wiring diagram INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 1754 of 4210

![INFINITI QX56 2010 Factory Service Manual FUEL PUMPEC-401

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Disconnect 15 A fuse.

3. Check 15 A fuse (No. 48).

OK or NG

OK >> GO TO 7.

NG >> Replace fuse.

7.CHECK CONDENSER-2 P INFINITI QX56 2010 Factory Service Manual FUEL PUMPEC-401

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Disconnect 15 A fuse.

3. Check 15 A fuse (No. 48).

OK or NG

OK >> GO TO 7.

NG >> Replace fuse.

7.CHECK CONDENSER-2 P](/img/42/57032/w960_57032-1753.png)

FUEL PUMPEC-401

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Disconnect 15 A fuse.

3. Check 15 A fuse (No. 48).

OK or NG

OK >> GO TO 7.

NG >> Replace fuse.

7.CHECK CONDENSER-2 POWER SUPPLY

CIRCUIT-II FOR OPEN AND SHORT

1. Disconnect IPDM E/R harness connector E119.

2. Check harness continuity between IPDM E/R terminal 13 and condenser-2 terminal 1. Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK CONDENSER-2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between condenser-2 terminal 2 and ground. Refer to Wiring Diagram.

2. Also check harness for short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to power in harness or connectors.

9.CHECK CONDENSER-2

Refer to EC-402, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> Replace condenser-2.

10.CHECK FUEL PUMP POWER SUPPLY AND GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness con- nector.

3. Disconnect IPDM E/R harness connector E119.

4. Check harness continuity between IPDM E/R terminal 13 and

“fuel level sensor unit and fuel pump” terminal 1, “fuel level sen-

sor unit and fuel pump” terminal 3 and ground.

Refer to Wiring Diagram.

5. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E41, C1

• Harness for open or short between fuel pump and IPDM E/R

• Harness for open or short between fuel pump and ground

>> Repair open circuit or short to ground or short to power in harness or connectors.

Continuity should exist.

Continuity should exist.

Continuity should exist.

BBIA0583E

Revision: April 20092010 QX56

Page 1757 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-404

< COMPONENT DIAGNOSIS >[VK56DE]

ICC BRAKE SWITCH

4. Check voltage between ICC brake switch terminal 1 and ground

with CONSULT-III or tester.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

3.CHECK ICC B INFINITI QX56 2010 Factory Service Manual EC-404

< COMPONENT DIAGNOSIS >[VK56DE]

ICC BRAKE SWITCH

4. Check voltage between ICC brake switch terminal 1 and ground

with CONSULT-III or tester.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

3.CHECK ICC B](/img/42/57032/w960_57032-1756.png)

EC-404

< COMPONENT DIAGNOSIS >[VK56DE]

ICC BRAKE SWITCH

4. Check voltage between ICC brake switch terminal 1 and ground

with CONSULT-III or tester.

OK or NG

OK >> GO TO 6.

NG >> GO TO 3.

3.CHECK ICC BRAKE SWITCH POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ICC brake hold relay.

3. Check harness continuity between ICC brake switch terminal 1 and ICC brake hold relay terminal 3.

Refer to Wiring Diagram

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK ICC BRAKE HOLD RE LAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check the voltage between ICC brake hold relay terminal 4 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 8.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M31, E152

• Fuse block (J/B) connector M4

• 10 A fuse (No.15)

• Harness for open or short between ICC brake hold relay and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

6.CHECK ICC BRAKE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORTVoltage: Battery voltage

PBIB0857E

BBIA0471E

Continuity should exist.

Voltage: Battery voltage

MBIB0059E

Revision: April 20092010 QX56

Page 1758 of 4210

![INFINITI QX56 2010 Factory Service Manual ICC BRAKE SWITCHEC-405

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ICC brake INFINITI QX56 2010 Factory Service Manual ICC BRAKE SWITCHEC-405

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ICC brake](/img/42/57032/w960_57032-1757.png)

ICC BRAKE SWITCHEC-405

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ICC brake switch terminal 2 and ECM terminal 108, ICC brake switch

terminal 2 and ICC unit terminal 29.

