wheel INFINITI QX56 2010 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2010, Model line: QX56, Model: INFINITI QX56 2010Pages: 4210, PDF Size: 81.91 MB

Page 451 of 4210

BR-6

< FUNCTION DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

FUNCTION DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005147889

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

BR-7

, BR-9

DLN-184, "

NVH Troubleshooting Chart

" (2F1310),

DLN-194, "

NVH Troubleshooting Chart

" (2S1410)

DLN-208, "

NVH Troubleshooting Chart

" (FFD),

DLN-242, "

NVH Troubleshooting Chart

" (RFD)

FAX-5, "

NVH Troubleshooting Chart

" (FAX),

RAX-5, "

NVH Troubleshooting Chart

" (RAX)

FSU-5, "

NVH Troubleshooting Chart

" (FSU),

RSU-5, "

NVH Troubleshooting Chart

" (RSU)

WT-43, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

PROPELLER SHAFT

DIFFERENTIAL

DRIVESHAFT

SUSPENSION

TIRES AND ROAD WHEEL

STEERING

Symptom Noise

××× × × × × ××

Shake ×× ××××

Shimmy, Shudder ××××××× × × ××

Revision: April 20092010 QX56

Page 452 of 4210

FRONT DISC BRAKEBR-7

< BASIC INSPECTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BASIC INSPECTION

FRONT DISC BRAKE

BRAKE PAD

BRAKE PAD : Front Pad InspectionINFOID:0000000005147890

PA D W E A R

Check pad thickness from the inspection holes on cylinder body.

Check using a scale if necessary.

DISC ROTOR

DISC ROTOR : Front Rotor InspectionINFOID:0000000005147891

VISUAL

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace as necessary.

RUNOUT

1. Attach disc rotor to wheel hub using wheel nuts (at two or more positions).

2. Inspect runout using a dial gauge placed at 10 mm (0.39 in) inside the disc edge.

NOTE:

Before measuring, make sure that wheel bearing axial end play

is within the specification. Refer to RAX-6, "

On-Vehicle Inspec-

tion and Service".

3. When runout exceeds limit value, displace mounting positions of disc rotor by one hole. And then find a position of the minimum value for runout.

4. If runout is outside the specified value after performing the above operation, turn disc rotor using Tool.

THICKNESS

Standard thickness : Refer to BR-46, "Front Disc

Brake".

Repair limit thickness : Refer to BR-46, "

Front Disc

Brake".

WFIA0522E

Runout limit : Refer to BR-46, "Front Disc

Brake".

(with it attached to the vehicle)

Tool number : 38-PFM90.5 ( — )

BRA0580D

Revision: April 20092010 QX56

Page 454 of 4210

REAR DISC BRAKEBR-9

< BASIC INSPECTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : Rear Pad InspectionINFOID:0000000005147892

PA D W E A R

Check pad thickness from the inspection holes on cylinder body.

Check using a scale if necessary.

DISC ROTOR

DISC ROTOR : Rear Rotor InspectionINFOID:0000000005147893

VISUAL

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace as necessary.

RUNOUT

1. Attach disc rotor to wheel hub using wheel nuts (at two or more positions).

2. Inspect runout using dial gauge placed at 10 mm (0.39 in) inside disc edge.

NOTE:

Before measuring, make sure that wheel bearing axial end play

is within the specification. Refer to RAX-6, "

On-Vehicle Inspec-

tion and Service".

3. When runout exceeds limit value, displace mounting positions of disc rotor by one hole. And then find a position of the minimum value for runout.

4. If runout is outside the specified value after performing the above operation, turn disc rotor using Tool.

THICKNESS

Check the thickness of the disc rotor using a micrometer. Replace

disc rotor if the thickness is less than the wear limit. Standard thickness : Refer to

BR-46, "

Rear Disc

Brake".

Repair limit thickness : Refer to BR-46, "

Rear Disc

Brake".

BRA0010D

Runout limit : Refer to BR-46, "Rear Disc Brake".

