wiring diagram INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1171 of 4210

![INFINITI QX56 2010 Factory Service Manual TRANSFER CONTROL UNITDLN-89

< ECU DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Wiring Diagram - A LL-MODE 4WD SYSTEM -INFOID:0000000005148854

ABDWA0015GB

Revision: April 20092010 QX56 INFINITI QX56 2010 Factory Service Manual TRANSFER CONTROL UNITDLN-89

< ECU DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Wiring Diagram - A LL-MODE 4WD SYSTEM -INFOID:0000000005148854

ABDWA0015GB

Revision: April 20092010 QX56](/img/42/57032/w960_57032-1170.png)

TRANSFER CONTROL UNITDLN-89

< ECU DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Wiring Diagram - A LL-MODE 4WD SYSTEM -INFOID:0000000005148854

ABDWA0015GB

Revision: April 20092010 QX56

Page 1185 of 4210

![INFINITI QX56 2010 Factory Service Manual 4WD SHIFT INDICATOR LAMP AND 4LO INDICATOR LAMP DO NOT TURN ON

DLN-103

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD SHIFT INDICATOR LAMP AND 4LO INDICATOR LAMP DO NOT

TURN ON

D INFINITI QX56 2010 Factory Service Manual 4WD SHIFT INDICATOR LAMP AND 4LO INDICATOR LAMP DO NOT TURN ON

DLN-103

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD SHIFT INDICATOR LAMP AND 4LO INDICATOR LAMP DO NOT

TURN ON

D](/img/42/57032/w960_57032-1184.png)

4WD SHIFT INDICATOR LAMP AND 4LO INDICATOR LAMP DO NOT TURN ON

DLN-103

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD SHIFT INDICATOR LAMP AND 4LO INDICATOR LAMP DO NOT

TURN ON

DescriptionINFOID:0000000005148857

4WD shift indicator lamp and 4LO indicator lamp do not turn ON for approx. 1 second when turning ignition

switch to ON.

Diagnosis ProcedureINFOID:0000000005148858

Regarding Wiring Diagram information, refer to DLN-89, "Wiring Diagram - ALL-MODE 4WD SYSTEM -".

1.CHECK TRANSFER CONTROL UNIT POWER SUPPLY AND GROUND CIRCUITS

Refer to DLN-22, "

Diagnosis Procedure".

Are the inspection results normal?

YES >> GO TO 2.

NO >> Repair as necessary.

2.CHECK COMBINATION METER POWER SUPPLY AND GROUND CIRCUITS

Refer to MWI-28, "

COMBINATION METER : Diagnosis Procedure".

Are the inspection results normal?

YES >> GO TO 3.

NO >> Perform repairs as necessary.

3.CHECK HARNESS BETWEEN TR ANSFER CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check continuity between the following terminals.

- Transfer control unit harness connector E142 (B) terminal 2 and combination meter harness connector M24 (A) terminal 38.

- Transfer control unit harness connector E142 (B) terminal 11 and combination meter harness connector M24 (A) terminal 29.

- Transfer control unit harness connector E142 (B) terminal 12 and combination meter harness connector M24 (A) terminal 39.

- Transfer control unit harness connector E142 (B) terminal 21

and combination meter harness connector M24 (A) terminal 28.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK INDICATOR LAMP CIRCUIT

1. Connect combination meter harness connector.

2. Turn ignition switch ON. Continuity should exist.

AWDIA0184ZZ

Revision: April 20092010 QX56

Page 1187 of 4210

![INFINITI QX56 2010 Factory Service Manual 4WD WARNING LAMP DOES NOT TURN ONDLN-105

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD WARNING LAMP DOES NOT TURN ON

DescriptionINFOID:0000000005148859

4WD warning lamp does not INFINITI QX56 2010 Factory Service Manual 4WD WARNING LAMP DOES NOT TURN ONDLN-105

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD WARNING LAMP DOES NOT TURN ON

DescriptionINFOID:0000000005148859

4WD warning lamp does not](/img/42/57032/w960_57032-1186.png)

4WD WARNING LAMP DOES NOT TURN ONDLN-105

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

4WD WARNING LAMP DOES NOT TURN ON

DescriptionINFOID:0000000005148859

4WD warning lamp does not turn ON when turning ignition switch to ON.

Diagnosis ProcedureINFOID:0000000005148860

Regarding Wiring Diagram information, refer to DLN-89, "Wiring Diagram - ALL-MODE 4WD SYSTEM -".

