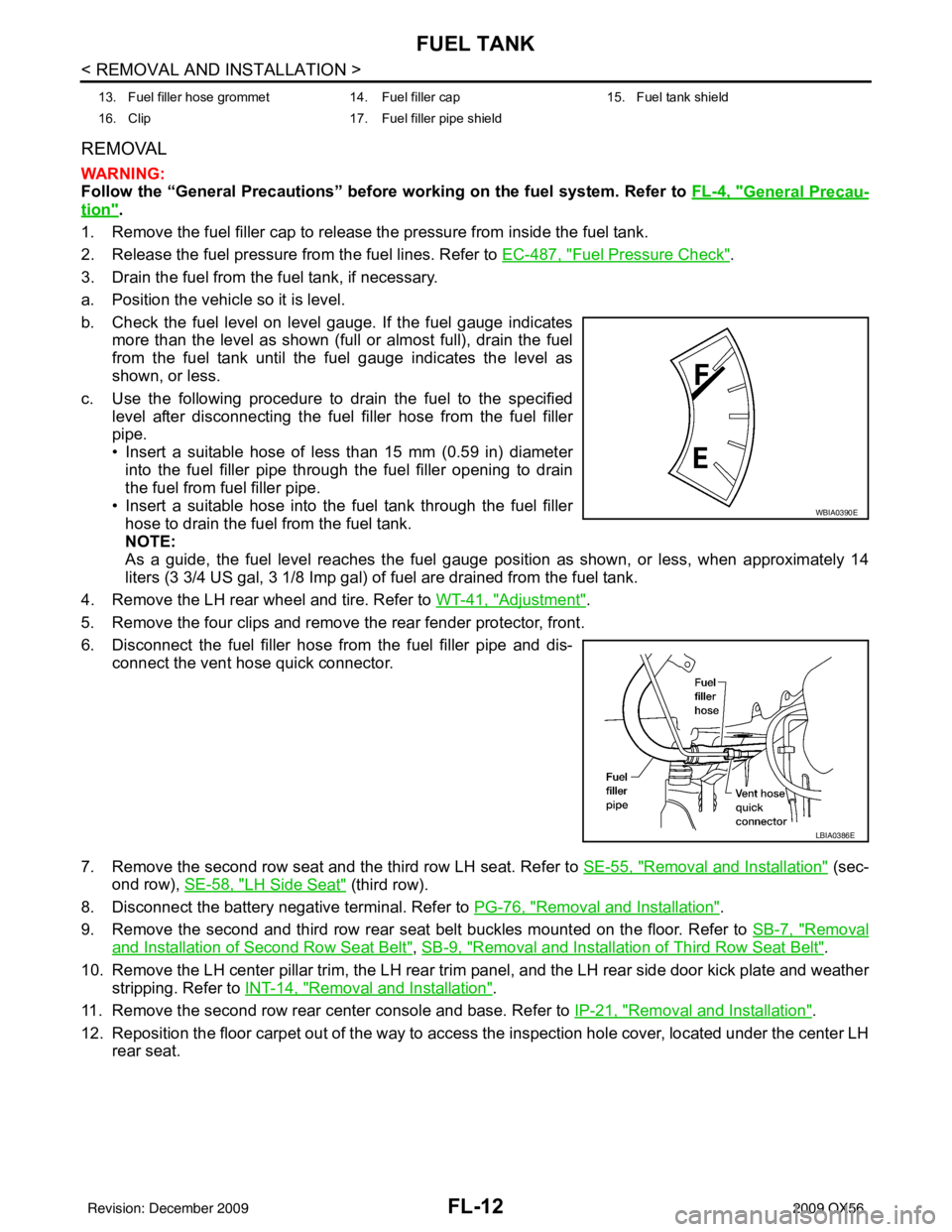

3. Drain the fuel from the fuel tank, if necessary.

a. Position the vehicle so it is level.

b. Check the fuel level on level gauge. If the fuel gauge indicates more than the level as shown (full or almost full), drain the fuel

from the fuel tank until the fuel gauge indicates the level as

shown, or less.

c. Use the following procedure to drain the fuel to the specified level after disconnecting the fuel filler hose from the fuel filler

pipe.

