torque INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 3216 of 4210

SERVICE DATA AND SPECIFICATIONS (SDS)RSU-29

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel AlignmentINFOID:0000000005148142

Ball JointINFOID:0000000005148143

Camber

Degree minute (decimal degree) Minimum

0° 0 ′ (0 °)

Nominal - 0° 30 ′ (-0.5 °)

Maximum - 1° 0 ′ (-1.0 °)

Cross camber 0° 45 ′ (0.75 °)

To e - i n Distance (A - B)

Minimum

0 mm (0 in)

Nominal 3.3 mm (0.130 in)

Maximum 6.6 mm (0.260 in)

Cross toe 2 mm (0.079 in)

Angle (left, right)

Degree minute (decimal degree) Minimum

0° 0 ′ (0 °)

Nominal 0° 7 ′ (0.11 °)

Maximum 0° 14 ′ (0.22 °)

Cross toe 0° 8 ′ (0.14 °)

SFA234AC

Swinging force (A)

(measurement point: cotter pin hole of ball stud) 11.4 - 145.5 N (1.16 - 14.8 kg, 2.56 - 32.7 lb)

Turning torque (B) 0.5 - 6.4 N·m (0.06 - 0.65 kg-m, 5 - 56 in-lb)

Vertical end play (C) 0 mm (0 in)

SFA858A

Revision: April 20092010 QX56

Page 3318 of 4210

SE-46

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for WorkINFOID:0000000005147404

• When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and keep them.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After re-installation is completed, be sure to check that each part works normally.

• Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water wit h mild detergent (concentration: within 2 to 3%), and wipe

the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

• Do not use organic solvent such as thinner, benzene, alcohol, or gasoline.

• For genuine leather seats, use a genuine leather seat cleaner.