Refer Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK ICC BRAKE SWITCH

Refer to EC-343, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> Replace ICC brake switch.

8.CHECK ICC BRAKE HOLD RELAY POWER SUPPL Y AND GROUND CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ICC brake hold relay terminal 1 and ICC unit terminal 47, ICC brake hold relay terminal 2 and ground.

Refer to Wiring Diagram

2. Also check harness for short to ground or short to power in harness or connectors.

OK or NG

OK >> GO TO 9.

NG >> Repair or replace.

9.CHECK ICC BRAKE HOLD RELAY

Refer to EC-343, "

Component Inspection".

OK >> GO TO 10.

NG >> Replace ICC brake hold relay.

10.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

How to Check Terminal" and GI-38, "Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000005149481

ICC BRAKE SWITCH

1. Turn ignition switch OFF.

2. Disconnect ICC brake switch harness connector.

3. Check continuity between ICC brake switch terminals 1 and 2

under the following conditions.

If NG, adjust ICC brake switch installation, refer to BR-15,

"Inspection and Adjustment", and perform step 3 again.

Continuity should exist.

Continuity should exist

Condition

Continuity

Brake pedal: Fully released. Should exist.

Brake pedal: Slightly depressed. Should not exist.

PBIB1536E

Revision: April 20092010 QX56

Page 1761 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-408

< COMPONENT DIAGNOSIS >[VK56DE]

IGNITION SIGNAL

OK >>

INSPECTION END

NG >> GO TO 10.

4.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF, wait at least 10 seconds and then INFINITI QX56 2010 Factory Service Manual EC-408

< COMPONENT DIAGNOSIS >[VK56DE]

IGNITION SIGNAL

OK >>

INSPECTION END

NG >> GO TO 10.

4.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF, wait at least 10 seconds and then](/img/42/57032/w960_57032-1760.png)

EC-408

< COMPONENT DIAGNOSIS >[VK56DE]

IGNITION SIGNAL

OK >>

INSPECTION END

NG >> GO TO 10.

4.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

2. Check voltage between ECM terminals 119, 120 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 5.

NG >> Go to EC-82

.

5.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect condenser-1 harness connector.

3. Turn ignition switch ON.

4. Check voltage between condenser-1 terminal 1 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 8.

NG >> GO TO 6.

6.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E119.

3. Check harness continuity between IPDM E/R terminal 4 and condenser-1 terminal 1. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> Go to EC-82.

NG >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32 Voltage: Battery voltage

MBIB0034E

BBIA0358E

Voltage: Battery voltage

PBIB0624E

Continuity should exist.

Revision: April 20092010 QX56

Page 1762 of 4210

![INFINITI QX56 2010 Factory Service Manual IGNITION SIGNALEC-409

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Harness for open or short between condenser-1 and IPDM E/R

>> Repair open circuit or short to ground or short INFINITI QX56 2010 Factory Service Manual IGNITION SIGNALEC-409

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Harness for open or short between condenser-1 and IPDM E/R

>> Repair open circuit or short to ground or short](/img/42/57032/w960_57032-1761.png)

IGNITION SIGNALEC-409

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Harness for open or short between condenser-1 and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK CONDENSER-1 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser-1 terminal 2 and ground. Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to power in harness or connectors.

9.CHECK CONDENSER-1

Refer to EC-410, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> Replace condenser-1.

10.CHECK IGNITION COIL POWER SUPPLY CIRCUIT-IV

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Disconnect ignition coil harness connector.

4. Turn ignition switch ON.

5. Check voltage between ignition coil terminal 3 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between ignition coil and harness connector F32 Continuity should exist.

