wiring diagram INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2234 of 4210

HOW TO READ WIRING DIAGRAMSGI-11

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

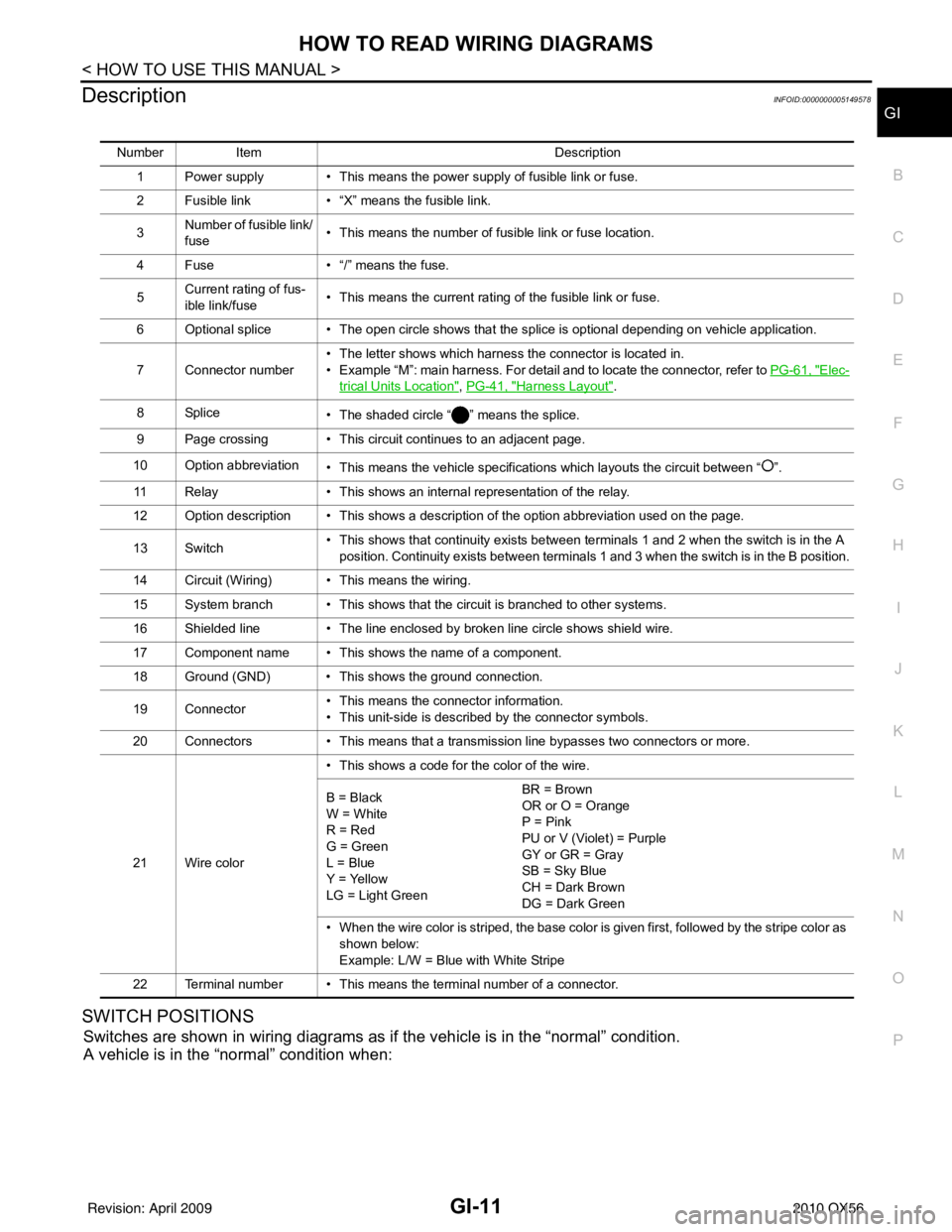

DescriptionINFOID:0000000005149578

SWITCH POSITIONS

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

Number Item Description

1 Power supply • This means the power supply of fusible link or fuse.

2 Fusible link • “X” means the fusible link.

3 Number of fusible link/

fuse • This means the number of fusible link or fuse location.