Revision: April 20092010 QX56

Page 3644 of 4210

ST-6

< PREPARATION >

PREPARATION

Commercial Service Tool

INFOID:0000000005147858

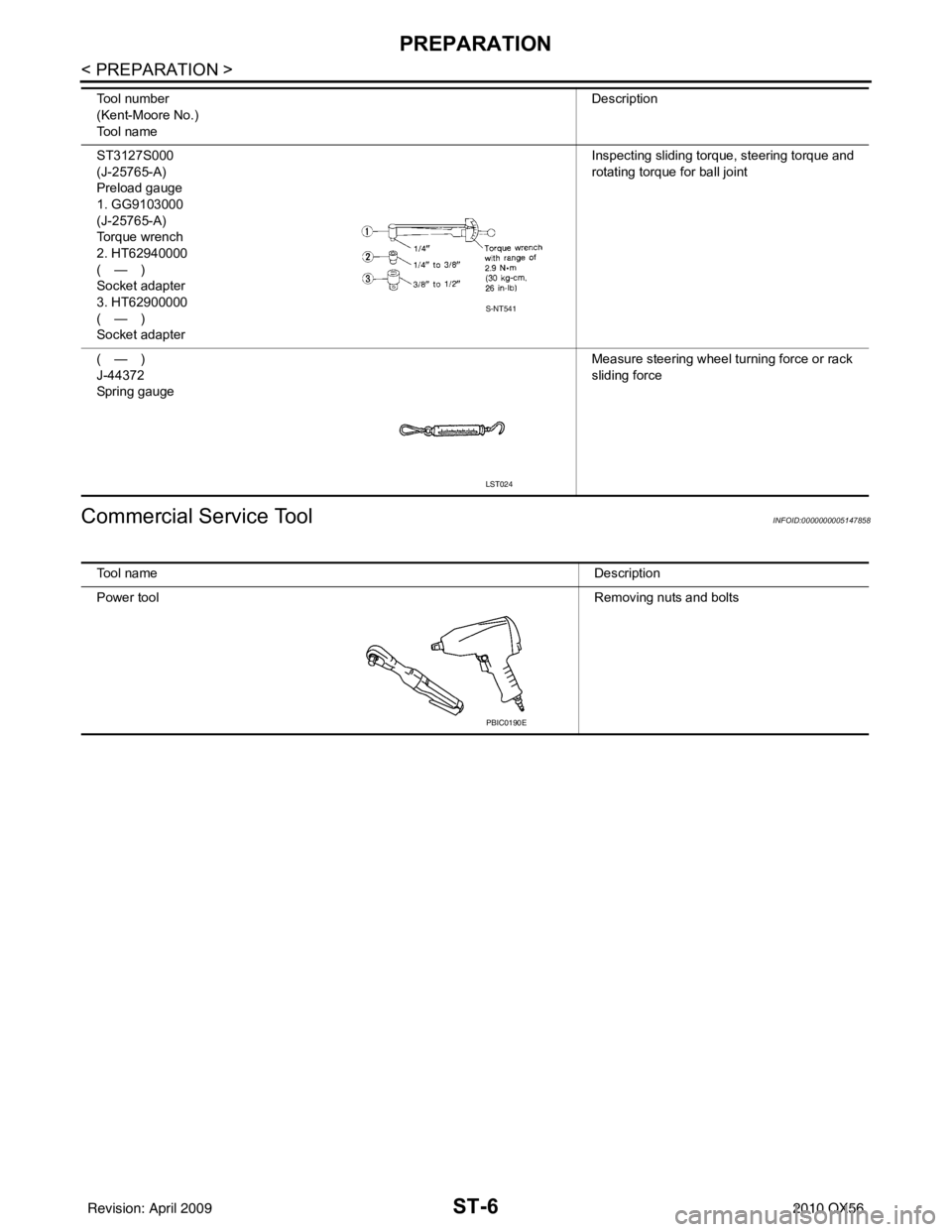

ST3127S000

(J-25765-A)

Preload gauge

1. GG9103000

(J-25765-A)

Torque wrench

2. HT62940000

(—)

Socket adapter

3. HT62900000

(—)

Socket adapter Inspecting sliding torque, steering torque and

rotating torque for ball joint

(—)

J-44372

Spring gauge Measure steering wheel turning force or rack

sliding force

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT541

LST024

Tool name

Description

Power tool Removing nuts and bolts

PBIC0190E

Revision: April 20092010 QX56

Page 3650 of 4210

ST-12

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005147864

Use chart below to help you find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

ST-13, "

Checking Fluid Level

"

ST-13, "

Air Bleeding Hydraulic System

"

ST-36ST-36ST-36ST-13ST-35ST-37

EM-13, "

Checking Drive Belts

"

ST-35ST-35ST-37ST-35ST-20ST-37

DLN-184, "

NVH Troubleshooting Chart

"

DLN-208, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

FSU-5, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

WT-43, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

BR-6, "

NVH Troubleshooting Chart

"

Possible cause and suspect-

ed parts

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

FRONT FINAL DRIVE

WHEEL HUB

SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom

Noise

× × ××××× × × ××××××× ×

Shake ×××× ××××× ×

Vibration ××××× × ××× ×

Shimmy ××× × ×××× ×

Shudder × × ×××× ×

Revision: April 20092010 QX56

Page 3664 of 4210

ST-26

< REMOVAL AND INSTALLATION >

POWER STEERING OIL PUMP

POWER STEERING OIL PUMP

Removal and InstallationINFOID:0000000005147874

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove engine room cover. Refer to EM-24, "

Removal and Installation".

3. Remove air duct assembly. Refer to EM-25, "

Removal and Installation".

4. Remove power steering reservoir tank.

5. Remove serpentine drive belt belt from auto tensioner and power steering pump. Refer to EM-13,

"Removal and Installation".

6. Disconnect pressure sensor electrical connector.

7. Remove high pressure and low pressure piping from power steering oil pump. Refer to ST-27

.

8. Remove bolts, then remove power steering pump.

INSTALLATION

Installation is in the reverse order of removal. Refer to ST-27 for tightening torque.

• After installation, bleed air. Refer to ST-13, "

Air Bleeding Hydraulic System".

NOTE:

Belt tension is automatic and requires no adjustment.

