wiring diagram INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2744 of 4210

MIR-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION MIR

A

B

MIR

N

O P

CONTENTS

MIRRORS

COMPONENT DIAGNOSIS ..........................2

DOOR MIRROR .............................................. .....2

Wiring Diagram ................................................... ......2

INSIDE MIRROR .................................................5

Wiring Diagram ................................................... ......5

PRECAUTION ...............................................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

8

Handling for Adhesive and Primer ............................9

PREPARATION ...........................................10

PREPARATION .............................................. ....10

Special Service Tool ............................................ ....10

Commercial Service Tool ........................................10

REMOVAL AND INSTALLATION ...............11

INSIDE MIRROR ...............................................11

Wiring Diagram - I/MIRR - ................................... ....11

Removal and Installation .........................................12

DOOR MIRROR ................................................13

Wiring Diagram - MIRROR -Without Power Fold-

ing Mirrors ................................................................

13

Wiring Diagram - H/MIRR - ......................................15

Door Mirror Assembly ..............................................17

Door Mirror Glass ....................................................17

DISASSEMBLY AND ASSEMBLY ..............19

DOOR MIRROR ................................................19

Mirror Actuator ..................................................... ....19

Revision: April 20092010 QX56

Page 2745 of 4210

MIR-2

< COMPONENT DIAGNOSIS >

DOOR MIRROR

COMPONENT DIAGNOSIS

DOOR MIRROR

Wiring DiagramINFOID:0000000005146590

ABLWA0538GB

Revision: April 20092010 QX56

Page 2748 of 4210

INSIDE MIRRORMIR-5

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

INSIDE MIRROR

Wiring DiagramINFOID:0000000005146591

ABLWA0042GB

Revision: April 20092010 QX56

Page 2754 of 4210

INSIDE MIRRORMIR-11

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

REMOVAL AND INSTALLATION

INSIDE MIRROR

Wiring Diagram - I/MIRR -INFOID:0000000005146596

WIWA2061E

Revision: April 20092010 QX56

Page 2756 of 4210

DOOR MIRRORMIR-13

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

DOOR MIRROR

Wiring Diagram - MIRROR -Wit hout Power Folding MirrorsINFOID:0000000005146598

WIWA2063E

Revision: April 20092010 QX56

Page 2758 of 4210

