torque INFINITI QX56 2010 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1950 of 4210

ENGINE UNITEM-99

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

• When the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of the

bearing must protrude. Refer to EM-83, "

Disassembly and Assem-

bly" for the tightening procedure.

• If standard is not met, replace main bearings.

CRUSH HEIGHT OF CONNECTING ROD BEARING

• When connecting rod bearing cap is removed after being tightened to the specified torque with the connecting rod bearings installed,

the tip end of the bearing must protrude. Refer to EM-83, "

Disas-

sembly and Assembly" for tightening procedure.

• If standard is not met, replace connecting rod bearings.

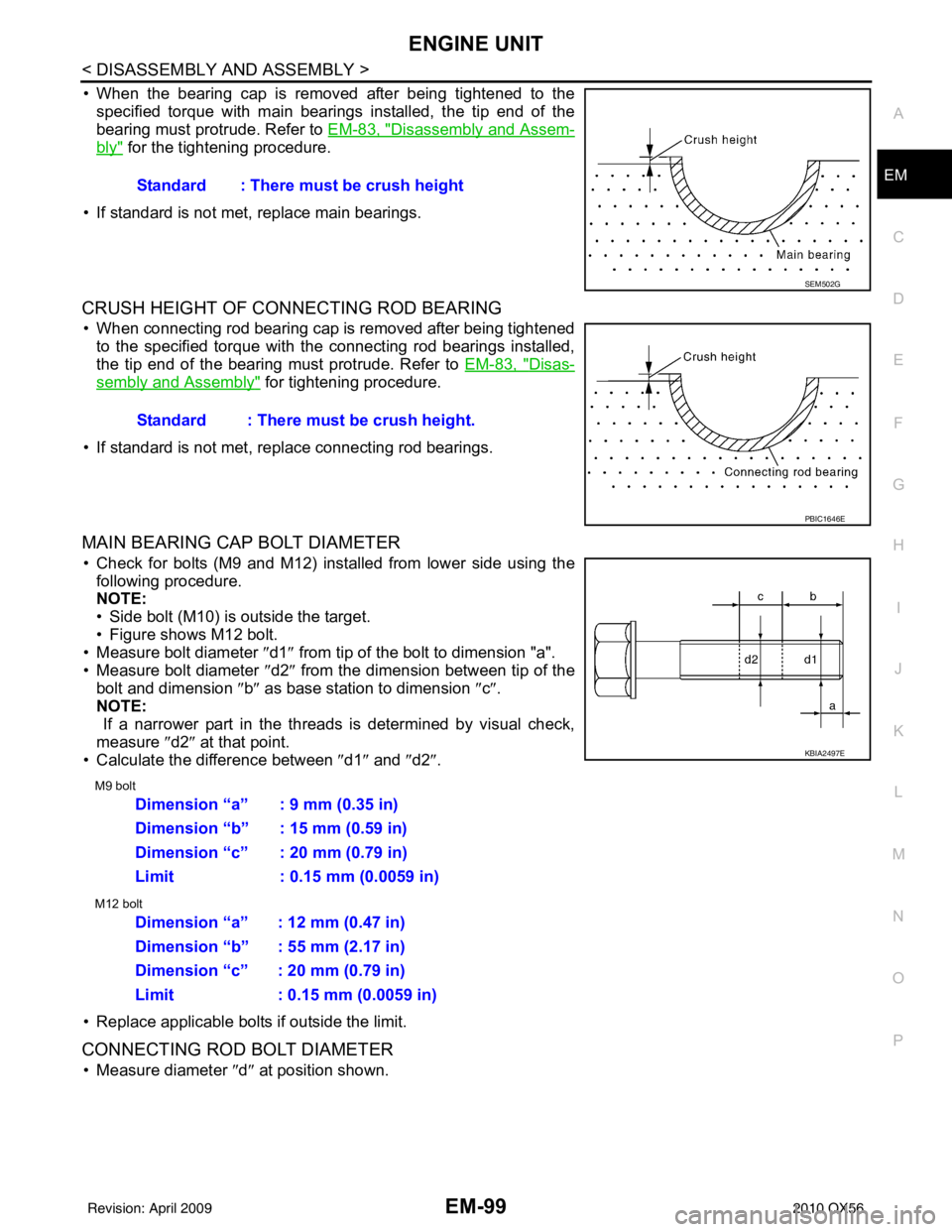

MAIN BEARING CAP BOLT DIAMETER

• Check for bolts (M9 and M12) installed from lower side using the following procedure.