4 Fuse • “/” means the fuse.

5 Current rating of fus-

ible link/fuse • This means the current rating of the fusible link or fuse.

6 Optional splice • The open circle shows that the splice is optional depending on vehicle application.

7 Connector number • The letter shows which harness the connector is located in.

• Example “M”: main harness. For detail and to locate the connector, refer to

PG-61, "

Elec-

trical Units Location", PG-41, "Harness Layout".

8Splice • The shaded circle “ ” means the splice.

9 Page crossing • This circuit continues to an adjacent page.

10 Option abbreviation • This means the vehicle specifications which layouts the circuit between “ ”.

11 Relay • This shows an internal representation of the relay.

12 Option description • This shows a description of the option abbreviation used on the page.

13 Switch • This shows that continuity exists between terminals 1 and 2 when the switch is in the A

position. Continuity exists between terminals 1 and 3 when the switch is in the B position.

14 Circuit (Wiring) • This means the wiring.

15 System branch • This shows that the circuit is branched to other systems.

16 Shielded line • The line enclosed by broken line circle shows shield wire.

17 Component name • This shows the name of a component.

18 Ground (GND) • This shows the ground connection.

19 Connector • This means the connector information.

• This unit-side is described by the connector symbols.

20 Connectors • This means that a transmission line bypasses two connectors or more.

21 Wire color • This shows a code for the color of the wire.

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light Green BR = Brown

OR or O = Orange

P = Pink

PU or V (Violet) = Purple

GY or GR = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

• When the wire color is striped, the base color is given first, followed by the stripe color as shown below:

Example: L/W = Blue with White Stripe

22 Terminal number • This means the terminal number of a connector.

Revision: April 20092010 QX56

Page 2235 of 4210

GI-12

< HOW TO USE THIS MANUAL >

HOW TO READ WIRING DIAGRAMS

• ignition switch is “OFF”,

• doors, hood and trunk lid/back door are closed,

• pedals are not depressed, and

• parking brake is released.

MULTIPLE SWITCH

The continuity of multiple switch is described in two ways as shown below.

• The switch chart is used in schematic diagrams.

• The switch diagram is used in wiring diagrams.

SGI860

JSAIA0017GB

Revision: April 20092010 QX56

Page 2262 of 4210

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-39

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

lowing section illustrates ways to simulate the c onditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer . It is important for simulating the conditions of the

problem.

