wiring diagram INFINITI QX56 2010 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 2893 of 4210

![INFINITI QX56 2010 Factory Service Manual PCS-18

< COMPONENT DIAGNOSIS >[IPDM E/R]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000005146511

Regarding Wiring Diagram information, refer to

PCS- INFINITI QX56 2010 Factory Service Manual PCS-18

< COMPONENT DIAGNOSIS >[IPDM E/R]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000005146511

Regarding Wiring Diagram information, refer to

PCS-](/img/42/57032/w960_57032-2892.png)

PCS-18

< COMPONENT DIAGNOSIS >[IPDM E/R]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000005146511

Regarding Wiring Diagram information, refer to

PCS-27, "Wiring Diagram".

1. CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK BATTERY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check voltage between IPDM E/R harness connectors and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between IPDM E/R harness connectors and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

Terminal No. Signal nameFuses and fusible link No.

1 Battery A, D

2 Battery C

12 Ignition switch ON or START 59

TerminalsIgnition switch position

(+) (−) OFF ON START

Connector Terminal

E118 (A) 1

Ground Battery

voltage Battery

voltage Battery

voltage

2 Battery

voltage Battery

voltage Battery

voltage

E119 (B) 12 0VBattery

voltage Battery

voltage

AWMIA0023ZZ

IPDM E/R

GroundContinuity

Connector Terminal

E122 (A) 38

Ye s

E124 (B) 59

AWMIA0024ZZ

Revision: April 20092010 QX56

Page 2902 of 4210

![INFINITI QX56 2010 Factory Service Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

Wiring DiagramINFOID:0000000005146515

ABMWA0362GB

Revision: April 200 INFINITI QX56 2010 Factory Service Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

Wiring DiagramINFOID:0000000005146515

ABMWA0362GB

Revision: April 200](/img/42/57032/w960_57032-2901.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-27