DOOR MIRRORMIR-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K

M A

B

MIR

N

O P

Wiring Diagram - H/MIRR -INFOID:0000000005146599

WIWA1387E

Revision: April 20092010 QX56

Page 2764 of 4210

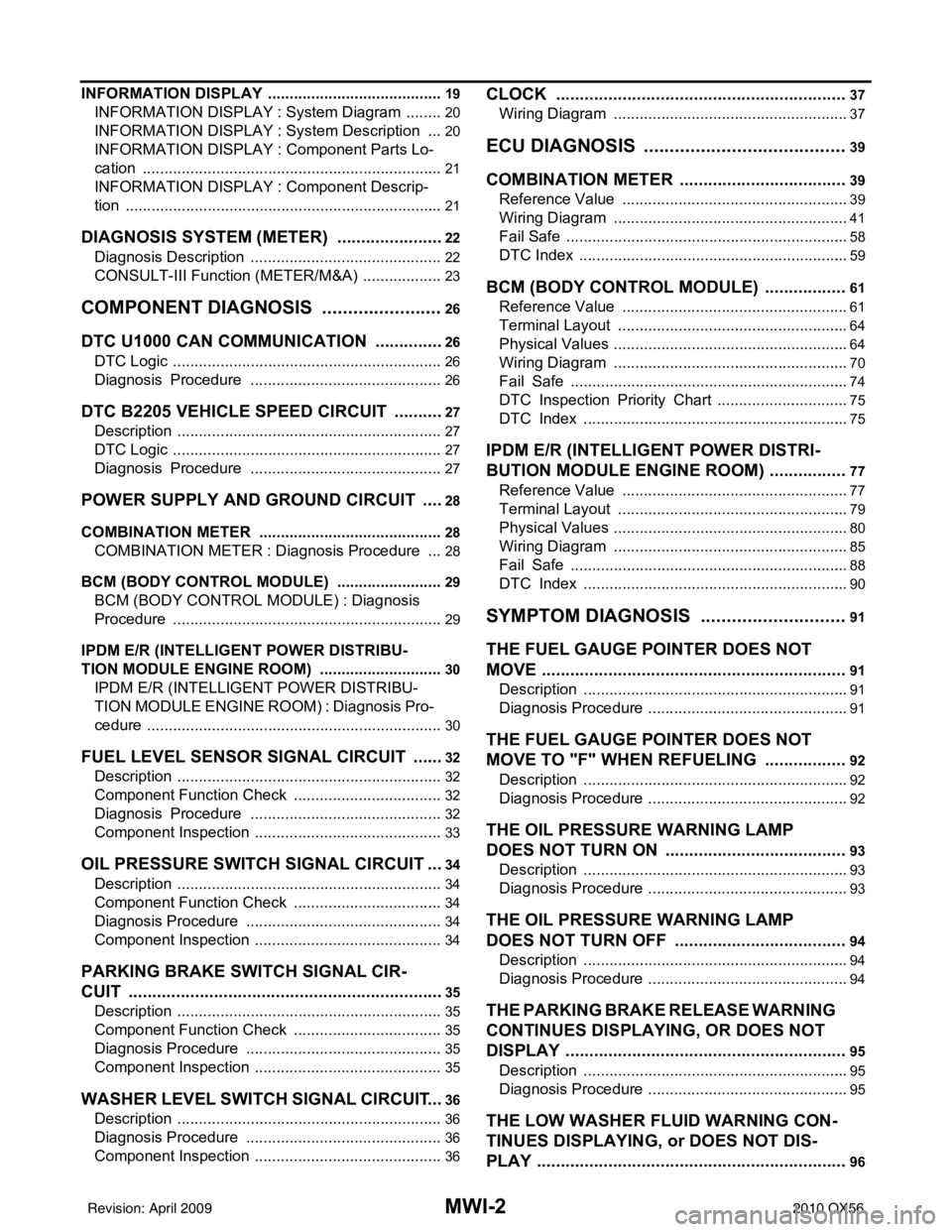

MWI-2

INFORMATION DISPLAY .........................................19

INFORMATION DISPLAY : System Diagram .........20

INFORMATION DISPLAY : System Description ....20

INFORMATION DISPLAY : Component Parts Lo-

cation ................................................................... ...

21

INFORMATION DISPLAY : Component Descrip-

tion ....................................................................... ...

21

DIAGNOSIS SYSTEM (METER) .......................22

Diagnosis Description .......................................... ...22

CONSULT-III Function (METER/M&A) ................ ...23

COMPONENT DIAGNOSIS ........................26

DTC U1000 CAN COMMUNICATION ............ ...26

DTC Logic ............................................................ ...26

Diagnosis Procedure .............................................26

DTC B2205 VEHICLE SPEED CIRCUIT ...........27

Description ........................................................... ...27

DTC Logic ...............................................................27

Diagnosis Procedure .............................................27

POWER SUPPLY AND GROUND CIRCUIT .....28

COMBINATION METER ........................................ ...28

COMBINATION METER : Diagnosis Procedure ....28

BCM (BODY CONTROL MODULE) ...................... ...29

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ...............................................................

29

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .......................... ...

30

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .....................................................................

30

FUEL LEVEL SENSOR SIGNAL CIRCUIT .......32

Description ........................................................... ...32

Component Function Check ...................................32

Diagnosis Procedure .............................................32

Component Inspection ............................................33

OIL PRESSURE SWITCH SIGNAL CIRCUIT ...34

Description ..............................................................34

Component Function Check ...................................34

Diagnosis Procedure ..............................................34

Component Inspection ............................................34

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ...................................................................