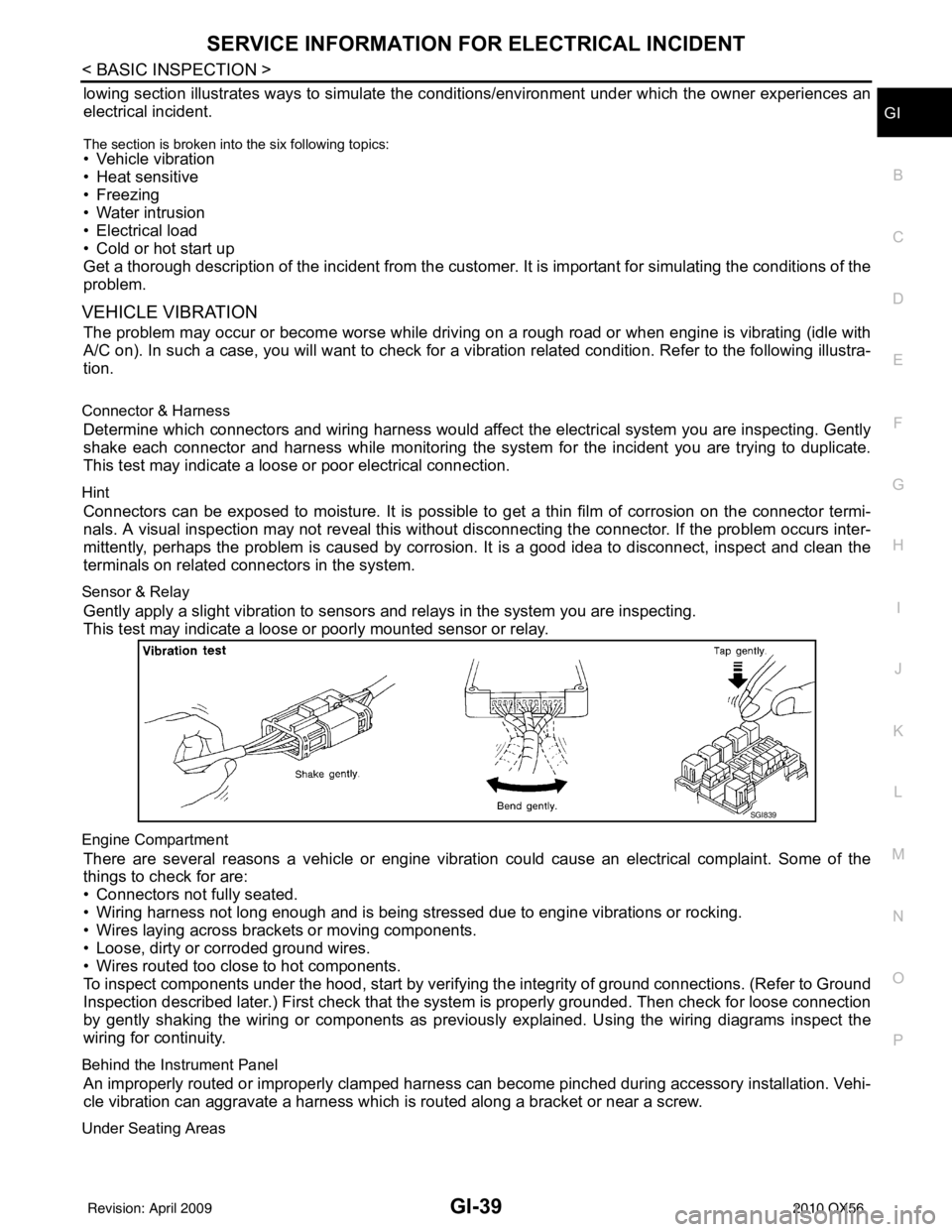

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the syst em for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosi on. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

• Connectors not fully seated.

• Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

• Wires laying across brackets or moving components.

• Loose, dirty or corroded ground wires.

• Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

SGI839

Revision: April 20092010 QX56

Page 2270 of 4210

CONSULT-III CHECKING SYSTEMGI-47

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

x : Applicable

*1: With intelligent cruise control

*2: With 4-wheel drive

*3: With front and rear sonar system

*4: With security card installed

CONSULT-III Data Link Connector (DLC) CircuitINFOID:0000000005149611

INSPECTION PROCEDURE

If the CONSULT-III cannot diagnose the sys tem properly, check the following items.

NOTE:

The CAN and DDL2 circuits from DLC pins 6, 7 and 14 may be connected to more than one system. A short in

any circuit connected to a control unit in one system may affect CONSULT-III access to other systems.

Passenger AirbagDisplays the STATUS (readiness) of the front passenger

air bag. ----x-----------

AV COMM monitor The condition of AV communication can be indicated. ------------x---

Configuration Sets control module parameters to match vehicle options.------x---------

PIN read

*4This mode shows the BCM-specific 5-digit code. ------x---------

Control unit

initialization

*4All registered ignition key IDs in NATS components can be

initialized and new IDs can be registered. ------x---------

Diagnostic test

mode Function

ENGINE

TRANSMISSION

ICC

*1

ABS

AIR BAG

IPDM E/R BCM

METER/M&A

INTELLIGENT KEY

AUTO DRIVE POS.

REARVIEW CAMERA AIR LEVELIZER MULTI AV

ALL MODE AWD/4WD

*2

HVAC

SONAR

*3

Symptom Check item

CONSULT-III cannot access

any system. • CONSULT-III DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4)

CONSULT-III cannot access in-

dividual system. (Other sys-

tems can be accessed.) • Power supply and ground circuit for the control unit of the system (For detailed circuit, refer to wiring

diagram for each system.)