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

Wiring DiagramINFOID:0000000005146515

ABMWA0362GB

Revision: April 20092010 QX56

Page 2911 of 4210

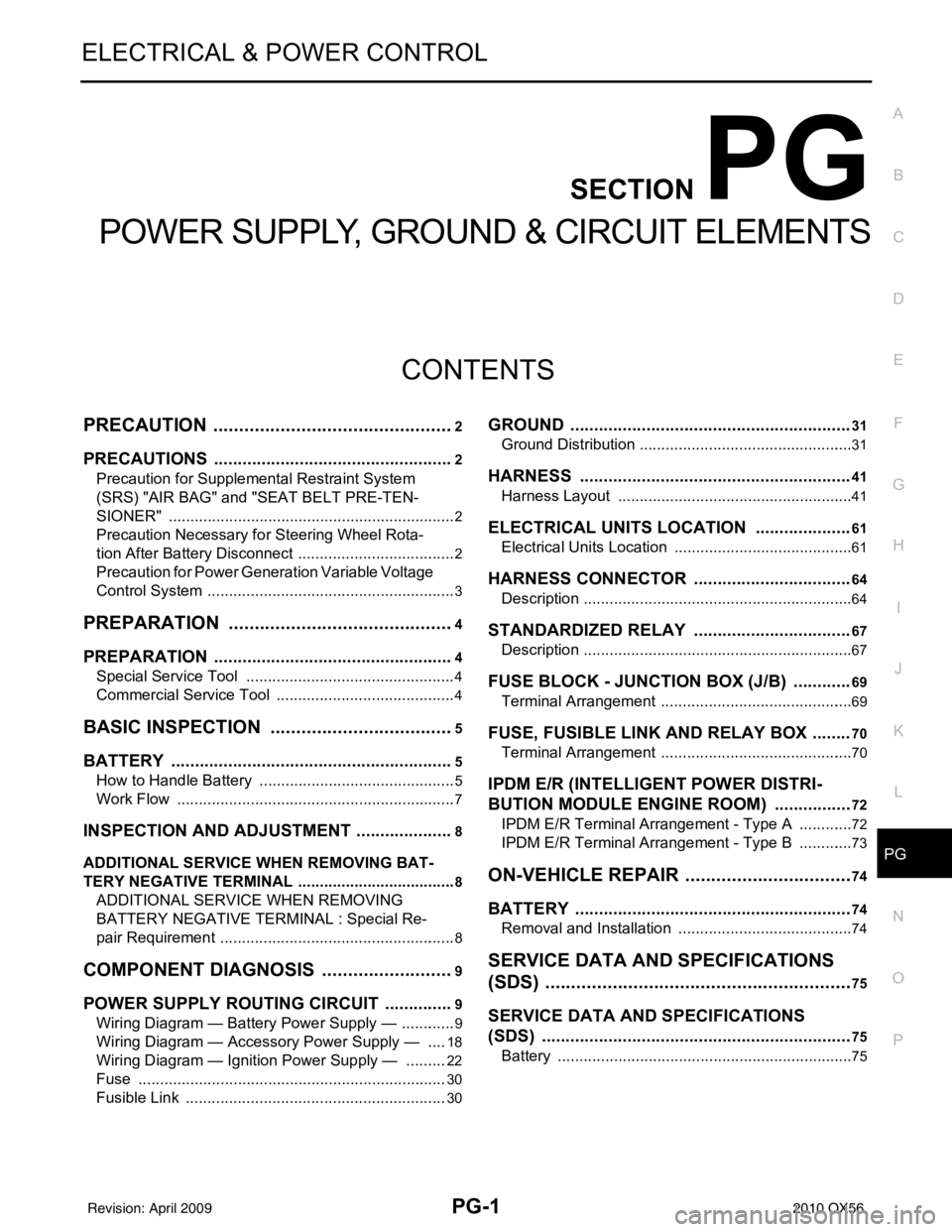

PG

PG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PG

A

O P

N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION .......

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

BATTERY ....................................................... .....5

How to Handle Battery ........................................ ......5

Work Flow ........................................................... ......7

INSPECTION AND ADJUSTMENT .....................8

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ......

8

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement ................................................. ......

8

COMPONENT DIAGNOSIS ..........................9

POWER SUPPLY ROUTING CIRCUIT .......... .....9

Wiring Diagram — Battery Power Supply — ....... ......9

Wiring Diagram — Accessory Power Supply — .....18

Wiring Diagram — Ignition Power Supply — ..........22

Fuse ........................................................................30

Fusible Link .............................................................30

GROUND ...........................................................31

Ground Distribution .............................................. ....31

HARNESS .........................................................41

Harness Layout ................................................... ....41

ELECTRICAL UNITS LOCATION ....................61

Electrical Units Location ..........................................61

HARNESS CONNECTOR .................................64

Description ...............................................................64

STANDARDIZED RELAY .................................67

Description ...............................................................67

FUSE BLOCK - JUNCTION BOX (J/B) ............69

Terminal Arrangement .............................................69

FUSE, FUSIBLE LINK AND RELAY BOX ........70

Terminal Arrangement .............................................70

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

72

IPDM E/R Terminal Arrangement - Type A .............72

IPDM E/R Terminal Arrangement - Type B .............73

ON-VEHICLE REPAIR .................................74

BATTERY ..........................................................74

Removal and Installation ..................................... ....74

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

75

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

75

Battery ................................................................. ....75

Revision: April 20092010 QX56

Page 2919 of 4210

PG

POWER SUPPLY ROUTING CIRCUITPG-9

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

COMPONENT DIAGNOSIS

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram —Battery Power Supply —INFOID:0000000005146576

ABMWA0428GB

Revision: April 20092010 QX56

Page 2928 of 4210

PG-18

< COMPONENT DIAGNOSIS >

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram —Accessory Power Supply —

INFOID:0000000005146577

ABMWA0433GB

Revision: April 20092010 QX56

Page 2932 of 4210

PG-22

< COMPONENT DIAGNOSIS >

POWER SUPPLY ROUTING CIRCUIT

Wiring Diagram —Igniti on Power Supply —

INFOID:0000000005146578

ABMWA0066GB

Revision: April 20092010 QX56

Page 2983 of 4210

PG

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-73

< COMPONENT DIAGNOSIS >

C

D E

F

G H

I

J

K L

B A

O P

N

IPDM E/R Terminal Ar

rangement - Type BINFOID:0000000005370328

NOTE:

Numbers preceded by an "F" represent the fuse number s imprinted on the IPDM E/R. The other numbers

represent the fuse numbers as they appear in the wiring diagrams.