NOTE:

• Side bolt (M10) is outside the target.

• Figure shows M12 bolt.

• Measure bolt diameter ″ d1″ from tip of the bolt to dimension "a".

• Measure bolt diameter ″d2″ from the dimension between tip of the

bolt and dimension ″b ″ as base station to dimension ″c″ .

NOTE:

If a narrower part in the threads is determined by visual check,

measure ″d2″ at that point.

• Calculate the difference between ″d1″ and ″d2″ .

M9 bolt

M12 bolt

• Replace applicable bolts if outside the limit.

CONNECTING ROD BOLT DIAMETER

• Measure diameter ″d ″ at position shown.

Standard : There must be crush height

SEM502G

Standard : There must be crush height.

PBIC1646E

KBIA2497E

Dimension “a” : 9 mm (0.35 in)

Dimension “b” : 15 mm (0.59 in)

Dimension “c” : 20 mm (0.79 in)

Limit : 0.15 mm (0.0059 in)

Dimension “a” : 12 mm (0.47 in)

Dimension “b” : 55 mm (2.17 in)

Dimension “c” : 20 mm (0.79 in)

Limit : 0.15 mm (0.0059 in)

Revision: April 20092010 QX56

Page 2173 of 4210

WHEEL HUBFAX-7

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

REMOVAL AND INSTALLATION

WHEEL HUB

Removal and InstallationINFOID:0000000005148944

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Without disassembling the hydraulic lines, remove caliper torque member bolts using power tool. Then

reposition brake caliper aside with wire. Refer to BR-31, "

Removal and Installation of Brake Caliper and

Rotor" .

NOTE:

Do not press brake pedal while brake caliper is removed.