1.CHECK TRANSFER CONTROL UNIT POWER SUPPLY AND GROUND CIRCUITS

Refer to DLN-22, "

Diagnosis Procedure".

Are the inspection results normal?

YES >> GO TO 2.

NO >> Repair as necessary.

2.CHECK COMBINATION METER POWER SUPPLY AND GROUND CIRCUITS

Refer to MWI-28, "

COMBINATION METER : Diagnosis Procedure".

Are the inspection results normal?

YES >> GO TO 3.

NO >> Perform repairs as necessary.

3.CHECK HARNESS BETWEEN TR ANSFER CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit and combination meter harness connectors.

3. Check continuity between the following terminals.

- Transfer control unit harness connector E142 (A) terminal 5 and combination meter harness connector M23 (B) terminal 49.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK INDICATOR LAMP CIRCUIT

1. Connect combination meter harness connector.

2. Turn ignition switch ON. (Do not start engine.)

3. Ground the following terminal using suitable wiring.

- Transfer control unit harness connector E142 terminal 5 and ground.

Does 4WD warning lamp turn on?

YES >> GO TO 5.

NO >> Replace combination meter. Refer to MWI-100,

"Removal and Installation".

5.SYMPTOM CHECK

Check again.

Are the inspection results normal?

YES >> Inspection End. Continuity should exist.

AWDIA0187ZZ

SDIA2774E

Revision: April 20092010 QX56

Page 1191 of 4210

![INFINITI QX56 2010 Factory Service Manual ATP WARNING LAMP DOES NOT TURN ONDLN-109

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ATP WARNING LAMP DOES NOT TURN ON

DescriptionINFOID:0000000005148863

ATP warning lamp does not INFINITI QX56 2010 Factory Service Manual ATP WARNING LAMP DOES NOT TURN ONDLN-109

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ATP WARNING LAMP DOES NOT TURN ON

DescriptionINFOID:0000000005148863

ATP warning lamp does not](/img/42/57032/w960_57032-1190.png)

ATP WARNING LAMP DOES NOT TURN ONDLN-109

< SYMPTOM DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ATP WARNING LAMP DOES NOT TURN ON

DescriptionINFOID:0000000005148863

ATP warning lamp does not turn ON when the transfer case is switched in or out of 4LO with the A/T selector

lever in N position.

Diagnosis ProcedureINFOID:0000000005148864

Regarding Wiring Diagram information, refer to DLN-89, "Wiring Diagram - ALL-MODE 4WD SYSTEM -".

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to DLN-18, "

CONSULT-III Function (ALL MODE AWD/4WD)".

Do the self-diagnostic results indicate CAN communication?

YES >> Perform trouble diagnosis for CAN communication line.

NO >> GO TO 2.

2.CHECK SYSTEM FOR 4WD SHIFT SWITCH

Perform trouble diagnosis for 4WD shift switch system. Refer to DLN-32, "

Diagnosis Procedure".

Are the inspection results normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK SYSTEM FOR TRANSMIS SION RANGE SWITCH SIGNAL

Perform trouble diagnosis for transmission range switch signal system. Refer to DLN-39, "

Diagnosis Proce-

dure".

Are the inspection results normal?

YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK SYSTEM FOR ATP SWITCH

Perform trouble diagnosis for ATP switch system. Refer to DLN-116, "

Diagnosis Procedure".

Are the inspection results normal?

YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK HARNESS BETWEEN TR ANSFER CONTROL UNIT AND COMBINATION METER

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and combination meter harness connector.

3. Check continuity between the following terminals.

- Transfer control unit harness connector E142 (B) terminal 15 and combination meter harness connector M23 (A) terminal 43.

Continuity should exist.

AWDIA0185ZZ

Revision: April 20092010 QX56

Page 1198 of 4210

![INFINITI QX56 2010 Factory Service Manual DLN-116

< SYMPTOM DIAGNOSIS >[ATX14B]

ATP SWITCH

ATP SWITCH

DescriptionINFOID:0000000005148873

The ATP indicator is ON when the transfer case is not in neutral.

Diagnosis ProcedureINFOID:0000000005148 INFINITI QX56 2010 Factory Service Manual DLN-116

< SYMPTOM DIAGNOSIS >[ATX14B]

ATP SWITCH

ATP SWITCH

DescriptionINFOID:0000000005148873

The ATP indicator is ON when the transfer case is not in neutral.