AAMIA0364GB

Revision: April 20092010 QX56

Page 2987 of 4210

PWC-2

PASSENGER SIDE : Description ...........................25

PASSENGER SIDE : Compo nent Function Check

...

25

PASSENGER SIDE : Diagnosis Procedure ........ ...25

REAR LH ................................................................ ...28

REAR LH : Description ...........................................28

REAR LH : Component Function Check ................28

REAR LH : Diagnosis Procedure ............................28

REAR RH ............................................................... ...30

REAR RH : Description ..........................................31

REAR RH : Component Function Check ................31

REAR RH : Diagnosis Procedure ...........................31

DOOR SWITCH .................................................34

Description ..............................................................34

Component Function Check ...................................34

Diagnosis Procedure ..............................................34

Component Inspection ............................................35

DOOR KEY CYLINDER SWITCH ......................36

Description ........................................................... ...36

Component Function Check ...................................36

Diagnosis Procedure ..............................................36

Component Inspection ............................................37

POWER WINDOW SERIAL LINK .....................39

POWER WINDOW MAIN SWITCH ........................ ...39

POWER WINDOW MAIN SWITCH : Description ...39

POWER WINDOW MAIN SWITCH : Component

Function Check .......................................................

39

POWER WINDOW MAIN SWITCH : Diagnosis

Procedure ...............................................................

39

FRONT POWER WINDOW SWITCH ..................... ...40

FRONT POWER WINDOW SWITCH : Descrip-

tion ..........................................................................

40

FRONT POWER WINDOW SWITCH : Compo-

nent Function Check ...............................................

40

FRONT POWER WINDOW SWITCH : Diagnosis

Procedure ...............................................................

41

REAR POWER WINDOW SWITCH ....................... ...42

REAR POWER WINDOW SWITCH : Power Win-

dow Serial Link Check Rear LH or RH ...................

42

POWER WINDOW LOCK SWITCH ...................43

Description ........................................................... ...43

Component Function Check ...................................43

REAR POWER VENT WINDOW SWITCH

CIRCUIT CHECK ...............................................

44

Description ........................................................... ...44

Diagnosis Procedure ..............................................44

REAR POWER VENT WINDOW MOTOR LH

CIRCUIT CHECK ...............................................

45

Description ........................................................... ...45

Diagnosis Procedure ..............................................45

REAR POWER VENT WINDOW MOTOR RH

CIRCUIT CHECK ...............................................

46

Description ........................................................... ...46

Diagnosis Procedure ...............................................46

REAR POWER VENT WINDOW RELAY

(OPEN) CHECK .................................................

47

Description ........................................................... ...47

Diagnosis Procedure ...............................................47

REAR POWER VENT WINDOW RELAY

(CLOSE) CHECK ...............................................

49

Description ........................................................... ...49

Diagnosis Procedure ...............................................49

ECU DIAGNOSIS .......................................51

POWER WINDOW MAIN SWITCH ................ ...51

Reference Value .................................................. ...51

Wiring Diagram .......................................................53

Fail Safe .................................................................64

FRONT POWER WINDOW SWITCH ................66

Reference Value .................................................. ...66

Wiring Diagram .......................................................68

Fail Safe .................................................................79

BCM (BODY CONTROL MODULE) ..................81

Reference Value .................................................. ...81

Terminal Layout ......................................................84

Physical Values .......................................................84

Wiring Diagram .......................................................90

Fail Safe .................................................................94

DTC Inspection Priority Chart ...............................95

DTC Index ..............................................................95

SYMPTOM DIAGNOSIS ............................97

NONE OF THE POWER WINDOWS CAN BE

OPERATED USING ANY SWITCH ................ ...