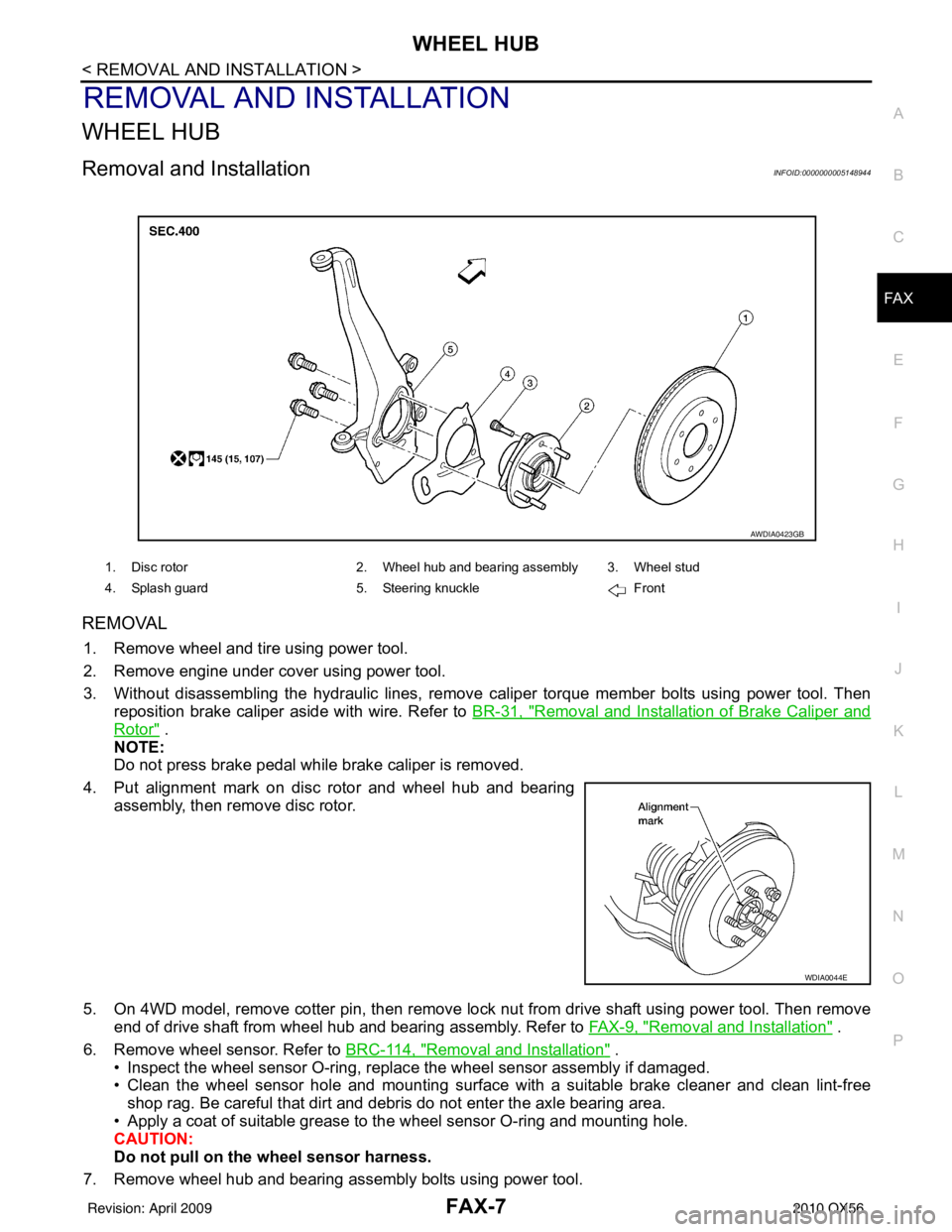

4. Put alignment mark on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

5. On 4WD model, remove cotter pin, then remove lock nut from drive shaft using power tool. Then remove end of drive shaft from wheel hub and bearing assembly. Refer to FAX-9, "

Removal and Installation" .

6. Remove wheel sensor. Refer to BRC-114, "

Removal and Installation" .

• Inspect the wheel sensor O-ring, replac e the wheel sensor assembly if damaged.

• Clean the wheel sensor hole and mounting surface with a suitable brake cleaner and clean lint-free shop rag. Be careful that dirt and debris do not enter the axle bearing area.

• Apply a coat of suitable grease to the wheel sensor O-ring and mounting hole.

CAUTION:

Do not pull on the wheel sensor harness.

7. Remove wheel hub and bearing assembly bolts using power tool.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle Front

