sensor INFINITI QX56 2009 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 96 of 4171

ADP-82

< COMPONENT DIAGNOSIS >

TILT SENSOR

TILT SENSOR

DescriptionINFOID:0000000003775609

The tilt sensor is installed to the steering column assembly.

The resistance of tilt sensor is changed according to the up/down position of steering column.

The terminal voltage of automatic drive positioner c ontrol unit will be changed according to a change of tilt

sensor resistance. Automatic drive positioner contro l unit calculates the tilt position from the voltage.

Component Function CheckINFOID:0000000003775610

1. CHECK FUNCTION

1. Select “TILT SEN” in “Data monitor” mode with CONSULT-III.

2. Check the tilt sensor signal under the following condition.

Is the indication normal?

YES >> Inspection End.

NO >> Perform diagnosis procedure. Refer to ADP-82, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000003775611

1. CHECK TILT SENSOR SIGNAL

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> GO TO 2

2. CHECK HARNESS CONTINUITY

Monitor item Condition Value

TILT SEN Tilt position Change between

1.2 V (Close to top)

3.4 V (Close to bottom)

Connector Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M33 7 Ground Tilt top position 2

Tilt bottom position 4

LIIA0485E

Revision: December 20092009 QX56

Page 97 of 4171

TILT SENSORADP-83

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Disconnect automatic drive positi oner control unit and tilt motor

assembly.

2. Check continuity between autom atic drive positioner connector

M33 (A), M34 (B) terminals 7, 33, 41 and tilt motor assembly

connector M85 (C) terminals 2, 3, 4.

3. Check continuity between automat ic drive positioner control unit

connectors M33 (A), M34 (B ) terminals 7, 33, 41 and ground.

Is the inspection result normal?

YES >> Replace tilt motor assembly. Refer to ST-19, "Removal

and Installation".

NO >> Repair or replace harness.

3. CHECK DOOR MIRROR OPERATION

1. Connect automatic drive positioner c ontrol unit and tilt motor assembly.

2. Turn ignition switch ON.

3. Check door mirror operation with memory function.

Is the operation normal?

YES >> Replace tilt motor assembly. Refer to ST-19, "Removal and Installation".

NO >> Replace automatic drive positioner control unit. Refer to ADP-166, "Removal and Installation"

.

4. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace automatic drive posit ioner control unit. Refer to ADP-166, "Removal and Installation".

NO >> Repair or replace the malfunctioning part. 7 - 3 : Continuity should exist.

33 - 2 : Continuity should exist.

41 - 4 : Continuity should exist.

7 - Ground : Continuity should not exist.

33 - Ground : Continuity should not exist.

41 - Ground : Continuity should not exist.

ALJIA0291ZZ

Revision: December 20092009 QX56

Page 98 of 4171

ADP-84

< COMPONENT DIAGNOSIS >

PEDAL ADJUSTING SENSOR

PEDAL ADJUSTING SENSOR

DescriptionINFOID:0000000003775612

The pedal adjusting sensor is installed to the pedal assembly.

The resistance of pedal adjusting sensor is changed according to the forward/backward position of pedalassembly.

The terminal voltage of automatic drive positioner control unit will be changed according to a change of

pedal adjusting sensor resistance. Automatic drive pos itioner control unit calculates the pedal assembly

position from the voltage.

Component Function CheckINFOID:0000000003775613

1. CHECK FUNCTION

1. Select “PEDAL SEN” in “Dat a monitor” mode with CONSULT-III.

2. Check the pedal sensor signal under the following condition.

Is the indication normal?

YES >> Inspection End.

NO >> Perform diagnosis procedure. Refer to ADP-84, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000003775614

1. CHECK PEDAL ADJUSTING SENSOR SIGNAL

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> GO TO 2

2. CHECK PEDAL ADJUSTING SENSOR CIRCUIT

Monitor item Condition Value

PEDAL SEN Pedal position Forward 0.5V

Backward 4.5V

Te r m i n a l

ConditionVoltage (V)

(Approx.)