Revision: April 20092010 QX56

Page 3666 of 4210

ST-28

< REMOVAL AND INSTALLATION >

HYDRAULIC LINE

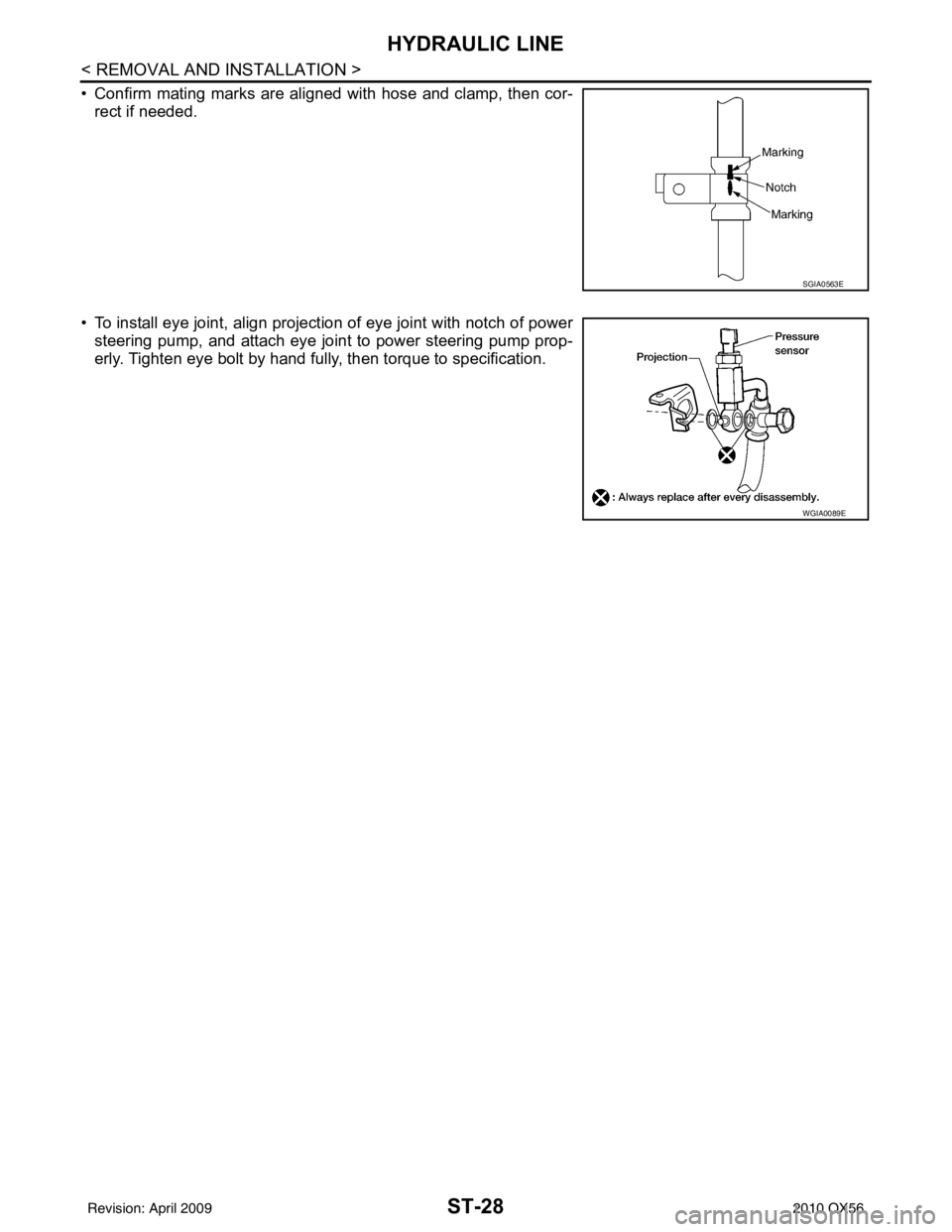

• Confirm mating marks are aligned with hose and clamp, then cor-rect if needed.

• To install eye joint, align projection of eye joint with notch of power steering pump, and attach eye joint to power steering pump prop-

erly. Tighten eye bolt by hand fully, then torque to specification.

SGIA0563E

WGIA0089E

Revision: April 20092010 QX56

Page 3670 of 4210

ST-32

< DISASSEMBLY AND ASSEMBLY >

POWER STEERING GEAR AND LINKAGE

Gear Housing Assembly

Check gear housing assembly for dents, cracks or damage. Replace as an assembly if necessary.