AWDIA0423GB

WDIA0044E

Revision: April 20092010 QX56

Page 2205 of 4210

FSU-6

< ON-VEHICLE MAINTENANCE >

ON-VEHICLE SERVICE

ON-VEHICLE MAINTENANCE

ON-VEHICLE SERVICE

Front Suspension PartsINFOID:0000000005148108

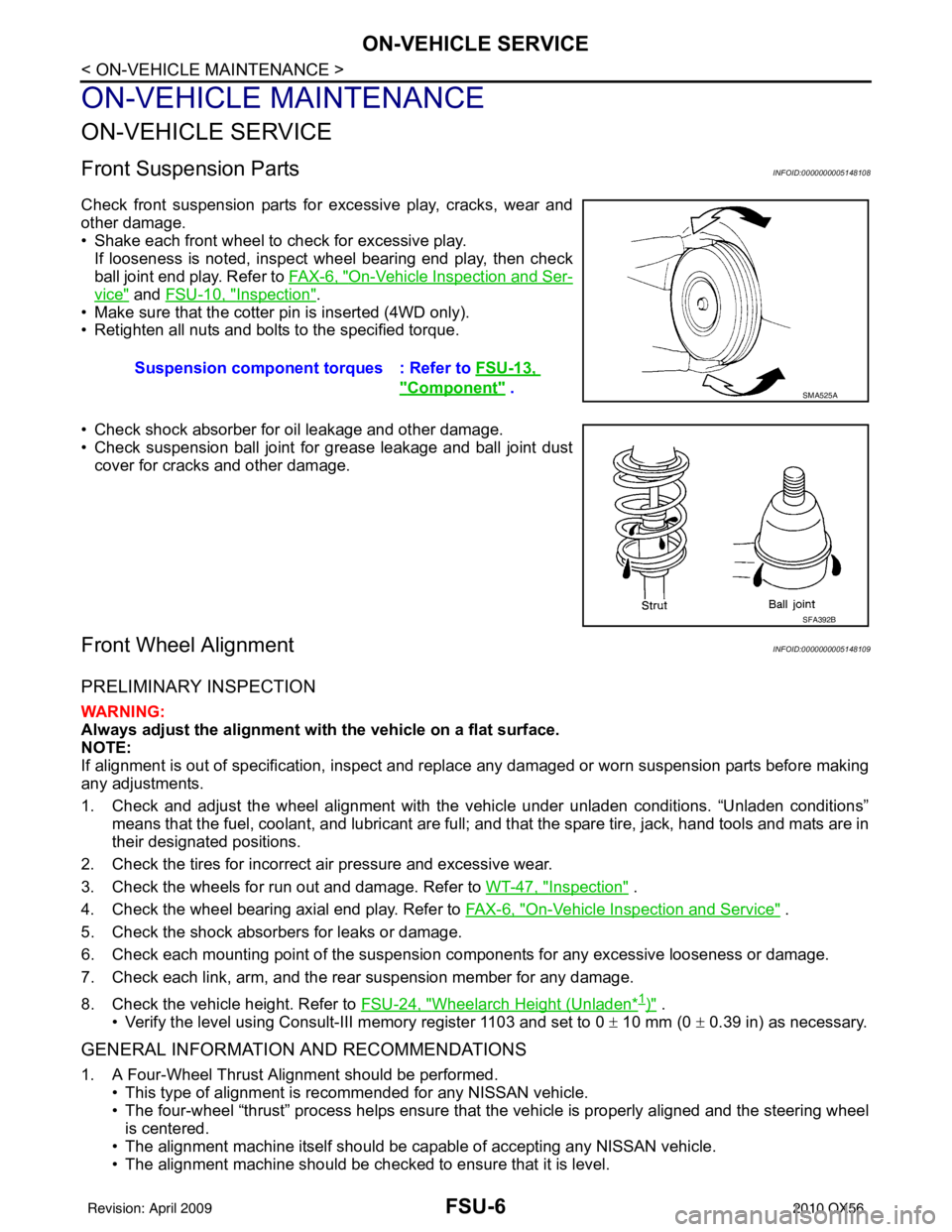

Check front suspension parts for excessive play, cracks, wear and

other damage.

• Shake each front wheel to check for excessive play.If looseness is noted, inspect wheel bearing end play, then check

ball joint end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Ser-

vice" and FSU-10, "Inspection".

• Make sure that the cotter pin is inserted (4WD only).

• Retighten all nuts and bolts to the specified torque.

• Check shock absorber for oil leakage and other damage.

• Check suspension ball joint for grease leakage and ball joint dust cover for cracks and other damage.

Front Wheel AlignmentINFOID:0000000005148109

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specificat ion, inspect and replace any damaged or worn suspension parts before making

any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-47, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to FSU-24, "

Wheelarch Height (Unladen*1)" .

• Verify the level using Consult-III memory register 1103 and set to 0 ± 10 mm (0 ± 0.39 in) as necessary.

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level. Suspension component

torques : Refer to FSU-13,

"Component" . SMA525A

SFA392B

Revision: April 20092010 QX56

Page 2209 of 4210

FSU-10

< ON-VEHICLE MAINTENANCE >

UPPER BALL JOINT AND LOWER BALL JOINT

UPPER BALL JOINT AND LOWER BALL JOINT

InspectionINFOID:0000000005148110

• Check the ball joint for excessive play. Replace the upper or lower link assembly if any of the followingexists:

- Ball joint stud is worn.