(+)

(-)

Automatic

drive position- er control unit Te r m i n a l

M33 8 Ground Pedal as-

sembly

positionForward 0.5

Backward 4.5

PIIA4569E

Revision: December 20092009 QX56

Page 99 of 4171

PEDAL ADJUSTING SENSORADP-85

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Disconect automatic drive positioner control unit and pedal adjusting motor assembly.

2. Check continuity between automat ic drive positioner control unit

harnnes connector and pedal adjusting motor assembly harness

connector.

3. Check continuity between automat ic drive positioner control unit

harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK DOOR MIRROR OPERATION

1. Connect automatic drive positioner control unit and pedal adjusting motor assembly.

2. Turn ignition switch ON.

3. Check door mirror operation with memory function.

Is the operation normal?

YES >> Replace pedal adjusting motor assembly. Refer to ADP-169, "Removal and Installation".

NO >> Replace automatic drive positioner control unit. Refer to ADP-166, "Removal and Installation"

.

4. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace automatic drive posit ioner control unit. Refer to ADP-166, "Removal and Installation".

NO >> Repair or replace the malfunctioning part.

Automatic drive posi-

tioner

control unit connector Te r m i n a lPedal adjusting

motor assembly connector Terminal Continuity

M33 (A) 8 E110 (B)4

Ye s

M34 (C) 33 3

41 5

Automatic drive positioner control unit connector Te r m i n a l

Ground Continuity

M33 (A) 8 No

M34 (C) 33

41

ALJIA0327ZZ

Revision: December 20092009 QX56

Page 100 of 4171

ADP-86

< COMPONENT DIAGNOSIS >

MIRROR SENSOR

MIRROR SENSOR

DRIVER SIDE

DRIVER SIDE : DescriptionINFOID:0000000003775615

The mirror sensor LH is installed to the door mirror actuator LH.

The resistance of 2 sensors (horizontal and vertical) is changed when the door mirror LH is operated.

Automatic drive positioner control unit calculates the door mirror position according to the change of the volt-

age of 2 sensor input terminals.

DRIVER SIDE : Component Function CheckINFOID:0000000003775616

1. CHECK FUNCTION

1. Select “MIR/SEN LH U-D”, “MIR/SEN LH R-L” in “Data monitor” with CONSULT-III.

2. Check mirror sensor (driver side) signal under the following condition.

Is the indication normal?

YES >> Inspection End.

NO >> Perform diagnosis procedure. Refer to ADP-86, "DRIVER SIDE : Diagnosis Procedure"

.

DRIVER SIDE : Diagnosis ProcedureINFOID:0000000003775617

1. CHECK DOOR MIRROR LH SENSOR SIGNAL

1. Turn ignition switch to ACC.

2. Check voltage between door mirror LH harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5

NO >> GO TO 2

2. CHECK DOOR MIRROR LH SENSOR CIRCUIT 1

Monitor item Condition Value

MIR/SEN LH U-D Door mirror LHClose to peak 3.4V

Close to valley 0.6V

MIR/SEN LH R-L Close to right edge 3.4V

Close to left edge 0.6V

Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+)

(–)

Door mirror

LH connector Te r m i n a l

D4 7

Ground Door

mirror

LHClose to peak 3.4

Close to valley 0.6

8 Close to right edge 3.4

Close to left edge 0.6

LIIA1482E

Revision: December 20092009 QX56

Page 101 of 4171

MIRROR SENSORADP-87

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and door mir- ror LH.

3. Check continuity between automat ic drive positioner control unit

harness connector and door mirror LH harness connector.

4. Check continuity between automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK DOOR MIRROR LH SENSOR CIRCUIT 2

1. Check continuity between automat ic drive positioner control unit

harness connector and door mirror LH harness connector.

2. Check continuity between automat ic drive positioner control unit

harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK PEDAL ADJUSTING OPERATION

1. Connect driver seat control unit and door mirror LH.

2. Turn ignition switch ON.

3. Check pedal adjusting operation with memory function.

Is the operation normal?