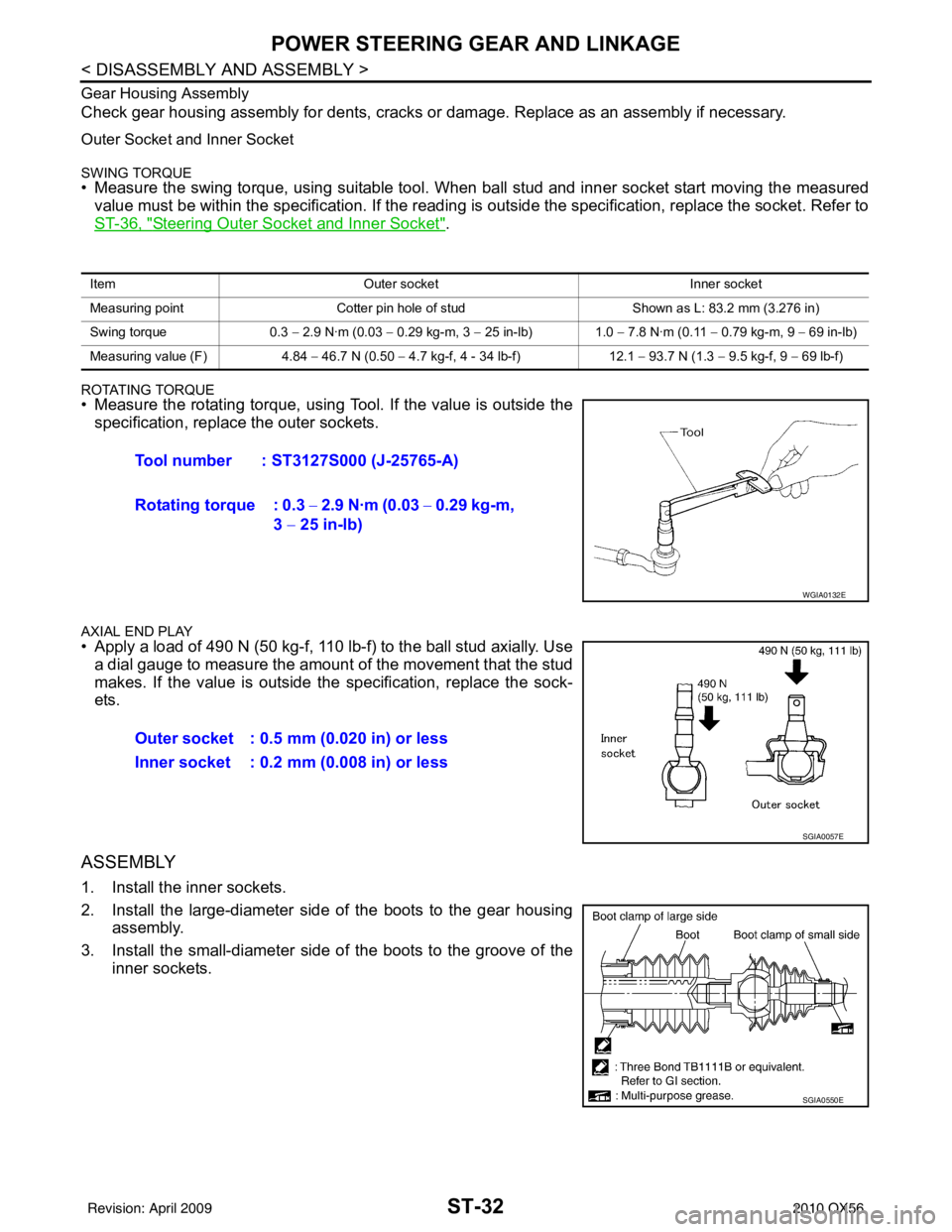

Outer Socket and Inner Socket

SWING TORQUE• Measure the swing torque, using suitable tool. When ball stud and inner socket start moving the measured

value must be within the specification. If the reading is outside the specification, replace the socket. Refer to

ST-36, "

Steering Outer Socket and Inner Socket".

ROTATING TORQUE• Measure the rotating torque, using Tool. If the value is outside the specification, replace the outer sockets.

AXIAL END PLAY• Apply a load of 490 N (50 kg-f, 110 lb-f) to the ball stud axially. Usea dial gauge to measure the amount of the movement that the stud

makes. If the value is outside the specification, replace the sock-

ets.