- Ball joint is hard to swing.

- Ball joint play in axial directions or end play is excessive.

Swinging Force

NOTE:

Before checking the axial forces and end play, turn the lower ball joint at least 10 revolutions so that the ball

joint is properly broken in.

1. Measure the ball joint swinging force using a suitable tool.

• Measure at the cotter pin hole for upper ball joint as shown.

• Measure at the groove for lower ball joint as shown.

2. Verify the ball joint swinging force is within specification.

Turning Force

Check the turning torque using a suitable tool.

NOTE:

Before checking the axial forces and end play, turn the lower ball

joint at least 10 revolutions so that the ball joint is properly broken in.

Vertical End Play

Check dust cover for damage. Replace it and the cover clamp if necessary.

NOTE:

WEIA0076E

Swinging force (A)

Upper ball joint : 8.1 - 103.2 N (0.8 - 10.5 kg-f, 1.8 - 23.2 lb-f)

Lower ball joint : 11.4 - 145.5 N (1.1 - 14.8 kg-f, 2.5 - 32.7 lb-f)

SFA858A

Turning torque (B) : 0.5 - 6.4 N·m (0.05 - 0.65 kg-m, 4 - 57 in-lb)

SFA858A

Revision: April 20092010 QX56

Page 2219 of 4210

FSU-20

< REMOVAL AND INSTALLATION >

KNUCKLE

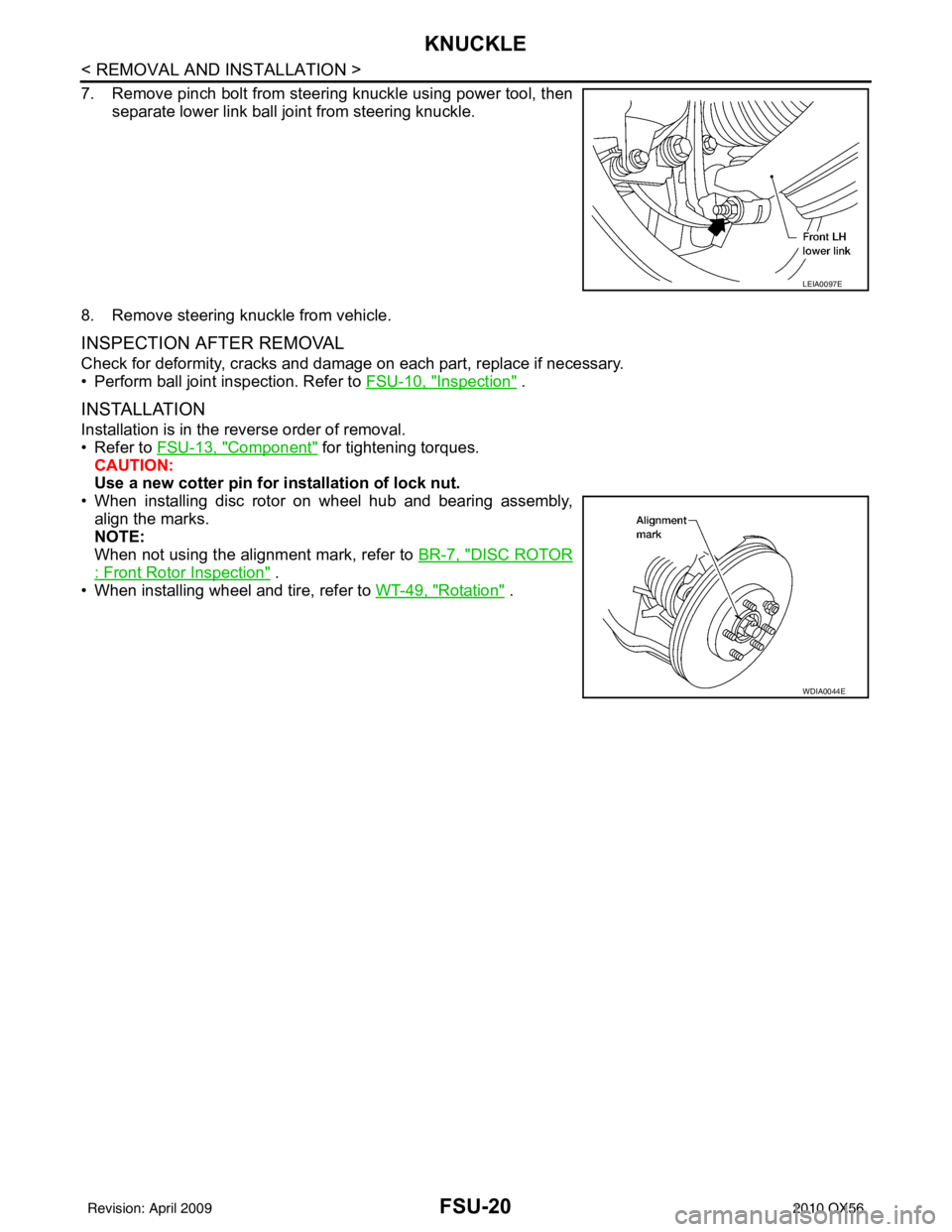

7. Remove pinch bolt from steering knuckle using power tool, thenseparate lower link ball joint from steering knuckle.

8. Remove steering knuckle from vehicle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

• Perform ball joint inspection. Refer to FSU-10, "

Inspection" .

INSTALLATION

Installation is in the reverse order of removal.

• Refer to FSU-13, "

Component" for tightening torques.

CAUTION:

Use a new cotter pin for installation of lock nut.

• When installing disc rotor on wheel hub and bearing assembly, align the marks.

NOTE:

When not using the alignment mark, refer to BR-7, "

DISC ROTOR

: Front Rotor Inspection" .

• When installing wheel and tire, refer to WT-49, "

Rotation" .

LEIA0097E

WDIA0044E

Revision: April 20092010 QX56

Page 2223 of 4210

FSU-24

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

*2: Target value 37° 31 ′ (37.52 °)

*3: Target value 33 ° 59 ′ (33.98 °)

*4: Target value 37 ° 44 ′ (37.73 °)

*5: Target value 33 ° 29 ′ (33.48 °)

Ball JointINFOID:0000000005148123

*1 Measure at cotter pin hole

*2 Measure at groove

Wheelarch Height (Unladen*1)INFOID:0000000005148124

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Verify the vehicle height. If vehicle height is not within ± 10 mm (0.39 in) of the specification, perform the control unit initialization pro-