• Insert a suitable hose of less than 15 mm (0.59 in) diameterinto the fuel filler pipe through the fuel filler opening to drain

the fuel from fuel filler pipe.

• Insert a suitable hose into the fuel tank through the fuel filler hose to drain the fuel from the fuel tank.

NOTE:

As a guide, the fuel level reaches the fuel gauge position as shown, or less, when approximately 14

liters (3 3/4 US gal, 3 1/8 Imp gal) of fuel are drained from the fuel tank.

4. Remove the LH rear wheel and tire. Refer to WT-41, "

Adjustment".

5. Remove the four clips and remove the rear fender protector, front.

6. Disconnect the fuel filler hose from the fuel filler pipe and dis- connect the vent hose quick connector.

7. Remove the second row seat and the third row LH seat. Refer to SE-55, "

Removal and Installation" (sec-

ond row), SE-58, "

LH Side Seat" (third row).

8. Disconnect the battery negative terminal. Refer to PG-76, "

Removal and Installation".

9. Remove the second and third row rear seat belt buckles mounted on the floor. Refer to SB-7, "

Removal

and Installation of Second Row Seat Belt", SB-9, "Removal and Installation of Third Row Seat Belt".

10. Remove the LH center pillar trim, the LH rear trim panel, and the LH rear side door kick plate and weather

stripping. Refer to INT-14, "

Removal and Installation".

11. Remove the second row rear center console and base. Refer to IP-21, "

Removal and Installation".

12. Reposition the floor carpet out of the way to access the inspection hole cover, located under the center LH

rear seat.

13. Fuel filler hose grommet 14. Fuel filler cap 15. Fuel tank shield

16. Clip 17. Fuel filler pipe shield

WBIA0390E

LBIA0386E

Revision: December 20092009 QX56

Page 2246 of 4171

GW-4

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

68370-4B000: 15×25 mm (0.59× 0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for inst rument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005867457

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Revision: December 20092009 QX56

Page 2527 of 4171

INT-4

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

68370-4B000: 15×25 mm (0.59× 0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for inst rument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000003775403

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Revision: December 20092009 QX56

Page 2539 of 4171

INT-16

< ON-VEHICLE REPAIR >

FLOOR TRIM

FLOOR TRIM

Removal and InstallationINFOID:0000000003775411

REMOVAL

1. Remove the front seats. Refer to SE-50, "Removal and Installation".

• Remove the subwoofer. Refer to AV-176, "

Removal and Installation".

• Remove the navigation display control unit. Refer to AV-170, "

Removal and Installation".

2. Remove the second row seats. Refer to SE-55, "

Removal and Installation" and SE-51, "Exploded View", if

equipped.

3. Remove the third row rear seats. Refer to SE-56, "

Exploded View".

4. Remove the lower seat belt anchors. Refer to SB-14, "

Removal and Installation".

5. Remove the lower body side trim. Refer to INT-14

.

6. Remove the luggage lower side finishers (left / right). Refer to INT-19

.

7. Remove the kicking plates. Refer to INT-14

.

8. Remove the center console. Refer to IP-20, "

Removal and Installation".

9. Remove the rear console, if equipped. Refer to IP-21, "

Removal and Installation".

10. Remove the rear lower finisher. Refer to INT-19

.

11. Remove the carpet.

12. Remove the floor mat hooks from the front carpet.

INSTALLATION

Installation is in the reverse order of removal.