(With it attached to the vehicle)

Tool number : 38-PFM90.5 ( — )

BRA0697D

Standard thickness : Refer to BR-46, "Rear

Disc Brake".

Repair limit thickness : Refer to BR-46, "

Rear

Disc Brake".

Thickness variation

(Measured at 8 positions) : Refer to

BR-46, "

Rear

Disc Brake".

SFIA2284E

Revision: April 20092010 QX56

Page 458 of 4210

BRAKE TUBE AND HOSEBR-13

< BASIC INSPECTION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE TUBE AND HOSE

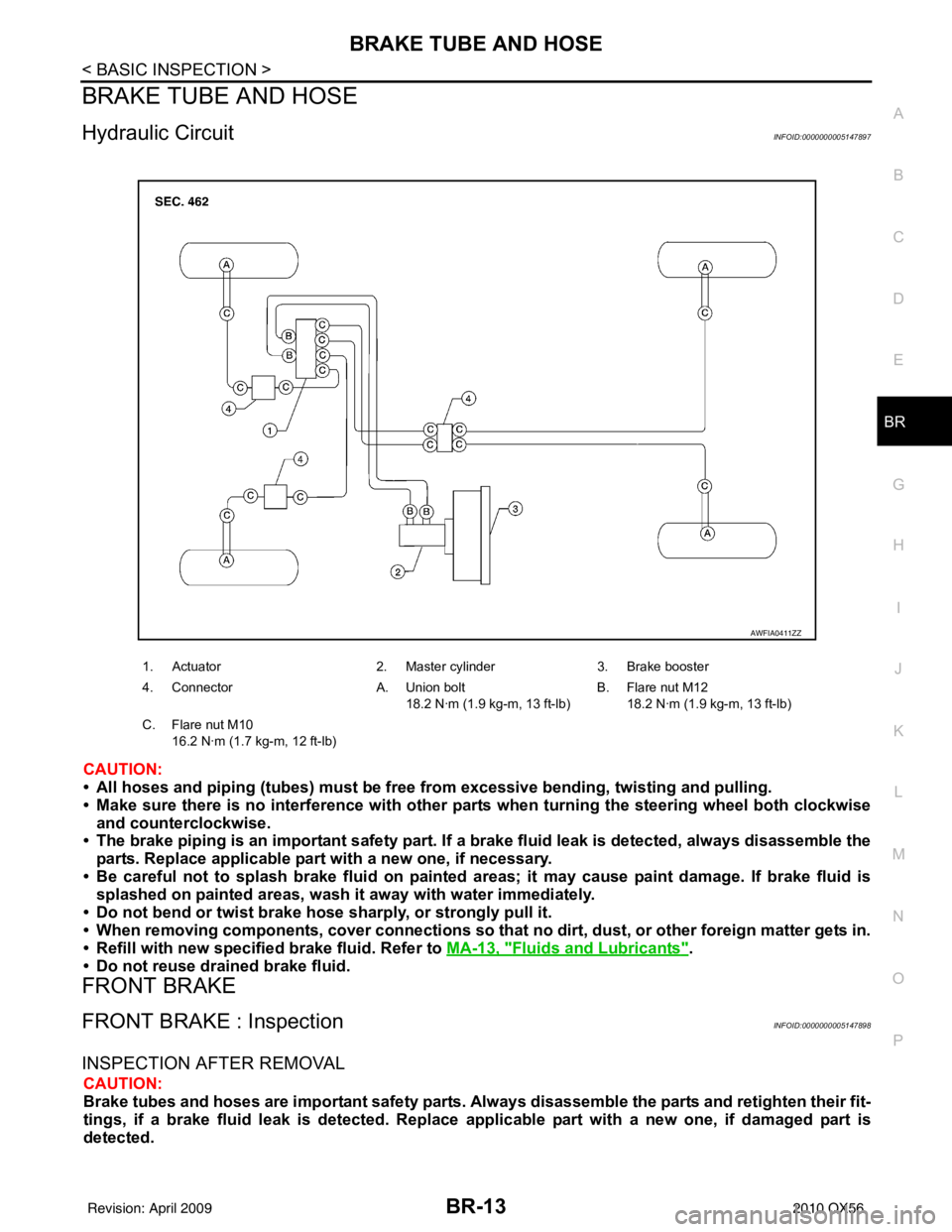

Hydraulic CircuitINFOID:0000000005147897

CAUTION:

• All hoses and piping (tubes) must be fr ee from excessive bending, twisting and pulling.