YES >> Replace door mirror actuator LH. Refer to MIR-14, "Mirror Actuator".

NO >> Replace automatic drive positioner control unit. Refer to ADP-166, "Removal and Installation"

.

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace automatic drive posit ioner control unit. Refer to ADP-166, "Removal and Installation".

NO >> Repair or replace the malfunctioning part.

Automatic drive

positioner control unit connector Te r m i n a l

Door mirror LH

connector Terminal Continuity

M33 6

D4 7

Ye s

22 8

Automatic drive positioner control unit connector Te r m i n a l

Ground Continuity

M33 6

No

22

LIIA1484E

Automatic drive

positioner control unit connector Te r m i n a l

Door mirror LH

connector Terminal Continuity

M34 33

D4 5

Ye s

41 6

Automatic drive positioner control unit connector Te r m i n a l

GroundContinuity

M34 33

No

41

LIIA1483E

Revision: December 20092009 QX56

Page 102 of 4171

ADP-88

< COMPONENT DIAGNOSIS >

MIRROR SENSOR

PASSENGER SIDE

PASSENGER SIDE : DescriptionINFOID:0000000003775618

The mirror sensor RH is installed to the door mirror actuator RH.

The resistance of 2 sensors (horizontal and vertical) is changed when the door mirror RH is operated.

Automatic drive positioner control unit calculates the door mirror position according to the change of the volt-

age of 2 sensor input terminals.

PASSENGER SIDE : Component Function CheckINFOID:0000000003775619

1. CHECK FUNCTION

1. Select “MIR/SEN RH U-D”, “MIR/SEN RH R- L” in “Data monitor” with CONSULT-III.

2. Check the mirror sensor RH signal under the following conditions.

Is the indication normal?

YES >> Inspection End.

NO >> Perform diagnosis procedure. Refer to ADP-88, "PASSENGER SIDE : Diagnosis Procedure"

.

PASSENGER SIDE : Diagnosis ProcedureINFOID:0000000003775620

1. CHECK DOOR MIRROR RH SENSOR SIGNAL

1. Turn ignition switch to ACC.

2. Check voltage between door mirror RH harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5

NO >> GO TO 2

2. CHECK DOOR MIRROR RH SENSOR HARNESS CONTINUITY

Monitor item Condition Value

MIR/SEN RH U-D Door mirror RHClose to peak 3.4V

Close to valley 0.6V

MIR/SEN RH R-L Close to right edge 3.4V

Close to left edge 0.6V

Te r m i n a l s

ConditionVoltage (V)

(Approx.)

(+)

(–)

Door mirror

RH con-

nector Te r m i n a l

D107 7

Ground Door mirror

RH Close to peak 3.4

Close to valley 0.6

8 Close to right edge 3.4

Close to left edge 0.6

LIIA1485E

Revision: December 20092009 QX56

Page 103 of 4171

MIRROR SENSORADP-89

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and door mir- ror RH.

3. Check continuity between automat ic drive positioner control unit

harness connector and door mirror RH harness connector.

4. Check continuity between automatic drive positioner control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK DOOR MIRROR RH SENSOR POWER SUPPLY CIRCUIT

1. Check continuity between automat ic drive positioner control unit

harness connector and door mirror RH harness connector.

2. Check continuity between automat ic drive positioner control unit

harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

4. CHECK PEDAL ADJUSTING OPERATION

1. Connect driver seat control unit and door mirror RH.

2. Turn ignition switch ON.

3. Check pedal adjusting operation with memory function.

Is the operation normal?

YES >> Replace door mirror actuator RH. Refer to MIR-14, "Mirror Actuator".

NO >> Replace automatic drive positioner control unit. Refer to ADP-166, "Removal and Installation"

.

5. CHECK INTERMITTENT INCIDENT

Refer to GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES >> Replace automatic drive posit ioner control unit. Refer to ADP-166, "Removal and Installation".

NO >> Repair or replace the malfunctioning part.