Diagnosis ProcedureINFOID:0000000005148](/img/42/57032/w960_57032-1197.png)

DLN-116

< SYMPTOM DIAGNOSIS >[ATX14B]

ATP SWITCH

ATP SWITCH

DescriptionINFOID:0000000005148873

The ATP indicator is ON when the transfer case is not in neutral.

Diagnosis ProcedureINFOID:0000000005148874

Regarding Wiring Diagram information, refer to

DLN-89, "Wiring Diagram - ALL-MODE 4WD SYSTEM -".

1.CHECK ATP SWITCH SIGNAL

With CONSULT-III

1. Start engine.

2. Select DATA MONITOR mode for ALL MODE AWD/4WD with CONSULT-III.

3. Read out the value of ATP SWITCH.

Without CONSULT-III

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminal and ground.

Are inspection results normal?

YES >> GO TO 5.

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND ATP SWITCH

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the ATP switch harness connector.

3. Check continuity between transfer control unit harness connec- tor E143 terminal 40 and ATP switch harness connector F55 ter-

minal 8.

Also check harness for short to ground and short to power.

Are inspection results normal?

YES >> GO TO 3.

NO >> Repair or replace damaged parts.

Condition Display value

• Vehicle stopped

• Engine running

• A/T selector lever N

• Brake pedal de-

pressed 4WD shift switch

: 4H to 4LO or 4LO to 4H

(While actuator motor is operating.)

ON

Except the above OFF

Connector TerminalConditionVoltage

(Approx.)

E143 40 -

Ground • Vehicle stopped

• Engine running

• A/T selector lever

N

• Brake pedal de-

pressed 4WD shift switch: 4H

to 4LO or 4LO to 4H

(While actuator motor

is operating.)

0V

Except the above Battery

voltage

SDIA2755E

Continuity should exist.