• Make sure there is no interference with other parts when turning the steering wheel both clockwise

and counterclockwise.

• The brake piping is an important safety part. If a brake fluid leak is detected, always disassemble the

parts. Replace applicable part with a new one, if necessary.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Do not bend or twist brake hose sharply, or strongly pull it.

• When removing components, cover connections so that no dirt, dust, or other foreign matter gets in.

• Refill with new specified brake fluid. Refer to MA-13, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

FRONT BRAKE

FRONT BRAKE : InspectionINFOID:0000000005147898

INSPECTION AFTER REMOVAL

CAUTION:

Brake tubes and hoses are important safety parts. Always disassemble the parts and retighten their fit-

tings, if a brake fluid leak is det ected. Replace applicable part with a new one, if damaged part is

detected.

1. Actuator 2. Master cylinder3. Brake booster

4. Connector A. Union bolt

18.2 N·m (1.9 kg-m, 13 ft-lb) B. Flare nut M12

18.2 N·m (1.9 kg-m, 13 ft-lb)

C. Flare nut M10 16.2 N·m (1.7 kg-m, 12 ft-lb)

AWFIA0411ZZ

Revision: April 20092010 QX56

Page 463 of 4210

BR-18

< ON-VEHICLE MAINTENANCE >

BRAKE FLUID

3. Fully depress brake pedal 4 to 5 times.

4. With brake pedal depressed, loosen bleed valve to let the air out, and then tighten it immediately.

5. Repeat steps 3 and 4 until no more air comes out.

6. Tighten bleed valve to the specified torque. Refer to BR-31, "

Exploded View of Brake Caliper" (front disc

brake), BR-35, "

Exploded View of Brake Caliper" (rear disc brake).

7. Repeat steps 2 through 6 at each wheel, with master cylinder reservoir tank filled at least half way, bleed- ing air in order from the front left, rear left, and front right bleed valves.