Automatic drive posi-

tioner control unit connector Te r m i n a l

Door mirror RH

connector Terminal Continuity

M33 5

D107 7

Ye s

21 8

Automatic drive positioner control unit connector Te r m i n a l

GroundContinuity

M33 5

No

21

LIIA1473E

Automatic drive posi-

tioner control unit connector Te r m i n a l

Door mirror RH

connector Terminal Continuity

M34 33

D107 5

Ye s

41 6

Automatic drive positioner control unit connector Te r m i n a l

GroundContinuity

M34 33

No

41

LIIA1486E

Revision: December 20092009 QX56

Page 123 of 4171

DRIVER SEAT CONTROL UNITADP-109

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

ADP

N

O P

Te r m i n a l Wire

Color Item Condition Voltage (V)

(Approx.)

1 W UART LINE (RX) Pedal adjusting switch ON (FOR-

WARD or BACKWARD operation)

3 L/B CAN-H — —

6 R Ignition switch (START) Ignition switch (START position) Battery voltage

9 R/B Reclining motor sensor signal ON (seat reclining motor opera-

tion)

Other than above 0 or 5

10 B/R Rear lifting motor sensor signal ON (rear lifting motor operation)

Other than above 0 or 5

11 Y / R Sliding switch BACKWARD sig-

nal ON (seat sliding switch BACK-

WARD operation)

0

Other than above Battery voltage

12 L/W Reclining switch BACKWARD

signal ON (seat reclining switch BACK-

WARD operation)

0

Other than above Battery voltage

13 V Front lifting switch DOWN signal ON (front lifting switch DOWN op-

eration)

0

Other than above Battery voltage

14 P/L Rear lifting switch DOWN signal ON (rear lifting switch DOWN op-

eration)

0

Other than above Battery voltage

15 SB Pedal adjusting switch BACK-

WARD signal ON (pedal adjusting switch BACK-

WARD operation)

0

Other than above Battery voltage

16 R/W Seat sensor power Ignition switch ON 5

17 Y/R UART LINE (TX) Pedal adjusting switch ON (FOR-

WARD or BACKWARD operation)