1. Ignition coils (with power transistor)

(bank 2) 2. Ignition coils (with power transistor)

(bank 1)

Voltage: Battery voltage

BBIA0777E

PBIB0138E

Revision: April 20092010 QX56

Page 1763 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-410

< COMPONENT DIAGNOSIS >[VK56DE]

IGNITION SIGNAL

>> Repair or replace harness or connectors.

12.CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harnes INFINITI QX56 2010 Factory Service Manual EC-410

< COMPONENT DIAGNOSIS >[VK56DE]

IGNITION SIGNAL

>> Repair or replace harness or connectors.

12.CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harnes](/img/42/57032/w960_57032-1762.png)

EC-410

< COMPONENT DIAGNOSIS >[VK56DE]

IGNITION SIGNAL

>> Repair or replace harness or connectors.

12.CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and ground. Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open circuit or short to power in harness or connectors.

13.CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 46, 60, 61, 62, 65, 79, 80, 81 and ignition coil terminal 1.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 14.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

14.CHECK IGNITION COIL WITH POWER TRANSISTOR

Refer to EC-410, "

Component Inspection".

OK or NG

OK >> GO TO 15.

NG >> Replace ignition coil with power transistor.

15.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

How to Check Terminal" and GI-38, "Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000005149484

IGNITION COIL WITH POWER TRANSISTOR

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Disconnect ignition coil harness connector.

3. Check resistance between ignition coil terminals as follows.

4. If NG, replace ignition coil with power transistor.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Reconnect all harness connectors disconnected. Continuity should exist.

Continuity should exist.

Terminal No. (Polarity)

Resistance Ω [at 25 °C (77 °F)]

1 and 2 Except 0 or ∞

1 and 3 Except 0

2 and 3

PBIB0847E

Revision: April 20092010 QX56

Page 1773 of 4210

![INFINITI QX56 2010 Factory Service Manual EC-420

< COMPONENT DIAGNOSIS >[VK56DE]

REFRIGERANT PRESSURE SENSOR

Refer to EC-85, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK REFRIGERANT PRESSURE INFINITI QX56 2010 Factory Service Manual EC-420

< COMPONENT DIAGNOSIS >[VK56DE]

REFRIGERANT PRESSURE SENSOR

Refer to EC-85, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK REFRIGERANT PRESSURE](/img/42/57032/w960_57032-1772.png)

EC-420

< COMPONENT DIAGNOSIS >[VK56DE]

REFRIGERANT PRESSURE SENSOR

Refer to EC-85, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Disconnect refrigerant pressure sensor harness connector.

2. Turn ignition switch ON.

3. Check voltage between refrigerant pressure sensor terminal 1 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair harness or connectors.

5.CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between refrigerant pressure sensor terminal 3 and ECM terminal 67. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

BBIA0354E

BBIA0445E

Voltage: Approximately 5 V

PBIB0188E

Continuity should exist.

Revision: April 20092010 QX56

Page 1774 of 4210

![INFINITI QX56 2010 Factory Service Manual REFRIGERANT PRESSURE SENSOREC-421

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open INFINITI QX56 2010 Factory Service Manual REFRIGERANT PRESSURE SENSOREC-421

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open](/img/42/57032/w960_57032-1773.png)

REFRIGERANT PRESSURE SENSOREC-421

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK REFRIGERANT PRESSURE SENSOR IN PUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 70 and refrigerant pressure sensor terminal 2.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 9.

NG >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

How to Check Terminal" and GI-38, "Intermittent Incident".

OK or NG

OK >> Replace refrigerant pressure sensor.

NG >> Repair or replace. Continuity should exist.