97

Diagnosis Procedure ............................................ ...97

DRIVER SIDE POWER WINDOW ALONE

DOES NOT OPERATE ......................................

98

Diagnosis Procedure ............................................ ...98

FRONT PASSENGER SIDE POWER WIN-

DOW ALONE DOES NOT OPERATE ...............

99

Diagnosis Procedure ............................................ ...99

REAR LH SIDE POWER WINDOW ALONE

DOES NOT OPERATE .....................................

100

Diagnosis Procedure ............................................ .100

REAR RH SIDE POWER WINDOW ALONE

DOES NOT OPERATE .....................................

101

Diagnosis Procedure ............................................ .101

ANTI-PINCH SYSTEM DOES NOT OPERATE

NORMALLY (DRIVER SIDE) ...........................

102

Diagnosis Procedure ............................................ .102

Revision: April 20092010 QX56

Page 2997 of 4210

PWC-12

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

COMPONENT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

POWER WINDOW MAIN SWITCH

POWER WINDOW MAIN SWITCH : DescriptionINFOID:0000000005147171

• BCM supplies power.

• It operates each power window motor via corresponding power window switch and makes window move up/down when main power window and door lock/unlock switch is operated.

POWER WINDOW MAIN SWITCH : Component Function CheckINFOID:0000000005147172

Main Power Window And Door Lock/Unlock Switch

1. CHECK MAIN POWER WINDOW AND DO OR LOCK/UNLOCK SWITCH FUNCTION

Does power window motor operate with main power window and door lock/unlock switch operation?

Is the inspection result normal?

YES >> Main power window and door lock/unlock switch power supply and ground circuit are OK.

NO >> Refer to PWC-12, "

POWER WINDOW MAIN SWITCH : Diagnosis Procedure".

POWER WINDOW MAIN SWITCH : Diagnosis ProcedureINFOID:0000000005147173

Regarding Wiring Diagram information, refer to PWC-53, "Wiring Diagram".

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between main power window and door lock/ unlock switch connectors and ground.

Is the measurement value within the specification?

YES >> GO TO 3

NO >> GO TO 2

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and main power window and door lock/unlock switch.

3. Check continuity between BCM connector and main power win- dow and door lock/unlock switch connectors.

Te r m i n a l

Voltage (V)(Approx.)

(+)

(–)

Main power window and

door lock/unlock switch

connector Te r m i n a l

D7 (A) 10

Ground Battery voltage

D8 (B) 19

ALKIA0273ZZ

BCM connector Terminal Main power window and

door lock/unlock switch connector Terminal Continuity

M20 (A) 68

D7 (B) 10

Ye s

69 D8 (C) 19

LIIA2215E

Revision: April 20092010 QX56

Page 2999 of 4210

PWC-14

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

FRONT POWER WINDOW SWIT CH : Diagnosis Procedure

INFOID:0000000005147176

Regarding Wiring Diagram information, refer to PWC-68, "Wiring Diagram".

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between power window and door lock/unlock switch RH connector and ground.

Is the measurement value within the specification?

YES >> GO TO 3

NO >> GO TO 2

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and power window and door lock/unlock switch RH.

3. Check continuity between BCM connector and power window and door lock/unlock switch RH connector.

4. Check continuity between BCM connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window and door lock/unlock switch RH.

3. Check continuity between power window and door lock/unlock switch RH connector and ground.

Is the inspection result normal?

YES >> Replace power window and door lock/unlock switch RH. Refer to PWC-118, "

Removal and Installation".

NO >> Repair or replace harness.

Te r m i n a l

Voltage (V)(Approx.)

(+)

(–)

Power window and door lock/

unlock

switch RH connector Te r m i n a l

D105 10Ground Battery voltage

ALKIA0301ZZ

BCM connector Terminal Power window and

door lock/unlock

switch RH connector Terminal Continuity

M20 (A) 69 D105 (B)10 Yes

BCM connector Terminal

GroundContinuity

M20 (A) 69 No

LIIA2364E

Power window and door

lock/unlock switch RH Te r m i n a l

Ground Continuity

D105 11 Yes

ALKIA0303ZZ

Revision: April 20092010 QX56