SDIA2756E

Revision: April 20092010 QX56

Page 1360 of 4210

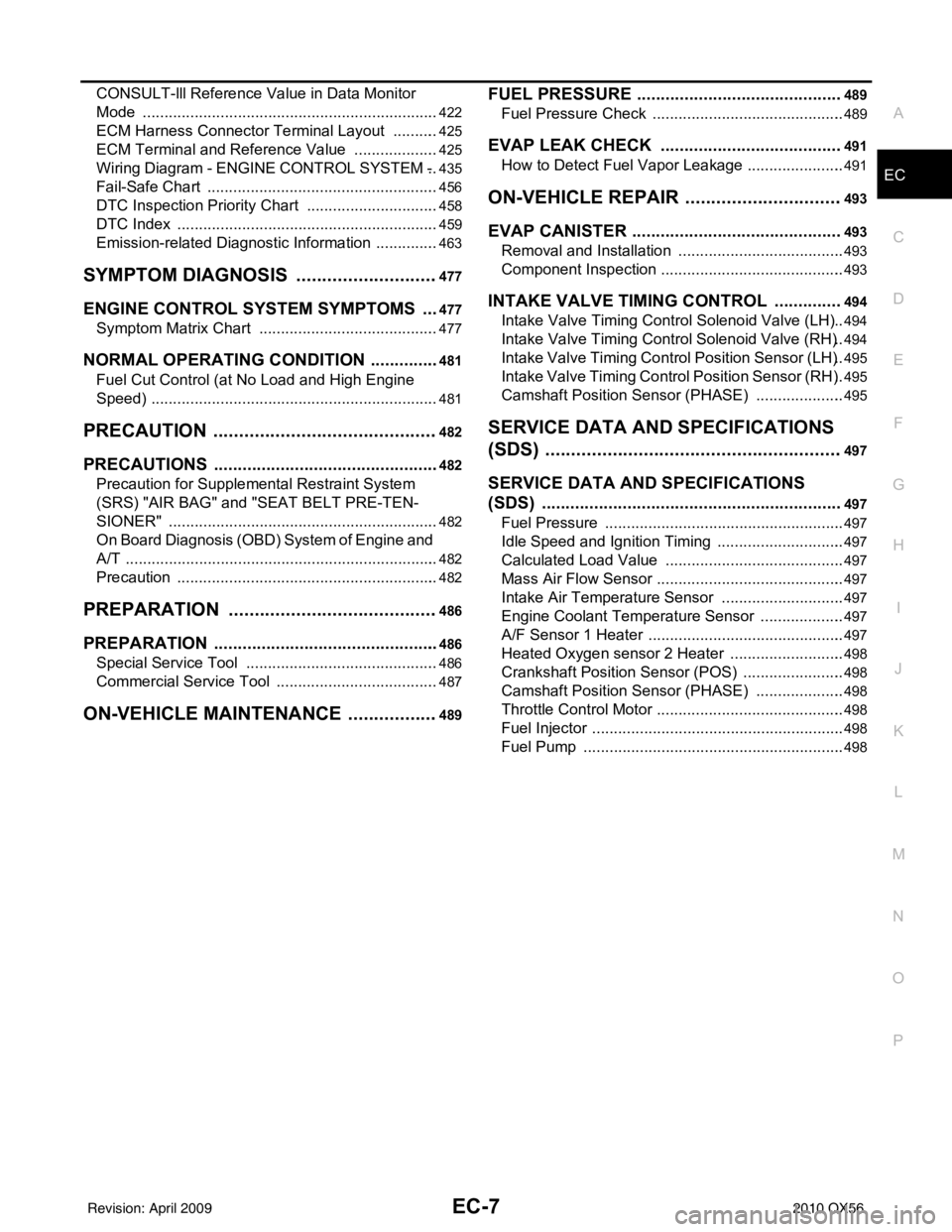

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

CONSULT-lll Reference Va

lue in Data Monitor

Mode ................................................................... ..

422

ECM Harness Connector Terminal Layout ...........425

ECM Terminal and Reference Value ....................425

Wiring Diagram - ENGINE CONTROL SYSTEM - ..435

Fail-Safe Chart .................................................... ..456

DTC Inspection Priority Chart ............................. ..458

DTC Index ........................................................... ..459

Emission-related Diagnostic Information ...............463

SYMPTOM DIAGNOSIS ..... .......................477

ENGINE CONTROL SYSTEM SYMPTOMS .. ..477

Symptom Matrix Chart ........................................ ..477

NORMAL OPERATING CONDITION ...............481

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

481

PRECAUTION ............................................482

PRECAUTIONS .............................................. ..482

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

482

On Board Diagnosis (OBD) System of Engine and

A/T .........................................................................

482

Precaution .............................................................482

PREPARATION .........................................486

PREPARATION .............................................. ..486

Special Service Tool ........................................... ..486

Commercial Service Tool ......................................487

ON-VEHICLE MAINTENANCE ..................489

FUEL PRESSURE ...........................................489

Fuel Pressure Check ........................................... ..489

EVAP LEAK CHECK ......................................491

How to Detect Fuel Vapor Leakage .......................491

ON-VEHICLE REPAIR ...............................493

EVAP CANISTER ............................................493

Removal and Installation ..................................... ..493

Component Inspection ...........................................493

INTAKE VALVE TIMING CONTROL ..............494

Intake Valve Timing Control Solenoid Valve (LH) ..494

Intake Valve Timing Cont rol Solenoid Valve (RH) ..494

Intake Valve Timing Control Position Sensor (LH) ..495

Intake Valve Timing Control Position Sensor (RH) ..495

Camshaft Position Sensor (PHASE) .....................495

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... .

497

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

497

Fuel Pressure ...................................................... ..497

Idle Speed and Ignition Timing ..............................497

Calculated Load Value ..........................................497

Mass Air Flow Sensor ............................................497

Intake Air Temperature Sensor .............................497

Engine Coolant Temperature Sensor ....................497

A/F Sensor 1 Heater ..............................................497

Heated Oxygen sensor 2 Heater ...........................498

Crankshaft Position Sensor (POS) ........................498

Camshaft Position Sensor (PHASE) .....................498

Throttle Control Motor ............................................498

Fuel Injector ...........................................................498

Fuel Pump .............................................................498

Revision: April 20092010 QX56

Page 1435 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-82

< COMPONENT DIAGNOSIS >[VK56DE]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000005149085

1.INSPECTION START

Start engine.

Is engine running?

Ye INFINITI QX56 2010 Factory Service Manual EC-82

< COMPONENT DIAGNOSIS >[VK56DE]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000005149085

1.INSPECTION START

Start engine.

Is engine running?

Ye](/img/42/57032/w960_57032-1434.png)

EC-82

< COMPONENT DIAGNOSIS >[VK56DE]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000005149085

1.INSPECTION START

Start engine.

Is engine running?

Ye s o r N o

Ye s > > G O T O 8 .

No >> GO TO 2.

2.CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF and then ON.

2. Check voltage between ECM terminal 109 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• 10A fuse (No. 59)

• Harness for open or short between ECM and fuse

>> Repair harness or connectors.

4.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body. Refer to EC-85, "

Ground Inspection".

OK or NG

OK >> GO TO 5.

NG >> Repair or replace ground connections.