Revision: April 20092010 QX56

Page 466 of 4210

BRAKE TUBE AND HOSEBR-21

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE TUBE AND HOSE

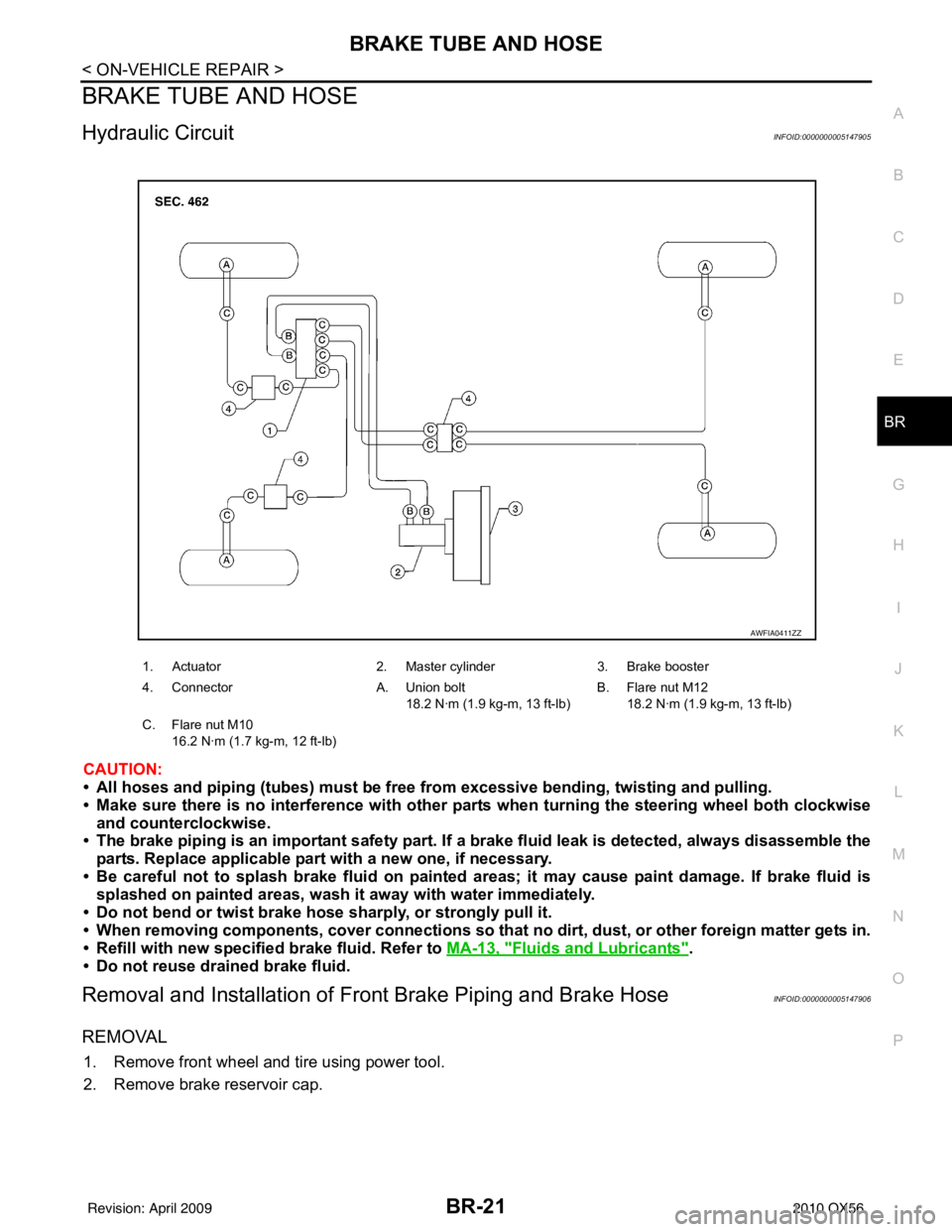

Hydraulic CircuitINFOID:0000000005147905

CAUTION:

• All hoses and piping (tubes) must be fr ee from excessive bending, twisting and pulling.

• Make sure there is no interference with other parts when turning the steering wheel both clockwise

and counterclockwise.

• The brake piping is an important safety part. If a brake fluid leak is detected, always disassemble the

parts. Replace applicable part with a new one, if necessary.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Do not bend or twist brake hose sharply, or strongly pull it.

• When removing components, cover connections so that no dirt, dust, or other foreign matter gets in.

• Refill with new specified brake fluid. Refer to MA-13, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

Removal and Installation of Fr ont Brake Piping and Brake HoseINFOID:0000000005147906

REMOVAL

1. Remove front wheel and tire using power tool.

2. Remove brake reservoir cap.

1. Actuator 2. Master cylinder3. Brake booster

4. Connector A. Union bolt

18.2 N·m (1.9 kg-m, 13 ft-lb) B. Flare nut M12

18.2 N·m (1.9 kg-m, 13 ft-lb)

C. Flare nut M10 16.2 N·m (1.7 kg-m, 12 ft-lb)

AWFIA0411ZZ

Revision: April 20092010 QX56

Page 467 of 4210

BR-22

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

3. Remove brake tube from brake hose, using a suitable tool.

4. Remove lock plate and brake hose from bracket.

5. Remove union bolt and then remove brake hose from cylinderbody.

INSTALLATION

1. Install brake hose by aligning with the protrusion on cylinderbody, then install the union bolt and new copper washers and

tighten to specification. Refer to BR-13, "

Hydraulic Circuit".

CAUTION:

Do not reuse copper washer.