cedure. Refer to SCS-7, "

CONSULT-III Function".

Swinging force (A)

Upper ball joint

8.1 – 103.2 N (0.8 – 10.5 kg-f, 1.8 – 23.2 lb-f) *1

Lower ball joint 11.4 – 145.5 N (1.1 – 14.8 kg-f, 2.5 – 32.7 lb-f) *2

Turning torque (B) 0.5 - 6.4 N·m (0.05 - 0.65 kg-m, 4 - 57 in-lb)

Vertical end play (C) 0 mm (0 in)

SFA858AWEIA0076E

Suspension type

Air leveling*2

Applied model2WD4WD

Front wheelarch height (Hf) 920

(36.22) 937

(36.89)

Rear wheelarch height (Hr) 917

(36.10) 937

(36.89)

LEIA0085E

Revision: April 20092010 QX56

Page 2224 of 4210

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector symbols ............................................. ......9

Sample/wiring diagram -example- ...........................10

Description ..............................................................11

ABBREVIATIONS .......................................... ....13

Abbreviation List .................................................. ....13

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

14

Tightening Torque Table .........................................14

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ............................................ ....

15

Recommended Chemical Products and Sealants ....15

TERMINOLOGY .................................................16

SAE J1930 Terminology List ............................... ....16

FEATURES OF NEW MODEL .....................20

IDENTIFICATION INFORMATION .....................20

Model Variation ................................................... ....20

Identification Number ..............................................21

Identification Plate ...................................................22

Dimensions .............................................................23

Wheels & Tires .................................................... ....23

PRECAUTION ..............................................24

PRECAUTIONS .................................................24

Description ........................................................... ....24

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

24

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

24

Procedures without Cowl Top Cover .......................25

General Precautions ................................................25

Three Way Catalyst .................................................27

Precaution for Fuel (Unleaded Premium Gasoline

Required) .................................................................