1. Carpet 2. Floor mat hooks

AWJIA0408ZZ

Revision: December 20092009 QX56

Page 2545 of 4171

IP-1

BODY INTERIOR

C

DE

F

G H

I

K L

M

SECTION IP

A

B

IP

N

O P

CONTENTS

INSTRUMENT PANEL

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

6

Work Flow ........................................................... ......6

Generic Squeak and Rattle Troubleshooting ............8

Diagnostic Worksheet .............................................10

ON-VEHICLE REPAIR .................................12

INSTRUMENT PANEL ASSEMBLY .............. ....12

Exploded View .................................................... ....12

Removal and Installation .........................................13

CLUSTER LID A ............................................. ....15

Exploded View .................................................... ....15

Removal and Installation .........................................15

CLUSTER LID C ...............................................16

Exploded View ..................................................... ....16

Removal and Installation .........................................16

INSTRUMENT LOWER PANEL RH AND

GLOVE BOX .....................................................

17

Exploded View .........................................................17

Removal and Installation .........................................17

INSTRUMENT UPPER PANEL RH ..................18

Exploded View .........................................................18

Removal and Installation .........................................18

A/T FINISHER ...................................................19

Removal and Installation .........................................19

FRONT CENTER CONSOLE ............................20

Exploded View .........................................................20

Removal and Installation .........................................20

REAR CENTER CONSOLE ..............................21

Removal and Installation .........................................21

DISASSEMBLY AND ASSEMBLY ..............22

FRONT CENTER CONSOLE ............................22

Exploded View ..................................................... ....22

Disassembly and Assembly .....................................23

REAR CENTER CONSOLE ..............................24

Exploded View .........................................................24

Disassembly and Assembly .....................................25

Revision: December 20092009 QX56

Page 2552 of 4171

IP-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

68370-4B000: 15×25 mm (0.59× 0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for inst rument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000003775419

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Revision: December 20092009 QX56

Page 2557 of 4171

INSTRUMENT PANEL ASSEMBLYIP-13

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

Removal and InstallationINFOID:0000000003775422

REMOVAL

CAUTION:

Disconnect both the negative and positive battery terminals in advance.

1. Disconnect both negative and positive terminal s, then wait at least 3 minutes.

2. Remove front center console. Refer to IP-20, "

Removal and Installation".

3. Remove steering column assembly. Refer to ST-20, "

Removal and Installation".

4. Remove combination meter. Refer to MWI-102, "

Removal and Installation".

5. Remove instrument panel upper cover and disconnect rear sonar speaker (if equipped).

6. Remove cluster lid C. Refer to IP-16, "

Removal and Installation".

7. Remove display assembly. Refer to AV-168, "

Removal and Installation".

8. Remove instrument lower/upper panel RH and glove box. Refer to IP-17, "

Removal and Installation" and

IP-18, "

Removal and Installation".

9. Release the clips, disconnect the optical sensor harness and remove defroster grille.

10. Release the clips, disconnect the connectors and remove RH, LH, and center speakers.

11. Remove RH/LH front pillar finishers. Refer to INT-14, "

Removal and Installation".

12. Remove the passenger air bag module nuts and disconnect the connectors. Refer to SR-10, "

Removal

and Installation".

13. Disconnect remaining optional equipment connectors (if equipped).

14. Remove instrument panel and pad assembly screws.

15. Release instrument panel and pad assembly lifting rearward away from steering member, then carefully remove through front door opening.

1. Defroster grille 2. Center speaker grille3. Speaker center

4. Speaker grille outer 5. Speaker outer6. Instrument panel upper cover

7. Instrument panel and pad assembly 8. Side ventilator assembly LH 9. Combination meter

10. Instrument upper panel LH 11. Cluster lid A 12. Key cylinder escutcheon

13. Lower knee protector 14. Instrument lower panel LH 15. Steering column cover upper

16. Steering column cover lower 17. Cluster lid C lower 18. 4WD switch (if equipped)

19. Hazard switch 20. Cluster lid C21. Instrument lower cover RH

22. Fuse access cover 23. Glove box 24. Instrument lower panel RH

25. Audio switch RH 26. A/C and AV switch assembly 27. Audio unit

28. Audio switch LH 29. Center ventilator assembly LH 30. Display assembly

31. Center ventilator assembly RH 32. Side ventilator assembly RH 33. Instrument upper panel RH Metal clip Clip

ALJIA0083ZZ

Revision: December 20092009 QX56