• Open or short circuit between the system and CONSULT-III DLC (For detailed circuit, refer to wiring

diagram for each system.)

• Open or short circuit CAN communication line. Refer to LAN-14, "

Trouble Diagnosis Flow Chart".

Revision: April 20092010 QX56

Page 2271 of 4210

GI-48

< BASIC INSPECTION >

CONSULT-III CHECKING SYSTEM

Wiring Diagram

INFOID:0000000005149612

ABAWA0027GB

Revision: April 20092010 QX56

Page 2342 of 4210

HAC-2

Rear Air Control Component Function Check ........58

Air Mix Door Motor (Rear) Diagnosis Procedure ....59

Mode Door Motor (Rear) Diagnosis Procedure ......63

MAGNET CLUTCH ............................................68

System Description .............................................. ...68

Magnet Clutch Component Function Check ........ ...68

Magnet Clutch Diagnosis Procedure ................... ...68

WATER VALVE CIRCUIT ..................................73

Description ........................................................... ...73

Water Valve Diagnosis Procedure ..........................73

AMBIENT SENSOR ...........................................75

Component Description ....................................... ...75

Ambient Sensor Diagnosis Procedure ....................75

Ambient Sensor Component Inspection .................76

IN-VEHICLE SENSOR .......................................78

Component Description ....................................... ...78

In-Vehicle Sensor Diagnosis Procedure .................78

In-Vehicle Sensor Component Inspection ..............80

OPTICAL SENSOR ...........................................81

Component Description ..........................................81

Optical Sensor Diagnosis Procedure ......................81

INTAKE SENSOR ..............................................83

System Description .............................................. ...83

Intake Sensor Diagnosis Procedure .......................83

Intake Sensor Component Inspection ................. ...84

POWER SUPPLY AND GROUND CIRCUIT

FOR CONTROLLER ..........................................

86

Component Description ....................................... ...86

A/C Auto Amp. Component Function Check ..........86

A/C Auto Amp Power and Ground Diagnosis Pro-

cedure .................................................................. ...

87

ECU DIAGNOSIS .......................................89

AIR CONDITIONER CONTROL ..................... ...89

A/C Auto Amp. Terminals Reference Values ..........89

Wiring Diagram .................................................... ...91

SYMPTOM DIAGNOSIS ...........................107

AIR CONDITIONER CONTROL ..................... ..107

Symptom Matrix Chart ........................................ .107

INSUFFICIENT COOLING ................................108

Component Function Check ................................ .108

Diagnostic Work Flow ...........................................109

Performance Chart ................................................111

Trouble Diagnoses for Abnormal Pressure ...........112

INSUFFICIENT HEATING ................................116

Component Function Check .................................116

NOISE ...............................................................118

Component Function Check ................................ .118

MEMORY FUNCTION DOES NOT OPERATE ..120

Memory Function Check ...................................... .120

PRECAUTION ...........................................121

PRECAUTIONS .............................................. ..121

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

121

Working with HFC-134a (R-134a) ........................ .121

Precaution for Service Equipment ........................122

Revision: April 20092010 QX56

Page 2366 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-26

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

MODE DOOR MOTOR

The mode door motor (front) is attached to the heater & cooling unit

assembly. It rotates so that air is discharged from the o INFINITI QX56 2010 Factory Service Manual HAC-26

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

MODE DOOR MOTOR

The mode door motor (front) is attached to the heater & cooling unit

assembly. It rotates so that air is discharged from the o](/img/42/57032/w960_57032-2365.png)

HAC-26

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

MODE DOOR MOTOR

The mode door motor (front) is attached to the heater & cooling unit

assembly. It rotates so that air is discharged from the outlet as indi-

cated by the A/C auto amp. Motor rotation is conveyed to a link

which activates the mode door.