27

Multiport Fuel Injection System or Engine Control

System .....................................................................

27

Hoses ......................................................................27

Engine Oils ..............................................................28

Air Conditioning .......................................................29

LIFTING POINT .................................................30

Pantograph Jack ......................................................30

Garage Jack and Safety Stand ................................30

2-Pole Lift ................................................................30

TOW TRUCK TOWING .....................................32

Tow Truck Towing ...................................................32

Vehicle Recovery (Freeing a stuck vehicle) ............33

BASIC INSPECTION ...................................34

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

34

Work Flow ............................................................ ....34

Control Units and Electrical Parts ............................34

How to Check Terminal ...........................................35

Intermittent Incident ............................................. ....38

Circuit Inspection .....................................................41

CONSULT-III CHECKING SYSTEM .................46

Revision: April 20092010 QX56

Page 2226 of 4210

HOW TO USE THIS MANUALGI-3

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O PHOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

DescriptionINFOID:0000000005149567

This volume explains “Removal, Disassembly, Inst allation, Inspection and Adjustment” and “Trouble Diag-

noses”.

Te r m sINFOID:0000000005149568

• The captions WARNING and CAUTION warn you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNING indicates the possibility of personal injury if instructions are not followed.

CAUTION indicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTS except WARNING and CAUTION give you helpful information.

Standard value: Tolerance at inspection and adjustment.

Limit value: The maximum or minimum limit val ue that should not be exceeded at inspection and adjust-

ment.

UnitsINFOID:0000000005149569

• The UNITS given in this manual are primarily expressed as the SI UNIT (International System of Unit), and

alternatively expressed in the metric system and in the yard/pound system.

Also with regard to tightening torque of bolts and nuts, there are descriptions both about range and about the

standard tightening torque.

“Example”

Range

Standard

ContentsINFOID:0000000005149570

• A QUICK REFERENCE INDEX , a black tab (e.g. ) is provided on the first page. You can quickly find the

first page of each section by matching it to the section's black tab.

• THE CONTENTS are listed on the first page of each section.

• THE TITLE is indicated on the upper portion of each page and shows the part or system.

• THE PAGE NUMBER of each section consists of two or three letters which designate the particular section

and a number (e.g. “BR-5”).

• THE SMALL ILLUSTRATIONS show the important steps such as ins pection, use of special tools, knacks of

work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary. Outer Socket Lock Nut : 59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

Drive Shaft Installation Bolt : 44.3 N·m (4.5 kg-m, 33 ft-lb)