PIIA4813E

SIIA0692J

SIIA0693J

PIIA4814E

Revision: December 20092009 QX56

Page 124 of 4171

ADP-110

< ECU DIAGNOSIS >

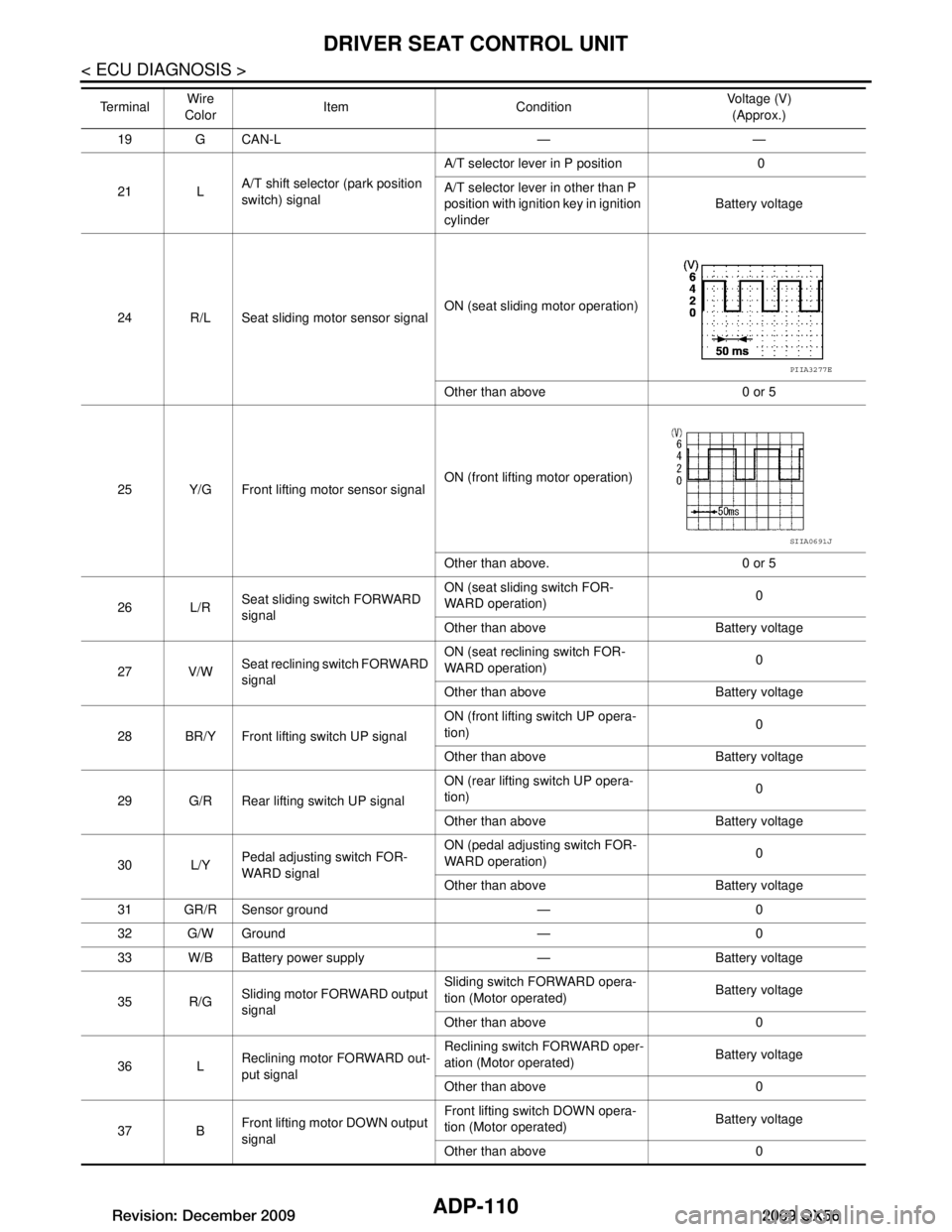

DRIVER SEAT CONTROL UNIT

19 G CAN-L — —

21 LA/T shift selector (park position

switch) signal A/T selector lever in P position 0

A/T selector lever in other than P

position with ignition key in ignition

cylinder

Battery voltage

24 R/L Seat sliding motor sensor signal ON (seat sliding motor operation)

Other than above 0 or 5

25 Y/G Front lifting motor sensor signal ON (front lifting motor operation)

Other than above. 0 or 5

26 L/R Seat sliding switch FORWARD

signal ON (seat sliding switch FOR-

WARD operation)

0

Other than above Battery voltage

27 V/W Seat reclining switch FORWARD

signal ON (seat reclining switch FOR-

WARD operation)

0

Other than above Battery voltage

28 BR/Y Front lifting switch UP signal ON (front lifting switch UP opera-

tion)

0

Other than above Battery voltage

29 G/R Rear lifting switch UP signal ON (rear lifting switch UP opera-

tion)

0

Other than above Battery voltage

30 L/Y Pedal adjusting switch FOR-

WARD signal ON (pedal adjusting switch FOR-

WARD operation)

0

Other than above Battery voltage

31 GR/R Sensor ground — 0

32 G/W Ground — 0

33 W/B Battery power supply — Battery voltage

35 R/G Sliding motor FORWARD output

signal Sliding switch FORWARD opera-

tion (Motor operated)

Battery voltage

Other than above 0

36 L Reclining motor FORWARD out-

put signal Reclining switch FORWARD oper-

ation (Motor operated)

Battery voltage

Other than above 0

37 B Front lifting motor DOWN output

signal Front lifting switch DOWN opera-

tion (Motor operated)

Battery voltage

Other than above 0

Te r m i n a l

Wire

Color Item Condition Voltage (V)

(Approx.)

PIIA3277E

SIIA0691J

Revision: December 20092009 QX56