Mode Door Motor (Front)

Component Function CheckINFOID:0000000005147688

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OP ERATIONAL CHECK - DISCHARGE AIR

1. Press mode switch four times and then press the (DEF) switch. Each position indicator should change shape (on display).

2. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-16, "

Discharge

Air Flow (Front)".

NOTE:

Confirm that the compressor clutch is engaged (visual inspection) and intake door position is at FRESH

when DEF ( ) or D/F ( ) is selected.

Is the inspection result normal?

YES >> Inspection End.

NO >> Go to diagnosis procedure. Refer to HAC-26, "

Mode Door Motor (Front) Diagnosis Procedure".

Mode Door Motor (Front) Diagnosis ProcedureINFOID:0000000005147689

Regarding Wiring Diagram information, refer to HAC-91, "Wiring Diagram".

SYMPTOM:• Air outlet does not change.

• Mode door motor does not operate normally.

1.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the mode switch to the B/L ( ) mode.

3. Check voltage between A/C auto amp. harness connector M49 terminal 19 and terminal 20 while pressing the mode switch to

the floor ( ) mode.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK MODE DOOR MOTOR CIRCUITS FOR SHORT TO GROUND

WJIA0587E

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 20

19Press

mode

switch Battery

voltage

AWIIA0095ZZ

Revision: April 20092010 QX56

Page 2372 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-32

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

AIR MIX DOOR MOTOR

Air Mix Door Motor (Driver) Diagnosis Procedure

INFOID:0000000005147692

Regarding Wiring Diagram information, refer to HAC INFINITI QX56 2010 Factory Service Manual HAC-32

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

AIR MIX DOOR MOTOR

Air Mix Door Motor (Driver) Diagnosis Procedure

INFOID:0000000005147692

Regarding Wiring Diagram information, refer to HAC](/img/42/57032/w960_57032-2371.png)

HAC-32

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

AIR MIX DOOR MOTOR

Air Mix Door Motor (Driver) Diagnosis Procedure

INFOID:0000000005147692

Regarding Wiring Diagram information, refer to HAC-91, "Wiring Diagram".

SYMPTOM:

• Discharge air temperature does not change.

• Air mix door motor does not operate.

DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (DRIVER)

1.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Rotate temperature control dial (driver) to 32 °C (90° F).

3. Check voltage between A/C auto amp. harness connector M49

terminal 17 and terminal 18 while rotating temperature control

dial (driver) to 18 °C (60° F).

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK AIR MIX DOOR MOTOR (DRIVE R) CIRCUITS FOR SHORT TO GROUND

1. Turn ignition switch OFF.

2. Disconnect the A/C auto amp. harness connector.

3. Check continuity between A/C auto amp. harness connector M49 terminal 17, 18 and ground.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

NO >> Repair or replace harness as necessary.

3.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Rotate temperature control dial (driver) to 32 °C (90° F).

3. Check voltage between A/C auto amp. harness connector M49 terminal 17 and terminal 18 while rotating temperature control

dial (driver) to 18 °C (60° F).

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace A/C auto amp. Refer to VTL-7, "

Removal and Installation".

ConnectorTe r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 17 18

Rotate temp

control dial Battery

voltage

AWIIA0112ZZ

17 - Ground : Continuity should not exist.

18 - Ground : Continuity should not exist.

AWIIA0114ZZ

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 18 17 Rotate temp

control dial Battery

voltage

AWIIA0115ZZ

Revision: April 20092010 QX56

Page 2375 of 4210

![INFINITI QX56 2010 Factory Service Manual AIR MIX DOOR MOTORHAC-35

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Turn ignition switch OFF.

2. Disconnect the air mix door motor (driver) harness connec INFINITI QX56 2010 Factory Service Manual AIR MIX DOOR MOTORHAC-35

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Turn ignition switch OFF.

2. Disconnect the air mix door motor (driver) harness connec](/img/42/57032/w960_57032-2374.png)

AIR MIX DOOR MOTORHAC-35

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

1. Turn ignition switch OFF.

2. Disconnect the air mix door motor (driver) harness connector and A/C auto amp. harness connector.

3. Check continuity between air mix door motor (driver) harness connector M147 (B) terminal 4 and A/C auto amp. harness con-

nector M49 (A) terminal 6.