5.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 1, 115, 116 and ground. Refer to Wiring Diagram.

3. Also check harness for short to power. Voltage: Battery voltage

MBIB0015E

BBIA0354E

Continuity should exist.

Revision: April 20092010 QX56

Page 1437 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-84

< COMPONENT DIAGNOSIS >[VK56DE]

POWER SUPPLY AND GROUND CIRCUIT

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open INFINITI QX56 2010 Factory Service Manual EC-84

< COMPONENT DIAGNOSIS >[VK56DE]

POWER SUPPLY AND GROUND CIRCUIT

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open](/img/42/57032/w960_57032-1436.png)

EC-84

< COMPONENT DIAGNOSIS >[VK56DE]

POWER SUPPLY AND GROUND CIRCUIT

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

11 .CHECK ECM POWER SUPPLY CIRCUIT-VI

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E119.

3. Check harness continuity between ECM terminal 111 and IPDM E/R terminal 7. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 12.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK 20 A FUSE

1. Disconnect 20 A fuse from IPDM E/R.

2. Check 20 A fuse (No. 53).

OK or NG

OK >> GO TO 16.

NG >> Replace 20 A fuse.

13.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground three screws on the body. Refer to EC-85, "

Ground Inspection".

OK or NG

OK >> GO TO 14.

NG >> Repair or replace ground connections.

14.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 1, 115, 116 and ground. Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 16.

NG >> GO TO 15.

15.DETECT MALFUNCTIONING PART Continuity should exist.

Continuity should exist.

BBIA0354E

Continuity should exist.

Revision: April 20092010 QX56

Page 1443 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-90

< COMPONENT DIAGNOSIS >[VK56DE]

P0011, P0021 IVT CONTROL

Refer to EC-85, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK INTAKE VALVE TIMING CONT INFINITI QX56 2010 Factory Service Manual EC-90

< COMPONENT DIAGNOSIS >[VK56DE]

P0011, P0021 IVT CONTROL

Refer to EC-85, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK INTAKE VALVE TIMING CONT](/img/42/57032/w960_57032-1442.png)

EC-90

< COMPONENT DIAGNOSIS >[VK56DE]

P0011, P0021 IVT CONTROL

Refer to EC-85, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK INTAKE VALVE TIMING CONTROL PO SITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect intake valve timing control position sensor harness connector.

2. Turn ignition switch ON.

3. Check voltage between intake valve timing control position sen- sor terminal 3 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between intake valve timing control position sensor and ECM

• Harness for open or short between intake valve timing control position sensor and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK INTAKE VALVE TIMING CONTROL POSI TION SENSOR GROUND CIRCUIT FOR OPEN AND

SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between intake valve timing control position sensor terminal 1 and ground.

Refer to Wiring Diagram.

BBIA0354E

1. Intake valve timing control position

sensor (bank 2) 2. Intake valve timing control solenoid

valve (bank 2) 3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1) 6. Intake valve timing control position

sensor (bank 1)

Voltage: Battery voltage

BBIA0771E

PBIB2613E

Revision: April 20092010 QX56

Page 1444 of 4210

![INFINITI QX56 2010 Factory Service Manual P0011, P0021 IVT CONTROLEC-91

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Also check harness for short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING INFINITI QX56 2010 Factory Service Manual P0011, P0021 IVT CONTROLEC-91

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Also check harness for short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING](/img/42/57032/w960_57032-1443.png)

P0011, P0021 IVT CONTROLEC-91

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Also check harness for short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between intake valve timing control position sensor and ground

>> Repair open circuit or short to power in harness or connectors.

7.CHECK INTAKE VALVE TIMING CONTROL POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN

AND SHORT1. Disconnect ECM harness connector.

2. Check harness continuity between the following; ECM terminal 72 and intake valve timing control position sensor (Bank 1) terminal 2 or

ECM terminal 53 and intake valve timing contro l position sensor (Bank 2) terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK INTAKE VALVE TIMING CONTROL POSITION SENSOR

Refer to EC-93, "

Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> Replace malfunctioning intake valve timing control position sensor. Refer to EC-495

.

9.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Reconnect ECM harness connector.

2. Disconnect intake valve timing control solenoid valve harness connector.

3. Turn ignition switch ON. Continuity should exist.

Continuity should exist.

1. Intake valve timing control position

sensor (bank 2) 2. Intake valve timing control solenoid

valve (bank 2) 3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1) 6. Intake valve timing control position

sensor (bank 1)

BBIA0771E

Revision: April 20092010 QX56