ASSEMBLY

1. Install the inner sockets.

2. Install the large-diameter side of the boots to the gear housing assembly.

3. Install the small-diameter side of the boots to the groove of the inner sockets.

Item Outer socket Inner socket

Measuring point Cotter pin hole of stud Shown as L: 83.2 mm (3.276 in)

Swing torque 0.3 − 2.9 N·m (0.03 − 0.29 kg-m, 3 − 25 in-lb) 1.0 − 7.8 N·m (0.11 − 0.79 kg-m, 9 − 69 in-lb)

Measuring value (F) 4.84 − 46.7 N (0.50 − 4.7 kg-f, 4 - 34 lb-f) 12.1 − 93.7 N (1.3 − 9.5 kg-f, 9 − 69 lb-f)

Tool number : ST3127S000 (J-25765-A)

Rotating torque : 0.3 − 2.9 N·m (0.03 − 0.29 kg-m,

3 − 25 in-lb)

WGIA0132E

Outer socket : 0.5 mm (0.020 in) or less

Inner socket : 0.2 mm (0.008 in) or less

SGIA0057E

SGIA0550E

Revision: April 20092010 QX56

Page 3674 of 4210

ST-36

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Inspection After Installation

Steering Outer Socket and Inner SocketINFOID:0000000005147881

Unit: mm (in)

Range “A”18°

Tilt mechanism range (Manual tilt) 3° per notch at 5 steps

WGIA0083E

Tie-rod ball joint outer socket Swinging torque (F)

0.3 − 2.9 N·m (0.03 − 0.29 kg-m, 3 − 25 in-lb)

Measurement on spring balance

• Measuring point: cotter pin hole of stud 4.84

− 46.7 N (0.50 − 4.7 kg-f, 4 − 34 lb-f)

Rotating torque 0.3 − 2.9 N·m (0.03 − 0.29 kg-m, 3 − 25 in-lb)

Axial end play 0.5 mm (0.020 in) or less

Tie-rod ball joint inner socket Swinging torque

1.0 − 7.8 N·m (0.11 − 0.79 kg-m, 9 − 69 in-lb)

Measurement on spring balance

• Measuring point: L mark see above, L=83.2 mm (3.276 in). 12.1

− 93.7 N (1.3 − 9.5 kg-f, 9 − 69 lb-f)

Axial end play 0.2 mm (0.08 in) or less

SGIA0358E

Inner socket length “L” 102.2 (4.02)