2. Insert brake hose end through bracket, then secure it to bracket with lock plate.

3. Install brake tube to brake hose, then tighten the flare nut using a suitable tool. Refer to BR-13, "

Hydraulic Circuit".

4. Refill brake fluid and bleed air. Refer to BR-17, "

Drain and Refill".

5. Install front wheel and tire using power tool. Refer to WT-49, "

Rotation".

Removal and Installation of Rear Brake Piping and Brake HoseINFOID:0000000005147907

REMOVAL

1. Remove rear wheel and tire using power tool.

2. Remove brake reservoir cap.

LFIA0213E

LFIA0214E

SFIA1137E

LFIA0213E

Revision: April 20092010 QX56

Page 468 of 4210

BRAKE TUBE AND HOSEBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

3. Remove brake tube from brake hose, using a suitable tool.

4. Remove lock plate and brake hose from bracket.

5. Remove union bolt and then remove brake hose from cylinder body.

INSTALLATION

1. Install brake hose by aligning with the protrusion on cylinderbody, then install the union bolt and new copper washers and

tighten to specification. Refer to BR-13, "

Hydraulic Circuit".

CAUTION:

Do not reuse copper washer.

2. Insert brake hose end through bracket, then secure it to bracket with lock plate.

3. Install brake tube to brake hose, then tighten the flare nut using a suitable tool. Refer to BR-13, "

Hydraulic Circuit".

4. Refill brake fluid and bleed air. Refer to BR-17, "

Bleeding Brake System".

5. Install rear wheel and tire using power tool. Refer to WT-49, "

Rotation".

Inspection After InstallationINFOID:0000000005147908

CAUTION:

Brake tubes and hoses are important safety parts. Always disassemble the parts and retighten their fit-

tings, if a brake fluid leak is detected. Replace applicable part with a new one, if a damaged part is

detected.