Revision: April 20092010 QX56

Page 2227 of 4210

GI-4

< HOW TO USE THIS MANUAL >

HOW TO USE THIS MANUAL

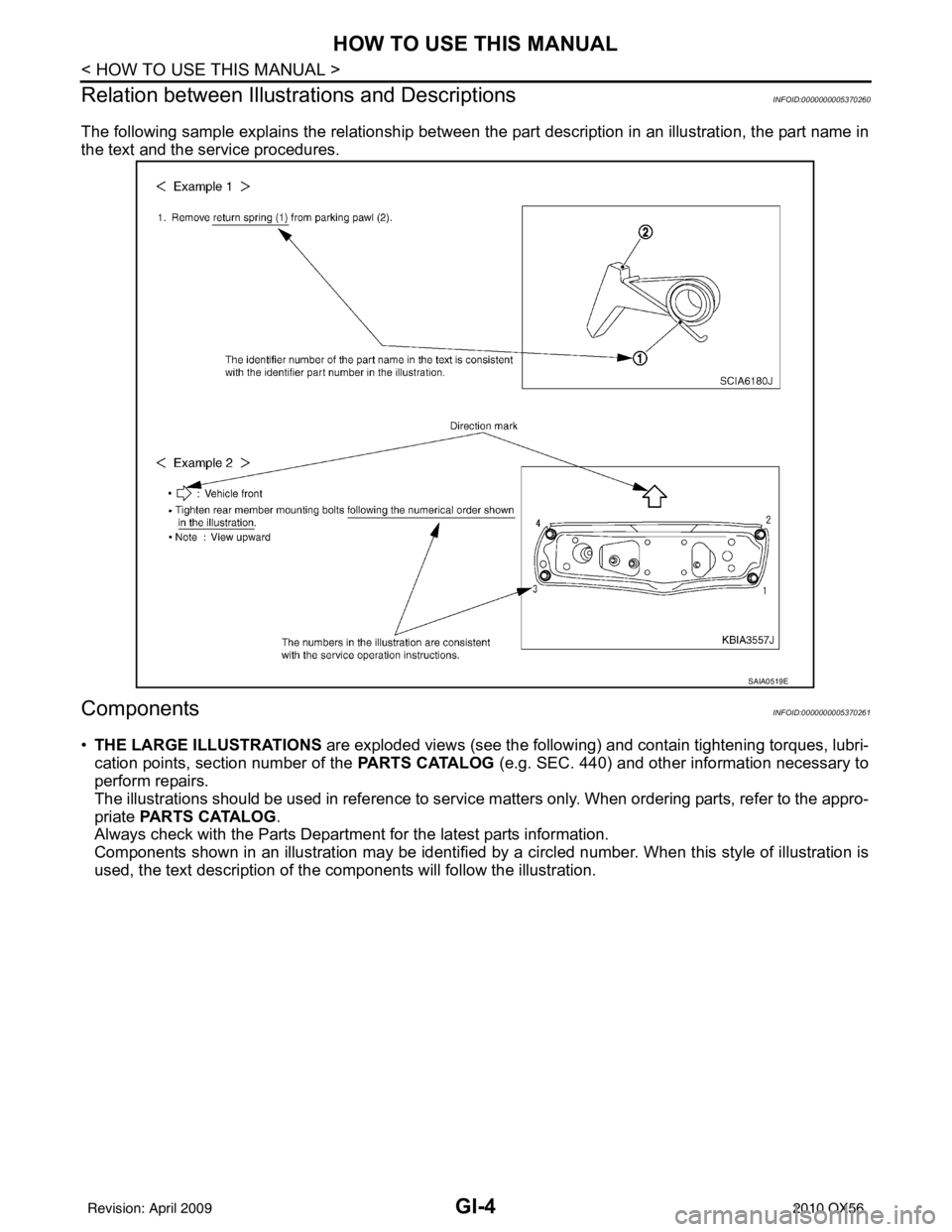

Relation between Illustrations and Descriptions

INFOID:0000000005370260

The following sample explains the relationship between t he part description in an illustration, the part name in

the text and the service procedures.

ComponentsINFOID:0000000005370261

• THE LARGE ILLUSTRATIONS are exploded views (see the following) and contain tightening torques, lubri-

cation points, section number of the PARTS CATALOG (e.g. SEC. 440) and other information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the appro-

priate PARTS CATALOG .

Always check with the Parts Department for the latest parts information.

Components shown in an illustration may be identified by a circled number. When this style of illustration is

used, the text description of the components will follow the illustration.

SAIA0519E

Revision: April 20092010 QX56

Page 2228 of 4210

HOW TO USE THIS MANUALGI-5

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

SYMBOLS

1. Union bolt 2. Copper washer3. Brake hose

4. Cap 5. Bleed valve6. Sliding pin bolt

7. Piston seal 8. Piston9. Piston boot

10. Cylinder body 11. Sliding pin12. Torque member mounting bolt

13. Washer 14. Sliding pin boot15. Bushing

16. Torque member 17. Inner shim cover18. Inner shim

19. Inner pad 20. Pad retainer21. Pad wear sensor

22. Outer pad 23. Outer shim24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease 2: Rubber grease

: Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Revision: April 20092010 QX56