SGIA0167E

Revision: April 20092010 QX56

Page 3697 of 4210

TM-2

On Board Diagnosis Logic ......................................50

Possible Cause .......................................................50

DTC Confirmation Procedure .................................50

Diagnosis Procedure ..............................................51

P0725 ENGINE SPEED .....................................53

Description ........................................................... ...53

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

53

On Board Diagnosis Logic ......................................53

Possible Cause .......................................................53

DTC Confirmation Procedure .................................53

Diagnosis Procedure ..............................................53

P0731 1GR INCORRECT RATIO ......................55

Description ........................................................... ...55

On Board Diagnosis Logic ......................................55

Possible Cause .......................................................55

DTC Confirmation Procedure .................................55

Diagnosis Procedure ..............................................56

P0732 2GR INCORRECT RATIO ......................57

Description ........................................................... ...57

On Board Diagnosis Logic ......................................57

Possible Cause .......................................................57

DTC Confirmation Procedure .................................57

Diagnosis Procedure ..............................................58

P0733 3GR INCORRECT RATIO ......................59

Description ........................................................... ...59

On Board Diagnosis Logic ......................................59

Possible Cause .......................................................59

DTC Confirmation Procedure .................................59

Diagnosis Procedure ..............................................60

P0734 4GR INCORRECT RATIO ......................61

Description ........................................................... ...61

On Board Diagnosis Logic ......................................61

Possible Cause .......................................................61

DTC Confirmation Procedure .................................61

Diagnosis Procedure ..............................................62

P0735 5GR INCORRECT RATIO ......................63

Description ........................................................... ...63

On Board Diagnosis Logic ......................................63

Possible Cause .......................................................63

DTC Confirmation Procedure .................................63

Diagnosis Procedure ..............................................64

P0740 TORQUE CONVERTER .........................65

Description ........................................................... ...65

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

65

On Board Diagnosis Logic ......................................65

Possible Cause .......................................................65

DTC Confirmation Procedure .................................65

Diagnosis Procedure ..............................................65

P0744 TORQUE CONVERTER .........................67

Description ........................................................... ...67

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

67

On Board Diagnosis Logic ......................................67

Possible Cause .......................................................67

DTC Confirmation Procedure ..................................67

Diagnosis Procedure ...............................................68

P0745 PRESSURE CONTROL SOLENOID A ...69

Description ........................................................... ...69

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

69

On Board Diagnosis Logic ......................................69

Possible Cause .......................................................69

DTC Confirmation Procedure ..................................69

Diagnosis Procedure ...............................................69

P1705 TP SENSOR ...........................................71

Description ..............................................................71

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

71

On Board Diagnosis Logic ......................................71

Possible Cause .......................................................71

DTC Confirmation Procedure ..................................71

Diagnosis Procedure ...............................................71

P1710 TRANSMISSION FLUID TEMPERA-

TURE SENSOR .................................................