35

Description ........................................................... ...35

Component Function Check ...................................35

Diagnosis Procedure ..............................................35

Component Inspection ............................................35

WASHER LEVEL SWITCH SIGNAL CIRCUIT ...36

Description ........................................................... ...36

Diagnosis Procedure ..............................................36

Component Inspection ............................................36

CLOCK ..............................................................37

Wiring Diagram .................................................... ...37

ECU DIAGNOSIS .......................................39

COMBINATION METER ................................. ...39

Reference Value .................................................. ...39

Wiring Diagram .......................................................41

Fail Safe ..................................................................58

DTC Index ...............................................................59

BCM (BODY CONTROL MODULE) ..................61

Reference Value .................................................. ...61

Terminal Layout ......................................................64

Physical Values .......................................................64

Wiring Diagram .......................................................70

Fail Safe .................................................................74

DTC Inspection Priority Chart ...............................75

DTC Index ..............................................................75

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

77

Reference Value .................................................. ...77

Terminal Layout ......................................................79

Physical Values .......................................................80

Wiring Diagram .......................................................85

Fail Safe .................................................................88

DTC Index ..............................................................90

SYMPTOM DIAGNOSIS ............................91

THE FUEL GAUGE POINTER DOES NOT

MOVE .............................................................. ...

91

Description ........................................................... ...91

Diagnosis Procedure ...............................................91

THE FUEL GAUGE POINTER DOES NOT

MOVE TO "F" WHEN REFUELING ..................

92

Description ........................................................... ...92

Diagnosis Procedure ...............................................92

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON .................................... ...

93

Description ........................................................... ...93

Diagnosis Procedure ...............................................93

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF .................................. ...

94

Description ........................................................... ...94

Diagnosis Procedure ...............................................94

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY ............................................................

95

Description ........................................................... ...95

Diagnosis Procedure ...............................................95

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY ..................................................................

96

Revision: April 20092010 QX56

Page 2790 of 4210

MWI-28

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000005146078

Regarding Wiring Diagram information, refer to MWI-41, "Wiring Diagram".

1.CHECK FUSES

Check for blown combination meter fuses.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect combination meter connector M24.

2. Check voltage between combination meter harness connector M24 terminals 21, 37, 40 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Check harness for open between combination meter and fuse.

3.GROUND CIRCUIT CHECK

1. Turn ignition switch OFF.

2. Disconnect combination meter connector M23.

3. Check continuity between combination meter harness connector M23 terminal 47, 52 and ground, and connector M24 terminal 20

and ground.

Is the inspection result normal?

Unit Power source Fuse No.

Combination meter Battery 3

Ignition switch ON or START 14

Ignition switch ACC or ON 4

TerminalsIgnition switch position

(+) (–) OFF ACC ON START

Connector Terminal

M24 21

Ground 0V 0V

Battery

voltage Battery

voltage

37 0VBattery

voltage Battery

voltage 0V

40 Battery

voltage Battery

voltage Battery

voltage Battery

voltage

AWNIA0204ZZ

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

A: M23 47

Ground Yes

52

B: M24 20

AWNIA0205ZZ

Revision: April 20092010 QX56

Page 2791 of 4210

MWI

POWER SUPPLY AND GROUND CIRCUITMWI-29

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

YES >> Inspection End.

NO >> Check ground harness.

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000005380655

Regarding Wiring Diagram information, refer to MWI-70, "Wiring Diagram".

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

ConnectorTe r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON

or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

LIIA2415E

Revision: April 20092010 QX56

Page 2792 of 4210

MWI-30

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DIST RIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000005380656

Regarding Wiring Diagram information, refer to MWI-85, "Wiring Diagram".

1. CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK BATTERY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check voltage between IPDM E/R harness connectors and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Terminal No. Signal nameFuses and fusible link No.

1 Battery A, D

2 Battery C

12 Ignition switch ON or START 59

TerminalsIgnition switch position

(+) (−) OFF ON START

Connector Terminal

E118 (A) 1

Ground Battery

voltage Battery

voltage Battery

voltage

2 Battery

voltage Battery

voltage Battery

voltage

E119 (B) 12 0VBattery

voltage Battery

voltage

AWMIA0023ZZ

Revision: April 20092010 QX56