LFIA0213E

LFIA0212E

SFIA1137E

LFIA0213E

Revision: April 20092010 QX56

Page 474 of 4210

FRONT DISC BRAKEBR-29

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

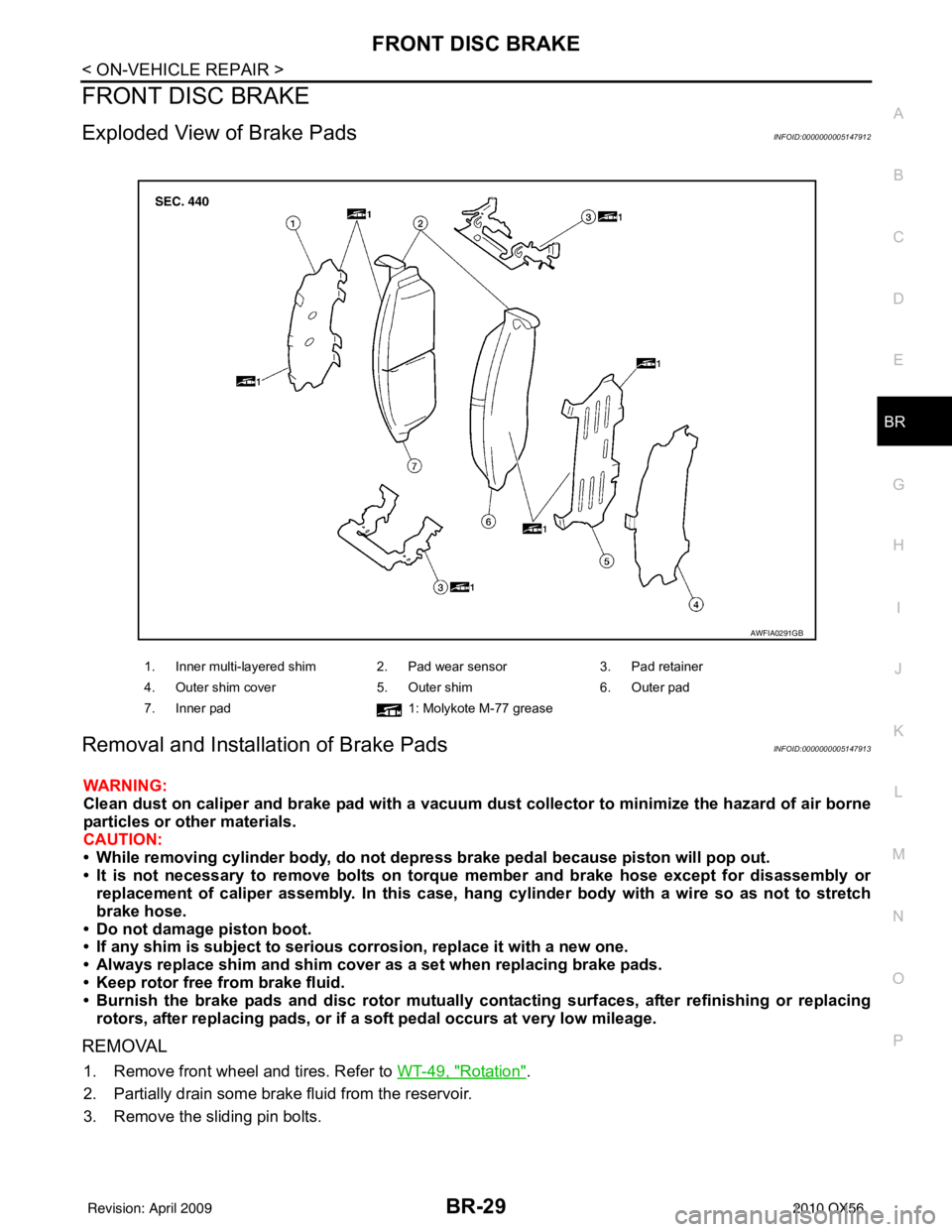

Exploded View of Brake PadsINFOID:0000000005147912

Removal and Installation of Brake PadsINFOID:0000000005147913

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing rotors, after replacing pads, or if a so ft pedal occurs at very low mileage.