73

Description ........................................................... ...73

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

73

On Board Diagnosis Logic ......................................73

Possible Cause .......................................................73

DTC Confirmation Procedure ..................................73

Diagnosis Procedure ...............................................73

Component Inspection ............................................74

P1721 VEHICLE SPEED SIGNAL ....................76

Description ..............................................................76

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

76

On Board Diagnosis Logic ......................................76

Possible Cause .......................................................76

DTC Confirmation Procedure ..................................76

Diagnosis Procedure ...............................................76

P1730 INTERLOCK ...........................................78

Description ..............................................................78

On Board Diagnosis Logic ......................................78

Possible Cause .......................................................78

DTC Confirmation Procedure ..................................78

Judgment of Interlock ..............................................78

Diagnosis Procedure ...............................................78

P1731 1ST ENGINE BRAKING .........................80

Description ........................................................... ...80

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

80

On Board Diagnosis Logic ......................................80

Possible Cause .......................................................80

DTC Confirmation Procedure ..................................80

Revision: April 20092010 QX56

Page 3699 of 4210

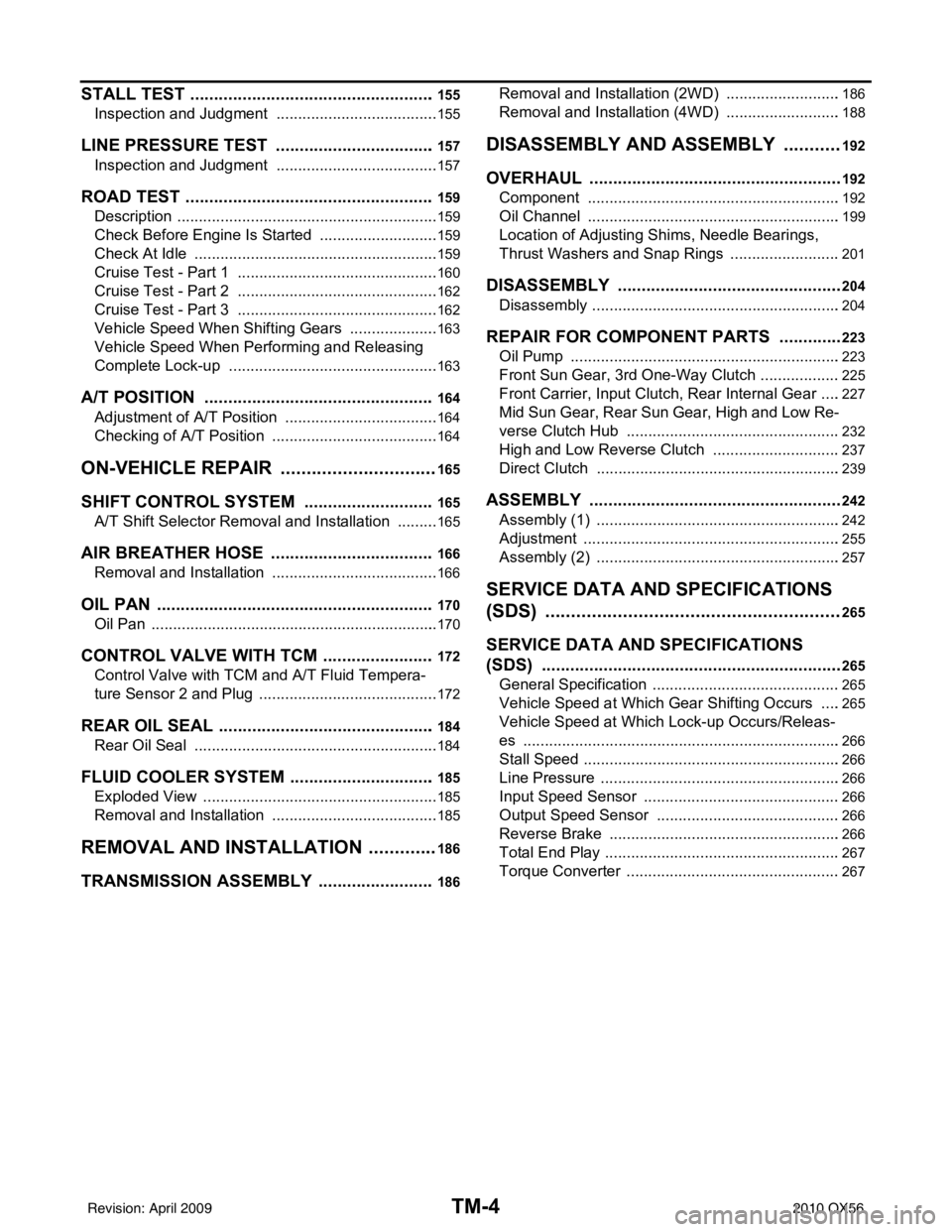

TM-4

STALL TEST ....................................................155

Inspection and Judgment .................................... ..155

LINE PRESSURE TEST ..................................157

Inspection and Judgment .................................... ..157

ROAD TEST .....................................................159

Description ........................................................... ..159

Check Before Engine Is Started ............................159

Check At Idle ....................................................... ..159

Cruise Test - Part 1 ...............................................160

Cruise Test - Part 2 ...............................................162

Cruise Test - Part 3 ...............................................162

Vehicle Speed When Shifting Gears .....................163

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

163

A/T POSITION .................................................164

Adjustment of A/T Position .................................. ..164

Checking of A/T Position .......................................164

ON-VEHICLE REPAIR ...............................165

SHIFT CONTROL SYSTEM ........................... .165

A/T Shift Selector Removal and Installation ..........165

AIR BREATHER HOSE .................................. .166

Removal and Installation ..................................... ..166

OIL PAN ...........................................................170

Oil Pan ................................................................. ..170

CONTROL VALVE WITH TCM ........................172

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 and Plug ........................................ ..

172

REAR OIL SEAL ..............................................184

Rear Oil Seal ....................................................... ..184

FLUID COOLER SYSTEM ...............................185

Exploded View ..................................................... ..185

Removal and Installation .......................................185

REMOVAL AND INSTALLATION ..............186

TRANSMISSION ASSEMBLY ........................ .186

Removal and Installation (2WD) .......................... .186

Removal and Installation (4WD) ...........................188

DISASSEMBLY AND ASSEMBLY ...........192

OVERHAUL ......................................................192

Component .......................................................... .192

Oil Channel ...........................................................199

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

201

DISASSEMBLY .............................................. ..204

Disassembly ......................................................... .204

REPAIR FOR COMPONENT PARTS ..............223

Oil Pump .............................................................. .223

Front Sun Gear, 3rd One-Way Clutch ...................225

Front Carrier, Input Clutch, Rear Internal Gear .....227

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ................................................. .

232

High and Low Reverse Clutch ..............................237

Direct Clutch .........................................................239

ASSEMBLY .................................................... ..242

Assembly (1) ........................................................ .242

Adjustment ............................................................255

Assembly (2) .........................................................257

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

265

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

265

General Specification ........................................... .265

Vehicle Speed at Which Gear Shifting Occurs .....265

Vehicle Speed at Which Lock-up Occurs/Releas-

es ......................................................................... .

266

Stall Speed ............................................................266

Line Pressure ........................................................266

Input Speed Sensor ..............................................266

Output Speed Sensor ...........................................266

Reverse Brake ......................................................266

Total End Play .......................................................267

Torque Converter ..................................................267

Revision: April 20092010 QX56