Is the inspection result normal?

YES >> Replace air mix door motor (driver). Refer to VTL-31,

"Removal and Installation".

NO >> Repair or replace harness as necessary.

Air Mix Door Motor (Passen ger) Component Function CheckINFOID:0000000005272349

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE INCREASE

1. Turn the temperature control dial (passenger) clockwise until 32 °C (90 °F) is displayed.

2. Check for hot air at discharge air outlets.

>> GO TO 2.

2.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE DECREASE

1. Turn the temperature control dial (passenger) counterclockwise until 18° C (60°F) is displayed.

2. Check for cold air at discharge air outlets.

Is the inspection result normal?

YES >> Inspection End.

NO >> Go to diagnosis procedure. Refer to HAC-35, "

Air Mix Door Motor (Passenger) Diagnosis Proce-

dure".

Air Mix Door Motor (Passe nger) Diagnosis ProcedureINFOID:0000000005147693

Regarding Wiring Diagram information, refer to HAC-91, "Wiring Diagram".

SYMPTOM:

• Discharge air temperature does not change.

• Air mix door motor does not operate.

DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (PASSENGER)

1.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Rotate temperature control dial (passenger) to 32 °C (90 °F).

3. Check voltage between A/C auto amp. harness connector M49

terminal 14 and terminal 2 while rotating temperature control dial

(passenger) to 18 ° C (60 °F).

Is the inspection result normal?

OK >> GO TO 3. Continuity should exist.

AWIIA0124ZZ

Connector

Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 2 14 Rotate temp

control dial Battery

voltage

AWIIA0125ZZ

Revision: April 20092010 QX56

Page 2380 of 4210

![INFINITI QX56 2010 Factory Service Manual HAC-40

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INTAKE DOOR MOTOR

COMPONENT DESCRIPTION

Intake door motor

The intake door motor is attached to the intake unit. It rotates so that

air is draw INFINITI QX56 2010 Factory Service Manual HAC-40

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INTAKE DOOR MOTOR

COMPONENT DESCRIPTION

Intake door motor

The intake door motor is attached to the intake unit. It rotates so that

air is draw](/img/42/57032/w960_57032-2379.png)

HAC-40

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INTAKE DOOR MOTOR

COMPONENT DESCRIPTION

Intake door motor

The intake door motor is attached to the intake unit. It rotates so that

air is drawn from inlets set by the A/C auto amp. Motor rotation is

conveyed to a lever which activates the intake door.

Intake Door Motor Component Function CheckINFOID:0000000005147695

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING

OPERATIONAL CHECK - REC ( )

1. Press the mode switch to vent mode( ).

2. Press REC ( ) switch. The REC ( ) indicator should illuminate.

3. Press REC ( ) switch again. The REC ( ) indicator should go out.

4. Listen for intake door position change (you should hear blower sound change slightly).

Is the inspection result normal?

YES >> Inspection End.

NO >> Go to diagnosis procedure. Refer to HAC-40, "

Intake Door Motor Diagnosis Procedure".

Intake Door Motor Diagnosis ProcedureINFOID:0000000005147696

Regarding Wiring Diagram information, refer to HAC-91, "Wiring Diagram".

SYMPTOM:

• Intake door does not change.

• Intake door motor does not operate normally.

DIAGNOSTIC PROCEDURE FOR INTAKE DOOR MOTOR

1.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Check voltage between A/C auto amp. harness connector M49 terminal 21 and terminal 22 while placing the HVAC system into

self-diagnostic mode.

Is the inspection result normal?

OK >> GO TO 3.

NO >> GO TO 2.

2.CHECK INTAKE DOOR MOTOR CIRCUITS FOR SHORT TO GROUND

WJIA0552E

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 21

22Self-diagnostic

mode Battery volt-

age

AWIIA0146ZZ

Revision: April 20092010 QX56