Revision: April 20092010 QX56

Page 1788 of 4210

![INFINITI QX56 2010 Factory Service Manual ECM

EC-435

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Wiring Diagram - ENGI

NE CONTROL SYSTEM -INFOID:0000000005149495

ABBWA0126GB

Revision: April 20092010 QX56 INFINITI QX56 2010 Factory Service Manual ECM

EC-435

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Wiring Diagram - ENGI

NE CONTROL SYSTEM -INFOID:0000000005149495

ABBWA0126GB

Revision: April 20092010 QX56](/img/42/57032/w960_57032-1787.png)

ECM

EC-435

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Wiring Diagram - ENGI

NE CONTROL SYSTEM -INFOID:0000000005149495

ABBWA0126GB

Revision: April 20092010 QX56

Page 1978 of 4210

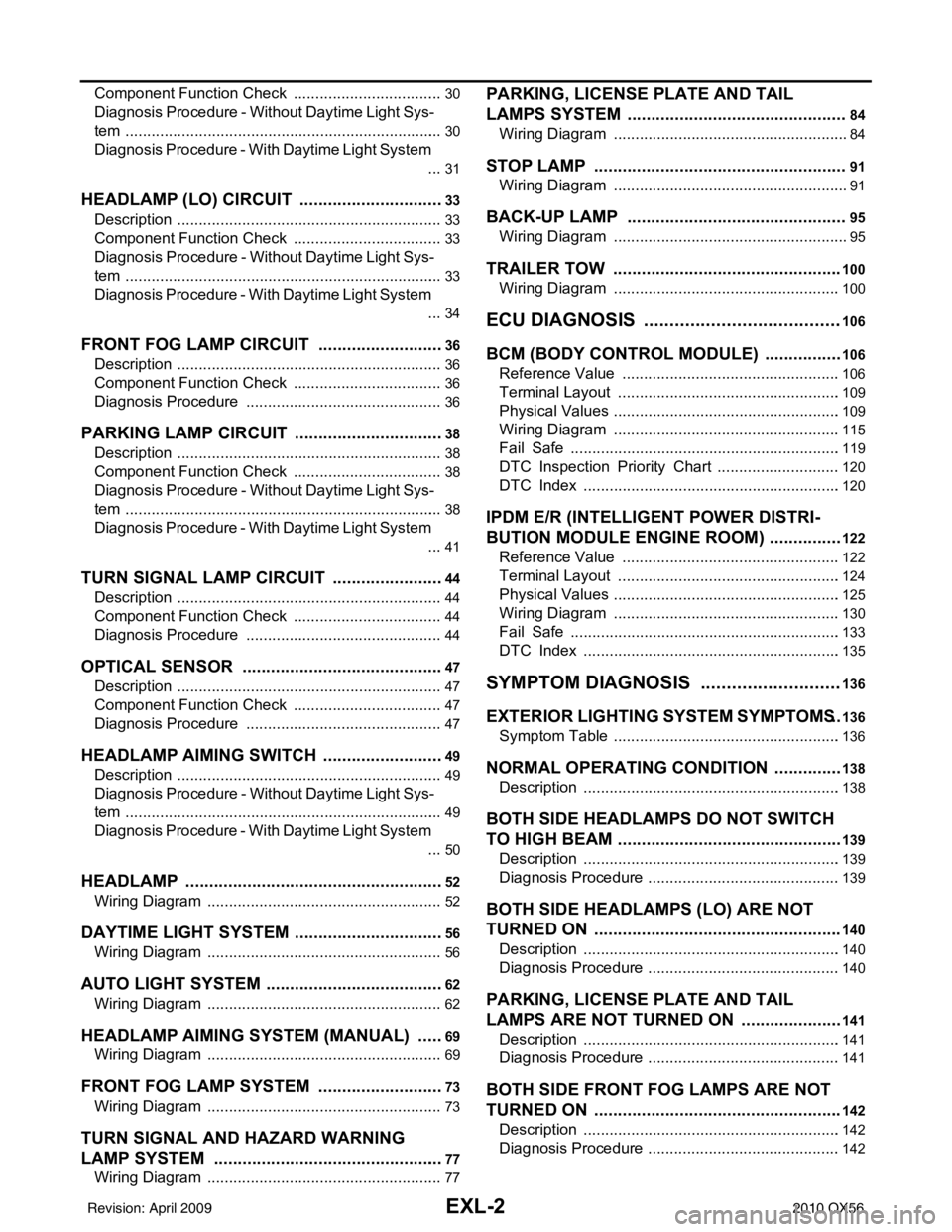

EXL-2

Component Function Check ...................................30

Diagnosis Procedure - Without Daytime Light Sys-

tem ..........................................................................