REMOVAL

1. Remove front wheel and tires. Refer to WT-49, "Rotation".

2. Partially drain some brake fluid from the reservoir.

3. Remove the sliding pin bolts.

1. Inner multi-layered shim 2. Pad wear sensor 3. Pad retainer

4. Outer shim cover 5. Outer shim6. Outer pad

7. Inner pad 1: Molykote M-77 grease

AWFIA0291GB

Revision: April 20092010 QX56

Page 475 of 4210

BR-30

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

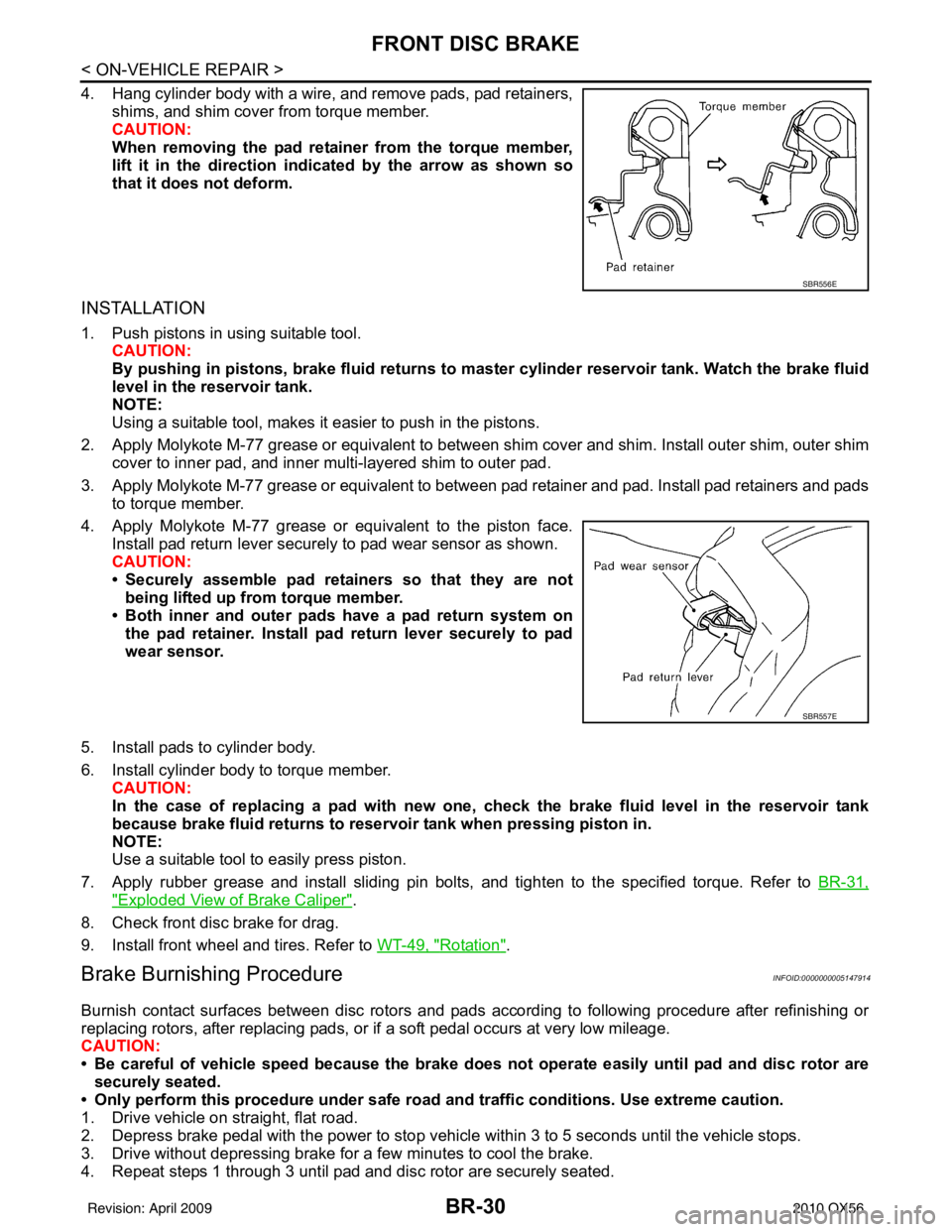

4. Hang cylinder body with a wire, and remove pads, pad retainers,shims, and shim cover from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indi cated by the arrow as shown so

that it does not deform.

INSTALLATION

1. Push pistons in using suitable tool.

CAUTION:

By pushing in pistons, brake fluid returns to m aster cylinder reservoir tank. Watch the brake fluid

level in the reservoir tank.

NOTE:

Using a suitable tool, makes it easier to push in the pistons.

2. Apply Molykote M-77 grease or equivalent to between shim cover and shim. Install outer shim, outer shim cover to inner pad, and inner multi-layered shim to outer pad.

3. Apply Molykote M-77 grease or equivalent to between pad retainer and pad. Install pad retainers and pads to torque member.

4. Apply Molykote M-77 grease or equivalent to the piston face. Install pad return lever securely to pad wear sensor as shown.

CAUTION:

• Securely assemble pad retainers so that they are not

being lifted up from torque member.

• Both inner and outer pads have a pad return system on

the pad retainer. Install pad return lever securely to pad

wear sensor.

5. Install pads to cylinder body.

6. Install cylinder body to torque member. CAUTION:

In the case of replacing a pad with new one, ch eck the brake fluid level in the reservoir tank

because brake fluid returns to reservoir tank when pressing piston in.

NOTE:

Use a suitable tool to easily press piston.

7. Apply rubber grease and install sliding pin bolts, and tighten to the specified torque. Refer to BR-31,

"Exploded View of Brake Caliper".

8. Check front disc brake for drag.

9. Install front wheel and tires. Refer to WT-49, "

Rotation".

Brake Burnishing ProcedureINFOID:0000000005147914

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are

securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

SBR556E

SBR557E

Revision: April 20092010 QX56