30

Diagnosis Procedure - With Daytime Light System

...

31

HEADLAMP (LO) CIRCUIT ...............................33

Description ........................................................... ...33

Component Function Check ...................................33

Diagnosis Procedure - Without Daytime Light Sys-

tem ..........................................................................

33

Diagnosis Procedure - With Daytime Light System

...

34

FRONT FOG LAMP CIRCUIT ...........................36

Description ........................................................... ...36

Component Function Check ...................................36

Diagnosis Procedure ..............................................36

PARKING LAMP CIRCUIT ................................38

Description ........................................................... ...38

Component Function Check ...................................38

Diagnosis Procedure - Without Daytime Light Sys-

tem ..........................................................................

38

Diagnosis Procedure - With Daytime Light System

...

41

TURN SIGNAL LAMP CIRCUIT ........................44

Description ........................................................... ...44

Component Function Check ...................................44

Diagnosis Procedure ..............................................44

OPTICAL SENSOR ...........................................47

Description ..............................................................47

Component Function Check ...................................47

Diagnosis Procedure ..............................................47

HEADLAMP AIMING SWITCH ..........................49

Description ........................................................... ...49

Diagnosis Procedure - Without Daytime Light Sys-

tem ..........................................................................

49

Diagnosis Procedure - With Daytime Light System

...

50

HEADLAMP .......................................................52

Wiring Diagram .................................................... ...52

DAYTIME LIGHT SYSTEM ................................56

Wiring Diagram .................................................... ...56

AUTO LIGHT SYSTEM ......................................62

Wiring Diagram .................................................... ...62

HEADLAMP AIMING SYSTEM (MANUAL) ......69

Wiring Diagram .................................................... ...69

FRONT FOG LAMP SYSTEM ...........................73

Wiring Diagram .................................................... ...73

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM .............................................. ...

77

Wiring Diagram .................................................... ...77

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ...............................................

84

Wiring Diagram .................................................... ...84

STOP LAMP ......................................................91

Wiring Diagram .................................................... ...91

BACK-UP LAMP ............................................ ...95

Wiring Diagram .................................................... ...95

TRAILER TOW .................................................100

Wiring Diagram .....................................................100

ECU DIAGNOSIS ......................................106

BCM (BODY CONTROL MODULE) ............... ..106

Reference Value .................................................. .106

Terminal Layout ....................................................109

Physical Values .....................................................109

Wiring Diagram .....................................................115

Fail Safe ...............................................................119

DTC Inspection Priority Chart .............................120

DTC Index ............................................................120

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

122

Reference Value .................................................. .122

Terminal Layout ....................................................124

Physical Values .....................................................125

Wiring Diagram .....................................................130

Fail Safe ...............................................................133

DTC Index ............................................................135

SYMPTOM DIAGNOSIS ...........................136

EXTERIOR LIGHTING SYSTEM SYMPTOMS ..136

Symptom Table .................................................... .136

NORMAL OPERATING CONDITION ...............138

Description ........................................................... .138

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM ................................................

139

Description ........................................................... .139

Diagnosis Procedure .............................................139

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON .....................................................

140

Description ............................................................140

Diagnosis Procedure .............................................140

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON ......................

141

Description ........................................................... .141

Diagnosis Procedure .............................................141

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON .....................................................

142

Description ............................................................142

Diagnosis Procedure .............................................142

Revision: April 20092010 QX56